Spark plug device

To understand how candles differ from each other, you need to understand their structure.

The fundamental design of the spark plug has not changed for many years.

Inside the metal case there is a central electrode (conductor), separated by a ceramic insulator. A current is supplied to the upper contact terminal of the spark plug, which, having passed inside along the entire length of the electrode, comes to a dead end. But next to it there is another electrode - a grounding (side) electrode connected to the spark plug body. In the air gap between the electrodes, a powerful (several thousand volts) electrical discharge occurs - a spark, which ignites the fuel-air mixture in the engine cylinder.

Why does the engine need spark plugs?

First, let's remember what function spark plugs perform in an engine. These devices are needed to ignite the fuel-air mixture in the combustion chamber (cylinder) of the engine by the spark formed during the ignition switching on. This mixture is ignited using an electrical discharge of several thousand or tens of thousands of volts, which occurs between the electrodes of the spark plug.

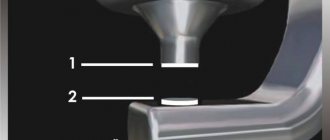

A standard spark plug consists of several components:

- contact terminal (designed to connect the spark plug to the high-voltage wires of the ignition system or directly to the ignition coil);

- insulator (protects the spark plug from overheating; the part of the insulator directly adjacent to the central electrode most strongly affects the quality of the spark plug);

- insulator ribs (prevent electrical breakdown along its surface);

- the central and side electrodes (a spark occurs between them, igniting the fuel-air mixture in the cylinder);

- seal (serves to prevent the penetration of hot gases from the combustion chamber).

An important characteristic of any spark plug is the size of the gap between the central and side (side) electrodes. It depends on it how effectively the mixture in the cylinder will be ignited. The larger the gap, the more powerful the spark and the larger the ignition zone. Accordingly, fuel will burn more efficiently, which means its consumption will be stable and engine operation will be smooth. On the other hand, when the gap between the electrodes of the spark plug is smaller, the spark appears earlier and breakdown occurs at a lower voltage. But at the same time, the spark energy is less, which is worse for igniting the mixture, and ultimately, with a reduced gap, the power and economical characteristics of the engine are reduced.

Also an important characteristic of spark plugs is their heat rating - this is information about the maximum permissible temperature load of the spark plug. Domestic spark plugs are produced with heat numbers of 8, 11, 14, 17, 20, 23 and 26. Foreign manufacturers do not adhere to a single heat number scale. Depending on the heat value, candles are divided into “cold”, “hot”, medium and unified. If you install spark plugs that are too “cold” (with a high heat rating), their self-cleaning process will become difficult and the engine will run intermittently. If they are too “hot”, so-called glow ignition is possible, which in its symptoms and destructive consequences resembles engine detonation.

Types of spark plugs

The main parameters by which all SZ differ:

- number of electrodes;

- central electrode material;

- heat number;

- case size.

Firstly, spark plugs can be single-electrode (classic with one electrode per ground) and multi-electrode (there can be two, three or four side elements). The second option has a longer life because the spark stably appears between one of these elements and the core. Some are afraid to purchase such a modification, thinking that in this case the spark will be distributed between all elements and therefore will be thin. In fact, current always follows the path of least resistance. Therefore, there will be only one arc and its thickness does not depend on the number of electrodes. Rather, the presence of several elements increases the reliability of sparking when one of the contacts burns.

Secondly, as already noted, the thickness of the central electrode affects the quality of the spark. However, thin metal quickly burns out when exposed to high heat. To eliminate this problem, manufacturers have developed a new type of spark plug with a platinum or iridium core. Its thickness is about 0.5 millimeters. The spark in such candles is so powerful that carbon deposits practically do not form in them.

Thirdly, the spark plug will work properly only when the electrodes are heated to a certain extent (the optimal temperature range is from 400 to 900 degrees). If they are too cold, carbon deposits will form on their surface. Excessive temperature leads to cracking of the insulator, and in the worst case, to glow ignition (when the fuel mixture is ignited by the temperature of the electrode, and then a spark appears). In both the first and second cases, this negatively affects the entire engine.

The higher the heat index, the less the SZ will heat up. Such modifications are called “cold” candles, and those with a lower indicator are called “hot” ones. In conventional engines, models with an average rating are installed. Industrial equipment often operates at lower speeds, so they are equipped with “hot” spark plugs that do not cool down so quickly. Sports car engines often operate at high speeds, so there is a risk of overheating of the electrodes. In this case, “cold” modifications are installed.

Fourthly, all SZs differ in the size of the edges for the key (16, 19, 22 and 24 millimeters), as well as the length and diameter of the thread. What size spark plug is suitable for a particular engine can be found in the owner's manual.

