A turbine is a complex power-injecting device. Unlike many other components of a modern car, its malfunction is not critical. However, it must be clarified that in this case there will be no normal operation, and the leakage of expensive oil and fuel will seriously hit the owner’s pocket. What signs of a diesel engine turbine malfunction can you detect on your own?

To begin with, it should be noted that the typical manifestations of a diesel turbine failure are very similar to the failure of other units and systems. Therefore, to accurately determine the cause of the appearance of a particular factor, it is necessary to carry out high-quality diagnostics using special stands and measuring instruments. An ordinary car enthusiast cannot do without contacting a service station.

Characteristic signs and possible causes

Often there is a combination of several obvious manifestations of a breakdown, but sometimes only one is observed. The malfunction can be determined by the following phenomena:

- increased oil consumption and leakage;

- change in color and visual increase in the amount of smoke;

- engine noise;

- temporary or permanent overheating;

- noticeable decrease in power and speed of acceleration;

- increased fuel consumption;

- increased emissions of harmful substances from the exhaust system and toxic odor;

- whistling or scratching in the turbine itself;

- floating idle.

The appearance of any of these items requires attention from the owner, prompt diagnosis and repair of the breakdown. The fact is that the lion's share of problems with diesel turbines, one way or another, relates to leakage and oil consumption. When it ends, the work surfaces will begin to wear off. To completely fail this mechanism, it is enough to work for just a few seconds without a lubricant. After this, restoration and repair will become impossible, all that remains is a complete replacement, and this is not cheap.

Variable geometry

The variable turbine casing cross-section is an ideal that has been sought since the installation of the gas turbine in the Chrysler automobile in 1958.

The interest in a variable geometry turbine is that it minimizes inertia and allows the turbine to operate optimally at higher speeds or at maximum load without the need for a control valve.

Until recently, all attempts to create such a turbine were unsuccessful due to the lack of suitable materials and technological limitations during production.

Currently, almost all turbocharger manufacturers have introduced their variable geometry systems.

Thus, Garrett offers a variable-section turbine T-25-VNT with a rotor that has additional movable blades, with the help of which the flow of exhaust gases is regulated at both low and high engine speeds.

There is also another design - Garrett T25-VAT. It has a single movable blade in the turbine channel, which reduces the cross section and, accordingly, the gas flow at low speeds. At higher rpm, the lobe is completely retracted to make the most of the turbine's output.

Both systems may have a safety valve installed to prevent overload.

The KKK company announced the start of production of a reliable and cheap turbocharger with variable geometry. In this design, the blades are not driven by a complex external system of levers, but oscillate freely on their own axes in such a way that maximum performance is ensured under any engine operating conditions. The degree of opening of the blades is limited by an adjusting ring, and the position of the ring is determined by the position of the accelerator pedal.

Smoke color and exhaust smell

The appearance of smoke in the exhaust system immediately draws attention. This is often accompanied by an unpleasant chemical odor that can be heard even while driving.

Black smoke

This phenomenon means the combustion of the fuel mixture in the turbine. The problem is caused by a lack of air in the fuel system. Need to check:

- tightness of connections of all pipes;

- ECU;

- air filter (most often this is the cause);

- performance of the fuel system;

- engine.

Bluish-gray color

In this case, oil enters the engine. Obviously, the reason lies in the leak. It is necessary to inspect all connections, and the reason lies in problems with the turbine or engine.

Milky white color

Most often this happens when the oil drain line is clogged.

Why doesn't the engine rev up? Possible causes and methods of eliminating them

Lack of engine speed when pressing the gas pedal is a common problem that most drivers have encountered. There are many reasons for this unpleasant situation: it can be either a transition from a gasoline engine to gas-cylinder equipment, or a simple engine malfunction. Let's study the reasons in more detail.

The engine does not pick up speed when you press the gas pedal: reasons

First of all, you need to pay attention to the “symptoms” of the problem: when it manifests itself, how, and whether there are additional signals indicating a malfunction. It is quite possible that the engine is fully operational and is being prevented from functioning normally by a sensor that was disconnected during repairs. The technician can fix this problem after a short inspection.

