Cars have components that can break down over time due to stress. One of these is a constant velocity joint (CV joint) or simply a grenade, which transmits power from the engine to the drive wheels in front- and all-wheel drive vehicles.

It consists of several parts, and different components are installed on the gearbox and wheel sides. Considering that they can break, you need to know how to determine a CV joint failure.

Causes of CV joint failure

The constant velocity joint may be faulty even in new cars with minimal mileage. There are several reasons for the unsuitability of a node; they are related to both lack of maintenance and operation:

- small amount of lubricant - the old lubricant can wash out or dry out, then the metal that does not have lubricant will grind off;

- incorrect installation;

- damage to the dust cover - each unit has protection - a boot that prevents contamination. If it is damaged, dust and water will enter inside, accelerating the wear of the unit;

- towing heavy objects and aggressive driving - these factors increase the load on the joints, because they are forced to pass more power through themselves;

- poor quality - if the unit is not original or is defective, this reduces its service life;

- damage - an accident, driving on broken roads, falling into a hole will cause the destruction of the hinge;

- ball joint play - wheels that are not securely fastened place more stress on the parts;

- natural wear and tear.

To increase the service life of the part, you should not overload it with sudden accelerations, regularly lubricate it, and carry out maintenance. Then the node will last longer, but will still deteriorate over time.

CV Joint Malfunctions: Signs and Symptoms

Let's start with the fact that the main cause of CV joint failure is wear of the balls, joint cage or tracks (working surface of the body). Less commonly, parts are destroyed, causing the hinge to separate. Given that the part experiences high loads, it is important to be able to accurately identify the problem.

Diagnostics of CV joints is somewhat different depending on their type (external or internal). Knowledge of the nuances discussed above allows you to more accurately carry out an inspection or timely identify a damaged part. The main thing is to pay attention to the failure of the CV joint and know the characteristic signs and symptoms of such a failure.

- So, the main sign of a problem with the CV joint is a crunching sound. This crunching noise occurs when the wheel turns during acceleration. Vibrations and slight shocks and jerking during acceleration may also be noticeable. Please note that these signs are generalized, that is, it is necessary to separate separately the malfunctions of the internal and external CV joints.

First of all, to understand which CV joint is crunching, internal or external, you need to consider the following:

- the outer “grenade” crunches when the car moves sharply or turns with the wheels turned in one direction or the other, since the outer joint bears heavy loads.

- Malfunctions of the internal CV joint, in addition to crunching, lead to obvious vibration, which is felt even when driving on a straight and level road.

Naturally, a malfunction of the internal CV joint is more difficult to determine. Let's look at this in more detail. The easiest way to check the internal grenade is to drive on an uneven road, where you can get maximum suspension travel, but without sudden shocks. It is optimal to check the hinges on a dry dirt road that has holes of medium depth washed out by rain.

When the car moves along such a road, the front suspension will be loaded, which will cause constant axial and angular displacements of the inner CV joint race. If the inner grenade wears out, such a hinge will crunch in the same way as the outer one.

If the check does not yield anything, then you can go to the ski lift. However, it should be borne in mind that when the wheels are suspended, the load on the CV joints is minimal and they may not show signs of problems.

Of course, experienced craftsmen often detect the malfunction anyway, as they are able to notice even small gaps. It happens that specialists can completely disassemble the suspension and remove the drives, remove the cover from the CV joint and immediately carry out troubleshooting.

At the same time, it can be difficult to detect a hidden problem on your own and without experience. An exception can be considered such an obvious play, when even with the wheels hanging (without load), the grenade knocks.

Symptoms of a problem

Since the part will break in any case, you need to find out in time and begin repairs. If this is not done, the hinge may collapse while driving, which will lock the drive shaft, abruptly immobilize the car, and may lead to an accident. For safe travel, you will need to find out whether the CV joint has one of the signs of failure:

- Crunching sound when turning a moving car.

- Backlash (dips) in joints.

- A crunching sound when starting to move, which intensifies during sudden acceleration.

- Jerks while accelerating.

All of the above factors can indicate problems not only with the grenade, but also with other components of the car.

Important! At the first suspicious sounds or deterioration in controllability, the car should be sent to a car service center to carry out a full diagnosis and identify the problem.

Signs of malfunction of the internal CV joint and types of breakdowns

Before considering the types of breakdowns, you need to learn how to identify them by their symptoms. After all, malfunctions of any unit lead to certain consequences, which are characterized by changes in the design. Let's consider the main signs of failure of the internal CV joint:

- Traces of grease on the rubber - if traces of grease appear along the edges of the tire on the inside, this at least indicates a crack in the boot. The worst option is damage to the mechanism itself if oil traces on the rubber were not immediately detected.

- Noise when turning the steering wheel - the crunch of the internal CV joint indicates damage or wear of this unit.

- Rough ride - if the car bounces even when driving on a smooth road, this unit is definitely damaged. You should not wonder whether the internal CV joint may be knocking on bumps, but urgently contact a car service center and perform diagnostics.