The main parameters of this part are discussed in the video:

How else are spark plugs classified?

Type of thread. The market requires spark plugs marked M10×1 (for mechanisms with single-cylinder two-stroke internal combustion engines), M12×1.25 (motorcycles), M14×1.25 (old-style cars), M18×1.5 (tractor, for “Soviet” cars production” and for gas piston engines).- About the length of the thread. Spark plugs are short (12 mm, for motorcycles and Soviet cars), long (19 mm, for modern domestic cars and foreign cars) and elongated (25 mm, for modern and forced internal combustion engines of luxury and sports cars).

- About the size of the head under the spark plug key. These spark plugs differ in their appearance and design, their sizes vary from 16 (modern internal combustion engines with 3-4 valves) and 19 (for motorcycles) to 20 (internal combustion engines with two valves), 22 (for Soviet car engines) and 24 mm .

- Regarding the method of sealing under the threaded part. Plugs can have either a flat squeezable ring or a cone seal without a ring. Why do you need a seal? To avoid loss of pressure, heat was removed and the expansion parameters of the cylinder head and spark plug body were compensated.

- Special candles. Certain categories of parts that are rarely used, mainly in engines of special designs. A striking example is torch candles, with cone resonators, plasma-prechamber with a side electrode in the form of a Laval nozzle.

What is the difference between all these spark plugs? Service life. A standard nickel part with stable engine operation lasts 30-40 thousand km. Iridium and platinum spark plugs last 3 times longer, up to 80-100 thousand km.

Replacement frequency

Different car models require different replacement intervals for spark plugs. It is always indicated by the manufacturer in the operating instructions for the vehicle.

There are a number of signs that indicate the need for replacement:

- increased fuel consumption;

- vibration when the engine is running;

- Difficulty starting the engine.

In most cases, replacement should be made every 20-30 thousand kilometers, on many foreign cars much later. Expensive iridium and platinum spare parts can easily withstand more than one hundred thousand mileage.

Only the entire set of spark plugs should be changed! This will avoid unstable operation of the motor in the near future.

Period of use

If the engine is in good condition, then, as a rule, the service life of the spark plugs is 30 thousand km for a classic ignition system and 20 thousand km for an electronic one. At the same time, as many experts note, the actual value is two times higher. This can only be achieved in laboratory conditions. Only here it is possible to create ideal conditions, which cannot be done during the operation of the vehicle in the usual mode. And often the appearance of spark plugs after work leaves much to be desired.

Rules for choosing spark plugs

Such products were first produced more than a hundred years ago; today the design of spark plugs has been significantly improved, and there are several types - each for a specific type of engine. Spark plugs are designed for gasoline engines, glow plugs are designed for engines running on diesel fuel.

Spark plugs vary in the number of electrodes - monoelectrode or multielectrode, and there are also torch products. One of the most important parameters that you should pay attention to when choosing spark plugs is the heat rating. It allows you to display the ability of the product to ensure ignition and combustion of the fuel-air mixture in the engine cylinder.

If the candle is not able to warm up to the required temperature, then the fuel does not burn completely, which causes carbon deposits on the candle, which causes its service life to be significantly reduced. If the candle heats up too much, then ignition will occur not from a spark, but from high temperature. Because of this, engine valves can burn out and change their geometric shapes. Eventually the motor will fail and will need major repairs.

For engines with low afterburner, hot spark plugs with a heat rating of 11-14 are the most suitable, cold spark plugs (value above 20) are optimal for powerful engines. Unified spark plugs are characterized by a semi-open structure, due to which they practically do not become clogged during operation.

Another important point is the spark gap, that is, the distance between the electrodes of the spark plug, in the very place where the spark occurs. Changing this parameter manually is strictly prohibited. This may result in no spark occurring at all. Overall dimensions are very important, since if a spark plug has a different thread, diameter and other parameters, then it simply will not be suitable for a given engine.

They also pay attention to the materials from which these products are made. The side electrode is made of alloy steel; nickel or manganese is used as an alloying material - these elements are characterized by a long service life. The central electrode is made of nickel or an alloy of copper and nickel. Such candles are highly resistant to soot and the formation of other contaminants, which also extends the service life of the structure.

When compiling our ranking of the best spark plugs, we took into account not only these factors, but also the price-quality ratio. Feedback from users and professional motorists and service station workers was also taken into account. We hope that after studying our review, you will be able to choose the most optimal spark plug option for your vehicle.

The purpose of spark plugs in a car

- The purpose of spark plugs in a car

- What are spark plugs for in a car?

