+8

First, you need to understand what the main function of a wheel bearing is, and why it is needed at all. A wheel bearing is a part that ensures smooth, uniform and stable rotation of the wheel around its axis.

In this article, we will look at the main signs and symptoms of a bad wheel bearing, what causes it to fail, how to identify a bad wheel bearing, and recommendations for installing it.

Types of wheel bearings

A faulty wheel bearing makes the rotation of the wheel uneven and the wheel begins, in other words, to wobble. Naturally, at high speeds such a breakdown can lead to an accident. Fortunately, a wheel bearing almost always warns the car owner at the initial stage of wear. At first it makes a characteristic noise at high speed, then the sound becomes louder and annoys the car owner. It becomes simply unbearable to drive. If you ignore such signals from the wheel bearing, then soon it will simply jam and the car will not be able to continue moving on its own. The most unpleasant thing that can happen is the wheel bearing jamming at high speed. One can only imagine what will happen if one of the wheels suddenly stops spinning at high speed.

Consequences of untimely replacement of the wheel bearing.

Wheel bearing. Causes of failure

Original wheel bearings (which are installed on the car from the factory) can travel more than 250 thousand km. with proper use. The bearings can withstand such mileage thanks to the durable and reliable materials from which they are made. The following will lead to earlier wheel bearing failure:

- Frequently falling into potholes at high speed. When falling into holes, the entire suspension of the car experiences enormous loads, the wheel bearing is no exception;

- Overheating of the wheel bearing , for example, due to a jammed caliper or excessive tightening. If you ignore a breakdown such as a jammed brake caliper, the hub will become very hot and lubricant will leak out of it. Further operation of the wheel bearing will become impossible;

- Loss of lubricant . A very common cause of breakdown. The manufacturer usually does not put enough lubricant in cheap wheel bearings; such a bearing will last no more than 30 thousand km. If you take a high-quality wheel bearing, then over time the lubricant from it simply burns out or loses its properties;

- Wheel bearing is not properly tightened When installing a wheel bearing, you must know at what torque to tighten it. It is very important ! Do not neglect this point under any circumstances. The bearing can either be over-tightened during installation or under-tightened. If the bearing is installed incorrectly, it can last no more than 1 thousand km.

- Improper pressing of the wheel bearing. When installing a new bearing, be sure to check for any distortions. If the bearing is pressed in crookedly, the loads will be distributed unevenly. It is easy to understand that such a bearing will not last long;

- Overloading the vehicle . If you like to load your car with a massive load, know that the first thing that takes the full impact is the wheel bearing. Rest assured, such operation of the car will definitely lead to the replacement of the wheel bearing;

- Installation of wheel rims with an offset not specified by the manufacturer or installation of spacers . Discs with a large offset will also lead to premature failure of the wheel bearings. When installing such discs, the load on the wheel bearing increases significantly.

Replacing the wheel bearing.

It becomes clear that you need to avoid large potholes on the road, buy only high-quality spare parts, trust your car only to trusted professionals and operate the car correctly.

If you follow these rules, the wheel bearing will serve you for a long time.

003_moto_0611_070

Often you have to deal with the steering column bearings. The main thing is to tighten them in a timely manner, without allowing it to play. In the steering columns of modern motorcycles, thrust ball bearings are often found, primarily supporting loads directed parallel to the axis of the steering column. If play appears in such a bearing, it begins to break quickly. At first, a slight click appears when braking, but if the situation is not corrected in time, the steering wheel will begin to rotate worse and may jam at the most inopportune moment. To tighten the steering bearing, you first need to find the nut that holds it in place. As a rule, it is located under the upper traverse and sometimes it is supported by a second one of the same kind. Often these nuts have a castle crown and require a special wrench. The motorcycle must be positioned so that the front wheel hangs in the air and the steering wheel rotates freely. Remove the upper crossbar and begin to tighten the bearing nut little by little, while checking that the system rotates easily. As soon as there is a force during rotation, stop tightening the nut and turn it back about a quarter of a turn. The steering wheel should rotate freely, and the play should disappear.

An important point: if clicks from the steering column appeared on a completely new motorcycle, it is possible that the bearing did not fully fit into its seats during assembly at the factory. In such cases, it is useful to first tighten it with a fairly large force, about 25–30 Nm, and only then loosen it and perform the procedure described above.

Replacing steering bearings is sometimes a difficult task and requires good equipment and skills. And if you can still handle wheel bearings in a garage, then you can’t do without the right equipment to work with steering bearings. Driving with worn bearings - no matter the wheels or steering column - is dangerous!

Every motorcycle has many other components where bearings work, but most of them are in the engine, and thanks to excellent lubrication and cleanliness, they last a long time and do not require replacement. And if it so happens that one of the bearings of the engine or gearbox fails, then there was a very serious reason for this (usually a problem with the lubrication system) and replacing the bearing alone will not end the matter. But let's not talk about sad things. After all, if you regularly monitor your motorcycle and maintain it properly, nothing bad will happen to it.

