How does it work

The principle of operation of a lambda probe is to compare the indicators of two electrodes, one of which is located in clean air, and the second in the exhaust manifold.

The VAZ 2110 lambda probe is made of heat-resistant materials, since the exhaust valve system and exhaust system have extremely high temperatures during prolonged engine operation.

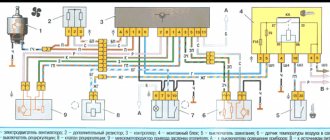

The main structural elements of the lambda probe are:

- steel body;

- external platinum electrode;

- internal zirconium electrode;

- ceramic insulator between the inner and outer electrodes;

- electric heater;

- protective casing for the outer electrode.

Also, lambda probes, with some technical differences, have a 4-pin connector:

- 1 contact - signal transmission to the electronic control unit;

- 2 - electrical power;

- 3 and 4 - electrical power supply to the electric heater.

The main task of the lambda probe is to determine the amount of unburned oxygen in the exhaust pipe.

The electronic control unit supplies the electrodes of the lambda probe with a voltage of 0.45 V.

The outer electrode determines the amount of ambient oxygen, the inner electrode determines the amount of oxygen in the exhaust gases. Having received the data, the sensor transmits the corresponding signal to the electronic control unit of the internal combustion engine. The transmitted signal is the difference between two indicators.

The control unit, having processed the received signal, makes adjustments to the operation of all components of the fuel system, and also ignites the combustible mixture earlier or later. This contributes to more stable and smooth engine operation.

On VAZ-2110 cars with 8-valve and 16-valve engines, on which an injector is installed, the sensor is located on the exhaust manifold of the car in front of the resonator.

A special feature of oxygen sensors on VAZ cars is their operating temperature. They begin to function when the temperature reaches 300–400 °C.

In the first minutes after starting the engine, its operation is monitored based on the readings of other sensors: mass air flow and internal combustion engine temperature, as well as the throttle opening sensor.

When the electric heater warms the device to the required temperature, the control unit begins to take into account its readings.

On previously produced VAZ-2110 cars, the manufacturer installed simpler lambda probes, the design of which did not include an electric heater. Consequently, the control unit read its readings only after the engine had sufficiently warmed up. At the same time, before warming up and subsequent monitoring of the operation of the internal combustion engine, the exhaust gases contained a significant amount of harmful elements.

After the approval of new legislation concerning a clean environment and a reduction in air pollution, car manufacturers began to install lambda probes that are able to independently warm up to the required temperature and, after a short period of time, provide less toxic emissions into the atmosphere.

Also, on a certain type of VAZ-2110 engine, the manufacturer installed a system of two lambda probes, which is also located on the exhaust system.

The first is located in front of the catalyst. It determines the quality of the exhaust gases before they enter the catalyst.

The second is after the catalyst, thereby checking the quality of its work, which consists of purifying exhaust gases to the level required by law.

What is this?

An oxygen sensor or lambda probe for a VAZ 2110 is a device that is located on the exhaust manifold in the exhaust system of your car.

Data transmitted from the device allows the electronic control unit to optimize the composition of the air-fuel mixture. If the mixture entering the combustion chamber turns out to be lean or excessively rich, the sensor reports this, after which the mixture begins to be adjusted.

Symptoms of malfunction

The main symptoms of a malfunction of the air flow sensor on a 16-valve VAZ-2112: checking the mass air flow sensor

Where is it installed

By the behavior of the car, you can quite easily determine that the lambda probe has become unusable:

- The car jerks while driving;

- The revolutions are floating;

- The catalyst is not working properly;

- Fuel consumption increases noticeably;

- Exhaust gases contain a large amount of toxins.

The operation of this sensor requires constant monitoring. According to the operating manual, the check is performed every 10 thousand kilometers traveled. But if the operating conditions of the car are difficult, you have to regularly drive in difficult conditions, or the engine is overloaded, then it is better to check it more often.

