Disabling the sensor

Many car owners ask the question, what will happen if you disconnect the lambda probe from the ECM circuit, and how to disconnect the oxygen sensor? The answer is simple - with the lambda disabled, the control unit will use the standard data of the program embedded in it, and fuel will be consumed almost as much as with a faulty sensor. On average, consumption will increase by 2-3 liters relative to engine operation with a working lambda probe. And disconnecting the sensor is very simple - you just need to disconnect the plug with the wires that fits the probe.

Replacing the oxygen sensor is very simple. Before carrying out work, it is necessary to cool the engine if it has been running. First of all, the sensor plug is disconnected, then it is unscrewed with a wrench.

Sometimes the lambda probe gets very stuck and cannot be moved. If the sensor still needs to be replaced, you can try tapping its seat - around the thread.

As a rule, this method helps to unscrew a part that cannot be removed. If the lambda does not unscrew, you need to tap again and again. As a result, the sensor is still removed.

https://youtube.com/watch?v=68L_IkIfRu4

If the oxygen sensor does not work, there is no need to rush to throw it away. Often, due to oil waste, carbon deposits form on the ceramic electrodes. You can try to remove carbon deposits, but do not use metal objects or sandpaper. To clean carbon deposits, use rust removers, for example, WD40. Perhaps the performance of the lambda probe will be restored.

Why does it fail?

There may be several reasons for the malfunction of the VAZ-2114 oxygen sensor. The most common is natural failure. This sensor contains a certain resource. Unlike foreign cars, where the lambda probe lasts for 100-120 thousand, on the Lada the sensor lasts no more than 80 thousand kilometers. Most VAZ-2114 cars in use today have long passed this period. But the sensor can break for other reasons. For example, this is a violation of the tightness of the contact of the sensor with the collector body. As a result, the device cannot receive a reliable signal. The element may also fail due to overheating of the sensitive tip. The next cause of malfunction is clogged contacts. Moreover, it is the internal part that is located in the exhaust manifold that becomes contaminated. What causes the sensor to become dirty? The reason may be the use of low-quality gasoline or increased oil consumption. The latter enters the combustion chamber and comes out with soot. Some of the carbon deposits settle on the exhaust manifold tube, including the lambda probe.

Also, the cause of carbon deposits can be a breakdown of the cylinder head gasket. Because of this, antifreeze comes out along with the exhaust gases (as is known, with such a malfunction the gases acquire a white tint).

Connecting an oxygen sensor to a VAZ 2114 if it fails

To replace a broken sensor, do the following:

go to a car store with a broken device. This is necessary so that you can compare the markings on the devices. Otherwise, the car enthusiast may purchase the wrong device that he needs. To prevent this from happening, you should carefully check the markings located on the device body; You must turn off the engine and let it cool. If you do not do this, you will not be able to replace the sensor; after this you need to disconnect all wires from the sensor; now you need to unscrew the oxygen sensor with a regular wrench; when this task is completed, the motorist only needs to install a new sensor

This is extremely simple to do, but you need to be careful, otherwise you can easily break the thread. In order to prevent such an unpleasant breakdown, it is necessary to screw in the sensor as slowly as possible; After this, you should start connecting the sensor contacts according to the pinout diagram.

Installed oxygen sensor

All operations to install a new sensor may require approximately 60-90 minutes

This will be quite enough to do everything as carefully and accurately as possible.

In order to better understand the features of this device, it is necessary to study the design of the lambda probe.

CHECKING THE LAMBDA PROBE

You can determine that the DC is faulty and the lambda umbrella needs to be checked by the following signs:

- Problems with the engine at low speeds - the fourteenth stalls or does not pick up speed well;

- Gasoline consumption has increased;

- After the engine is turned off, distinct crackling sounds are heard at the location of the DC.

The fact that it is necessary to check the oxygen sensor is also indicated by the presence of errors 131 and 134 on the dashboard. These errors indicate that the device is sending an incorrect signal, and the problem must be sought in the wiring of the sensor, or in poor grounding of the device on the car body. The presence of error 132 indicates that the supplied fuel mixture is too lean (large amount of oxygen in gasoline).

Before handling any electronic equipment, you need to familiarize yourself with its features. The oxygen sensor pinout looks like this:

Pinout

- A – contact of the positive sensing element;

- C – contact of the negative sensitive element;

- B – power wire of the heating device.