- Vibration – occurs from wear on the joints when they cannot achieve proper balancing during operation. At the same time, you will also hear how the internal CV joint crunches.

- Knocking while driving - it occurs from wear on the unit. In rear-wheel drive cars, both the internal and external CV joints can knock. In front-wheel drive vehicles, you can only hear the knock of the internal CV joint.

You don't have to know how to fix cars to recognize the signs above. As for diagnostics, the services of auto repairmen are needed. Thus, we examined the signs of breakdowns and answered questions about whether the inner CV joint can knock or crunch. Now let's look at the main failures of this unit.

Torn boot

This problem is especially common if the boot is rubber rather than thermoplastic. As mentioned above about the internal CV joint, signs of a malfunction of this nature are determined by lubricant stains on the inside of the wheel rubber. The boot ruptures due to mechanical stress, rubbing or exposure to negative temperatures. Mechanical damage most often occurs when the vehicle is driven off-road. Therefore, it is recommended to do a visual inspection of these parts after each such trip.

Production of rolling balls

This is the case when the inner CV joint is knocking because the balls are worn out due to high mileage. The problem can also arise if the boot is torn, since dirt trapped in the lubricant damages the surface of the balls. As a result, the inner CV joint crunches when entering a turn or knocks on a flat road.

Support bearing wear

This bearing is installed on an additional shaft, which is used to increase the length of the CV joint mechanism due to the fact that the engine is not always located strictly in the center. Checking the internal CV joint also involves diagnosing this bearing, which mainly fails due to wear. The negative consequences of such a design solution are that the entire CV joint needs to be replaced along with the bearing.

How to check the inner CV joint

The inner CV joint is located on the axle shaft on the gearbox side; it is the one that first takes on the torque and directs it further. It is quite easy to check its suitability; to do this, you need to drive in a straight line, loading the unit with strong acceleration.

Note!

If it starts to crunch, the mechanism is badly worn. You just need to listen to understand which direction the sound is coming from.

There is another method to check the internal grenade:

- Suspend the car on a lift.

- The first gear should be engaged, in which you should lightly press the gas pedal to make the wheels rotate.

- Free-hanging wheels will experience a load under which the internal grenade will be bent. The crunching sound of a faulty unit in this position can be heard more clearly.

How to check a tripod CV joint: video

There are ball and tripoid grenades, they are used in different types of cars and have different characteristics. The tripoid type of CV joint is more commonly used as it is resistant to loads, but vulnerable to contamination. It also needs to be checked, and a detailed video will help.

How to check the outer CV joint

The external hinge is checked in the same way as the internal one, but for this the car does not have to be disassembled and suspended. You just need to find a free area, turn the steering wheel all the way and go. The breakdown is easily diagnosed: if the steering wheel is turned to the right and a crunching sound is heard, the right CV joint is broken; if there are sounds while moving to the left, there is a malfunction in the left grenade.

If there is a sudden crunching sound in the wheel, and the car accelerates or steers worse when accelerating, the problem may be in the constant velocity joint (CV joint). It’s easy to diagnose the exact fault, but it’s better to equip yourself with a lift, so the fault can be determined more accurately and quickly.

What is the danger of a faulty internal CV joint?

A dangerous situation occurs when the needles of roller bearings fall off. The danger is that they get inside the gearbox. The oil flow lifts them to the gears, and the transmission fails completely. To prevent this, you need to watch for signs of tripod malfunction. Modern automatic transmissions can jam even a small solid particle of abrasive, and needles from a bearing can completely damage the unit. Now imagine what will happen if the inner CV joint breaks, followed by the gearbox jamming at high speed?

Malfunctions are also dangerous for the assembly itself. The axle shaft often fails, paralyzing the movement of the car due to a malfunction of the internal CV joint when it simply jams. The worst thing is when such breakdowns occur when driving at high speed or in mixed city traffic on crowded streets. To avoid breakdowns, it is necessary to monitor the symptoms of a malfunction of the internal CV joint or, at a minimum, check the condition of its boot every 5 thousand miles. After all, the breakdown of this unit begins precisely with damage to the boot, which opens access to lubricant for moisture and dirt.

The CV joint crunches at low temperatures, what to do?

As a rule, at low temperatures, the cause of crunching of CV joints is poor-quality lubricant, which is not able to perform its functions in extreme cold.

Car manufacturers, when supplying their products to Russia, must take into account the operating conditions.

The frozen lubricant binds the internal elements of the grenade and does not get into all the cavities of the assembly, which is why the crunch appears.

At this moment there is no need to turn sharply and pick up speed; after a few kilometers (20-30) the components will warm up and the crunching will disappear by itself.

But the problem is that the internal grenades warm up quickly, but the external ones at very low temperatures may not warm up and the crunch will remain.

There is an opinion (and not without reason) that the problem is not only in the lubrication, but also in the design of the CV joint itself. The fact is that the lubricant put into the product may not be suitable for this design, while on other car models it works well even at temperatures below -20 C.