- Design and principle of operation of spark plugs

- Types of spark plugs

- Marking and service life

- What to look for when purchasing

Undoubtedly, any element of a vehicle is its integral part, which is assigned certain functions. If with large units (motor, generator, battery, etc.) everything is more or less clear, then the question of the purpose of small parts is sometimes difficult to understand. It is these small components of the large structure of the car that are the spark plugs, which will be discussed further.

What are spark plugs for in a car?

If we draw an analogy with an ordinary wax candle, then a car spark plug is also capable of burning, only its flame is presented in the form of a short-term spark, which is responsible for igniting the air-fuel mixture in various types of heat engines. As for gasoline power units, the ignition of the fuel liquid is preceded by an electrical discharge, the voltage of which corresponds to several thousand or even tens of thousands of volts. Such a discharge appears between the electrodes of the spark plug, which fires during each cycle at a specific moment in the operation of the power unit.

It turns out that if you remove this element from the general operating chain, the mixture will not ignite and the motor will not be able to start working. We will also pay attention to how spark plugs work, but a little later.

Design and principle of operation of spark plugs

The main structural elements of automotive spark plugs include an insulator, a central electrode, a contact rod and, in fact, the housing itself in which all this is placed. The contact rod acts as a connecting element between the spark plug and the coil, or the spark plug and the high-voltage wire. The central electrode plays the role of a cathode made of alloy steel. The diameter of the electrode is in the range of 0.4-2.5 mm.

Today, to create this element, two metals are used at once: copper (the core is made from it) and steel (bimetallic electrode). The steel shell heats up well, thereby ensuring reliable and quick start of the power plant, and the copper core quickly removes heat.

To increase the service life of spark plugs, increase the resistance of parts to corrosion and damage under the influence of electrochemical processes, the core is made of a noble or rare earth alloy of steel (iridium, platinum, yttrium, tungsten or palladium). It was this fact that contributed to the appearance of additions to the name of the parts: iridium spark plug, platinum, etc.

The central electrode and the contact rod are connected using a conductive sealant, which is simply necessary to protect the motor electrical equipment from problems caused by sparking. Conductive glass melt often becomes such a sealant. The insulator serves as a connecting link that connects the contact rod to the central electrode. It is this element that provides electrical insulation and the established temperature regime of the spark plug.

All of these elements are enclosed in a metal case made of nickel alloy. It is supplemented with threads for screwing the spark plug into the cylinder head and holding it there. The lower part of the spark plug is presented in the form of a side electrode made of nickel alloy. There is a gap between the central and side electrodes, the size of which affects the quality of ignition of the fuel-air mixture.

The use of a spark plug with a large gap requires the use of a higher breakdown voltage, which increases the likelihood of misfire. As a result, we get an increase in fuel consumption and harmful exhaust gases. At the same time, too small a gap creates a small spark, as a result of which the efficiency of ignition of the fuel assembly is significantly reduced.

The principle of operation of a spark plug is quite simple: the air-fuel mixture is ignited by an electric discharge, the voltage of which reaches several thousand or even tens of thousands of volts. This voltage appears between the electrodes of the spark plug at a specific moment in each operating cycle of the machine’s power plant.

Types of spark plugs

One of the main criteria for dividing spark plugs into types is their design. So, taking into account the design of such “lighters”, they are divided into:

• two-electrode (classic version, in which there is one central and one side electrode);

• multi-electrode (provide for one central and several side electrodes).

The latter option is used when there is a desire to get a reliable spark plug with a long service life. The fact is that in the two-electrode version, a spark occurs only between two electrodes, causing them to quickly burn out, while a multi-electrode spark plug allows a spark to appear between the central and one of the side electrodes. Considering the reduced load on each side electrode, it is logical that the spark plug will last longer.

In addition, spark plugs can be divided into types based on the material they are made of. In this case, classic and platinum products are distinguished.

In the first case, most often, the electrodes are made of copper, but there are options in which the electrodes are coated with rare metals (for example, yttrium). This coating increases the durability of the electrodes, but has virtually no effect on other characteristics.

Platinum electrodes have high corrosion and temperature resistance, and they can be not only central, but also side elements. This type of spark plug is installed in turbo engines equipped with a turbo or mechanical supercharger. Compared to classic options, the service life of platinum products is relatively longer, but they are also more expensive.

Relatively recently, another type of spark plugs appeared - plasma-prechamber . In this case, the role of the side electrode is assigned to the body of the product, and the structure itself forms a spark annular gap in which the spark moves in a circle. It is generally accepted that this particular type of spark plug improves the self-cleaning of parts, thereby increasing their service life.

The central electrode of the spark plug is connected to the contact terminal via a special ceramic resistor, which perfectly reduces interference from the operating ignition system. Often the tip of the central electrode is made of iron-nickel alloys, to which chromium, copper and other rare earth metals are added.