If engine failures occur without any serious reasons, careful diagnostics are required.

Let's take a closer look at the reasons that the car owner can correct himself.

A key factor in reliable engine operation is the quality of the fuel mixture, the characteristics of its flow, ignition and combustion in the working area of the engine. Violation of any of the above processes leads to problems with engine speed. That is why, in case of failures in the internal combustion engine, the first thing you should pay attention to is the operation of the fuel and oxygen supply system.

- If dirt, a mixture of oil and sand has accumulated in the air filter, air will penetrate into the engine unevenly, which will lead to a loss of engine power and, accordingly, to “missed” revolutions.

2. Malfunction of the intake system leads to excessive air leaks. The failure may occur suddenly, or it may become chronic. The intake of a large amount of air depletes the mixture, and there are too few flammable vapors in it. In this case, the engine starts, but during the trip the car cannot reach the required speed.

Signs and malfunctions of a turbocharger

- Blue exhaust smoke is a sign of combustion of oil in the engine cylinders, which got there from the turbocharger or engine. Black means there is an air leak, while white exhaust gas indicates a clogged turbocharger oil drain.

- The cause of the whistle is an air leak at the junction of the compressor outlet and the engine, and the grinding indicates the rubbing elements of the entire turbocharging system.

- It is also worth checking all the elements of the turbine on the engine if it turns off or stops working .

There are three reasons behind all turbocharger malfunctions

Lack and low oil pressure

Occurs due to leakage or pinching of oil hoses, as well as due to their improper installation to the turbine. Leads to increased wear of the rings, shaft journal, insufficient lubrication and overheating of the turbine radial bearings. They will have to be changed.

Oil contamination

This happens due to untimely replacement of the old oil or filter, water or fuel getting into the lubricant, or the use of low-quality oil. Leads to bearing wear, blockage of oil channels, and damage to the axle. Faulty parts should be replaced with new ones. Thick oil also harms bearings, as it produces sediment and reduces the tightness of the turbine.

Foreign object entering the turbocharger

Leads to damage to the compressor wheel blades (therefore, air pressure drops); turbine wheel blades; rotor. On the compressor side, you need to replace the filter and check the intake tract for leaks. On the turbine side, it is worth replacing the shaft and checking the intake manifold.

Structure of a car engine turbine: 1. compressor wheel; 2. bearing; 3. actuator; 4. oil supply fitting; 5. rotor; 6. cartridge; 7. hot snail; 8. cold snail.

All about turbine breakdowns on a vehicle

According to turbocharger manufacturers, it is very wear-resistant and also durable.

According to the manual, the permissible operating life of the unit exceeds 10 years of uninterrupted operation, but this is only an assumption by the manufacturers themselves. The fact is that practice shows frequent occurrence of turbine malfunctions

, as well as about its periodic breakdown. It follows from this: regardless of the promised performance, sometimes you still have to resort to troubleshooting, regardless of the type of motor.

In order to detect a malfunction in a timely manner, it is necessary to pay attention to the unusual “behavior” of the vehicle.

Main signs of turbine failure

The turbocharger is faulty if:

- power has noticeably decreased;

- when the vehicle accelerates, the exhaust gases are blue or white;

- During engine operation, extraneous noises are clearly heard (grinding, whistling);

- there is an oil leak or its consumption has increased significantly;

- decrease in oil or air pressure.

If any of the above symptoms are detected, the turbine must be subjected to diagnostics. Let's talk in more detail about the signs and malfunctions of the turbine.

First of all, it should be noted that in almost all cases, breakdowns in the turbocharger area are directly related to oil.

- So, the first point is the presence of blue smoke. This defect will “speak” of the combustion of oil in the cylinders, which penetrates into them from the engine or turbine.

- The second point is the presence of a whistle. The reason is an air leak. As for the grinding noise, it indicates rubbing elements in the turbocharging system. Be sure to inspect all components of the turbine on the engine. It may turn off from time to time or not work at all.