Some car owners are guilty of using polyurethane boots, which can be installed on some brands of cars instead of rubber ones. They say that in the cold they tan and make sounds. This is a controversial opinion that requires verification.

The problem can be solved by replacing the lubricant; some car owners recommend LM47, VERYLUBE, XADO, they performed well at low temperatures. But it’s difficult to give any advice here, the choice on the market is huge and opinions vary.

But, you need to change the lubricant not just by pressing it under the boot, but completely remove the assembly, disassemble it and press the new lubricant as much as possible instead of the old one into hard-to-reach places. It is these places that cause crunching in severe frost, especially for external grenades.

The design and principle of operation of the CV joint

First of all, the hinge is designed to transmit driving force from the engine to the wheels of the car. The second important function is to maintain movement at different wheel planes. In simple words, when driving over a bump or hole, one of the wheels will be located higher than the second, while the movement of the car will remain unchanged. The complex design allows the wheels to move in different positions. The operating principle of each type of hinge is the same, only the design is different. The grenade can rotate at an angle of up to 70 degrees, while transmitting rotational motion to the wheels.

There is no fundamental difference in the operation scheme of the CV joint. One part of the drive is attached to the engine using a wheel bearing, the second is connected to the wheels. When the gear is engaged, the engine transmits movement through the transmission, and the car moves. Each CV joint consists of an internal and external part. Inside the structure there are special balls that connect the two elements into a rigid structure. The outer part is more mobile and can work at angles up to 70 degrees. The internal element operates within 20 degrees.

Lubrication is important in the operation of a grenade. All internal parts move at high speeds, so good lubrication can reduce friction and wear on structural elements. As a rule, each hinge is covered with a rubber cap to prevent dirt from getting inside

It is worth noting that rubber protection is of great importance in the operation of the mechanism. If the boot is damaged, the lubricant comes out, dirt gets on important elements and the hinge fails.

As a rule, each hinge is covered with a rubber cap to prevent dirt from getting inside. It is worth noting that rubber protection is of great importance in the operation of the mechanism. If the boot is damaged, the lubricant comes out, dirt gets on important elements and the hinge fails.

External CV joint

The external hinge is very easy to identify visually. It is located near the drive wheel, as a rule, equipped with an ABS system polyhedron and a large pyramid-shaped rubber boot. As we have already written, the boot protects the grenade from moisture, dirt and dust.

The design of the CV joint is somewhat reminiscent of a driveshaft. But the latter, due to its design, cannot rotate at critical angles. This is due to the fact that the operating angle of the cardan transmission is very small, and at critical angles jerks begin, which have a detrimental effect on the gearbox.

A completely different matter is the CV joint. The design allows for a small-sized mechanism that will rotate the wheel in different planes, while maintaining a smooth ride and a comfortable ride.

The external “grenade” consists of a body and axle shaft, as well as a protective casing. There are metal bearings (balls) inside the mechanism. All structural elements are connected to each other using a metal ring. The principle of operation is simple, the mechanism rotates in different directions, the balls rotate inside the body in special grooves, and a smooth transmission of rotational motion occurs.

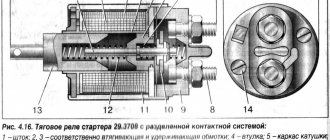

Inner CV joint

In some cases, the design of the internal “grenade” may be similar to the external one. But, as a rule, developers implement a different scheme. If the CV joint moves with the help of three bearings, it is called tripoidal. As practice shows, such a mechanism breaks down much less often. This is due to the fact that it is less subject to critical loads and changes in angles, since it is closer to the differential, that is, to the center of the car. Depending on the design, it may consist of balls of different sizes and diameters.

The principle of operation is similar to the external grenade, only due to the design features and location, the internal hinge operates at smaller degree ranges. Typically, the working angle is up to 20 degrees.

Video of the operation of the outer and inner CV joints on the drive shaft.

Outer and inner CV joints: differences and features

The external joint is considered to be connected to the wheel hub, and the internal one is located on the output side of the gearbox or drive axle gearbox.

Both of these units differ in design, which is due to the requirements placed on them:

- during operation, the drive assembly must change its length as the suspension moves from one extreme vertical position to another, this function is assigned to the internal hinge;

- ensuring the maximum angle of rotation of the front wheel is carried out by the outer CV joint, which is provided for during its design;

- the external splines of the outer “grenade” end with a threaded part onto which a nut is screwed, tightening the inner races of the wheel bearing;

- the splined end on the inside of the drive may have an annular groove for a retaining ring, or have a loose fit; the shaft is retained in the crankcase by other means;

- the internal hinge, due to its small deviations in angle, is sometimes made not according to the classic six-ball design, but in the form of a tripoid, that is, three spikes and needle bearings on them with spherical outer races, this is stronger, more durable, but does not work well at significant angles.

Otherwise, the units are similar, both consist of a housing with grooves for balls or spikes, an internal race, splines sitting on the drive shaft and a separator that positions the balls when rolling the working grooves.