Tuning and repair of VAZ 2110

Why did you start writing this article? All because I myself am the owner of a VAZ 2110. And then one day I encountered a problem when the engine’s operation became unstable: the speed began to fluctuate, and not constantly, fuel consumption increased, and even the check error light came on. Arriving at the service station, I did computer diagnostics and, lo and behold, the computer says that everything is fine. And then the employee says that this is possible if some kind of lambda probe fails. What is this was a huge question for me then. Or the problem is a clogged catalyst. Honestly, my first thought was that the service technician wants to make some money, so I refused the repair and decided to figure out the problem myself. And now I want to convey this information to you.

Replacing the oxygen sensor

Diagram, device of the VAZ 2110 gearbox. Replacing the airbag, signs of malfunction

If any damage occurs, the sensor must be replaced. You can try to do this yourself. Let's consider the situation of replacing a lambda probe on a VAZ 2114:

- We put the car on an overpass or drive it into a pit and remove the motor protection (to replace the sensor with the neutralizer).

- We are looking for the wires from the oxygen sensor, and follow them to the sensors themselves, they are located on the catalyst (the first before the converter, the second after).

- We cut the clamps and disconnect the connectors.

- Let the system cool down.

- We take a wrench for “22” or special. head and unscrew the sensor.

- We take a new sensor and install it in place of the old one. We tighten the nuts.

- We connect the wires to the connectors.

- Use new clamps to secure the wires to the cooling system (do not allow contact with the exhaust pipe).

- Install the protection in reverse order.

On other car models, replacing the sensor will be identical.

https://youtube.com/watch?v=68L_IkIfRu4

Replacement problems

When replacing, the old sensor may stick to the pipe. In this case, proceed like this:

Generously pour wd-40 and try to unscrew it. Turn on the engine, heat the exhaust system and unscrew the sensor. Try to heat (being careful) the sensor itself and unscrew it. Tap it lightly with a hammer and try to unscrew it again. If this does not help, try “thermal shock”. Pour cold water onto the well-heated sensor

Try unscrewing it again.

Oxygen sensor price

The price of an oxygen sensor will vary by region and model. It ranges from 1000 to 3000 rubles. Buy a lambda probe in specialized stores and only with a guarantee.

Causes of oxygen sensor failure

- Coolant or brake fluid has come into contact with the sensor housing.

- The fuel used has a high lead content

- Severe overheating of the sensor caused by unclean fuel (clogged cleaning filters)

- The sensor has simply expired

- Mechanical damage to the sensor while the vehicle is moving.

A failed sensor will affect the operation of the vehicle as a whole and lead to additional problems. But using them you can immediately determine a possible breakdown of the sensor and replace it in a timely manner.

Related problems when the oxygen sensor fails

- The car began to consume more fuel than usual

- The car began to move jerkily

- The engine became unstable

- The normal operation of the catalyst is disrupted

- When testing for exhaust gas toxicity, the result gives inflated values.

In conclusion, I would like to give advice: in order to avoid the problems described above in the future, monitor the performance of the lambda probe. Check its condition every five to ten thousand kilometers.

Causes of failure

Old and new samples

Before starting the test, it is necessary to determine the reasons why the sensor stopped working correctly.

- Coolant has leaked inside the device.

- Unsuitable cleaning agents were used to clean the body of the device.

- The gasoline you fill your car with contains large amounts of lead. A popular breakdown typical for cars of those owners who prefer cheap gas stations.

- A banal overheating of the heat-resistant sensor, which again occurs due to low-quality fuel.

Article on the topic: Why the stove on the VAZ 2114 does not heat up

How to understand that the lambda probe has failed and replace it: advice from car enthusiasts

Cleaning, replacement, malfunctions of the throttle position sensor (TPS), throttle assembly of the VAZ 2110

1. If the lambda probe is faulty, disturbances in engine operation will be noticeable.

“The main function of the lambda probe is to detect carbon monoxide in the exhaust gases of a particular vehicle. Taking into account the data received from the oxygen sensor, the fuel supply to the cylinders is regulated. When the lambda probe is faulty, problems with the engine are obvious: too much fuel consumption, a specific smell after turning off, etc. Replacing with a resistor is pointless, since the computer perceives the constant resistance of the resistor as a malfunction.”