Knowing what the lambda probe pinout looks like, you can start checking the device. First, let's study the location of the oxygen sensor according to the type of engine of the fourteenth:

- In cars with a 1.5 liter engine. it is located on the top of the receiving pipe, next to the resonator;

- Navaz 2114 with a 1.6 liter engine, the lambda probe is located in the engine compartment, directly on the engine exhaust manifold. Keep in mind that on the new models of the fourteenth, 2 DCs are installed at once: the second one is located next to the first one, it is not difficult to find it.

DK

You can check the oxygen sensor on a VAZ 2114 at home with a regular multimeter, which you can purchase at any auto store for 300-500 rubles.

Checking the oxygen sensor with a multimeter is performed as follows:

- We start the fourteenth and warm up the engine so that the DC reaches operating temperature;

- Let's go to the engine compartment to check the lambda probe with a tester. We connect one multimeter probe to the negative terminal of the engine, the second to contact “B” of the oxygen sensor. If the tester shows that the voltage at the oxygen sensor is 12 Volts, then the device is fully operational; if the result differs to a lesser extent, the DC contact circuit has broken.

- Next, we check the contacts of the sensitive elements “A” and “C”. We place the negative probe of the tester on contact “C”, the positive probe on contact “A”. If the sensor is working properly, the tester will show 0.45 V. If the readings are different, the DC must be changed.

Operating principle of a lambda probe

The main task of the lambda probe is to determine the chemical composition of exhaust gases and the level of oxygen molecules in them. This figure should range from 0.1 to 0.3 percent. Uncontrolled excess of this standard value can lead to unpleasant consequences.

During a standard car assembly, the lambda probe is mounted in the exhaust manifold in the area where the pipes connect, however, sometimes there are other variations in its installation. In principle, a different arrangement does not affect the operating performance of this device.

Today you can find several variations of the lambda probe: with a two-channel layout and a broadband type. The first type is most often found on older cars produced in the 80s, as well as on new economy class models. A broadband sensor is typical for modern mid- and high-class cars. Such a sensor is capable of not only accurately determining the deviation from the norm of a certain element, but also promptly balancing the correct ratio.

Thanks to the hard work of such sensors, the vehicle's operating life is significantly increased, fuel consumption is reduced and the stability of idle speed is increased.

From an electrical engineering point of view, it is worth noting that the oxygen sensor is not capable of creating a uniform signal, since this is prevented by its location in the collector zone, because a certain number of operating cycles may pass in the process of reaching the device with exhaust gases. Thus, we can say that the lambda probe reacts rather to destabilization of the engine, which it subsequently notifies the central unit about and takes appropriate measures.

Oxygen sensor fake

If symptoms of a malfunction of the catalytic converter or lambda probes appear, then a snag will help solve the problem. It can be either mechanical or electronic. The first one can be made independently if you have the required tools and skills.

To install a mechanical blende you must:

- Remove the original oxygen sensor from the vehicle.

- Screw the lambda probe into the snag. This may require the installation of sealing washers or rings.

The assembled structure of the sensor and blende should be screwed into the seat.

When using electronic snag, it is connected to the terminal block instead of the original lambda probe. A plug is placed in place of the sensor.

Welcome! Oxygen sensor - it is also called a lambda probe, thanks to it the car operates stably at idle speed when the engine is warm, and the car also has clean exhaust thanks to this sensor, because this sensor closely monitors this and does not allow too much emissions into the atmosphere harmful substances that will not lead to anything good, and thereby it makes the exhaust cleaner and controls it at different engine temperatures.

Note! In order to replace the oxygen sensor, you will need to stock up on: A basic set of wrenches and definitely gloves, because during operation this sensor heats up to very high temperatures due to which you can get very burned!

Where is the oxygen sensor located? On different engines it is located in different places, namely on the very first cars with a 1.5 engine, there was only one sensor installed and it is located on the very exhaust pipe of the car, at the very bottom of the car, for example, see the photo below in which this sensor is indicated by an arrow:

Now, regarding cars with a 1.6 engine, on these engines, in order to see the oxygen sensor, you no longer need to crawl under any car, you can just open the hood and you will immediately see it, the whole point is that this sensor is not located on the exhaust pipe of the car as on the 1.5 engine and it is immediately screwed into the exhaust manifold (In the photo below it is indicated by a red arrow), but in addition to this sensor, look carefully, you may have another exactly the same sensor (In the photo it is indicated by a blue arrow), then There are newer cars that have not just one sensor installed, but two, but again, not all cars have this second sensor, so carefully inspect the exhaust manifold before you start replacing the topmost oxygen sensor.