The edges of the central electrode are most susceptible to electronic erosion - burnout, which is why it is necessary to periodically clean off traces of erosion with sandpaper. However, today there is no need for such a procedure, since alloys with “noble” metals have begun to be used: tungsten, platinum, iridium, etc. There are variants of classic products in which the electrodes are coated with yttrium alloy, which also helps to increase the resistance of the electrodes to negative influences, and is a key feature of such spark plugs.

Another classification of the described parts is based on thermal characteristics, that is, according to the heat number, the candles are divided into: hot (heat number ranges from 11 to 14), medium candles (from 17 to 19) and cold (more than 20). There are also standardized products, the glow number of which corresponds to 11-20. Each engine requires the installation of spark plugs that ideally match its thermal characteristics. The type of thread of spark plugs is also the reason for their division into types, both by length and by wrench head size. All these parameters must be taken into account when choosing parts.

Marking and service life

The main parameters of spark plugs of any type are the connecting dimensions of the parts (length and diameter of the threaded part), heat rating, the presence of a built-in resistor and the position of the heat cone.

Domestic spark versions of such products, suitable for engines of almost all vehicles (cars and trucks, buses, motorcycles, etc.) fully meet the requirements of the international standard ISO MS 1919, thereby ensuring the possibility of replacing them with foreign analogues in terms of characteristics and dimensions.

The difference between the overall and connecting dimensions of spark plugs is explained by the variety of power units produced. Modern requirements to improve the quality of their operating parameters determine the main direction in the development of spark plugs: the threaded part is lengthened, while the diametrical dimensions are reduced. The markings of spark plugs produced in Russia are presented below.

Notes:

* — Spark plugs, the threaded part of the body of which corresponds to 9.5 mm. There are only options with M14x1.25 thread, and a turnkey hexagon size of 19.0 mm.

** — Products with a length of the threaded part of the body of 12.7 mm, which are produced only with a thread size of M14x1.25. In this case, the turnkey hexagon size is 16.0 and 20.8 mm.

*** — Serial number of the development. Information is provided on the size of the spark gap established by the manufacturer and (or) information on other design features that do not affect the overall performance of the spark plug.

He. - no designation is given.

How to choose NGK spark plugs: decoding the markings

Each spark plug from the NGK manufacturer is individually marked. The alphanumeric combination characterizes its applicability for specific conditions and the motor, which is extremely important for the buyer to know. Unlike other companies, NGK products are strictly standardized.

Now let’s look at two illustrative examples of how to choose the right NGK spark plugs based on the combination of marking letters, depending on the location of which the method of reading it also changes.

Example No. 1: decoding of NGK spark plug markings with the first letters A, B, C, D, E, AB, BC, BK, DC

NGK spark plug markings.

For example, let's take a spark plug from the NGK line marked BPR7ES-11:

- The first one or two letters indicate the diameter of the thread/hexagon. The letter B is 14 mm / 20.8 mm. Size values vary depending on what specific letter or combination of letters is written.

- The second letter reflects the structure. The letter P from the example is a modification with a protruding insulator.

- The third letter is the type of resistor that suppresses interference. The letter R from the example means the presence of a resistor.

- The number - an extremely important parameter in choosing a candle - means the heat number. Number 7 from the example characterizes the candle as medium, that is, neither cold nor hot.

- The fourth letter in the marking is the length of the thread. The letter E from the example is equal to 19 mm.

- The fifth letter characterizes the design features. S in the example means standard type.

- The number located after the dash indicates the size of the gap between the electrodes. 11 – equal to 1.1 mm.

Example No. 2: decoding the marking of NGK spark plugs with the first letters D, I, L, P, S, Z

Decoding NGK spark plugs.

In this example, assume that you need to decipher the marking of a spark plug from the manufacturer NGK with the inscription SGR2P-10:

- The first letter indicates the type of candle. The letter S means that the spark plug has increased ignition reliability; its design has a square-shaped platinum insert. It should be remembered here that several letters written in a row can be used to designate the type of candle.

- The second letter is either the size of the thread itself, or the parameters of the hex key opening. The G in the example stands for 14mm thread or 19mm O-ring solution.

- The third letter stands for noise suppression resistor. The letter R stands for resistor.

- The number characterizes the heat value. So, number 2 from the example indicates that the candle is hot.

- The fourth letter shows design features. From example P is a platinum electrode.

- The number following the dash shows the size of the gap between the electrodes. In the example it is 1 mm.

Electrode material

In how to choose spark plugs, it is very important to understand that the main materials that are used in the manufacture of the central electrode are nickel, iridium and platinum.