2. The main sign of a lambda probe failure is an increase in speed.

“When the lambda probe malfunctioned, I discovered several characteristic moments (increased speed, high gasoline consumption, etc.). But the most obvious sign for me was the increase in speed: the car first accelerates, then shuts down, and so on again and again. It feels like you are letting off the gas, and then squeezing it again. After replacing the sensor, all the problems described, including the speed increase, disappeared.”

3. Replacement of the lambda probe must be justified.

“I would like to say that the probability of deformation of the wires is much higher than the probability of failure of the sensor itself. At the first suspicion that the lambda probe is broken, you should disconnect the connector, carefully inspect it, and also inspect the wires for their integrity. At the points where they enter the connector, the wires often become pinched and lose their functionality. After this, it is necessary to check the operation of the sensor, namely: measure the voltage in various engine operating modes.”

4. When replacing a lambda probe, one very important nuance must be taken into account.

“The process of replacing the sensor cannot be called complicated, but it does require some preparation. The most important part of the pre-work process is preparing a special 22 key with a slot, which will be needed to remove the sensor.

Without such a device, the lambda probe may not respond. A standard open-end wrench, as a rule, does not allow you to grasp the base of the sensor due to the presence of ebbs on the exhaust manifold near it. If there are no ebbs, using a wrench can damage the edges of the sensor nut, because it sticks strongly to the exhaust manifold and is made of a rather soft metal.

Faced with this problem, I found out that the original key for a Honda car costs more than 70 euros, so I decided to make a device for removing the lambda probe myself.

I'll tell you how. First, I took a 22-size spanner and welded a 30-size nut to it. After that, I made a through slot on one side of the wrench and the nut welded to it. It is needed in order to insert the lambda wires into the key and nut, because the connector at the ends of the oxygen sensor wires does not pass through the 22-socket wrench.

So, the lambda probe connector needs to be threaded through an additional 30 socket wrench, which is already attached to a 30 nut welded to a 22 key. With these two keys you can unscrew even a tightly secured lambda. It turns out simple, economical and effective.”

5. The lambda probe can be replaced with your own hands.

“I was able to replace the lambda probe on my car myself.

The original device was single-wire, and as a replacement I also bought a single-wire lambda probe from Bosh.

I will describe the replacement algorithm:

- We heat up the engine (this will make it easier to unscrew the screws securing the exhaust manifold cover and the sensor itself).

- Disconnect the negative battery.

- Disconnect the lambda connection connector.

- Let's analyze the situation: see if it is possible to unscrew the lambda probe and whether there is a tool suitable for this purpose (read about how to make a device for removing the lambda a little higher).

- Unscrew the sensor. We try to install a replacement, check whether the thread is suitable, and look at the screw-in depth.

- At a distance of 15 cm from the lambda probe body, cut off the wires. The steps described in this paragraph and the next are relevant if you are dealing with a non-original sensor.

- We connect the wire of the new sensor with the wire from the old lambda probe. The standard package for the device usually includes a connecting tube measuring 2-3 cm. We insert the wire of the new sensor into the thermal tube, which is also included in the kit.

We strip the wires (no more than 1 cm) and insert them into the tube on both sides. Then we squeeze the tube with maximum force and check the reliability of the connection. At the end, the heat tube should be inserted into the joint and heated up this area with a lighter (do not forget to rotate the joint during the heating process).

- We screw in the new sensor and connect the connector.

- Install the collector protective cover.

- We connect the negative battery, turn on the engine, and then check its operation.”

Description of the oxygen sensor

Let's start with a description of the device. We invite you to familiarize yourself with its purpose, structure, and operating principle.

Purpose and location

The VAZ 2110 lambda probe largely influences the stable functioning of the engine, ensuring the normal operation of its parameters. This controller is an electronic device used to determine the amount of oxygen present in the exhaust gases. This is necessary in order to reduce the volume of harmful impurities and elements contained in exhaust gases. In order to ensure the required proportion of the air-fuel mixture, which affects the reduction in the concentration of impurities, air must be supplied to the engine in the required quantity.