When should you change the oxygen sensor? It must be replaced if your car begins to become dull, to put it mildly, namely, it begins to consume much more fuel than necessary, and also begins to idle unstably, accelerates worse, etc.

All these signs indicate a malfunction of this sensor, oh yes, approximately the oxygen sensor becomes unusable after 60,000 thousand kilometers or more, so if you haven’t changed this sensor for a long time and your car starts to slow down, then most likely it’s the problem, but that’s all In order not to make mistakes, in this article we will post a video clip on how to check this sensor for functionality.

What can cause an oxygen sensor to fail faster? One of the most frequently asked questions to us, in general, this sensor fails most quickly only for several reasons, namely because of low-quality gasoline, because of worn-out oil scraper rings, and because of an incorrectly configured working mixture and incorrectly set ignition, this sensor fails prematurely and temporarily.

Replacing the lambda probe

In most cases, a part such as a lambda probe cannot be repaired, as evidenced by statements about the impossibility of repair from many automobile manufacturers. However, the inflated cost of such a unit from official dealers discourages anyone from purchasing it. The optimal way out of this situation could be a universal sensor, which costs much less than its native analogue and is suitable for almost all car brands. Also, as an alternative, you can purchase a used sensor, but with a warranty period, or a completely exhaust manifold with a lambda probe installed in it.

However, there are cases when the lambda probe operates with a certain error due to severe contamination as a result of combustion products deposited on it. In order to make sure that this is really the case, the sensor must be checked by specialists. After the lambda probe has been checked and its full functionality has been confirmed, it must be removed, cleaned and reinstalled.

In order to dismantle the oxygen level sensor, it is necessary to warm its surface to 50 degrees. After removal, the protective cap is removed from it and only after that you can start cleaning. It is recommended to use phosphoric acid as a highly effective cleaning agent, which can easily cope with even the most stubborn flammable deposits. At the end of the soaking procedure, the lambda probe is rinsed in clean water, thoroughly dried and installed in place. At the same time, do not forget about lubricating the threads with a special sealant, which will ensure complete tightness.

It is very complex, so it needs constant maintenance and timely preventive maintenance. Therefore, if there is a suspicion that the lambda probe is faulty, it is necessary to immediately diagnose its performance and, if the fact of failure is confirmed, replace the lambda probe. Thus, all the most important functions of the vehicle will be maintained at the same level, which will guarantee the absence of further problems with the engine and other important elements of the car.

Domestic cars are equipped with multiple devices and sensors to ensure proper engine operation. These controllers take into account various parameters so that the car engine can operate normally. One of these regulators is 2114. You can learn more about such devices, as well as their replacement, from this material.

[Hide]

How does he work

We have already noted that the DC begins to work only after heating to a certain temperature - 350 degrees Celsius. Because of this, the first variations of the probe were installed in close proximity to the exhaust manifold.

Over time, the sensor was improved, a heating element was built in, which made it possible to quickly bring it to operating parameters. Because of this, the location of the probe in the exhaust system has lost its significance.

If you study the design of the device, it will include several main components.

- Ceramic tips with protective screens and sampling holes. On the one hand, they serve to take in exhaust, and on the other, outside air. These elements are contained in a middle element inside a ceramic insulator. They are the main working components of the recreation center. These are electrodes from which readings of potentials and their differences are taken.

- Conductive heating element. It should be looked for inside the tips.

- Electrical signal current collector. This component is located in the middle part of the DC.

- In addition to the sensitive elements of the tips, all other components of the DC are located inside a metal case equipped with a thread. It is necessary in order to fix the device on the receiving pipe body.

- Modern recreation centers are equipped with wires and a sealing collar. They are called four-wire lambda probes.

- Two white wires are the contacts of the heating system.

- The black wire is the signal wire.

- Black and white striped wiring - grounding.

The other end of the wire, using a plug box, connects the device to the on-board computer. He receives information from the DC about the current state of the air-fuel mixture. Moreover, at idle speed, a request from the ECU to the DC is sent twice per second, and with increasing speed even more often. Depending on the information received, the electronic control unit adjusts the amount of fuel supplied to the engine, creating a rich or lean mixture.

The ECU always strives to ensure that the lambda ratio is as close as possible to the ideal - 14.7:1.