All acceptable turbocharger failures are based on three reasons:

- lack of oil or low oil pressure;

- oil contamination;

- penetration of some foreign object into the turbine.

So, let's dwell a little on each of these reasons.

- Insufficient oil or low oil pressure may result from a leak or pinched hoses. You may also encounter a situation where the hoses are incorrectly connected to the turbine. In this case, the wear of the rings and journal (on the shaft) increases significantly, and a lack of lubrication occurs and overheating of the radial bearings is possible. They will need to be replaced. The fact is that after running dry for just a few seconds, the turbine can not only harm itself, but also the entire unit.

- As for oil contamination, it is generally accepted that failure to replace the oil or filter in a timely manner, the presence of water or fuel in the lubricant, and the use of low-quality oil are the most common reasons. The consequences may be:

- sudden wear of bearings;

- formation of blockage in the area of oil supply channels;

- damage to the axle.

If such defects are detected, all faulty elements must be replaced.

- And a little about the penetration of any object into the inside of the turbine. Consequences:

- damage to the blades on the turbine and compression wheels, as well as the rotor.

Is it possible to carry out repair work yourself?

The turbine design itself is not quite simple. If you have already dealt with turbine repair, you will be able to figure it out. To deal with this yourself, you should know: the model, engine number, and manufacturer. As for the parts, it is best to purchase a repair kit specifically for your type of turbine. You will need:

- inspect the turbocharger;

- dismantle the turbine;

- take it apart;

- replace all components;

- install it in its original location.

Is it possible to repair the turbine yourself?

The design of the turbocharger seems simple and straightforward. And all you need to repair a turbine is to know the turbine model, engine number, as well as the manufacturer and have spare parts or a factory repair kit for turbines on hand.

You can independently carry out visual diagnostics of the turbocharger, dismantle it, disassemble and replace defective turbine elements, and install them in place. Inspect the air, fuel, cooling and oil systems with which the turbine closely interacts, check their operation.

Preventing turbine breakdowns

To extend the life of your turbocharger, follow these simple rules:

- Change air filters promptly.

- Fill with original oil and high-quality fuel.

- Completely change the oil in the turbocharging system after every 7 thousand km .

- Monitor the boost pressure.

- Be sure to warm up a car with a diesel engine and turbocharger.

- After a long drive, allow the hot engine to cool down by idling for at least 3 minutes before turning it off. There will be no carbon residue that harms the bearings.

- Carry out regular diagnostics and ensure professional maintenance.

Turbocharged engines are rapidly gaining popularity. If previously turbochargers were installed in heavy or powerful sports cars, now turbines can be seen in passenger cars, both with a gasoline engine and a diesel one.

Diesel engine turbines usually have a service life much shorter than that of the engine itself. In order to carry out preventive maintenance on time and not face the need to pay for expensive parts, you need to periodically check the operation of the turbine. This can be done independently, without contacting a car service.

Everything about turbochargers, or the Supercharger

We study the main malfunctions of turbochargers and technologies for their restoration.

Many motorists are wary of repairing turbochargers. And for good reason. At the same time, manufacturers allow some turbines to be repaired and even produce original components, while others even engage in industrial restoration of units. The reason for the low service life of rebuilt turbines is often the notorious human factor.

Presumption of innocence

A turbocharger (TC) operates at the crossroads of several engine systems, and its health depends on the health of other components. Therefore, if any complaints arise about the operation of the TC, it is important to conduct a thoughtful diagnosis of the unit as part of the motor. Diagnostics is also necessary in the event of a turbine failure - it will serve as a guarantee that a new or repaired turbine will not fail after a couple of thousand kilometers.