To differentiate between the three different types of spark plugs, note that the nickel electrode will be the thickest, while the platinum and iridium electrodes will be the thinnest.

Nickel electrode.

By installing spark plugs with such an electrode, you are likely to have problems starting the engine in winter.

Read on the topic: Car won’t start, reasons.

The fact is that such candles are very easy to fill. A drop of fuel easily lingers on a thick electrode and there can be no talk of any sparking.

Iridium spark plugs.

The electrode is thin, which means it’s difficult to fill it in; there’s simply no place for the droplet to stay. A very good option for winter.

Platinum.

The most expensive candles, but also the most reliable. The electrode is thin. Suitable for complex engines, expensive foreign cars, where each replacement of spark plugs is very expensive.

The long period of their work smooths out this high cost.

Candles for contactless ignition.

For contactless ignition on domestic cars, A17DVR spark plugs are used, the operating principle of which is based on creating a spark discharge between the electrodes.

The standard gap between the electrodes in such spark plugs should vary within 0.7 - 0.8 mm.

You can get more detailed information here - VAZ 2109 ignition system.

Spark Plug Replacement Tools

You don't need many tools to replace spark plugs. The most important of them is a socket wrench with extension and spark plug socket. Candle sockets come in two sizes: 5/8" (16 mm) and 13/16" (21 mm). Most spark plug sockets have a rubber insert that prevents the plug from slipping. You may also need a universal joint if the spark plug is installed in a hard to reach place. The universal joint allows you to tilt the key along one axis and rotate it around another axis. If you don't have enough space to work with a wrench and extension to get to the spark plug, then a universal joint may come in handy. When replacing spark plugs, it is important not to overtighten them. Over-tightening the spark plug can damage the spark plug itself or the cylinder head threads. To avoid over-tightening, use a torque wrench. Torque wrenches indicate the amount of torque you apply when turning the wrench. Although almost all modern spark plugs are sold with a preset gap, it is better to have a gauge on hand. A gap gauge allows you to ensure that the spark plug center electrode is the correct distance from the ground electrode. It is this part of the candle that gives the spark. You may also need spark plug cap pliers, a rubber tube, a clean rag, rubbing alcohol, anti-seize agent, and a can of compressed air. The absence of these things is not critical, but they can make your work easier.

Next, we will talk in detail about how to change spark plugs.

What problems occur with spark plugs?

These parts fail for various reasons. How to check spark plugs if there are suspicions? It is important to ensure the presence of one or more characteristic “symptoms”:

- the engine “troits” (runs with the ignition off, twitches at idle);

- the engine power has decreased, which is noticeable with a sharp increase in speed and when climbing;

- Gasoline consumption is increasing without objective reasons, and the percentage of CO in exhaust gases has increased.

Often, problems in the operation of spark plugs are caused by the wrong choice of part relative to engine parameters.

Removing old spark plugs

Look in your service and repair manual to see where the spark plugs are located on the top of the cylinders. Check the wire attachment points for dirt. Clean the area around the spark plug with compressed air. This will help prevent dirt from getting into the cylinder during operation. You can also use rags and alcohol. Yes, before we start yet, remember - it is best to change the candles one at a time. If you accidentally connect the wire to the wrong spark plug, problems may arise. It's easier to change spark plugs one at a time to avoid confusion. Once you're done with one candle, move on to the next. Locate the wire connected to the spark plug. Disconnect the wire by pulling the cap - the connector at the end of the wire. Spark plug wire caps are usually rubber or plastic. Do not pull on the wire itself, because you may damage it in the process. If a rubber cap is installed, we recommend shaking it slightly from side to side. This should loosen the connection. If the cap still does not give in, then you will need pliers to remove the spark plug caps. Plastic caps are easier to remove - you just need to gently pull it. Once you have disconnected the wire, use a socket wrench to remove the old spark plug. Install the socket on the spark plug and turn the key counterclockwise. If the cylinder is installed at an awkward angle, use a universal joint. The spark plug should unscrew easily. If it doesn't work, then it's better to stop working. Additional force when unscrewing may damage the spark plug or engine. It is better to contact a service center and have a mechanic remove the stubborn spark plug than to spend money on repairing the cylinder head. But usually the spark plug comes out easily. After you have removed the candle, set it aside. Check the threads. If it is dirty, wipe it with a cloth moistened with alcohol. Now you are ready to install the new spark plug.

Spark plug. What can they say about the engine's performance?

The engine is the “heart” of any car. If you do not monitor its condition, sooner or later this can lead to a serious malfunction in its operation and expensive repairs. To prevent this from happening, it is necessary in a timely manner, or better yet in advance, to eliminate malfunctions in the operation of the engine and the car as a whole. But how can you find out the condition of the motor? Just look at the carbon deposits on the spark plugs.