Checking the oxygen sensor lambda probe on a VAZ 2114

The lambda probe sensor on the fourteenth is part of the system that powers the engine. It estimates how much oxygen is contained in the exhaust pipe. This is necessary in order to adequately regulate the mixture for the operation of the wheelbarrow. By the way, such devices are installed only on the injector.

Before you check the lambda probe, you need to understand the main characteristics of its operation.

The sensor, or rather what works in it, is a housing made of ceramics with platinum. The operating temperature is from 350 degrees, while it is dialed by the lambda probe, the mixture is combined by the engine power system according to the readings of other sensors.

It works like this: the exhaust fills the body (working) of the oxygen sensor, it reads the difference in the oxygen level from the exhaust and the atmosphere and sends it to the electronic control unit, which already processes it.

Diagnostics

As always, before replacing any device, it must be checked for functionality. To diagnose a lambda probe, a regular multimeter will do; its reading scale may have the following values:

- 0.8-0.9V – normal indicator of the upper signal level;

- 0.1-0.2V is the standard for the lower one.

According to the manufacturer, the operational life of the device is more than 80 thousand km. But only on the condition that all GOST requirements during the manufacturing process of the oxygen sensor were met. Reviews from experienced drivers truly confirm the high service life of the product. Moreover, according to them, on average, a lambda probe lasts twice as long, and this is no more or less - 160 thousand km.

What effect does DC have on engine performance?

A working oxygen sensor is the key to the smooth functioning of the power unit. A minimal decrease in the characteristics of the air and fuel mixture, which this particular device controls, leads to a decrease in engine efficiency. Stable speed, absence of fluctuations and, in principle, correct operation of the engine directly depend on the lambda probe.

If, when you sharply press the gas pedal, the car jerks and the power unit noticeably shakes, there is a possibility of the DC failure. It is very possible that this behavior of the car is caused by the inability of the lambda probe to adjust the mixture to the engine speed.

In addition, when an increased emission of exhaust gases into the environment is noticed, the cause is also most likely in the oxygen sensor. After all, it is he who is responsible for destroying the remaining harmful substances in the exhaust pipe.

What is the secret of the device’s effectiveness?

If you do not want to resort to the procedure of replacing the lambda probe before its service life expires, we recommend following some recommendations:

- do not ignore the requirements specified in the manual for the VAZ 2114, use only the optimal brand of gasoline;

- When adding individual additives to fuel, make sure their quality and compatibility with your car brand;

- say no to sealants as a fixing element during sensor installation;

- if you have problems starting the engine, do not torture the car by continuously turning the starter, always maintain a certain pause between attempts;

- When diagnosing cylinders, never turn off the spark plugs;

- The lambda probe has its own temperature limit, which is 950 degrees, so avoid overheating the exhaust system;

- aggressive chemical substances can damage the electrodes of the oxygen sensor, eliminate the possibility of their use for processing the main element of the DC;

- The connection between the lambda probe and the exhaust pipe must always be sealed, make sure this is done.

Main symptoms of malfunctions

Every car owner knows that the car always warns of a future breakdown. The hints may be completely different, but the fact remains a fact! Therefore, if you are extremely attentive to the behavior of your vehicle, the problem can be solved even before it appears.

If we talk specifically about the VAZ 2114 oxygen sensor, signs of malfunctions may be as follows:

- unstable speed, the car stalls when you gently press the accelerator pedal;

- reduction in the dynamic characteristics of the car;

- increased fuel consumption;

- constant crackling in the catalyst area after turning off the engine;

- the appearance of an aroma reminiscent of rotten eggs - this stench is simply explained by the fact that there is too much unburned gasoline in the catalyst.

Even if the failure of the oxygen sensor is obvious, do not rush to buy it. The fact is that, depending on the year of manufacture, the VAZ 2114 can be equipped with different modifications of the recreation center. So on old cars the manufacturer installed single-wire devices, now four-wire ones are in use.

What happens if you turn off the lambda probe?

Those who intend to ignore the manufacturer's requirements and disable the oxygen sensor should prepare for detrimental consequences for the engine:

- the motor will not work correctly;

- the level of harmful substances in exhaust gases will increase significantly;

- consumption will increase;

- there will be a need to reinstall the ECU software.

Based on this, each owner of the fourteenth model must draw certain conclusions. In order not to make a mountain out of a mountain, it’s easier to fix everything in a timely manner with your own hands. Or, as a last resort, visit a service station.

