Published:

03.06.2016

The flawless operation of any vehicle depends not only on its operating conditions, but also on the quality of the fuel used. Surely every motorist has more than once encountered the fact that some gas stations sell contaminated fuel containing mechanical impurities and tiny particles of water.

To eliminate possible engine contamination due to low-quality gasoline or diesel fuel, coarse and fine fuel filters are used. Such devices are capable of eliminating small particles of dirt, dust, and rust, thereby ensuring the supply of cleaner fuel to the engine.

Filtration stages and types of devices

It is important to note that the system that makes the fuel in the car cleaner is divided into 2 stages:

- rough cleaning, removing all large particles of dirt;

- fine cleaning that removes small particles of dirt and dust from the fuel.

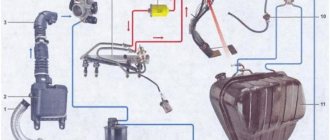

Not all drivers know where the fine fuel filter is located, as well as the coarse filtration device. Screening out foreign particles can be carried out in the fuel tank before the flammable substance enters the fuel system of the car, or the device can be located in the engine compartment under the bottom of the car. And the element for purifying small particles is located between the pump and the carburetor.

Based on their design properties, filters are divided into:

- Collapsible - mesh elements made of brass or ceramic located in collapsible structures clean gasoline quite efficiently. Among the advantages of such devices is the ability to disassemble and wash them. After this you can use it again.

- Non-removable - such cleaners are usually installed in front of the fuel pump. They are inexpensive and, due to their spiral design, last longer and provide high-quality fuel filtration.

- With a transparent body - they do an excellent job of filtration, allow the driver to assess the degree of contamination and change the element in a timely manner.

It is important to understand that the fuel systems of different cars may have their own characteristics. When selecting a part, it is worth taking this into account.

Sometimes the fuel system may contain not two, but as many as four stages of purification.

Replacement

Sooner or later, the coarse cleaning device will have to be replaced. The replacement process, of course, is provided for by technology: there is a hole in the roof, closed with a plug, which is designed to remove air during the replacement. A competent filter replacement can be done at a service center with a good reputation.

Coarse cleaning devices will remain relevant for a long time due to insufficient filtration of fuel before it enters the fuel system. However, even if one day the fuel is completely clean, careful people will still install filters and do the right thing. This will allow you to insure yourself in case of the presence of certain impurities. Situations are different, and, of course, it is better to provide for any, even unlikely, options.

Clean fuel and an easy road for you!

All about coarse filters

A coarse fuel filter is used not only to eliminate coarse particles, but also to prevent water particles from entering the vehicle system. It is capable of trapping particles larger than 0.1 mm. Water retention is especially important for vehicles running on diesel fuel, as it has a certain moisture content. Due to the fact that water is heavier than diesel fuel, it settles and accumulates at the bottom of the purifier.

Diesel fuel also contains paraffin. It tends to crystallize at low temperatures. This can lead to complete disruption of the entire fuel system. That is why filters for diesel engines are equipped with a heating element. The device may also have a special sensor that notifies the driver about the water level in the part.

Choice

The correct strategy for choosing a fuel filter is to follow the recommendations of the car manufacturers. They are designed taking into account the needs of the engine. You should not experiment by installing an unsuitable filter just because it is cheap.

Some motorists try to compensate for poor cleaning quality by frequently replacing the fuel cell. This is the wrong approach. The main task of the filter is to prevent foreign particles larger than a certain size from entering the fuel equipment and cylinders. Filtration fineness is one of the characteristics that does not change during operation. Neither old nor new element, which is not able to retain small particles, will protect the engine from breakdown.

Filtration fineness is one of the filter characteristics that does not change during operation.

Filters with similar parameters are produced by different companies. Well-known brands Mann, Knecht (Mahle), Bosch, UFI, Delphi and others occupy a leading position in the market, as they produce high-quality products that car manufacturers install on new cars. To select a suitable filter, use online catalogs. Choose only those models whose description contains a direct recommendation for your car.

Bosch filters are some of the cheapest among well-known brands Mann offers the widest range of filters for various purposes Delphi is one of the few companies that has mastered the production of filters for Common Rail diesel engines Knecht-Mahle is a prestigious German brand The Italian company UFI supplies filters to the Volkswagen assembly line

We recommend: How to easily unscrew the crankshaft pulley - simple instructions

All about fine filters

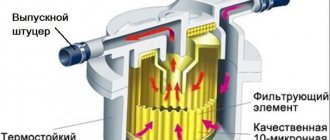

For high-quality engine operation, clean fuel is necessary. Even mechanical inclusions invisible to humans are quite dangerous for the engine. The fine fuel filter allows you to retain impurities whose size does not exceed 60 microns.

A big mistake is made by drivers who do not use a fine fuel filter, but rely only on the “grids” that are located on the carburetor and the tank neck. Even the smallest invisible inclusions can cause serious damage to the motor.