At first glance, spark plugs are just a combination of metal and ceramic, but they are an excellent marker by which you can judge the performance of the engine. The appearance of a spark plug can say a lot both about the work of the “heart” of the car itself, and about its individual components. Each driver can “read” the spark plugs of his car and get valuable information - how the car’s engine works, what it lacks and what’s wrong.

I propose to consider in more detail the options for carbon deposits on spark plugs in order to understand what problems they indicate.

The average service life of spark plugs is 30 thousand km. mileage, but a properly selected high-quality spark plug can work twice as long. The working life directly depends on the material from which the electrodes are made, their type and quality. For example, spark plugs with bimetallic electrodes work longer and more reliably. Spark plugs with multiple electrodes have a long service life and do not require adjustment of the spark gap, and with platinum coating they work very stably. In any case, it is necessary to select candles in accordance with the manufacturer's requirements.

Naturally, in order to “read” the spark plug and evaluate engine problems, it must first be removed. To do this you will need a spark plug wrench.

It’s worth saying right away that checking the condition of the engine using spark plugs is necessary on a warm car: the car must travel a decent distance for the engine to operate under good load. Then let it cool, since unscrewing them from an engine that has not cooled down will be problematic.

A correctly selected spark plug, when the engine is working properly, has a small amount of coffee or light brown soot without any signs of oil. In this case, the electrode burns out evenly and there is no noticeable damage on its surface. If everything is so, then your car’s fuel consumption is minimal, the amount of oil is stable, and the car starts easily and without interruption. If the carbon deposits on the spark plugs have a different color and character, then the “heart” of the car has a malfunction.

If you find abundant dry black carbon on the spark plug, the engine is running on a too rich fuel mixture. There are several reasons for this: an incorrectly adjusted carburetor, a faulty injector, a clogged air filter, a malfunction of the fuel damper, or improper operation of the engine starting system. The result is high fuel consumption and unstable operation of a cold engine.

The opposite situation also happens - the air-fuel mixture is too lean. In this case, the electrode has a color from light gray to white. If you continue to operate the car in this mode, and even under heavy loads, this can lead to serious problems - overheating of the spark plug itself, as well as the combustion chamber, which, in turn, leads to burnout of the exhaust valves.

If you see that the spark plug is splashed with gasoline, this indicates that the injector or carburetor ignition system needs adjustment or repair. If this happens in winter, then there is a high probability that the fuel simply does not have time to burn at low temperatures. In this case, the candles must be blown out and wiped with alcohol.

Red (brick) carbon deposits on the spark plug skirt occur when the engine is running on fuel containing an excessive amount of metal particles (often manganese, which increases the octane number of gasoline). This kind of deposit has high conductivity, which negatively affects the operation of the spark plug. In addition, the spark plug may also become covered with a yellow coating, which indicates the presence of additives containing lead in the fuel. It also leads to unstable operation of the candle.

An oily spark plug (interspersed with gasoline or small metal shavings) indicates that one of the valves or partitions between the piston rings has broken down. With such problems, the engine does not run smoothly when starting (troits), the exhaust has a white-blue color when warming up, and fuel consumption increases significantly. There is only one way out - a major overhaul, and, of course, replacing spark plugs and adjusting the fuel system.

It happens that the spark plug electrode and its ceramic skirt are destroyed. There are several reasons: a defective spark plug, ignition too early, prolonged engine operation with detonation, or fuel with a low octane number. In this case, the engine runs smoothly and fuel consumption increases by 1.5-2 times. The most unpleasant thing is if part of the electrode gets stuck under the exhaust valve - repair of the cylinder head is guaranteed.

If the spark plug electrode is covered with ash deposits (no matter what color), the fuel system is faulty. This type of formation is caused by severe wear or jamming of the oil scraper piston rings. The result is increased oil consumption. At the same time, when you re-gas, strong smoke comes out of the exhaust system with a smell like that of a motorcycle. Here it is necessary to replace the spark plugs and preferably change the oil.

Electrode erosion (of any type) can be caused by an overly bent electrode or a missed spark plug replacement date. In this case, the engine operates at reduced power, does not “start” the first time, often stalls, and even when warmed up is unstable. In addition, erosion can occur as a result of using fuel with leaded additives. Prolonged use of this type of gasoline can lead to rapid destruction of the electrode, and sometimes to its complete dissolution.

