Every modern car, including the VAZ 2109, is equipped with a variety of sensors and devices, each of which plays its own important role. One such device is the oil pressure sensor. It is located in the engine compartment. Regardless of which engine the car is equipped with, an injector or a carburetor, the sensor is located on top of the cylinder block on the intake manifold side.

A protective cover is installed on top of the oil pressure sensor. To ensure stable operation of the engine and the entire machine as a whole, it is necessary to ensure that the sensor is working properly. An oil filter is located next to the sensor.

Sensor design

The oil pressure sensor in modern cars is quite simple. It includes an outer casing, a hard elastic membrane and a transfer device. The principle of interaction of the device is the interaction of oil with an elastic partition.

The membrane reacts to the force with which the oil presses on it. The oscillations of the partition, the opening and closing of the contacts of the electrical circuit, communicate with the rheostat. Changes in rheostat indicators are displayed on the dashboard of the VAZ-2109.

A malfunction of the sensor is indicated by a light on the panel. When an alarm icon appears, you must immediately check the serviceability of the sensor. But before doing this, you should make sure that the engine oil level is correct.

Today there are several oil pressure sensors for the VAZ-2109, which any owner of this car can purchase if necessary. The table shows the types of sensors, as well as their article numbers and prices.

| Sensor | vendor code | Cost, in rubles |

| Oil pressure sensor analog MM120D | SOP20101O7 | 80 |

| Oil pressure sensor VAZ Samara | 33000 | 150 |

| Oil pressure sensor (BCG) | OS3518-BCG | 150 |

| Oil pressure sensor ERA | 11260 | 100 |

Device

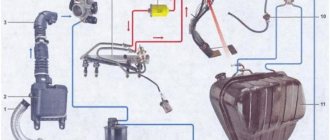

The device in question may schematically look like this:

Main elements of the oil pressure sensor:

- frame;

- wire connection location;

- thread for fixation in the cylinder block;

- diaphragm;

- a spring that resists deformation of the diaphragm;

- positive and negative contacts.

The oil pressure sensor is located on the left side on the back of the engine. This makes it fairly easy to diagnose or replace.

Sensor check

In practice, there are several proven methods for checking the oil pressure sensor.

The first method involves removing the device and idling the starter. If, when the device for mechanical engine starting is turned on, oil begins to pour out from the location of the sensor, then the device is in working order.

You need to carefully inspect the sensor, then treat it with a degreasing liquid, for example, gasoline. Then the sensor must be returned to its original place. If in this case the light on the dashboard remains on, it means that the sensor has failed and needs to be replaced.

The second verification method is more thorough. In this case, you should do the following:

- Check oil level.

- Start the engine and warm up the car.

- Unscrew the sensor and connect it to the device for testing. An adapter from a pressure gauge should be installed in place of the sensor.

- Ensure that the pressure gauge is in contact with the ground (ground).

- Connect the positive LED from the battery to the sensor contact.

- Start the engine, press the gas pedal.

- If the pressure gauge shows a value of 1.2-1.6 bar, the LED will turn off; if not, then the sensor has failed.

Often a light comes on on the dashboard of the VAZ-2109, indicating problems with oil volume

The third method involves checking the oil pressure sensor using the crankshaft. To do this, you need to crank the crankshaft without turning on the engine. At the same time, pour oil into the place where the sensor was screwed in. If the light is on, it means the device is unusable and needs to be replaced.

How to check the controller

Every motorist knows that everything that is directly or even indirectly related to pressure is checked with a pressure gauge. To do this, simply unscrew the pressure sensor and install a pressure gauge in its place, after which you should start the engine.

If everything is in order and there are no breakdowns, the pressure gauge readings at idle should be at least 0.65 kg per 1 cm2. That is, in this case, both the engine itself and the oil pressure in the system are fine, but the oil pressure sensor on the VAZ 2108 and 2109 needs to be replaced.

What to do if a breakdown occurs suddenly somewhere in the middle of the highway? Naturally, in this case there will be no pressure gauge at hand, and the light blinks furiously.

In fact, everything is extremely simple:

- To check, you just need to unscrew the sensor and carefully, so as not to start the engine, crank it using the starter.

- You can tell if the controller is faulty by the oil that starts flowing through the sensor socket when the starter rotates.

The best thing you can do in road conditions is to wash it in gasoline or diesel fuel. If you have a syringe or pump on hand, you can use them. After carrying out the simplest manipulations, the sensor is screwed into place and the control panel is checked.

If the light continues to burn, you should visit the store at the first opportunity to purchase a new controller, since they, as a rule, cannot be repaired and there is no point in repairing it when the cost is relatively low.

Replacing the sensor

The process of removing and installing the sensor is quite accessible to any car enthusiast. Before screwing in the new sensor, you need to check the markings.

Experts recommend installing a new sensor with the same markings as the old one.

- First you need to disconnect the wire with the protective cover from the sensor.

- Using a wrench, unscrew the bolt and remove the sensor.

- Install the new sensor in place.

- After this, you should tighten it until it stops with a wrench.

Finally, you should start and stop the engine several times to check its operation and absence of malfunctions.

Reasons for the indicator light and diagnostic methods

A sufficiently experienced car owner can independently diagnose or repair this system. Otherwise, it is recommended to contact a service center for help.