Lambda probe installation location

This is not always achieved, and the reasons may be different. If the controller fails, the carbon monoxide content in the exhaust gases will be about 3-7%, while the standard value is 0.3%. As for the location, this sensor on a VAZ is installed on the exhaust pipe of the muffler, from below. The readings recorded by the lambda probe are transmitted to the motor control unit. And the ECU, focusing on them, adjusts the composition of the combustible mixture, thus setting the required time for the injection phase.

Design and principle of operation

The VAZ 2110 oxygen sensor consists of the following elements:

- steel body;

- insulator component, which is made from ceramics;

- O-ring with wiring and cuffs;

- a special case with holes for ventilation;

- ceramic tip;

- conductive contact;

- a special shield, which also has holes through which gases are released;

- filament coil.

The device is based on two electrodes - internal and external, the first is made of zirconium, and the second is made of platinum. The zirconium electrode is in direct contact with the exhaust gases, and the platinum electrode is in contact with the air. The values that the controller receives are based on the potential difference between these elements. To ensure optimal operation of the oxygen controller, the device must be heated to 300-400 degrees (video author - MotorState channel).

The temperature is quite high, it is achieved through the use of a special heating component, which is built into the structure of the lambda probe. When the engine starts, the control unit adjusts the composition of the combustible mixture based on the readings of other controllers, and not just the lambda probe. In particular, we are talking about mass air flow sensor, throttle opening sensor, antifreeze temperature in the system, etc. And the control unit begins to refer to the lambda probe readings only after the device has warmed up to operating temperature.

Kinds

The first “Ten” injection engines used standard oxygen controllers from the manufacturer Bosch. In 2004, when these car models began to be equipped with more modern injection systems, which were called January 7.2, Bosch M7.9.7, the cars began to be equipped with modernized versions of VAZ oxygen regulators. The latest version differs from the earlier one in that it is equipped with a ceramic heating element, thanks to which less electricity consumption is achieved.

But even this allowed the controller to warm up faster. Currently, Bosch produces seven different types of oxygen sensors with different powers - 12 and 18 W. It should be noted that these devices differ from each other, perhaps, in the values of energy consumption and the number of contacts. In all other respects they are identical.

GENERAL INFORMATION AND OPERATING PRINCIPLE

What is a lambda probe (oxygen sensor)

As can be understood from the name of the part, an oxygen sensor (OS) is a device through which the ECU receives information about the amount of oxygen remaining in the exhaust gases.

The DC is a rather complex device in terms of design. It consists of a ceramic electrolyte that can withstand extremely high temperatures, up to four hundred degrees. The electrolyte is made of zirconium dioxide, the surface of which is treated with yttrium oxide. The surface of the oxide is coated with platinum. The use of platinum is due to the fact that it is a material with maximum thermal conductivity.

In addition to the main electrolyte, the design of the lambda umbrella consists of the following parts:

- Protective shielded tips on both sides of the electrolyte, on which there are holes for air intake and exhaust gas. The tips, paired with an electrolyte, are the main functional part of the oxygen sensor, by which the analyzing device determines the potential difference;

- The tips are a kind of housing, inside of which there is an element with high current conductivity (collector);

- Between the tips there is a device that reads the resulting electrical signal;

- All structural elements of the oxygen sensor are located inside a metal housing. The lambda probe is connected to a wiring of four wires: 2 white wires, which are responsible for powering the device, and two black wires - the first transmits the received data to the ECU, the second is grounding.

The principle of operation of a lambda umbrella is as follows: the electrolyte, located in the exhaust gas flow of the car, is heated to a temperature of 300 to 400 degrees thanks to the built-in heating element. This temperature is necessary for the zirconium to reach its maximum conductivity and for the system to start working. The DC is installed in such a way that the tip on one part of it is in contact exclusively with exhaust gases, and the second tip is in contact with clean atmospheric air.

Article on the topic: How to connect the State on-board computer to a VAZ 2110 (instructions)

When a sufficient amount of oxygen accumulates inside the manifold located inside the tip, the potential difference changes on the electrolyte, data about which is transmitted to the ECU, and the electronic systems of the fourteenth change the amount of fuel supplied to the cylinders.