It also happens that a metal strip (lightning) appears on the outer insulator of the spark plug. This occurs if the spark gap between the electrodes has greatly expanded due to their wear. In this case, the required voltage between the electrode pins is higher than the insulator can withstand. In addition, this can also happen if the insulator itself is worn out. Owners of cars with turbocharged engines may encounter this situation, since they require higher voltage. If this happens, it is necessary to replace the spark plugs and spark plug wires.

Based on all of the above, you will agree that diagnosing engine operation based on the condition of the spark plugs is not so difficult. It is important to remember that timely identification of the problem can save you from a number of problems and significantly save your budget.

veddro.com

We put new candles

Before installing a new spark plug, treat the threads with an anti-seize agent. The anti-seize agent will prevent the spark plug from getting stuck in the cylinder. The next time you change the spark plugs, they will come off easier. Avoid getting anti-seize agent on the electrodes as this may cause spark plug failure. If necessary, use a socket wrench extension. Turn the key counterclockwise a little to make sure the spark plug is seated better, then start turning it clockwise. The spark plug should turn in easily, if it doesn't you should stop and turn the key counterclockwise before trying again. After installing the spark plug, use an extension or torque wrench to tighten the spark plug. It is necessary that the spark plug washer is pressed tightly. Do not overtighten the spark plug. Install the spark plug wire cap. If you have a plastic cap, then it is simply put on until it clicks. If the cap is rubber, we recommend treating its inner surface with dielectric grease, which will make it easier to remove next time. Once you are done replacing one spark plug, move on to the next one. That's all! Replacing spark plugs is one of the few car repair jobs that anyone can do. Just follow the instructions and you'll soon be able to hit the road with your new spark plugs.

Something about heat number

When choosing spark plugs, this is the very first thing experienced car enthusiasts pay attention to. This parameter indicates at what pressure the glow ignition will occur. This means the ignition of the air-fuel mixture, which occurs not through the resulting spark, but from contact with a heated electrode.

Regarding any type of spark plugs in a car, this characteristic is very important, and it must necessarily comply with the requirements of the internal combustion engine. Sometimes you can use candles with a high heat rating for a short time. At the same time, products for which it is below the requirements are prohibited from use. Otherwise, it leads to undesirable consequences. This is burnout of pistons and valves, breakdown of the cylinder head gasket.

What you need to know about carbon deposits on spark plugs?

These parts are designed for 25-35 thousand km. In order not to miss problems, you need to look under the hood of your car from time to time and check the condition of the spark plugs. Anyone can perform diagnostics by type; the presence of malfunctions is indicated by carbon deposits on the ignition cone and a certain color of the cone:

- Black soot indicates excess oil. If it is dry, then the load is insufficient; if it is white, then early ignition occurs. A working spark plug should have no carbon deposits on the cone, and the color of the cone should be light brown or light gray.

- A black color with a bluish tint will indicate that the engine is running on an over-rich mixture. In this case, the power system requires diagnostics and repair.

- A whitish color indicates that the mixture in the engine cylinders is lean; you need to go to a car service center as quickly as possible and show the car to a specialist.

- Black oily deposits with soot flakes are a sign of the presence of engine oil and water in the cylinders. You can’t waste a minute here, the engine needs urgent repairs.

You can clean the spark plug from carbon deposits with sandpaper or a wire brush. At the same time, you need to check the gap between the electrodes. If it is more than 0.6-0.7mm, then it needs to be adjusted to this value. Often candles are washed in gasoline, then dried and soaked in a hot solution of 20% acetate.

Spark plugs should be cleaned of carbon deposits every 10-15 thousand kilometers. A good measure to prevent the formation of carbon deposits is to maintain the temperature in the crankcase at 500-600 degrees Celsius. With this heating, the candles self-clean well.

How to select and change spark plugs correctly?

To choose a part suitable for the motor, you need to take into account a number of important parameters:

ignition (contact, contactless, battery, electronic);- power supply (burettor, engineer, mono-/multi-point injection);

- degree of engine speed (compression and compression levels);

- types of fuel (boosted, supercharged, turbocharged, etc.).

- engine operating conditions and factors affecting operation.

In any internal combustion engine, the ignition system is finely tuned, but this will not slow down the natural wear of the spark plugs. It is easy to determine the degree of wear of this part by the gap between the electrodes. Over time, it will increase, and the electrodes themselves will begin to burn out.

What gap should be between the spark plugs to make it clear that it is time to change them? More than 0.6-0.7 mm. The larger the gap, the weaker the spark and misfire in the cylinder. This means you cannot wait until the gap becomes too large. Some craftsmen press the burnt-out electrodes with pliers, but this gives results only for a short time.

When is the best time to change spark plugs? It is clear that you cannot wait until they fall apart, then unscrewing them will be problematic. But every candle has its most vulnerable part. This is an insulator. If it is ceramic, then you need to handle the part carefully. The slightest deformation indicates the need for replacement.