Sensor malfunction

To check the serviceability of the sensor, it is necessary to perform a number of operations:

- Turn the ignition key to the first position (turn on the ignition).

- Make sure the pressure indicator lights up.

- Open the engine compartment and disconnect the sensor wire.

- Make sure the indicator is not lit.

- Attach the bare end of the wire to ground, for example to the engine housing.

- The indicator on the dashboard should light up. If so, the wire is OK and the cause of the malfunction lies in the sensor.

The manufacturer does not recommend disassembling or repairing the sensor. It needs to be replaced.

Violation of the integrity of electrical wiring

Due to large temperature changes, ingress of fuels and lubricants, natural drying or mechanical damage in the engine compartment, electrical wiring is a vulnerable part of the vehicle's electrical systems.

Checking its integrity can be visual, by inspecting visible parts, or using a multimeter to check the conductivity and resistance of the wire.

This check is carried out strictly in accordance with the electrical diagram of the VAZ 2109 car.

Low engine oil level

During the operation of the vehicle, minor consumption of engine oil is allowed. Checking its level should be done using a special dipstick with the engine cold or not running for more than 10 minutes.

It is necessary to check its level using the dipstick and, if necessary, top up. The indicator is then rechecked with the engine running.

Low oil levels can also be caused by oil leaks.

Engine wear

Engine operation involves constantly rubbing metal surfaces. No matter how well they are lubricated, wear is inevitable.

What to do if the sensor lights up

If the oil pressure light on the dashboard comes on and does not go away for a long time, it can be assumed that there are problems with the engine. Sometimes this may be due to a loose wire.

There are several main reasons why the warning light on your dashboard comes on. These include:

- installation of a low-quality oil filter. Low quality filters are not able to retain oil after the car is stopped. The solution is to replace the oil filter;

- insufficient oil level. In this case, it is necessary to add oil to the required level and find the cause of the leak;

- oil pump damage. It is recommended to have this problem repaired at a service station.

Thus, the oil pressure sensor on the VAZ-2109, despite its small size, plays a rather important role in ensuring the correct and stable operation of the car.

It requires constant monitoring and, if minimal signs of malfunction appear, mandatory replacement. This is the only way to extend the life of the engine of any car and avoid unnecessary financial costs that may arise due to sensor malfunctions.

Where is the oil pump on the VAZ 2109

Its location is behind the crankshaft pulley. As a result of this circumstance, it will not be possible to get to it without removing some parts, in particular, the pulley itself and the oil pan. Below is a photo showing the oil pump in its seat.

When to change the oil pump

If the pump fails, the following things happen:

- The oil pressure drops, as a result of which the corresponding control light on the dashboard lights up.

- Oil consumption increases, and it constantly has to be topped up (however, this does not always happen).

How to replace the oil pump on a VAZ 2109, 2108, 21099

Tools:

Before you begin the replacement, prepare all the necessary tools. This is a set of wrenches, a set of sockets, a universal joint and an extension. If the pump is replaced with a new one, then buy the necessary spare part (its catalog number is “2108-1011010″). Also, drive the car into a hole or overpass, otherwise it will be very difficult for you to get to the pump.

Removal:

1) Remove the crankshaft position sensor. It should be noted that this is only relevant for an injection engine; if the engine is carburetor, skip this point.

2) Drain the engine oil.

3) Next, remove the toothed pulley.

4) Now you can remove the oil pan. Then find the oil receiver and unscrew the bolts that secure it, and then remove it.

5) Take the correct size socket and extension and use them to remove the 6 bolts that secure the oil pump to the engine block. Be extremely careful as there are washers under the bolts and it is very important not to lose them.

6) Ideally, after step 6, the pump should be removed, but in practice this does not always happen. If this is your case, take a thicker screwdriver, insert it between the pump and the main bearing and gently wiggle it (remember, do not damage the bearing!).

7) Carefully remove the oil pump.

Checking the oil pressure in the engine lubrication system 2108 (21081, 21083)

On the engines of VAZ 2108, 2109, 21099 cars and their modifications, it is impossible to accurately determine the oil pressure in the lubrication system. Unlike some “classic” VAZ models, they do not have a standard pressure gauge, but only an oil pressure sensor and a control light connected to it on the instrument panel.

Checking the engine oil pressure on engines 2108, 21081, 21083 of these cars is sometimes necessary for in-place diagnosis of faults that have arisen in them. For example, by measuring the oil pressure, you can determine the wear of the crankshaft journals or its bearings or check the performance of the oil pressure sensor itself and the efficiency of the oil pump.

To check the engine oil pressure in the engine, you will need a pressure gauge with a flexible hose and an adapter for the sensor hole.

Checking the engine oil pressure on engines 2108, 21081, 21083 of VAZ 2108, 2109, 21099 cars and their modifications

— Warm up the engine to operating temperature (80-90 degrees)

— We unscrew the oil pressure sensor and screw the tip of the pressure gauge into its hole

— We start the engine and check the pressure gauge readings at idle and at a shaft speed of about 5000 rpm

— We decipher the pressure gauge readings

At idle speed, the engine oil pressure of a working engine should be within 2 bar, and the pressure at high shaft speeds should be 4.5-6.5 bar.

Notes and additions

— If the engine oil pressure at high crankshaft speed is higher than normal, the oil pump pressure reducing valve is faulty.

Source