For vehicles with a diesel engine, a fine diesel fuel filter is also extremely necessary. If you ignore this fact and do not install a fine fuel filter for a diesel engine, the efficiency of the engine will significantly decrease and engine breakdowns will become more frequent.

An injection engine is quite demanding on the quality of gasoline. Owners of such vehicles also install an additional sediment filter, which is made of high-strength plastic and steel. It ensures high-quality exclusion of unnecessary impurities and promotes long-term, uninterrupted operation of the injector.

It is worth noting that if the car runs on gasoline, the fuel purifier must be cleaned or replaced in a timely manner. It is important to do this at least once every 25–30 thousand kilometers. This will ensure reliable and trouble-free operation of the motor.

Features of the diesel fuel filter

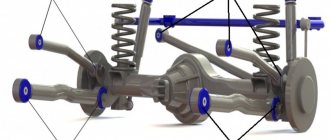

Fuel filters are installed on both gasoline and diesel cars. But the requirements for filtration quality are higher in the case of a diesel engine, and the filter elements themselves are changed more often.

It's all about the design features of a diesel engine: the pressure under which diesel fuel is injected into the cylinders is much higher than in the case of a gasoline internal combustion engine. High pressure requires greater tightness, therefore, the gaps in the pumps and injectors that supply fuel to the combustion chamber must be minimal. And the particles that the fuel filter allows through must be smaller than the gap, otherwise the elements will wear out.

Hence such high requirements for the cleanliness of diesel fuel : condensate, sediment, foreign impurities, metal dust and shavings - all these are direct threats to the durability of diesel fuel equipment.

It should be taken into account that diesel fuel becomes contaminated from the very beginning of the process of its production and further during storage: oxidation occurs in it, suspensions appear, it becomes cloudy, mixes with condensate (water) from the walls of the tank, and in winter it thickens, forming a paraffin deposit.

- If the fuel is of questionable quality or an air lock has formed in the line, the parts of the fuel equipment are no longer lubricated by fuel, and metal dust, shavings, foreign impurities with large particles enter the fuel supply system, which clog the nozzles and injector needles, “wash out” the channels in the injector valves, irreversibly damage the fuel injection pump, accelerating the wear of expensive elements.

Water inevitably enters the fuel system as a result of condensation of water vapor; this occurs both at the gas station and in the car tank.

- If the filter does not separate water from the fuel, it gets on the elements and causes their corrosion, for example, on the fuel injection pump blades. And it can even get into the engine cylinders, causing detonation during fuel combustion.

Thus, effective cleaning of diesel fuel with a fuel filter directly affects the reliability and service life of the diesel engine.

Design and principle of operation of a diesel fuel filter

Fuel purification in the diesel power system takes place in several stages:

- First, the fuel enters the tank. Some of the large impurities precipitate and remain at the bottom of the tank, the other part is filtered out by a coarse mesh, which is installed at the outlet (sometimes at the inlet) of the fuel tank;

- then the diesel fuel enters the coarse filter, which, depending on the design of the car, can be located either inside the fuel tank, in a kind of glass, or on a section of the fuel line. The brass mesh of the coarse filter retains particles and fractions in diesel fuel ranging in size from 0.5 to 1 mm.

- After the coarse cleaning stage, diesel fuel passes through a fine filter. It is capable of trapping the smallest particles, and the size of the filter element cells determines how clean the fuel gets into the engine cylinders. The fine filter is installed on a section of the fuel line between the tank and the injection pump, or in the engine compartment.

On different car models and depending on the type of diesel fuel equipment, fuel filters have different designs and are also arranged differently.

The most popular device options:

- when the fuel filter is a single unit, where the coarse and fine filter elements are combined in one housing;

- when the coarse filter and the fine filter are two separate units;

- when the fuel filter is an integral part of other elements of the fuel system, mainly built into the fuel pump or connected to the fuel level sensor in the tank.

The ease of access to it and the ability to change the part yourself depend on the location and design features of the fuel filter.

The main difference between a fuel filter for a diesel engine and an analogue for a gasoline engine is that diesel filters have a special container where all the filtered moisture is collected, and this container must be cleaned periodically to prevent water from getting into the engine.

Also, heating elements are often installed in the diesel filter so that it does not freeze in cold weather and the engine can be started in winter without problems.

Filters for diesel engines are:

- collapsible, where only the filter element itself can be replaced, and the housing remains in place;

- non-separable, essentially disposable, where you have to change the filter along with the housing.

When is it time to change the fuel filter?

On most cars with a diesel engine, it is not possible to check the condition of the fuel filter, so they change it according to mileage data.

On average, the service life indicated by manufacturers is 15-40 thousand km, depending on the type of filter:

- for conventional external type filters (“barrels”) - up to 20-30 thousand km;

- for filter cartridges - from 60 to 120 thousand km.

The former are usually used on public sector cars, and the latter on premium cars from Japanese, Korean and American manufacturers.