How to extend the life of candles?

There are several simple recommendations that will help these parts work stably throughout their entire service life:

- Use high-quality gasoline recommended by the manufacturer. This information is indicated in the data sheet.

- Constantly monitor the ignition system. It must be in good working order and work stably.

- Spark plugs need to be screwed in carefully, selected taking into account the parameters of the car and changed in a timely manner.

Proper care of spark plugs is of great importance. To change them less often, follow these rules:

- take into account the heat rating, do not install too “hot” or “cold” spark plugs, so that this does not lead to serious engine damage and expensive repairs;

- help the spark plugs self-clean - run the engine at maximum speed to increase the temperature to 500°C and clean the parts from carbon deposits;

- for cars with gas equipment, buy special spark plugs with a thin central electrode and specially designed solders;

- Do not under any circumstances replace spark plugs with mechanical seals with parts with conical seals, as this will reduce operating efficiency and the degree of cooling;

- change spark plugs strictly according to the manufacturer's recommendations, focus on a mileage of 15-20 thousand km, trust diagnostics and repairs only to service station specialists.

Remember: untimely replacement of the spark plug can provoke breakdown of the insulator under pressure at high speeds and elevated temperatures. This will lead to loss of engine power, excessive fuel consumption and other malfunctions.

Soljery › Blog › How spark plugs can affect engine performance...

Good day everyone, today I am with useful information borrowed from the VK resource:

So that information is always at hand, or for the benefit of the reader of this blog, I am duplicating the whole thing in my blog^^

Very often, problems with a car engine arise due to the fact that the gap between the electrodes in the spark plugs is incorrectly set. This situation is often provoked by the fact that the manufacturers of these parts in most cases declare that there is no need to adjust the gap in the spark plugs. But this statement is completely incorrect and unfounded, so every car owner would do well to know how to check and adjust the gap in the spark plugs.

It is clear that if, for example, there is no spark on the ignition coil, then the gap in the spark plugs has absolutely nothing to do with it. But still, this value has an important impact on the operation of the engine. In order to better understand this, we should consider the processes that occur in the combustion chamber when the air-fuel mixture is ignited by a spark. At this moment, the filling of the cylinder is compressed using a piston. At the same time, the hydrocarbon-air mixture is compacted to the limit, and in order for the spark to pass successfully through such a dense substance, a potential difference is needed.

☑ Why is spark plug gap adjustment important?

In standard gasoline engines, the ignition system is designed in such a way that it can only operate normally if all elements of the mechanism are in working order. In particular, it won’t hurt you to know how to check the coil, how to diagnose the generator, because each of these components affects the performance of the engine.

And even a small violation in this entire complex mechanism, for example, carbon deposits on spark plugs, can cause not only deterioration in engine performance, but also its breakdown. As for the gap in the spark plugs, for example, if there is a natural increase in it, the spark may simply not have enough power to break through the dense mixture of air and hydrocarbon. Naturally, you will have to spend more energy on breaking through and, as a result, the spark fuse decreases, which in turn, in most cases, reduces engine power.

When studying the process of operation of automobile spark plugs, one often encounters some factors that have not been fully studied. That is why if the question arises “which spark plugs should be installed on your car,” the answer should be clear – the original ones recommended by the manufacturer. Periodic checking of the spark plugs is also important, which involves determining the gap size and adjusting it if necessary. As a rule, each engine manufacturer gives recommendations on the required clearance and it is better to follow them; this is the only way to guarantee high-quality operation and full serviceability of the engine.

☑ Experienced drivers who already have a clear understanding of the design of spark plugs, by changing the gap in the spark plugs, can influence the power and operation of the engine. But it should be remembered that an incorrectly set gap can have a negative impact on engine power and fuel consumption, and will also cause an increased load on the crankshaft and piston system.

It should also be noted that in older engine models, the spark plug gap is not as important as in modern ones. In the operation of engines of the latest modifications, the most compressed mixtures are used, and therefore the requirements for the accuracy of the gaps are very high. For example, if you violate the spark plug gap on a four-stroke, two-liter, four-cylinder, eight-valve engine by just 1/5 of a millimeter, this will increase fuel consumption by 4% and cause the engine to lose power by about the same amount.

You can check and adjust the gap in the spark plugs either at a service center or yourself. To set the gap correctly, it is best to follow the manufacturer’s recommendations or the advice of experienced motorists. Do not forget that this procedure must be repeated at least every 15 thousand kilometers. This is the only way your car will always be in order and will delight you with maximum speed and power.

This is interesting: Why are fog lights needed?

I hope this information will be useful) Peace everyone