Sometimes in a car there is a need to connect parts together not rigidly, using threaded, press or welding fits, but with a certain degree of freedom. In such cases, the connections are called hinged. Hinges can have different designs, depending on the required properties. In particular, with programmed elasticity in all directions of movement of the component parts.

To solve the tasks, silent blocks are used. Where they are installed, what types they are and what their disadvantages are, we will consider below.

Is this a silent block?

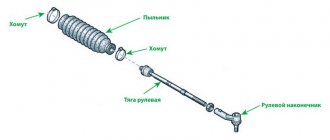

A silent block is a rubber-metal ball that looks like two bushings connected to each other by a rubber insert. There is a hole in the inner frame through which the parts are tightly fixed. Such a fastening system increases the resource of the unit.

The part got its name due to the fact that it does not creak. In addition, the silent block does not require special care. If an element breaks, it is quickly replaced with a new one.

The silent block does not need to be lubricated during operation of the machine. The part is highly resistant to dust and moisture. There are no spare parts in the design that would “rub” against each other. The movement occurs due to the bending of a flexible ball.

Design features

So, two bushings with a rubber layer - it would seem that everything is elementary. But this design is simple only at first glance. How to fix the elastic element in the bushing? A fairly obvious method is strong compression (in other words, tension), however, in this case the connection will be too rigid, which will affect the smoothness of movement.

There is a second option - “gluing” rubber to metal using the vulcanization method - there is almost no compression. But in this case, the rigidity of the connection is clearly insufficient. The angle of torsion and skew increases (relative to the longitudinal axis of the silent block), which entails unfavorable changes in wheel alignment angles while the vehicle is moving. And, accordingly, accelerated uneven tire wear.

Taking these difficulties into account, in the design of modern silent blocks a combined fixation scheme is used: simultaneously by compression (of moderate force) and vulcanization.

Further, the rubber part itself can be solid, or maybe with additional slots. Let's take, for example, the Polo sedan that came to us on a turnkey basis. On it, the rear silent block of the front suspension arm (just the MacPherson type) is installed vertically and there are cutouts in its rubber part.

What are they needed for? To limit the movement of the lever in the longitudinal direction, the stiffness of the bushing should be maximum; but we do not need maximum rigidity when moving the lever in the vertical plane (when hitting an obstacle, for example). To maintain these properties, to put it simply, excess rubber was removed. The bushing provides decent smoothness and rigid fixation of the lever in the longitudinal direction at the same time.

Kinds

There are different types of silent blocks. They are divided not only by type of material, but also by design features. Products have one bushing, two bushings, or do not have metal elements. Criteria that indicate the quality of parts: wear resistance, reliability, durability.

Polyurethane blocks serve drivers the longest. They make driving smoother.

The advantages of polyurethane products include:

High quality material and increased rigidity;

Resistance to temperature fluctuations;

Chemical resistance;

Excellent shock absorption.

Compared to other similar silent blocks, they work 5 times longer. That is why they ask a high price for them. As for rubber silent blocks, they are much cheaper than polyurethane ones, but at the same time less reliable and short-lived.

A little about the renovation

The silent blocks need to be replaced as an assembly. This stems quite logically from the fact that this element is non-separable. But in modern designs, silent blocks can be part of complex and expensive suspension units, where the elastic insert is only a small part of the price of the element. But when it wears out, it must be replaced.

Many companies that produce repair bushings for such parts are trying to correct this injustice. Usually there is no additional installation information, except that an adapter for pressing is included.

A rubber-metal hinge assembled in this way is no longer a silent block. Its load-bearing capacity is significantly reduced, and when the load is much less than the rated load, it can go into the operating mode of a simple rubber bushing. As a result, its seat in the lever will change its geometry and will be unsuitable for further use. Unfortunately, this situation is very common. The problem could have been avoided by using significantly more preload or using adhesive for better fixation, since the modern chemical industry provides a good selection of reliable methods for joining rubber or polyurethane to metal ferrules. And if your connection is in tension or torsion, then try not to use dubious recovery methods.

An even more serious mistake is made by those who use grease to simplify the pressing of an elastic bushing or simply lubricate squeaking components. Lubrication only harms any RMS: the connection between rubber and metal must be as reliable as possible. For repairs, try to use replacement elements with already vulcanized metal clips: it may be difficult to ensure a high-quality connection outside the factory.

Purpose

The silent block is designed in such a way as to reduce suspension vibrations. Sometimes these rubber-metal hinges are placed on the “engine” or other moving components. The weaker the vibrations, the more comfortable the ride.

During operation, parts experience severe loads. Over time, this leads to wear on the hinges. It is for this reason that you need to regularly check the condition of the elements in order to replace them on time. It is recommended to replace it every 50 thousand kilometers.

Silent blocks are small in size, but at the same time perform a large function. They directly affect the performance of the suspension. A “worn out” joint has a negative impact on vehicle control. When the driver moves at high speeds, he is acutely aware of the breakdown. As a rule, it manifests itself in the form of creaking, play in the steering wheel and periodic roll.

Silent block purpose:

Ensuring transport stability by reducing deformation of suspension parts.

Reducing noise in the car interior.

Absorbs vibration or shock during off-road driving.

Rubber-metal hinges have another purpose: their flexibility makes it possible to reduce the requirements for precision fit of parts.

Where are they installed?

The installation of silent blocks is determined by the design of the suspension. As a rule, they are provided in places where elements interface with each other or with the supporting system - body side members, subframe or car frame.