Replacing wheel bearings (using the example of Suzuki DR-Z 250):

Source

Signs and Symptoms of a Dying Wheel Bearing

As I said, most often when it fails, the wheel bearing begins to hum at high speed. A hum in the wheel bearing appears due to the lack of sufficient lubrication. Gradually, as the bearing wears, this sound begins to appear at lower speeds. The sound will come directly from the wheel itself. It can only be confused with a faulty outboard bearing (the problem is very popular on Peugeot 307, 308) and a faulty gearbox (if, for example, there is not enough oil in it). An experienced technician can easily diagnose a faulty wheel bearing.

In addition to the hum, the wheel bearing may make a crunching or grinding noise . In such cases, the bearing warns you that it will soon seize. Such sounds indicate mechanical damage to the bearing .

Another sign of a bad wheel bearing is vibration, which is transmitted to the steering wheel and the entire car. This usually occurs within a certain speed range (for example, when driving between 60 and 80 km/h). In this case, only an experienced technician can accurately diagnose a wheel bearing malfunction, because some other faulty suspension part can transmit vibration to the steering wheel.

When the bearing is already worn out, the car may pull to the side. This situation indicates that the wheel already has significant play. In this case, it will be increasingly difficult to control the car. Operating the vehicle is strictly prohibited.

Consequences of untimely replacement of the wheel bearing.

The hub bearing is humming: how long can you drive?

Newbie motorists often ask this question. It must be said that the distance depends on the quality of the roads. In some places, the road surface can easily ruin even the chassis of an SUV. Therefore, once again there is no need to take risks, human life is one.

Professional auto mechanics claim that it is still possible to drive, but this is allowed as long as the hum is still barely audible. Driving is allowed only at low speeds. At the same time, you need to go around small holes and potholes. Even drivers who like to take risks are sure that driving more than 200 km with such symptoms is dangerous. Now you know how to determine which wheel bearing is humming. These tips should help novice motorists who have just gotten behind the wheel of a vehicle.

How to determine whether a wheel bearing is faulty

In most cases, the characteristic sounds of a faulty wheel bearing are difficult to confuse with something else. With the symptoms mentioned above, it is highly likely that the wheel bearing is faulty, and not something else. But still, you can be 100% sure that the cause of extraneous sounds is the bearing. To do this, you need to hang out (jack up) the wheel from which extraneous sounds are coming, and shake it in a vertical plane . If the wheel has even slight play relative to the hub, the wheel bearing will most likely have to be replaced. The only exception would be if your wheel bearing is not tightened enough; to do this, check the tightening torque of the wheel nut.

Remember - a wheel with a working bearing should not have any play.

If the wheel has no play in the vertical plane, try rotating the wheel by hand ; if you feel uneven rotation, or the wheel makes strange sounds, the wheel bearing needs to be replaced.

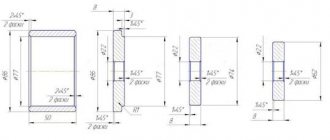

Installing bearings: how to properly secure and install, installation diagram

In this article we will analyze the installation diagram of angular contact bearings and tell you how they are mounted on the shaft and in the housing in different ways. The choice of the most suitable one depends on the type of support unit, its size, the load taken and many other factors. Sometimes the process requires the use of additional devices for more reliable installation. Let's consider the most popular paths recommended for installation, as well as possible problems associated with incorrect implementation of the procedure.

Recommendations for installing the wheel bearing

So, you have diagnosed a problem - the wheel bearing.

- First of all, I repeat, you should only buy a new wheel bearing from a trusted company; it is best to read reviews about the selected part. Take this issue seriously, because how long it will serve you depends on this stage. I have already told you how to choose and buy spare parts for a car.

- Most wheel bearings come with non-removable boots, under which there is grease, in which case you will not be able to check its quantity. But if you get an open bearing, be sure to check the amount of lubricant that the manufacturer supplied.

- Before installing the wheel bearing, make sure that the contact surfaces of the hub are not damaged, there are no burrs, dimples, burrs or signs of use. They could have formed during operation or pressing out the old bearing.

- On some cars, the wheel bearing comes together with the ABS ring (like on the Peugeot 307), so be careful when installing; some would-be masters install the bearing with the other side.

- Before pressing the bearing, lubricate the contact surfaces with a soap solution, this will make pressing the bearing easier.

- When installing the retaining ring, be careful not to damage the bearing boot.

- To install a wheel bearing, in most cases you need a special device - a press. Without it, it is extremely difficult to seat the bearing correctly and evenly in the hub. If in your case a press is required when replacing a bearing, then it is better to entrust this work to a trusted car service center.

Pressing in the wheel bearing using a press

Subscribe to our YandexZen

16 888

Wheel bearings - what are they?