The optimal ratio of fuel and oxygen in the combustible mixture is 14.7 to 1; it is with this proportion that the greatest efficiency of the power unit is observed.

HOW TO CHECK THE LAMBDA PROBE

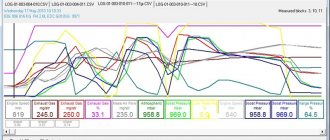

Check one of the sensor terminals, namely the signal terminal. For this:

- Or use a scanner.

- Or using a motor tester. Using the probes, the connection is made and the recorder is turned on. Thanks to the second method, you can see the waveform, current and peak values. The serviceability of the sensor can be determined by the signal shape.

So that you are not mistaken, I will explain that the main indicator for a lambda probe is not the mixture composition or ignition timing, but the oxygen content. How the process occurs: A reference voltage of 0.45 V is sent from the electronic control unit to the signal pin of the sensor. To be sure, you can remove the terminal from the sensor and take measurements using a multimeter. If everything is so, then the sensor is working.

OPERATION PROCESS OF OXYGEN SENSOR

When the volume of oxygen in the exhaust gases increases, the voltage supplied to the sensor decreases to 0.1 V, when there is less oxygen than required, it increases to 0.9 V. The VAZ 2110 features a zirconium oxygen sensor, due to which the voltage jump, depending on the volume of oxygen, occurs as a percentage stoichiometric mixture, with a ratio of 14.7:1. Given this, the fuel-air mixture ignites.

If you understand how the lambda probe works, you will understand how to make a diagnosis. Well, let’s say the ECU (electronic control unit) error P0131 pops up, which says “Low signal level of oxygen sensor 1”. Here you need to understand that the sensor checks the state of the system and therefore if the mixture is lean, it will report an error. In such cases, replacing the lambda probe is not relevant.

You may ask, “So how do we define a problem? How to find out the problem is in the system or in the sensor? For understanding, I want to consider several situations:

- Case one. So, an error about a “lean mixture” appeared, we check the voltage with a multimeter - low. We perform the following actions: add gasoline supply (you can pinch the return drain hose). If this is not available, you can use a syringe to pour some fuel into the intake manifold. And see if the sensor responds. If the sensor shows that the mixture is rich, then the breakdown is not in the lambda probe, but in the fuel supply system. Fuel is supplied in less quantity than required.

- Random number2. The sensor indicates an over-enriched mixture. We make an artificial suction. You need to lift the vacuum hose and also check the voltage on the lambda probe; if it decreases, then the sensor is working.

- And the last third case. This situation is rare, but still unpleasant. We clamp the return line (by making a suction) and at the same time 0.45 V remains on the sensor - we can say that the lambda probe is faulty. Since it must react to any changes in the fuel-air mixture by changing the voltage at the signal pin, reporting an error. During normal operation of the sensor, during a sharp change in the quality of the air mixture, it should also change the voltage sharply. If the voltage changes smoothly, then the sensor is worn out or clogged with carbon deposits. In this case, you can CLEAN the OXYGEN SENSOR or replace it with a new one.

There is one thing that can be confusing:

If there is a misfire, the output is a mixture with a large amount of fuel and air; the sensor interprets this as a large amount of oxygen in the exhaust gases, and will show errors even if you change the sensor to a new one.

Also, do not miss such a thing as the appearance of a gap in front of the oxygen sensor, through which oxygen can enter from the outside. And isn’t it difficult where this will lead? That's right, the sensor will report a lean mixture. Consequently, the mixture entering the engine will become over-rich, and the sensor will still report lean. In this case, it is not a bad idea to use a gas analyzer, which will show the truth whether the mixture is enriched.

That’s basically it, we figured out what a lambda probe is, how it works and how to diagnose it. I look forward to new meetings at vaz2110-remont.ru.

(votes: 4, average: 5.00 out of 5)

Diagnostics

It should be noted that checking the functionality of the lambda probe should be carried out in conjunction with vehicle maintenance, at intervals of every 10 thousand kilometers. However, if the car was operated in unfavorable climatic conditions, which is applicable to Moscow, or in aggressive mode, maintenance should be carried out more often. This is the manufacturer's recommendation.