| Even a rag left in the intake system while servicing a machine can damage the shaft impeller, not to mention lost bolts or washers. Even a rag left in the intake system while servicing a machine can damage the shaft impeller, not to mention lost bolts or washers. | One example of the characteristic destruction of a compressor wheel when a turbine is twisted. An experienced technician can determine this detrimental mode by the particular wear of the blades and shaft. One of the examples of the characteristic destruction of the compressor wheel when the turbine is twisted. An experienced master can determine this detrimental regime by the particular wear of the blades and shaft. |

| Complete coking of the oil supply tube is typical for gasoline turbines due to higher temperatures compared to diesel ones. Complete coking of the oil supply tube is typical for gasoline turbines due to higher temperatures compared to diesel ones. | A classic of the genre is overheating of the turbine shaft due to oil starvation. It cannot be processed or restored. A classic of the genre is overheating of the turbine shaft due to oil starvation. It cannot be processed or restored. |

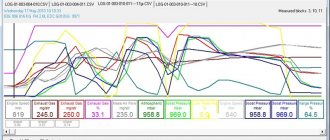

First, using a computer, the engine management system as a whole and individual sensors are checked. The vast majority of turbines are equipped with a boost pressure control mechanism; its failure could easily be the result of a trivial malfunction - for example, an incorrect signal from the air flow meter. There are often cases when, due to ignoring such diagnostics, specialized TV repair companies deliver... serviceable units.

Causes of malfunction

In order to inspect the turbine and identify a malfunction, it is necessary to understand what kind of breakdowns can occur in the turbocharger system.

Usually the most problematic elements are seals and bearings. Wear of these parts may cause backlash, noise, and you may encounter a turbine wedge. Operation may be disrupted due to a malfunction of the lubrication system, ventilation valves, or the piston rings are already sufficiently worn out. In this case, diesel fuel combustion products enter the crankcase and lead to negative consequences.

If smoke is noticed in the exhaust, most often blue, then you should pay attention to the PCV valve. Its incorrect operation increases the oil pressure in the turbine, which causes the lubricant to press through the seals. Once outside or into the forced air, the oil changes the composition of the mixture, causing the engine to significantly lose power and begin to emit the aforementioned smoke.

Downsizing

To combat boost inertia (slow response time to pressing the accelerator pedal) during sudden acceleration, turbocharger designers reduce the size of the turbines and increase their rotation speed.

KKK has developed new models of turbochargers (K-14, K-13, K-12, K-04, K-03) to replace the older K-24.

K-14 turbochargers, produced since 1984 (among others, they were installed on VW cars: Golf, Passat and Transporter), represent a development of the K-24 design.

The K-24 turbocharger weighs 8.1 kg, and its rotor diameter is 60 mm, while the K-14 turbocharger weighs only 4.9 kg, and its rotor diameter is 50 mm. The K-24 turbocharger rotor weighs 0.289 kg, and the K-14 only 0.191 kg. This results in a 40% reduction in inertial forces and results in a full second reduction in response time.

Garrett has also improved its turbochargers: from the older T-3 to the T-2, and from the T-25 to the T-15, the latter weighing only 3.3 kg and having a rotor diameter of 43 mm.

The reason for the desire to continually reduce the size of turbochargers is not limited only to considerations of boost inertia, but also lies in the fact that the turbocharger and the intercooler of the supply air are increasingly considered as a single unit. At the same time, car manufacturers are striving to use small engines in order to be able to improve the aerodynamic shape of their cars. It is also necessary to take into account the need to place additional devices that increase the comfort of the driver and passengers. The use of now mandatory catalysts and soot traps also requires additional space, so under the hood of a modern car it becomes simply cramped, and everything that is installed there must be of minimal dimensions.

When to check the turbine

If you use high-quality oil and treat the diesel unit with care, the turbocharger will operate properly for approximately 150 thousand kilometers. To detect any breakdown at its initial stage, you need to carefully monitor the turbine; just check the operation of the unit during an oil change.

Thus, the car owner can save significantly by repairing the problem at its initial stage, instead of replacing an expensive part.

Lack of turbocharger lubrication

4.1.Malfunctions of TC components and parts due to insufficient lubrication, both temporary and permanent

A lack of lubrication in a turbocharger has symptoms very similar to those that occur when the oil is chemically contaminated. In this case, a change in the color of the rotor and sleeve bearings is observed. From silver-white, these parts change color to yellow or even blue-black. Subsequently, if the cause of the lubrication deficiency is not eliminated, destruction of the rotor shaft may follow. The most serious consequence may be a turbine wheel coming off. The spacer bushings and plain bearings are also destroyed (photo 15-17).

