Master cylinder: its purpose and functions

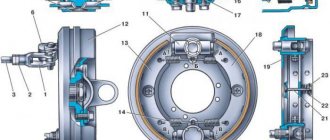

General view of the main brake cylinder

During the braking process, the driver directly acts on the brake pedal, which is transmitted to the pistons of the master cylinder. The pistons, acting on the brake fluid, actuate the working brake cylinders. From these, in turn, pistons extend, pressing the brake pads to the drums or discs. The operation of the brake master cylinder is based on the property of brake fluid not to be compressed under the influence of external forces, but to transmit pressure.

The master cylinder performs the following functions:

- transmission of mechanical force from the brake pedal using brake fluid to the working cylinders;

- ensuring effective braking of the car.

In order to increase the level of safety and ensure maximum system reliability, two-section master cylinders are installed. Each section serves its own hydraulic circuit. In rear-wheel drive cars, the first circuit is responsible for the brakes of the front wheels, the second - the rear. In a front-wheel drive car, the brakes of the right front and left rear wheels are served by the first circuit. The second is responsible for the brakes of the left front and right rear wheels. This scheme is called diagonal and is most widespread.

What is a brake master cylinder and what is it for?

Brake master cylinder and reservoir.

Braking is accomplished by pressing the pads against the disc. This is done by pistons that are driven by a hydraulic system containing brake fluid. However, for brake mechanics to work, pressure must be somehow transmitted by pressing the pedal. For this purpose, a master brake cylinder is needed, which transmits the mechanical action of the driver to the hydraulic system through a booster.

Considering the importance of the part, they try to make it as reliable as possible. But even greater reliability can only be ensured by an additional system, which is why all modern cars have a two-section GTZ. Each section serves an independent circuit, which, in the event of a breakdown of the first, will be duplicated, although with less efficiency.

The circuits can be connected in the following ways:

- Parallel (4+2). One circuit is used for all wheels and has insurance on the front ones.

- Parallel (2+2). One circuit is responsible for the front wheels, the second - for the rear.

- Diagonal (2+2). Each circuit operates on one front and one rear wheel diagonally.

As a rule, a diagonal system is used in front-wheel drive cars, and a parallel 2+2 in rear-wheel drive cars.

Master cylinder device

The principle of operation and design of the brake master cylinder is similar to the clutch master roller, given that in many cars one mechanism performs double duty. But in many cars, there are two pistons located in the brake drum to operate the front and rear or left and right circuits, depending on the make of the car. After disassembling the brake master cylinder, you can see the following main spare parts:

1, 2 — Tank cover with gasket. 3 - Brake master cylinder reservoir. 4 - Bushings for the bypass fitting. 7 - Tank body. 10, 28 — Return springs. 12, 26 — Internal cuffs. 13, 25 - Bypass valves. 14 - Piston that activates the front brakes. 15, 16 — External cuffs of the front drive brakes. 20, 22 — Outer cuffs of the rear brake drive. 24 - Piston responsible for operating the rear brakes.

Car brake master cylinder diagram

- brake booster rod;

- retaining ring;

- primary circuit bypass hole;

- compensation hole of the primary circuit;

- first section of the tank;

- second section of the tank;

- bypass hole of the secondary circuit;

- compensation hole of the second circuit;

- return spring of the second piston;

- master cylinder body;

- cuff;

- second piston;

- cuff;

- return spring of the first piston;

- cuff;

- outer cuff;

- anther;

- first piston.

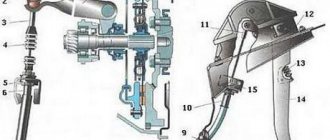

In the body of such a cylinder, two pistons (12 and 18) are placed, which are located one after the other. The second piston is freely installed, while the first piston interacts with the brake booster rod, which abuts against it. Rubber cuffs perform the functions of piston seals, which, as is already known, are located in the cylinder body. Return springs (2 pieces “9, 14”) hold and return the pistons.

Design and principle of operation

The master cylinder's job is to convert pressure on the brake pedal into force on each caliper. For reliability, all modern cylinders are made in two sections, with each section serving a separate circuit of the brake system. Therefore, even if there is damage in one area, the brakes will still work, although not as effectively.