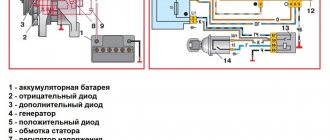

Among a huge number of types, rolling bearings were selected for the chassis. During extensive testing, it was found that this particular type provides the least rotational resistance. Depending on the make and model of the car, the following parts can be used in the chassis design:

— radial ball;

— radial roller;

— angular contact (conical) roller.

Bearings can have different designs. In the classic layout, when the front suspension is independent and the rear axle is driven, two tapered bearings are installed on each front hub, and one radial bearing on the rear ones (usually roller or double-row ball bearings).

The key to ensuring their performance is lubrication.

Radial bearings are manufactured with double-sided protection. At the manufacturer's factory, they are closed with plastic rings-anthers.

Naturally, a lubricant is placed inside the housing, which is enough for the entire service life. Many manufacturers prohibit opening their products and changing the lubricant. In this case, the tightness of the anthers is not guaranteed. The front wheel hub bearing is a thrust bearing and consists of three separate parts: an inner and outer race and a cassette with rollers. During installation, they are washed and lubricated with Litol-type lubricant, and are protected by oil seals, which are mounted separately on the hub.

Installation of rolling bearings

Installation of support units of this type requires compliance with certain rules and standards. Thus, the transmission of forces through the bodies providing rocking is not allowed, so as not to damage the parts. Therefore, special equipment is used in the process. The variety of types of rolling units dictates certain features. They must be taken into account, otherwise the procedure will become much more complicated. Here's what you need to take note of first:

There are other nuances that are difficult to take into account for people who are far from the technical side of the problem. If you have questions about how to fit, put on and secure a bearing onto a shaft or into a pipe, regardless of its type, shape, or size, it is better to seek advice from specialists. This will avoid errors and breakdowns and increase work efficiency. Considering that nodal supports operating on the rocking principle are mounted in complex, expensive equipment, doing this yourself is not always economically feasible.

Why bearings wear out

Typically, bearings can withstand 150,000-180,000 km, but under favorable operating conditions the technical life increases. At the same time, there are many examples where factory bearings do not withstand even 70,000 km.

Their performance is influenced by many factors: intensity of vehicle use, balancing, wheel alignment, and design features of the suspension. The latter concerns the geometry of the elements. Impacts when driving over obstacles, such as high curbs, have a destructive effect on the bearings.

Slipping, sharp turns or police turns have a negative impact on the service life. Another pressing and common problem is the careless attitude of service station foremen. So, during repair of the brake system when dismantling the unit, careless actions (for example, sharp, strong blows with a hammer) damage the bearing. After the repair is completed, it quickly collapses, and the owner is again forced to contact a service station. To avoid such problems, you need to use a specialized hydraulic press to carefully remove the bearings.

Application of plain bearings

Sliding bearings are different from rolling bearings, but their applications are similar. Such bearings are actively used for the manufacture of various equipment, railway equipment, the automotive industry, and the aviation industry. Radial plain bearings are especially popular.

Spheres and areas of application of sliding bearings also include agricultural machinery and construction equipment. Such bearings are actively used in cases where there is a possibility of high shock loads and unfavorable environmental conditions.

Of course, at the present stage of development of any industry it is impossible to do without the use of bearings. This area is actively developing in many countries of the world, including Ukraine.

Design features and operating principle

The wheel bearing is the most loaded part of an automobile mechanism, which must withstand the pressure of its entire mass. In addition, this part is also subject to additional loads of different directions, which arise as a result of the vehicle moving on an uneven road, sudden braking, etc. The safety of the vehicle on roads depends on the quality and reliability of this part. Therefore, it is extremely important that this element is of high quality, allowing it to constantly remain in good condition.

The hubs of the car mechanism are equipped with rolling bearings. All their modifications have a similar structure, which includes the following elements:

- rolling bodies;

- separator;

- outer and inner rings.

The outer and inner rings are a kind of supporting surfaces that secure the bearing in the axle area and in the hub hole.

To ensure that the rolling elements are evenly distributed around the circumference of the cage in the structure, a separator is used. Another important function is to prevent rolling elements located next to each other from coming into contact. Some models also have dust collectors that prevent dirt and dust from entering the unit. Nodes of this type are called closed.

Using the rear hubs

The rear hub is easier to operate. Although its design is almost the same as the front one. An exception may be the steering knuckle. The rear hub bearing, which is part of the rear suspension, is threaded onto the half shaft, being installed in the provided landing location. At the same time, the design of the rear wheels may differ from one car to another. Here's what the rear wheel hub might look like:

- if the suspension is dependent, then they are used on rollers or radials with balls;

- if the suspension is independent, then you only need to use conical ones, two on each side.

Since the rear wheel hub cannot be repaired, if the possibility of adjustment for pressing against the holder disappears, then if it is worn, it should be replaced. It is easy to buy, it has a specific serial number, which includes all the information about the individuality of the bearing. You should also buy a rear hub oil seal, which also deteriorates over time. But usually it changes along with replacing the hub.