Photo 15.

Photo 16.

Photo 17.

Possible causes of TC lubricant deficiency:

— general malfunction of the engine lubrication system, including wear of oil pump parts, malfunction of the oil pump pressure reducing valve, excessive clogging of the oil filter;

— presence in the crankcase pan of large deposits of coked oil and foreign objects (pieces of gaskets, metal fragments, etc.)

In this case, when the engine is idling, the oil pressure in the system is within normal limits. As the crankshaft rotation speed increases, the performance of the oil pump increases, which leads to the contaminants present in the sump being drawn to the oil receiver grid, and this can lead to a significant drop in pressure in the system just at the moment when the engine is running under load and needs lubrication. In this case, the emergency pressure sensor in the lubrication system does not work - the pressure in the system remains above the minimum, but it is not enough to ensure lubrication of the turbocharger, which operates in the most difficult conditions;

— reduction in the amount of oil supplied to the turbocharger due to improper condition of the supply tube. The tube may be clogged with coke deposits or mechanically damaged;

— clogging of the oil passages of the turbocharger housing. There may be several reasons for this phenomenon, and the most likely of them is the ingress of coke particles into the channels from the supply line of the TK lubrication system. When repairing the unit, it is recommended to replace the supply line with a new one. As a last resort, it is enough to thoroughly rinse and blow it to eliminate, if possible, the presence of contaminants in it. The oil channels of the TC housing may be blocked for other reasons. Some models of turbochargers have an additional oil filter, which is a fine mesh in a plastic housing. Plastic may break down during use. and its particles fall into the channels and block them. Also, the plastic housing can be destroyed as a result of improper installation.

First signs of trouble

Of course, if a car enthusiast does not have experience working with cars, you should not immediately disassemble the unit and try to identify the fault from the inside. There are several signs that indicate the turbocharger is not working properly:

- the appearance of bluish or black smoke during exhaust;

- very loud operation of the diesel unit under various loads;

- the engine often overheats;

- fuel consumption is steadily increasing, as is the rate of oil consumption;

- deterioration of traction, loss of power and dynamics.

Loss of diesel turbine power - causes, types of malfunctions

The emission of black or white smoke, noise and excessive fuel consumption are the main signs that indicate possible failures in the diesel engine turbine system. Loss of power from a diesel turbine can also be caused by other factors. Having detected the first malfunction signal, you need to immediately check the suitability of the mechanism, and, if possible, quickly fix the problem in the workshop.

Features of turbines for diesel engines

Diesel engines often use variable geometry turbines (abbr. TIG or VIG). In this mechanism, the bypass valve is replaced by special guide vanes that control the flow of exhaust gases that enter the turbocharger.

The guide vanes have the same operating principle as conventional turbine wastegates and are controlled by a vacuum system. A diesel turbine stops working when the blades in the diesel engine are closed and the exhaust gases are directed past the turbocharger. The disadvantage of such turbines is their sensitivity to high temperatures.

A variable geometry turbine reduces exhaust gas temperatures.

Turbine with variable geometry - diagram

There are only two car models in the world that use VIG turbines on gasoline rather than diesel engines - the Porsche 911 Turbo and the Porsche 718 Boxter.

The turbine does not wear out or break on its own if engine maintenance - changing oil and filters, using high-quality fuel - is strictly carried out in accordance with the manufacturer's manual. Malfunctions of the turbine can be caused by contamination on the filters, excess oil, or the ingress of foreign matter particles from the exhaust manifold. We list in detail the most common reasons why a diesel turbine loses power:

- Poor turbine lubrication. This is a consequence of low-quality fuel, clogged oil system of the car, clogged oil channels in the engine, clogged oil filter;

- "Hot parking" of a car. After a long drive, park the vehicle and immediately turn off the engine - this is how the turbocharger elements quickly wear out;

- The appearance of carbon in engine oil. Carbon accumulates in the turbocharger as deposits, which can also cause imbalance in the system;

- Output and construction of exhaust gas systems (diesel turbines are very sensitive here, because they have a built-in particulate filter). When the particulate filter is clogged, the pressure of the exhaust gases that enter the turbine increases. The shaft in the turbocharger cannot cope with the overload, and the mechanism emits a characteristic whistle;

- Foreign particles entering the turbine through the car's air intake. The unit fails when foreign particles damage the blades, the rotation balance is disrupted, and the shaft and bearings are severely damaged.