Hydraulic drive layout. a) Parallel 4+2 with double safety on the front axle. b) Parallel 2+2, used in rear-wheel drive cars. c) Diagonal 2+2, used in front-wheel drive cars. 1. Master brake cylinder. 2. Brake fluid pressure regulator on the rear axle. 3, 4. Working circuits.

The design of the GTZ is quite simple: inside the housing there are 2 pistons located in tandem (one after the other). When you press the brake pedal, the force is transmitted through the rod to the first piston. It moves forward, compressing the brake fluid and creating pressure in the first brake circuit. At the same time, it pushes forward the second piston, which creates pressure in the second circuit. Those compartments of the housing that expand when the pistons move receive liquid from the compensation tank. If the brake pedal is released, the pistons return to their original position due to the springs, and the pressure inside the cylinder is equalized, again, due to the liquid in the compensation tank.

Due to the fact that the fluid almost does not compress under pressure, the force is quickly and completely transmitted to each of the brake cylinders.

Design of the main brake cylinder. 1. Brake booster rod; 2. Retaining ring; 3. Primary circuit bypass; 4. Compensation hole of the primary circuit; 5. First section of the tank; 6. Second section of the tank; 7. Secondary circuit bypass; 8. Secondary circuit compensation hole; 9. Return spring of the second piston; 10. Master cylinder body; 11. Cuff; 12. Second piston; 13. Cuff; 14. Return spring of the first piston; 15. Cuff; 16. Outer cuff; 17. Anther; 18. First piston

The compensation tank is also divided into 2 sections, so that in the event of a leak, the required amount of liquid remains in at least one of them. In some versions, 2 separate tanks are installed on the GTZ, and then when monitoring the brake fluid level, you need to check both separately.

A level sensor is installed inside the expansion tank, and when the brake fluid level drops critically, a signal on the control panel will light up.

The main brake cylinder is a fairly reliable device due to its simplicity, lasts a long time and fails mainly due to wear and tear over time.

This is interesting: How to exit Valet Starline mode

Principle of operation

Single-circuit gas turbine engines, where there was only one piston, are no longer found in cars, so only a double-circuit one is worth considering. It is distinguished by the presence of two pistons, each of which is responsible for the pressure in its own branch of the system.

In this way, the brakes are duplicated, which is required for safety. If a fluid leak occurs, a branch that remains in good working order will allow you to stop the car without using the parking brake or other emergency techniques.

The first piston is directly connected to the pedal rod. Having started to move forward, it closes the bypass and compensation holes, after which the force through the volume of liquid will be immediately transferred to the primary circuit pads. They will press against the discs or drums, and deceleration will begin using frictional forces.

Interaction with the second piston is carried out through a short rod with a return spring and the primary circuit fluid. That is, the pistons are connected in series, hence such GTZs are called tandem. The piston of the second circuit works similarly to its branch of the system.

Typically, the working wheel cylinders operate diagonally, that is, one front and one rear wheel are connected to each circuit. This was done in order to use the front, more efficient brakes, at least partially, in any case.

But there are cars in which, for structural reasons, one circuit works only on the front wheels, and the second on all four, for which additional sets of wheel cylinders are used.

The principle of operation of the braking system

The operation of a hydraulic drive is based on the property of a liquid not to be compressed by external influences. Thanks to this, the liquid perfectly performs the role of a force transmitter without any losses, but provided that there is no gas in its composition.

The principle of operation of a hydraulic brake system is very simple: the driver presses the brake pedal, thereby beginning to act on the brake fluid located in sealed pipelines. Since it does not compress, the force leads to its movement through pipelines, the ends of which are connected to working mechanisms. Because of this, the pressure in the cavities of the mechanisms increases, and the pistons of the mechanisms come out of their seats, pressing the pads against the discs or drums - the movement slows down. When you stop pressing the pedal, the pressure drops (the fluid returns) and the pistons of the mechanisms return to their original position.

Correct operation of the master cylinder is the key to safe driving and ensuring the safety of the life of the driver and other road users. Therefore, monitoring the correct functioning of the braking system must be carried out regularly.