Symptoms of a problem

Now regarding the signs of malfunction. There may be several of them. Therefore, carefully monitor the behavior of your VAZ 2114. If you detect one of the signs, immediately take appropriate measures.

Location of the recreation center

- When gas is low, the power unit begins to operate unstably, may stall, and floating speeds appear;

- The dynamic parameters of the machine have deteriorated significantly;

- Under normal conditions, fuel consumption levels increase excessively;

- A cracking sound is observed in the catalyst zone after the engine is turned off;

- You can hear the characteristic smell of spoiled eggs. Such stench is caused by the ingress of a large volume of gasoline into the catalyst, which is not burned.

If you need to replace the DC, check whether such a probe is installed on your car. On earlier versions of the VAZ 2114, single-wire sensors were installed, and then four-wire sensors appeared. Their price ranges from 1200-3000 rubles, depending on the type of recreation center.

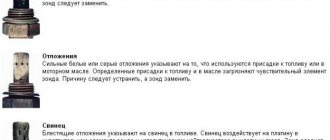

If, when removing the device, you find that there is carbon deposits on the device, but the measuring device shows a slight deviation from the norm, it is not necessary to change the DC. You just need to get rid of the carbon deposits.

To do this, heat the sensor very much and then cool it quickly. This will allow the carbon deposits to crack and fall off. All that remains is to lightly wipe the device with a brush.

What if without a recreation center?

Many people ask whether it is possible to disable the recreation center and how this is done. We categorically cannot recommend doing this, since it leads to serious negative consequences:

- The engine will begin to operate unstably and incorrectly;

- Fuel consumption will increase;

- The composition of the exhaust will deteriorate significantly;

- You will need to reflash the on-board computer.

Therefore, if you find problems with the lambda probe, take the necessary measures to eliminate them. It's not difficult to do it yourself.

How does the lambda probe affect engine operation, signs of its malfunction

The oxygen sensor lambda probe has a direct impact on the stable operation of the engine by maintaining the desired mixture composition for engine operation:

- the engine runs steadily, without hesitation, at idle speed;

- when you sharply press the gas pedal, a timely adjustment occurs in the engine's supply with a mixture corresponding to the changing speed, so there are no jerks or tripping;

- The best-burnt exhaust gases are released into the atmosphere due to the efficient operation of the catalyst, which burns harmful substances in the exhaust pipe.

To ensure normal conditions for the operation of the sensor and extend its life, a number of conditions must be met:

- Use only the gasoline recommended for the VAZ 2114.

- When working with additives, check their quality and permission for use.

- Under no circumstances should you use sealants, especially silicone, to secure the sensor.

- Avoid multiple startup attempts in a short period of time.

- Do not disconnect the spark plugs when checking the operation of the cylinders.

- Avoid overheating of the exhaust system due to the accumulation of unburnt fuel in it; the sensor can withstand temperatures only up to 950 degrees.

- Do not wash the tips with any chemically active liquids.

- Ensure that there is a tight seal at the junction of the sensor and the pipe.

Signs by which you can determine that the VAZ 2114 oxygen sensor needs to be replaced can be:

- at low throttle the engine runs unstably, the speed fluctuates or the engine stalls;

- there is a steady increase in fuel consumption under standard conditions;

- there was a deterioration in the dynamic characteristics of the car;

- characteristic crackling in the catalyst area after turning off the engine, as well as a specific smell of rotten eggs due to large amounts of unburnt gasoline entering the catalyst;

- signal on the on-board computer about errors associated with failures in the lambda probe.

Most often, with a faulty oxygen sensor, all of the listed symptoms should appear and, when a situation arises with its replacement, the question will arise which oxygen sensor is installed on the VAZ 2114. Depending on the year of manufacture of the car, the exhaust system may contain either single-wire sensors with ground from the body or and four-wire. The price of a VAZ 2114 lambda probe in this case can range from 1,200 to 3,000 thousand rubles.

When replacing the sensor, you should check it by testing it on an appropriate device; damage to the contacts in the heating line may have occurred, and then the oxygen sensor can be repaired.

If heavy deposits are found on the sensor after removal and it shows that the potential difference is not very different from the permissible ones, then this deposit can be removed. To do this, heat the sensor very much and then cool it sharply. The soot should crack and fly off, cover it with a soft bone.