The manufacturer also does not recommend performing independent diagnostics or repairs if there are signs of any malfunction. To fix it, you should contact a service center.

Diagnosis by visual inspection

The beginning of any diagnosis begins with a visual examination. Primary methods for diagnosing an oxygen sensor include:

- visual inspection of the electrical wiring of the lambda probe for integrity and absence of mechanical damage or rupture;

- inspection of the lambda probe itself. There should be no soot or hard deposits on its surface.

Carbon deposits on the oxygen sensor housing indicate a faulty electric heater or an excessively rich combustible mixture entering the combustion chambers.

Solid deposits on the sensor body indicate poor fuel quality and the presence of harmful impurities in it, or an incorrect proportion of the combustible mixture.

If there are no visible causes of the malfunction, more detailed diagnostics are performed.

Detailed diagnostics

At the service center, by connecting a diagnostic computer, all electronic systems of the car are checked. If one of them malfunctions, the on-board computer detects the error and stores it in its error register. Each error has its own code, which makes it easy to find out the source of the problem.

In the absence of a diagnostic computer, plumbing diagnostics are required, which involves partial disassembly and diagnostics with a voltmeter. It consists of the following operations:

- starting the engine and warming up to operating temperature;

- engine stop;

- disconnecting the sensor connector and connecting a voltmeter to it;

- restarting the internal combustion engine and one-time increase in idle speed to 2500 thousand per minute;

- disconnecting the vacuum pipe from the fuel pressure regulator;

- checking the voltmeter readings. If the reading is equal to or less than 0.8 V, the 2110 oxygen sensor is faulty. It cannot be repaired, therefore, replacement is necessary;

- checking the oxygen sensor to detect a lean fuel mixture. In this case, the air supply to the engine is artificially cut off. If the voltmeter reading is 0.2 V or less, the sensor is working. Other readings indicate a sensor malfunction.

Also in the service center, using a voltmeter, it is possible to check the signal supplied to the lambda probe from the electronic control unit. If the supplied voltage is higher than 0.45 V, more detailed diagnostics of the control unit is necessary.

Instrument testing

For such work, you can use a tester, oscilloscope or digital voltmeter. Considering the features of these devices, a voltmeter would be the optimal solution.

Examination

The check sequence will be as follows:

- Start the engine and let the car warm up.

- Next, we find the element we are interested in. If there are soot deposits or other external signs of a malfunction, there is no point in carrying out further testing with instruments. And so it is clear that it is out of order and needs to be replaced.

- Also check the condition of the wiring, the presence or absence of mechanical damage on the device.

- If everything looks fine, unplug the connector and connect a voltmeter.

- Now you can start the engine.

- Press the gas pedal in neutral to reach the 2500 rpm mark. After this, release the pedal.

- Remove the vacuum tube from the fuel pressure regulator.

- We check the oxygen sensor for functionality. To do this, look at what the voltmeter shows. If the reading is 0.8 volts or less, the probe is not working.

- It would be a good idea to check the device for a lean mixture. To do this, you need to turn on the air intake using a vacuum tube.

- If the voltmeter reads 0.2 W or less, the oxygen sensor is working normally. Deviation from these indicators indicates a breakdown of the device. Therefore, it needs to be replaced.

Article on the topic: Choosing a stove (heater) radiator for a VAZ 2114

How to repair a lambda probe

Repairing a lambda probe with your own hands is quite simple; to do this, you need to determine in which particular unit the failure occurred.

If the problem is related to the circuit contacts, then first of all you need to find the break point and check whether the contacts have oxidized. The signal may simply not come from the control unit. Therefore, check the lambda power supply. If the element contacts have oxidized, they must be treated with WD40.

If a lot of carbon deposits have formed on the probe body, it may be necessary to clean all parts of the system. And here a natural question arises: how to rinse the lambda probe. The fact is that it is strictly prohibited to process platinum electrodes and ceramic rods with sandpaper. Therefore, it is necessary to use specialized products designed to dissolve rust.