Symptoms of problems

The general technical condition of the car (including the brake system) can be checked using a personal diagnostic adapter - a car scanner. These types of devices are widespread and have a wide price range. We would like to draw your attention to the budget model of Korean production Scan Tool Pro Black Edition.

At a cost of about 2 thousand rubles. This scanner is capable of fully diagnosing your car (engine, gearbox, transmission, abs, srs and much more), which will pay for itself in 1-2 trips to the service station. The adapter is quite easy to use, has Russian-language software and is compatible with most cars produced in 1993. The device will also be useful when buying a used car, as it can show its real mileage and VIN.

The fluid brake system consists of many parts that can become unusable: pipes, wheel cylinders, calipers, drums and pads. Typical signs of a faulty master cylinder:

- After pressing the pedal, the car stops slowly. The reason is that the cuffs of one or two pistons have lost their tightness - they have cracked or “floated”.

- To slow down, you need to press the brake pedal hard. The phenomenon occurs due to swelling of the rubber of the piston seals.

- The brake pedal travel is too short. The fluid inside the cylinder has nowhere to go because the compensation hole is clogged. Another option is that the passage is blocked by a swollen rubber seal.

- A common symptom is pedal failure, the brakes coming on at the end of the stroke. This indicates complete wear of the cuffs; as a result, liquid penetrates behind the piston and rushes into the expansion tank - the cylinder “bypasses.”

- The pads do not release the brake discs and drums and get very hot when driving. Options: one of the pistons is jammed or the bypass hole is clogged.

The listed symptoms of a GTZ malfunction are similar to malfunctions of other elements. Pedal failure also occurs when a large amount of air enters the tubes or loss of fluid in one of the working cylinders. Sluggish deceleration and increased force on the pedal are often caused by a breakdown of the vacuum booster - a cracked membrane or a lack of tightness at the joints of the hose that takes off engine vacuum.

There are signs that clearly indicate the performance of the main hydraulic cylinder and the malfunction of other elements:

- during braking, the car pulls to the side - the problem lies in a certain circuit or wheel;

- jamming of the brake mechanisms of one wheel;

- creaking and squeaking when braking;

- heating the discs and pads on one wheel.

If you eliminate these symptoms, it will become easier to check the brake master cylinder in a garage. This also includes obvious brake fluid leaks and the knocking sound of worn calipers.

There are other symptoms indicating a malfunction of the gas turbine engine.

- When braking at speed, the car pulls to the side. This happens when one of the circuits or brake cylinders on the wheel is faulty.

- The appearance of a squeaking or knocking noise during braking. It could also be pads that are time to be replaced, but it happens that the problem is in the GTZ.

- The pads can jam, heat up and heat up the brake disc on a particular wheel.

Signs of a faulty master cylinder

Cars are often equipped with pressure sensors that can detect a drop in pressure in the circuit. They will notify the driver of problems on the dashboard. Still, it would be useful to find out the symptoms of certain brake system malfunctions, since the causes may be different.

First, let's look at the symptoms that do not indicate a broken cylinder:

- Pull to the side when braking;

- Creaks when braking;

- Heating the pads on a specific wheel.

All this may indicate problems with the wheels, circuits, or jammed pads. Leaks from the working cylinders may also occur, there may be problems in the vacuum booster, or the integrity of the compensation tank may be compromised. Increased pedal travel may indicate pad wear.

As for the GTZ, its main problems are:

- wear of cuffs, gaskets and seals;

- using low-quality brake fluid;

- small particles such as shavings or grains of sand getting into the hydraulics;

- leakage from connecting joints.

Signs of a faulty brake cylinder include the following:

- Slow braking. This may indicate a loss of sealing of the cuffs.

- Great force when pressing the pedal. Often caused by swelling of the rubber in the piston seals.

- Short brake pedal travel. It speaks of a clogged compensation hole due to which the fluid in the cylinder has nowhere to go. Sometimes the hole is blocked by swollen seals.

- The pedal falls towards the end of its stroke. This indicates wear on the cuffs, which leads to fluid flowing behind the piston.

- The pads continue to hold the discs. There may be a piston wedge or a blockage in the bypass hole.