Some motorists ask car mechanics how to disable the lambda probe of a VAZ 2114. The procedure itself is not complicated, but the need for this is highly questionable. In this case, the ECU begins to supply gasoline for injection at average values, and this will immediately affect the stable operation of the engine, increase fuel consumption and deteriorate exhaust characteristics. Not to mention the fact that the on-board computer will need to be re-flashed, since it will constantly give an error associated with the absence of an oxygen sensor.

We recommend

- Replacing the voltage regulator on a VAZ 2114

- Replacing the phase sensor on a VAZ 2114

- Phase sensor errors on VAZ 2114

- How to replace the license plate light bulb on a VAZ 2114?

Signs of a malfunctioning oxygen sensor

The main symptoms of problems with lambda probe 2114 are presented below:

- significant fuel consumption under standard conditions;

- unstable idle;

- deterioration of the dynamic characteristics and power of the car;

- signals on the on-board device indicating errors in the operation of the oxygen sensor (errors P0130, P0131, P0134, P0135, P0138, P1102, etc.);

- crackling in the catalyst zone when the engine is turned off;

- a specific smell that appears due to large quantities of unburnt gasoline entering the catalyst.

If all of the above symptoms occur, the oxygen sensor will most likely need to be replaced. A device of a certain type is selected taking into account the year of manufacture of the car, since one- or four-wire sensors can be used.

Purpose and malfunctions of VAZ-2115 sensors

Cars in Russia are now equipped with a variety of electronic control devices.

In this sense, the VAZ-2115 is no exception - it is equipped with various sensors. What are their purposes and possible malfunctions are described in this article. If any problem occurs in the engine, an alarm light immediately lights up on the instrument panel in the cabin. In a situation where the malfunction is minor, it goes out approximately a second after the power unit starts. This is approximately the amount of time it takes for the on-board computer to carry out diagnostics.

If the breakdown is serious enough, the ECU signals this by issuing certain error codes. So:

- 2 means that problems have arisen with the fuel level sensor;

- 13 – no information on air quality;

- 14-15 – antifreeze level is not controlled;

- 19 – incorrect readings from the crankshaft sensor;

- 21-22 – problems with the throttle valve;

- 23-25 – the device recording the air temperature has failed;

- 24 – speed meter does not work;

- 33-34 – problems with the mass air flow sensor;

- 35 – idle speed control is knocked down;

- 43 – failure of the knock sensor;

- 61 – data is not supplied from the device that measures the oxygen level.

Knowing the codes allows you to quickly resolve problems.

This is a sensor that records the position of the throttle valve. Its readings are needed so that the on-board computer can calculate:

- fuel injection duration;

- ignition timing advance angle;

- operating mode of the entire power plant;

- acceleration moment, etc.

If this device provides, then the information recorded by it is replaced by data from the DPKV and DMRV. The breakdown is usually accompanied by unstable engine operation.

In VAZ cars, this control device is a polymer film coated with graphite. In general, practice shows that it is this sensor that most often breaks down.

The car in this case:

- moves jerkily;

- braking by the power plant is often absent;

- There are “dips” during acceleration.

At the same time, the "Check Engine" light often does not turn on. The ECU detects a failure only if a short circuit occurs, but when the graphite tracks are partially worn out, the diagnosis has no effect. Complete loss of contact leads to the fact that the idle speed of the car is kept at a maximum of 1.5 thousand revolutions.

Sometimes there is a change in the readings of this monitoring device within the range of up to 5 percent when the gas is released. At the same time, the computer will believe that the driver is pressing the previously mentioned pedal with full force - as a result, the idle speed begins to “float” randomly. With such a problem, driving a car is simply dangerous.

Controls the functions of the fuel pressure regulator. As a rule, a VAZ is equipped with a mechanical type device that is not interfaced with an ECU. Consequently, the failure is not detected by the system. In this case, problems usually arise:

- regarding engine starting;

- increased fuel consumption;

- excessive CO content in the exhaust.

In 2115 it is installed on the ramp and is connected by a fuel return to the gas tank, and a hose to the air inlet manifold. The serviceability of this sensor can be determined using a pressure gauge connected directly to the fuel rail. Normally at idle the readings should be:

- up to 2.4 bar if the vacuum tube was put on;

- up to 3.25 if removed.

Low pressure often also indicates that the fuel pump is faulty. At the same time, a high level indicates a free flow of fuel from the line back into the tank.