To clean the sensor, follow these steps:

- Remove the lambda probe after heating its housing to 50 degrees.

- Remove the protective cap.

- Soak the sensor in phosphoric acid for 30 minutes (it will cope with even the most difficult deposits).

- Rinse the lambda in water, dry it and install the element back. Don't forget to lubricate the sensor threads with a special agent to create a complete seal (but don't use silicone sealant).

Since the cost of sensors ranges from 1000 - 3000 rubles per element, it is quite reasonable to try to repair the lambda probe yourself (see video below), and only then proceed to install a new element.

Is repair possible?

In some cases, you can try to restore a failed sensor. But this option is applicable only in cases where the cause of its breakdown is carbon deposits on the working elements of the device. Combustion products disrupt the normal operation of the lambda probe, distorting the output signal. In order to independently get rid of carbon deposits on the working surfaces of the sensor, we will need:

- hacksaw for metal;

- vice;

- gas burner (you can use a burner from a household gas stove);

- clean glass container;

- orthophosphoric acid;

- soldering iron, flux and solder.

First of all, disconnect the sensor connector and unscrew it from its seat. Now it needs to be sawed, because the probe cannot be disassembled. Carefully clamp it in a vice and saw off both protective caps to get to the ceramic rod. When this is done, heat the sensor over the burner. This is necessary to burn off carbon deposits. Under no circumstances should you attempt to remove combustion products mechanically. This will only damage the device.

After heating procedures, you can continue to restore the working elements of the sensor by placing it in phosphoric acid. It dissolves carbon deposits perfectly. But don't overdo it. It is not recommended to keep the probe in acid for more than 30 minutes.

Upon completion of work, the sensor must be assembled. To do this, you will need to solder the sawed-off caps to the body using a soldering iron, flux and solder.

Device

The design of the lambda probe includes the following elements:

- Body made of metal;

- An insulator made from ceramics;

- O-ring with cuffs and wiring;

- Protective cover with ventilation holes;

- A circuit contact through which current is conducted;

- Ceramic tip;

- Filament coil;

- Protective shield with holes that allow gases to escape.

As you may have noticed, the design involves the use of heat-resistant materials. Not surprising, since the oxygen sensor has to operate under extreme temperature loads.

In this case, devices range from single-wire to four-wire.

Symptoms of malfunction

Where is it installed

By the behavior of the car, you can quite easily determine that the lambda probe has become unusable:

- The car jerks while driving;

- The revolutions are floating;

- The catalyst is not working properly;

- Fuel consumption increases noticeably;

- Exhaust gases contain a large amount of toxins.

The operation of this sensor requires constant monitoring. According to the operating manual, the check is performed every 10 thousand kilometers traveled. But if the operating conditions of the car are difficult, you have to regularly drive in difficult conditions, or the engine is overloaded, then it is better to check it more often.

Oxygen sensor VAZ 2112

The lambda probe is installed in the exhaust system. Sensors are divided into two types: two-point and broadband.

The two-point sensor consists of ceramics, the elements of which are coated with zirconium dioxide on both sides. Installed in front of or behind the catalytic converter. The principle of operation is to measure the level of oxygen concentration in the environment and exhaust gases. If the level changes and becomes different, a voltage is created at the ends of the sensor elements, from low to high. Low voltage is created if there is excess oxygen in the system. Otherwise, if the system does not have the required level of oxygen, high voltage will be created. These signals are sent to the engine control unit, which distinguishes them by current strength.

How to check

Connect the adapter and run the engine at 2000 rpm. To ensure that the oxygen sensor remains hot throughout the entire measurement cycle. Do not disconnect the sensor connector to avoid disrupting the full feedback cycle in the fuel injection system. Connect an oscilloscope to the oxygen sensor signal lead. Be careful, there are heated sensors (three or four wires). In this case, you need to connect to the signal wire. An oscilloscope will show you waveforms of your sensor's performance and give you an idea of the signal levels in the signal chain.

Before taking measurements, check the scale marked on the measuring tool. It must be correct. A properly working oxygen sensor will show you a signal,