And yet, some signs are not always a consequence of failure of the gas turbine engine. Pedal dips can occur when the tubes are filled with air, and weak braking can indicate a breakdown of the brake booster. Be that as it may, any symptoms of deterioration in braking require immediate diagnosis of not only the cylinder, but the entire system.

Causes of malfunction in the GTZ device

If there is a leak in one of the circuits, the pressure between the primary and secondary cylinders is lost. This leads to the fact that the GTZ functions as if it had only one circuit. The pusher will begin to move both pistons in the good circuit until the piston of the faulty one reaches the end of the cylinder body. Accordingly, the required pressure will be ensured in the depressurized chamber. If the idle mechanism is properly adjusted, the vehicle will effectively slow down the vehicle even in conditions of its inferiority.

Here are some signs of a malfunction in the GTZ device:

- depressurization of the cylinder is determined by the presence of a leak in the body and a specific smell;

- brake pad wear is characterized by a characteristic squeak and leakage of brake fluid;

- jamming of the regulator, which distributes the brake force. In this case, it is necessary to clean the cylinder body. There is a low threshold of sensitivity of the brake pedal; it has to be literally “sunk” into the floor;

- the pedal falls to the floor - this damage occurs due to non-working pistons. If they are not able to generate the required pressure, then the pads cannot compress normally;

- An increase in the brake pedal travel is a sign that the vehicle has become airy. Operating a car in this condition is dangerous, since there is a high risk of overheating the vehicle to the point of boiling. Pumping will help eliminate this problem.

If any of the above happens constantly, we can talk about damage to the vacuum booster valve or a complete loss of tightness in the system. If the metal housing itself is damaged or there are scuffs on the piston, a complete replacement of the turbocharger is required. When the gasket wears out, all components of the repair kit (sealing collars, rubber gaskets, springs) are changed.

How to bleed the master brake cylinder? You need to unscrew the air release valve in the cylinder body and press the pedal until a perfectly uniform liquid flows out, without any air. Upon completion, the valve returns to its place and the reservoir must be refilled with liquid. The sequence of bleeding the mechanisms is as follows: 1 - rear right; 2 — front left; 3 — rear left; 4 - front right.

A common cause of malfunction of this element is loss of housing tightness and leakage of brake fluid. The defect that causes brake fluid leakage is a rear cuff leak, which can be determined by the presence of oil at the junction of the turbocharger and the vacuum booster. This may occur due to the breakdown of flexible tubes due to friction with the rotating wheel.

It’s good if, in the area where the highway passes through the arch, it is protected by a special spring that prevents the wheel from rubbing the element. If the fluid level is low, you need to check the tightness of the entire vehicle and replace the damaged tube.

Signs of GTZ failure

There are several signs of problems with the GTZ.

- Traces of brake fluid leaks. First of all, on the vacuum brake booster, located directly under the brake cylinder. The reason is the wear of the low pressure collar cuff.

- A brake pedal that is too “soft” indicates that the system has become depressurized and pedal force is not transmitted because the brake fluid is not compressed. This happens due to wear on the piston cuffs or the walls of the turbocharger itself, as a result of which it cannot pump the brake fluid.

- The brake pedal may jam when blockages clog the compensating hole of the turbocharger.

- The brake pedal may stick if the GTZ pistons are stuck. The reason is contaminants that appear in the brake fluid over time. That is why it needs to be changed regularly.

- The brake pedal does not return if the return springs can no longer return the GTZ pistons to their place. Although physical damage to the pedal itself is also possible.

There are also indirect signs, one of the reasons for which may be a faulty turbocharger. Among them are uneven wear of the pads and the car pulling to the side when braking.

How to check the brake master cylinder

Car maintenance and diagnostics include checking the brake fluid level every week: if it drops sharply, you can judge about leaks. In addition, it is important to change it in a timely manner, since over time the quality of the fluid deteriorates, which leads to premature wear of parts. It is also worth paying attention to compatibility with the cuffs, as some auto chemicals can damage them. And, of course, you should promptly change all rubber seals, paying attention to the service life declared by the manufacturer. It would be optimal to resort to a repair kit with all rubber bands every 100 thousand km, and it is better not to skimp on the quality of components.