Rubber-metal hinges are required:

- in the attachment points of longitudinal and transverse reaction rods;

- in the front and rear suspension arms;

- in the mounting supports of the anti-roll bars. In this case, the outer ring is removable, and the replaceable liner is mounted directly on the stabilizer itself.

In the suspension of high-class cars and SUVs, the levers and longitudinal rods are not stamped, but solidly forged. In this case, the role of the outer ring of the silent block can be performed by the suspension part itself.

Principle of operation

Having figured out why silent blocks are needed, drivers must understand what their operating principle is. As already mentioned, the part has bushings fastened with a flexible insert. The bushings, in turn, “fasten” the suspension parts, thereby eliminating vibrations arising from the suspension units.

High demands are placed on the quality of the gaskets that connect the bushings. They are usually made from polyurethane, natural rubber, rubber. The parts are subject to heavy loads from all sides, since in addition to absorbing vibrations, they smooth out sudden movements of the car.

In order for the driver to know exactly when he should replace the hinges, he must be aware of the durability of the part according to the manufacturer’s regulations. The products can withstand up to 100 thousand kilometers, but in “lighter” conditions. If the car is operated more harshly, then diagnostics should be carried out every 50 thousand km.

You can find out for sure whether silent blocks need to be replaced by contacting a service station. The technician will inspect the parts and also diagnose them for chips.

Replacement technology

The work is not difficult, but you will need a set of mandrels and a hydraulic or manual press. As a last resort, you can use yews with jaws of at least 150 mm.

When replacing the silent blocks of the levers, you will need a device for tightening the springs.

Also, along with enthusiasm, a certain amount of experience is required.

Theoretical training can be obtained by watching relevant videos on the Internet.

Important. You shouldn’t believe stories like “there’s nothing complicated there, in a normal service they do everything with one sledgehammer...”

Preparatory work:

- The units required for replacement have been purchased.

- The car is installed on a viewing hole or overpass.

- The body is jacked up and the corresponding wheel is removed.

- If we are working with the front suspension, the crankcase protection is removed.

Necessary safety measures. Before installing a jack to remove any wheel, place wheel chocks under the remaining wheels.

And one more thing - do not try to unscrew stuck nuts with a wrench with a meter pipe. Use kerosene or WD-40 penetrating fluid.

Pros and cons of parts

We figured out what silent blocks are needed for. It remains to be seen why rubber-metal joints are considered the best today.

The biggest advantage of this part is that it is maintenance-free. In other words, if the hinge fails, it will be replaced with a new one. They also do not require lubrication, as it will negatively affect their performance.

Due to the lack of friction, there is no noise. Metal does not come into contact with metal, and the vibrations quickly “dissolve” in the rubber cushion. In addition, silent blocks have good load-bearing capacity.

Another important feature of the part is its long service life, subject to operating conditions. If the products are not overheated and overloaded, they will last for several years.

As for the shortcomings, they are present, but there are not many of them. For example, their rigidity is directly related to the load-bearing capacity. They also do not tolerate aggressive influences, as they depend on the operating temperature. And the service life of the hinges depends on the working stroke and its amplitude.

In the process of replacing silent blocks, mistakes are often made. The hinge at the midpoint of the working stroke must have minimal deformation. To be more precise, the technician must tighten the suspension connections while the car is on the ground and not on a lift.

How to increase the service life of silent blocks

There is only one recipe - careful treatment of the suspension as a whole. You can't expect a passenger car to have the capabilities of a racing SUV. Strong impacts at maximum deflection angles tear the rubber, after which a chain reaction of destruction of the entire suspension begins.

But the service life can also be shortened as a result of improper replacement of parts. There are main principles for carrying out work on the installation of RMSH.

Replacement instructions

Sometimes it is possible to replace a hinge without removing the main part from the car, but usually the lever or rod must be removed.

The internal race of the RMSh, as a rule, is attached through the axle in the form of a regular bolt. Here the problem can only arise in corrosion of the threaded connection, which can be eliminated by one of the known methods - applying a penetrating composition, pressing or shock loads, in extreme cases, mechanically cutting the axle and replacing the fasteners.

This you need to know: How the power steering works and works

The outer race is pressed out of the eye through a spacer of suitable size or with a specialized puller.

The force must be applied exclusively to the metal, the rubber will simply tear. The tension in the connections is small, no problems arise. In special cases, heating is used to burn out the rubber, after which the bushing can be sawed off.

The new part is carefully pressed into the cleaned eye using the same mandrel with the same requirements.

When installed on a car, the fastener is tightened only after the unit has been loaded normally, otherwise the hinge will be pre-tightened and will quickly collapse during operation. Only floating structures or individual rubber bushings can self-install.

Malfunctions

The silent blocks themselves are quite reliable parts, whose weighted average service life is more than 100 thousand kilometers. However, in Russia, road conditions are worse than in other countries, so joint diagnostics are carried out more often. The following signs will help determine that the products are faulty:

The car's handling has become worse, i.e. turning the steering wheel became slower.

There was a dull knock when driving over small potholes.

Uneven tire wear.

The wheel alignment parameters were violated for no particular reason.

The loss of directional stability began.

Silent blocks are severely damaged if, upon inspection from the pit, it is discovered that the rubber seals have deep cracks.

There are situations when these signs indicate a completely different breakdown. Ball joints sometimes make clunking noises, and cracked parts require repair. In any case, detailed diagnostics are required.