Turbine durability in a diesel engine

How long does a turbine run on a diesel engine? If the engine and vehicle are well maintained, the turbine begins to suffer wear only after 200,000 kilometers. If the car is mistreated, the turbine can break down even after 50-80,000 kilometers. Therefore, it cannot be said that for each turbine there is an exact date when it must break down. The only precaution to keep this component at its best is to always take care of the machine, check it and maintain it regularly.

Turbine malfunction - exceptions

The whistle of a diesel engine turbine does not always indicate its breakdown or malfunction. Some diesel engines, especially on older car models, have this drawback (a slight whistle is heard when decelerating and accelerating). So when buying a used car, a whistle can be a characteristic sign. The situation changes when the whistle becomes deafening and unnatural, and was absent during the test drive of the car.

A strong and persistent whistling noise can also come from worn bearings rather than from the turbine itself. If an unpleasant sound is heard even when the car is in neutral, we can rule out that the problem is caused by the turbine. In any case, if the vehicle owner is already hearing a strange noise and a deafening whistle, it is better not to make long trips and take the car to a workshop as quickly as possible.

Source: https://turbi.com.ua/poterja-moshhnosti-dizelnoj-turbiny/

Self check

The initial check can be carried out on your own, so as not to spend money on computer diagnostics, which often costs a lot of money. First, the turbocharger needs to be carefully inspected.

First of all, the level and quality of the engine oil used for the diesel engine is checked. Then you need to make sure that no foreign object has entered the compressor.

After the procedures are completed, it is necessary to evaluate the color of the exhaust. It can also point out specific problems with the turbine. If the exhaust color is black and a drop in power is noticed, then most likely you will have to deal with an over-enriched mixture. It appears due to a breakdown of the air intake-exhaust system. At the intake, insufficient air enters the cylinders, and at the exhaust there may be leaks, which lead to loss of power.

Blue or even white smoke from the exhaust pipe indicates that oil enters the cylinders and then burns in the working chamber. In this case, oil consumption can increase to about a liter per 1000 kilometers. It is necessary to check the operation of the rotor and the cleanliness of the filters. The rotor must have slight play and not touch the housing, otherwise the part requires immediate inspection and repair.

A heavily contaminated filter cannot pass the required amount of air, which creates different pressures in the turbocharger housing and in the cartridge with bearings. From this cartridge the oil enters the compressor. If the problem is not in the filter, then you need to check the entire oil supply system, hoses and pipes for bends, cracks and crevices.

The tightness of the pipe connections can be checked with the engine running. Whistling and creaking, as well as air breaking through the system, indicate that the clamps need to be tightened. Any leak or damage will result in insufficient air supply to the cylinders.

Another cause of turbine malfunction is improper oil drainage due to gases entering the crankcase. It is necessary to check the ventilation system so that the diesel engine does not start to breathe.

Turbine malfunctions

There are 4 main causes of turbine damage:

- — lack of oil (oil starvation);

- — ingress of foreign objects;

- — contaminated oil;

- - crankcase gas pressure.

Lack of oil (oil starvation)

Bearings are the first to fail due to lack of oil. After the failure of one or more bearings, other damage may follow, such as friction of turbine and compressor rotors, wear of o-rings. In the worst case, the turbine shaft may break.

Under normal conditions, the turbocharger shaft and bearings operate at a temperature of 60-90ºС.