If symptoms of a gas turbine engine malfunction appear, it is advisable to check it, and you need to start with a visual inspection. If, when inspecting the housing, drops of brake fluid are found, the hydraulic cylinder should be removed to look for a leak problem. Also common problems include fluid flowing through the seals, which is easy to check: if gurgling is heard from the reservoir when you press the pedal, the seals must be replaced. And, of course, special attention should be paid to the behavior of the pedal: as already noted, a short stroke or dips may indicate the need to clean the cylinder and replace all rubber elements. The best way to judge their condition is by dismantling the part and disassembling it: sometimes, in addition to minor damage to the gaskets, you can also find a crack in the cylinder itself. In this case, the entire part will have to be replaced.

Video on the topic

GTZ malfunctions

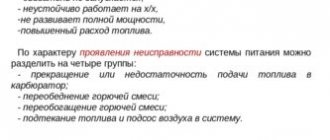

The VAZ 2101 brake system has many parts that can fail due to wear, poor quality or untimely maintenance. The following characteristic symptoms of problems can be identified:

- slow stopping of the vehicle after pressing the brake pedal. One of the reasons is that the lip seals of the pistons have become unusable, which led to a loss of tightness;

- high pedal effort. This problem appears when the cuffs increase in size, for example, when installing a low-quality repair kit;

- The brake pedal has a short stroke. The working environment, i.e. the brake fluid, has nowhere to go due to the fact that the compensation hole is clogged. In addition, the canal may be blocked by swollen cuffs;

- The car only brakes when the pedal is pressed to the floor. This indicates a complete failure of the lip seals when the liquid goes into the tank and not into the system;

- Brake pads do not move away from the discs and drums, causing them to become hot while driving.

The reason lies in the jamming of one of the pistons or the formation of a blockage in the bypass hole. If the seal is lost, liquid begins to flow out of the cylinder

These symptoms may also occur if there are problems with other parts of the braking system. For example, the pedal may fail if there is no fluid in one of the wheel cylinders or if air gets into the system

Therefore, for a final diagnosis, it is necessary to pay attention to additional features of the car’s behavior. For example, there are certain signs that clearly indicate problems with other components of the brake system, and not with the GTZ:

- pulling the car to the side when braking;

- jamming of the brake mechanisms on one of the wheels;

- the appearance of sounds uncharacteristic of normal brake operation (creaking, squeaking, grinding);

- heating of brake pads or discs on one wheel.

Checking the brake master cylinder

The most common cause of GTZ problems is wear of the seals. When replacing cuffs, you need to take into account that repairs only make sense if the piston and cylinder walls do not have wear. Otherwise, replacing the rubber seals will not bring any results and soon you will still have to install a new part. Before you start checking the main hydraulic brake drive, you should make sure that there are no problems with other elements of the system:

- Inspect the wheels from the inner surface to identify any leaks of brake fluid from the brake fluid brake system.

- Check the integrity of the tank and hoses connecting it to the gas turbine engine, as well as the presence of fluid and its level.

Fluid leaks on the inside of the wheel indicate a leak in the brake system.

A clear sign that there is a problem with the master cylinder is the appearance of liquid on the unit body. A working mechanism should always be dry without a hint of leakage. If the hydraulic drive has lost its seal, it must be dismantled for further disassembly and repair. You can determine that the gas turbine engine bypasses fluid, i.e., it does not enter the system, but returns to the expansion tank when you press the pedal:

- Open the tank lid.

- An assistant is seated in the driver's seat. The engine does not start.

- Your partner presses the brake pedal, and you listen to the sounds coming from the reservoir.

- If gurgling is heard from the container, and the pedal is pressed lightly, it means that the liquid is entering the tank instead of the system. The malfunction lies in the wear of the seals, which are unable to create the necessary pressure in the cylinder circuits.

Operation of the system when one of the circuits fails

Dual-circuit brake drive device

If there is a brake fluid leak in one of the circuits, the second will continue to operate. The first piston will move along the cylinder until it contacts the second piston. The latter will begin to move, due to which the brakes of the second circuit will be activated.