If the RTD fails, the following malfunctions are observed:

- the engine is running unsteadily;

- stalls at idle;

- crankshaft rotation speed is too low or high;

- loss of engine power;

- excessive consumption of gasoline.

This monitoring device monitors the level of mass air flow.

It is based on a platinum thread, cooled by the atmosphere. It is then heated with electricity. Depending on the voltage consumed, the current fuel and air consumption is calculated. If it fails, then the ECU replaces its readings with data coming from the DPZD and DPKV. The failure of this sensor manifests itself:

- too much fuel consumption;

- unstable engine operation at idle;

- sudden stop after increasing power;

- problems with starting.

The easiest way to determine its malfunction is to replace it with a known working device.

Lambda probe: signs of malfunction (VAZ-2114)

Failure of the “fourteenth” oxygen sensor is usually accompanied by the following symptoms:

- the “CHECK” warning light lights up on the instrument panel, warning the driver about an error;

- engine operation at idle speed is unstable (the speed fluctuates, the engine periodically stalls);

- a noticeable decrease in the power and traction characteristics of the power unit;

- the car “jerks” when accelerating;

- increased fuel consumption;

- excess level of toxic substances in exhaust gases (determined by measurement at a specialized station).

VESKO-TRANS.RU

VAZ-2114, lambda probe: signs of sensor malfunction and spoofing

Ensure stable engine operation A modern car uses a huge number of different sensors that collect information about the operation of a particular system. Based on its data, the electrical control unit regulates the quality of the fuel consistency, regulates its quantity to enter the combustion chambers, determines the appropriate ignition timing, and turns on and off various additional mechanisms.

In this article we will talk about what the VAZ-2114 oxygen sensor (lambda probe) is, consider its design and principle of operation. In addition, we will try to understand the shortcomings of this element and how to fix them.

What is an oxygen sensor

An oxygen sensor is an electromechanical device designed to measure the amount of oxygen in exhaust gases. Its use is mandatory for all cars with a higher environmental class “Euro 2”,

Why? The fact is that modern environmental standards require that a car have a low content of harmful compounds in the exhaust. They can only be reduced by forming an ideal (stoichiometric) fuel consistency. An oxygen sensor, or, as it is called, a lambda probe, is used specifically for these purposes. The electrical control unit, having received information about the oxygen content in the exhaust, increases or decreases the amount of air, forming a consistency.

Where is the oxygen sensor located?

In VAZ-2114 cars, the Lambda probe can be placed in different places, depending on the engine modification. In the “fourteenth”, equipped with 1.5-liter power units, it is located on top of the exhaust pipe. This can only be achieved from below by driving the vehicle into an inspection hole or overpass. The 1.6 liter VAZ-2114 Lambda probe is placed even more conveniently. Screws into the top of the exhaust manifold housing. You'll immediately see him lift his hood.

Like an oxygen sensor

The VAZ-2114 lambda probe has a fairly traditional design. It is based on a clay element with 2 electrodes. They are usually plated with zirconium. One of the electrodes comes into contact with air (removed beyond the exhaust gas communications), and the other. with exhaust gases.

The mechanism of operation of the device is based on the potential difference that occurs between the contacts of the device when the engine is running. Lambda probe VAZ 2110 2112 inches Lambda probe VAZ 2110: signs of malfunction. The electrical control unit sends an electronic pulse to the sensor and analyzes its configuration. Based on the increase or decrease in voltage on the contact probes, the ECU “makes a conclusion” about the amount of oxygen in the exhaust.

Lambda probe: symptoms of malfunction (VAZ-2114)

Failure of the “fourteenth” oxygen sensor is usually accompanied by the following symptoms:

- “CHECK” warning light on the instrument panel, warning the driver of an error;

- the engine is idling unstable (the speed floats, the engine stops periodically);

- a noticeable decrease in the power and traction characteristics of the power unit;

- the car "shifts" when it picks up speed;

- increased fuel consumption;

- excess toxic substances in exhaust gases (determined by measurement at a specialized station).

What can the electronic control device say?

If the warning light on the dashboard lights up, indicating engine errors, and engine combustion is accompanied by the above problems, it is recommended to check the controller. Today this can be done both at a service station and at home. Of course, if you have a special tester and a laptop (tablet, smartphone) with the appropriate software. Once connected, this device will give you codes for possible problems.