Due to the fact that the turbines on most diesel engines are cooled by oil passing through the housing, an insufficient amount of oil leads to a sharp increase in heat transfer to the turbine shaft from the turbine wheel side. This heat, combined with the heat generated by friction in the bearings, raises the temperature of the shaft to approximately 400°C, causing it to overheat and coke the remaining oil on the shaft. The oil supply holes of the bearings, as well as the middle turbine housing, are clogged with coke, which leads to an even greater shortage of oil.

Under all these conditions, the overheated shaft begins to rotate in the bearings almost “dry”, which leads to the breakdown of the oil wedge, wear of the tin layer on the bronze bearings, and sticking of bronze on the overheated shaft. Increased wear of the bearings occurs, the clearances in them increase to unacceptable levels, which leads to increased play of the entire shaft.

An increase in bearing clearances, in turn, leads to the fact that the turbine and compressor impellers, having taken up the entire gap between the housings, begin to wear out on them. Another force comes into play - an introduced imbalance, which becomes much greater than permissible and accelerates the process of dying of the turbocharger.

This is usually accompanied by characteristic sounds - grinding, whistling, or howling of the turbine.

In total, in the item “Lack of oil” there are three sub-items:

- Sharp (rapid) oil starvation

- Smooth (slow) oil starvation

- Intermittent oil fasting

- Severe (rapid) oil starvation occurs when the turbine suddenly loses its ability to be lubricated by flowing oil. This can be caused by a break in the oil supply tube, its kinking, a sharp decrease in the performance of the oil pump, lack of oil in the lubrication system, etc. This can also include a “dry start”, which sometimes happens when a turbocharger is installed incorrectly after repair or purchasing a new one. An air plug remains in the middle housing of the turbine, which the oil cannot press through for quite a long time, leading to the fact that when the engine is running, the turbine shaft rotates under conditions of insufficient oil, which inevitably leads to its overheating, the formation of coke deposits, sticking of bronze bearings and failure. building the entire turbocharger in a fairly short time.

- Smooth (slow) oil starvation is the gradual wear of parts of a turbocharger that operates under conditions of a constant slight lack of oil. It enters the turbine, but its quantity is not enough for cooling and operation at high loads. In such cases, all the processes described above occur slowly, the turbine does not die quickly, it can take months. This happens in cases of poor performance of the oil pump, coking of the oil supply line, kinks in the tubes, and the use of unsuitable oils.

- Periodic oil starvation is associated with improper operation of turbocharged engines. The main reason for such oil starvation is engine shutdown after active use. When operating at heavy loads, high speeds, the turbine on the engine heats up quite strongly, and cooling occurs either only by oil passing through the turbine, or by the engine cooling system (typical of gasoline engines). Therefore, when the engine suddenly stops, the supply of oil to cool it, or oil and coolant, stops supplying the heated turbine. This leads to the fact that the shaft, bearings and turbine housing, having a high residual temperature, heat the oil remaining in the turbine cavities to temperatures at which it begins to coke, deposits appear in the oil supply channels, which leads to a decrease in their cross-section and, subsequently, less oil throughput through these channels. Thus, we can say that the owner himself is slowly, systematically “killing” his turbocharger through improper operation. After active driving, work, heavy loads, the engine needs 2-3 minutes to cool with oil and coolant all the units that need it, first of all the turbine.

Examples of oil starvation:

Entry of foreign objects

The reason for the failure of a turbocharger, such as the ingress of foreign objects, can be divided into two parts:

- Getting into the compressor wheel

- Hitting a turbine wheel

Let's start in order.

1. The entry of foreign objects into the compressor wheel mostly indicates a malfunction of the air supply systems to the turbine. This may be a damaged air filter (or lack thereof), which does not prevent the entry of small particles and dust in the air; loose connections of the inlet pipes through which unfiltered air can flow, their damage. Moreover, the physical size of particles in the supplied unfiltered air can vary widely: from small ones, causing grinding of the compressor wheel blades, to large ones, causing serious deformations.