If a leak occurs in the secondary circuit, the brake master cylinder will operate differently. The first valve, due to its movement, activates the second piston. The latter moves unhindered until the stop reaches the end of the cylinder body. Due to this, the pressure in the primary circuit begins to increase, and the car brakes.

Even if the brake pedal travel increases due to a fluid leak, the car will maintain control. However, braking will not be as effective.

Why is GTZ needed?

The GTZ converts the energy of pressing the brake pedal into the energy of compression of the brake fluid. And the force is transmitted very quickly through the system.

Its task is to provide braking force in at least one of the circuits of the braking system. If one part of the system fails, another circuit always remains operational. This allows the car to brake, although not as effectively.

In modern cars, the GTZ works in tandem with the ABS system - the latter regulates the braking force on the wheels by controlling the pressure through the main brake cylinder.

Master cylinder repair

After the master brake cylinder has been removed, it is worth inspecting for mechanical damage; if there is none, you need to disassemble it and replace the failed spare parts with those found in the repair kit. After disassembling the master brake cylinder, in any case, you must change all the rubber spare parts - cuffs, etc. The principle of disassembling with your own hands is simple:

- Having previously secured it in a vice, unscrew the fluid supply fittings from the body;

- use a screwdriver to remove the retaining ring;

- Carefully disassemble and remove cuffs, pistons, springs and other spare parts.

After cleaning all the components and rinsing them in hydraulic fluid, you need to carefully inspect the internal mirror of the housing for scoring and other damage. If swollen cuffs are detected, it is worth changing the hydraulic fluid, the poor quality of which may be the cause of this phenomenon. One of the taboos is the adjustment and repair of a pressure regulator, the parameters of which are set by the manufacturer; its replacement is carried out as a kit.

Reassembling the brake master cylinder is carried out in the reverse order. Having replaced the spare parts that require replacement: a fitting, a set of cuffs and others with new ones, the question arises: how to check the brake master cylinder after assembly? For this, there is a special stand consisting of the following components:

- Bleeding valves.

- Pressure gauges.

- Absorbing rollers.

- Reservoir with hydraulic fluid.

- Maximum displacement indicator.

- Mechanical flywheel.

- Main roller housing.

This stand will help determine whether the assembly was done correctly by hand. After installing the main drum in place, you need to bleed the brake system. If mechanical damage is found on the body, then the master brake cylinder needs to be replaced with a new one.

Basic faults

Despite the simplicity of the design and the small number of moving elements, the GTZ often ceases to perform its functions normally due to malfunctions.

It is not difficult to detect a breakdown of the GTZ. The first signals of a malfunction will be given by the brake pedal. Any change in its behavior when pressed (lightness, increase in force, etc.) indicates a breakdown. But it will signal the emergence of problems throughout the system. Checking the system on the highway allows you to more accurately identify the malfunction (the car accelerates, and then emergency braking is performed). And then the traces determine how the system works. Afterwards, all that remains is to visually inspect all the components of the drive for leaks.

The main malfunctions of the master brake cylinder are:

- Depressurization.

- Air leak.

- One of the pistons is jammed.

The master cylinder loses its seal, usually due to severe wear or damage to the sealing collars. In this case, liquid can flow between the chambers and also come out of the housing. This allows air to enter the system. As a result, the pressure decreases significantly and the effectiveness of the braking system deteriorates.

Video:Replacing the master brake cylinder VAZ 2108 2109 2110

Air leaks in the system may occur due to blockage of the ventilation hole in the tank lid. Because of this, when the liquid moves, a vacuum is formed in the tank, which is compensated by air penetrating through the cuff. As a result, airing of the system causes a decrease in the efficiency of the system.

Piston jamming can occur for two reasons - debris entering the cylinder through the tank or the formation of rust on the internal surfaces of the housing. This causes one of the circuits to stop working.

Restoring the performance of the gas turbine engine is possible only in case of wear or damage to the seals or clogging. Special repair kits are sold for repairs.

Often, washing the cylinder and replacing rubber elements allows you to completely restore functionality. But there are also cases when such measures do not help and the problem can only be solved by replacing the assembly.