In VAZ-2114 cars, a faulty lambda probe can report a malfunction with the following errors:

Description of the oxygen sensor

What is a VAZ 2114 oxygen sensor, what are the symptoms of breakdowns that characterize this device, what is it used for? To begin with, we suggest that you familiarize yourself with the main characteristics of the regulator.

Purpose and location

A lambda probe is an electromechanical controller used to determine the oxygen volume content in exhaust gases. Operation is mandatory in these models due to environmental requirements above Euro 2. The bottom line is that environmental standards today require cars to have a minimum content of harmful impurities and substances in exhaust gases. And it is possible to reduce their level only as a result of the formation of an optimal air-fuel mixture.

As for the location of the lambda probe, this device can be installed in different places, in this case it all depends on the modification of the power unit. In “fours” equipped with a 1.5-liter internal combustion engine, the oxygen regulator is installed on the intake line; the device can only be accessed from under the bottom. In 1.6-liter engines, the location is more convenient, since it is installed on the top of the exhaust manifold housing.

Design and principle of operation

The main remaining elements of the regulator:

- Tips made of ceramic and equipped with protective screens, as well as technological holes for sampling exhaust gases and atmospheric air. These components are considered the main ones; they are electrodes from which the potential difference is measured.

- A conductive component that heats up to high temperatures. This part is installed inside the tips.

- The electrical impulse current collector is located on the middle part.

- Metal body with thread. All components except the sensitive parts of the tips are mounted in it. A thread is required to secure the device.

- Wires secured with a sealing element. As a rule, these are two white wires used for contact with the heating system, as well as one black wire - signal and white (or black) - ground, that is, grounding.

The principle of operation of the device is similar to galvanic components. The oxygen controller should heat up to 300-400 degrees during operation, this allows for the most optimal conductivity of the zirconium electrolyte. Accordingly, these indicators provide the most optimal functionality of the lambda probe.

The principle of operation is to measure the volume of oxygen concentration in the air and exhaust gases of the car. If the concentration changes, a voltage is generated at the regulator tips, which may be too high or too low, depending on the situation. The formation of low voltage is associated with an excess of oxygen in the system.

If the system does not have enough oxygen used, then high voltage will form at the tips of the device. Volume data is transmitted to the control unit, which, based on the data received, adjusts the air supply to the cylinders. Accordingly, this is how the volume of the combustible mixture is adjusted.

Photo gallery “Location and varieties”

Kinds

Several types of regulators can be used in “Fours”:

- Bosch, catalog number 0258005133, complies with Euro-2 toxicity standards. It has been used for a long time on 1.5-liter engines; on the VAZ 2114 with Euro-3 standards, such lambda probes were the first to be used; they were mounted before the catalyst. Controllers equipped with a “reverse” connector were used as the second regulator.

- Bosch, catalog number 0258006537. Such devices began to be installed on cars manufactured after October 2004. In such devices, the design involves the use of a heating component. It is possible to install oxygen controllers from other manufacturers, the main thing is that their design is identical (the author of the video is Dmitry Maznitsyn).

How to remove the oxygen sensor if WD-40 does not help?

If simply copious treatment with chemicals does not help, then you can warm up the system by starting the engine. And after heating it, moisten it generously with cold water and try to unscrew it; if this does not help, then you can resort to warming up the sensor with a blowtorch and cooling it sharply. But then the lambda probe will become unusable.

Such drastic measures, as a rule, are applied as a last resort, because frequent such methods of loosening threaded connections not only deteriorate the quality of the metal, but also pose a possible risk of fire near the repair space. Therefore, use all measures to prevent unexpected fire.

This method is the most productive, because when the metal is intensely heated, it expands, and when it cools sharply, it hardens. Thus, all foreign and derivative bodies that have arisen on the surface are peeled off and the joint is relaxed. Even if you used this method, you are unlikely to have to repeat it a second time, because by then the exhaust system will need to be replaced. This is due to the metal burning through under the constant influence of high temperatures and caustic gas formations from the inside, and corrosion from the outside.

- After some time and visible removal of rust, you can begin dismantling. After such operations, as a rule, the sensor is easily unscrewed.

- After dismantling, the sensor installation site should be carefully inspected for dirt and damage; if any are found, they must be removed. And clean out any existing irregularities with a fine file or sandpaper.

- Installing the lambda probe is done in the reverse order. The connector is put on and carefully laid and the wire is attached back to the cooling pipe with clamps. No special settings are required.