Damage to the compressor wheel can be caused not only by particles contained in unpurified air, but also by detached pieces of the filter, parts of a damaged air supply system; pieces of rags, tools and other hard and soft objects forgotten during engine repairs.

photo of damaged compressor wheels for example:

2. Damage to the turbine wheel can be caused by parts of damaged piston rings, valve seats, the valves themselves, as well as parts of burnt-out pistons. All these reasons are a consequence of a critical engine malfunction. It is urgent to find the problem and fix it.

An example of a foreign object getting into a turbine wheel:

Damage to the compressor or turbine wheels entails the appearance of an imbalance, even a small one, but at high rotor speeds it becomes critical, destructive, and subsequently leads to breakdown of the turbocharger.

Contaminated oil

The turbocharger is tightly integrated into the engine's life support system, as we discussed above, and is lubricated by the same oil as the engine, with one exception! Oil enters the turbine in most modern engines after it has passed through the main engine systems and lubricated them. In practice, this means that it enters the turbine very last, after which it drains directly into the crankcase. Rare exceptions occur when a separate line is provided for lubrication of the turbocharger, coming directly from the oil pump.

Checking with the engine running

The easiest way to check a turbine on a diesel engine requires the presence of at least two people.

- Start the engine.

- Locate the pipe between the turbocharger and the intake manifold.

- Pass it on.

- Press the gas for a few seconds.

When the turbine is operating correctly, you will feel that the pipe is noticeably inflated. If this does not happen, various cracks and defects in the collector are possible. You should seek qualified help to troubleshoot the problem.

It is very important to understand that you can carry out diagnostics yourself, but repairs must be entrusted to professionals.

Unqualified intervention can lead to the fact that a small malfunction will lead to the breakdown of the entire part and put the car owner in front of the need to change and repair the turbocharger. It is necessary to contact a trusted service center, where specialists will quickly and efficiently eliminate the malfunction and extend the life of the turbocharger on a diesel engine.

Turbine lifespan on diesel engines: opinion of car owners

- Still alive

“Judging by reviews of the repair of diesel engine turbines from most car owners, the operating rules are as follows: fill in high-quality lubricant and change it on time, adhere to the correct cooling mode when stopping. Then, throughout the entire service life, repairs to the turbine on a diesel engine will not be required. My car has 147,000 km on it, and the turbocharger was and is in perfect condition.” - The resource is no less than that of the engine itself

“I drove 226,000 kilometers on my two-liter Audi TDI. Not long ago I carried out a technical inspection; the turbine is original and works flawlessly. Servicemen reported that the service life of the turbocharger is exactly the same as that of a diesel engine. Moreover, the variator will last just as long. Germany has always made and will continue to make durable cars. After all, they have experience and a good brand reputation.” - Much depends on the fuel

“I had the opportunity to observe engines that have driven more than 200,000 kilometers. However, their owners take care of their cars, fill them with additives, use only high-quality fuel, and generally know these engines like the back of their hand. I believe that if the fuel is good, then everything will be fine with the car. But if you fill it with low-quality diesel fuel once, the mechanism will break.” - Mileage doesn't say much here.

“How does a turbine operate on a diesel engine? Imagine that you woke up a sleepy sprinter and forced him to run; he is unlikely to be the first to reach the finish line. And after running, his breathing will not immediately calm down. It's the same with a turbocharger. No matter how much you drive the car, it does not affect the performance of the turbine in any way. I had a car with a mileage of 240 kilometers, but the pressure in the turbine was normal, we were convinced of this when we took measurements at a car service center.” - You can easily ruin a new one

“Are you going to buy a used car or a contract turbocharger? There is no guarantee that repairs will not be required. Even if the engine and turbine are new, everything can be broken within a day. Moreover, it will no longer be possible to restore the power unit. Here you don’t even need to drive a car in extreme mode. Just turn off the engine incorrectly or turn off the ignition a couple of times if the engine is not running at XX speed, but much higher.” - It's all about care

“On my car, the turbocharger is cooled using antifreeze, and the mechanism is covered with a protective casing, and there is electrical control. I think that the turbine will serve for a very, very long time. I have already ridden 180,000 km without any problems. The blades are as clean as the first snow. The whole secret is in proper care."

This is interesting: Checking compression in cylinders with your own hands