It is better to carry out replacement work in the fall, before the onset of cold weather. The throughput capacity of the new filter will be higher, it will definitely be enough to pass fuel that thickens in the cold - which cannot be said about a filter that has been collecting impurities from diesel fuel for a season or two.

Outside of the regulations, it is necessary to change the filter if, after refueling the car, the engine begins to behave unusually (the sound of its operation has changed, the thrust has dropped, etc.) and the owner suspects that foreign impurities have entered the tank. Moreover, just replacing the filter will not do the job: you need to drain the suspicious fuel as quickly as possible and replace it with proven fuel - and in some cases, you will need to flush the tank.

Signs of a clogged fuel filter

Another way to determine when it's time to change the fuel filter is to carefully monitor the car's behavior.

The following signs will indicate that the filter throughput has dropped:

- the engine is reluctant to start

- noticeably loses power, especially when going uphill

- twitches, troits, idle speed fluctuates

- responds to pressing the gas pedal with a delay

- when moving under load, it is unstable, jerking is felt

- consumes more fuel

The problem should be looked for in the fuel filter if the listed symptoms intensify gradually over time.

If they occur unexpectedly, this is a reason to look for the cause in other problems with the fuel system.

What happens if you don't replace the fuel filter on time?

If these symptoms appear or when the replacement schedule arrives, you need to replace the filter without delay.

Otherwise, problems with engine behavior will increase, and the filter throughput will decrease to such a level that this will provoke serious breakdowns in other components of the car.

An approximate list of such breakdowns:

- failure of diesel fuel injectors

- failure of the injection pump and other elements of the fuel line

- Engine malfunction due to detonation (water in fuel)

It is worth remembering that the fuel system of a diesel car is one of the most expensive to repair. While replacing the filter is a relatively simple and inexpensive procedure.

How to extend the life of a fuel filter

- refuel only at trusted branded gas stations

- try not to refuel immediately after the fuel has been drained from the tank at a gas station: in the container the fuel mixes with sediment

- do not pour fuel into old rusty cans

- switch to high-quality winter diesel fuel in a timely manner

- periodically drain the remaining fuel from the sediment filter to maintain the cleanliness of the fuel system, rinse the fuel tank and remove it 1-2 times a year

- On long journeys and in winter, take a spare fuel filter with you

- change the fuel filter on time, reduce the replacement interval recommended by the manufacturer by 2-3 times, taking into account the quality of domestic diesel fuel and operating conditions.

Find out about typical problems of diesel car owners here.

You will find diesel fuel injectors in our catalog

View spare parts in stock

This is interesting: How to remove an air lock from the cooling system

When should you change the filter element?

There are several indicators that should indicate to the driver that it is time to change the fuel filtration device:

- engine power has become lower;

- when the speed decreases, the car often stalls;

- It’s difficult to drive uphill;

- the car periodically jerks and shakes;

- the engine doesn't start at all.

To summarize all of the above, it can be noted that high-quality, clean fuel is important for the operation of any type of vehicle engine. Even at trusted gas stations it is difficult to guarantee such a level of fuel products. There is only one way out - install devices that make the fuel clean, provide double filtration of the fuel from harmful impurities, dust particles, debris and water. When selecting such a part, it is important to take into account the make of the car, the type of engine, and the type of fuel used.

Where is

There can be no clear answer to this question. Depending on the vehicle model and the type of fuel system used, a variety of positions may be designated. However, in any case, the location will be between the engine and the fuel tank, because the pump pumps fuel from the gas tank to the engine. Therefore, the advisability of placing the filter in this interval is beyond doubt.

On carburetor models it is installed directly under the hood near the carburetor. Therefore, finding this element and dismantling it is quite simple.

After lifting the hood you can immediately see this element

In injection-type cars, the part is located under the bottom of the car - often on the rear beam.

It is easy to find along two highways

In diesel engines, cleaning is carried out by a filter, which is mounted between the fuel pump and the engine. Sometimes the part is placed inside the gas tank, less often - under the bottom of the car.

Coarse filter

The fuel filter for primary (coarse) fuel cleaning has a simple design: it is a cartridge with specific filter paper inside. In addition, each one is necessarily equipped with a mesh that can allow only the smallest particles to pass through.

Structurally, it is housed in a stainless steel or plastic housing and is secured in the desired position with bolts. A small distance is always maintained between the walls of the housing and the filter itself. This gap is used to introduce paronite liners. They provide increased tightness of the device. At the bottom there is a damper.

Fine filters

Such parts that are intended for secondary (fine) cleaning can be of two types:

- collapsible (which, in case of malfunctions, can be disassembled and the filter element replaced);

- non-removable (they are considered disposable, since they must be replaced in case of malfunctions).

They are usually changed more often than coarse cleaning, if we talk about diesel engines. Structurally, the parts are similar in structure to filters for primary purification, but have tiny holes in the mesh to trap particles and impurities with a diameter of less than 0.01 mm.

How to replace the fuel filter?

To replace the fuel filter, you will need common tools such as a wrench, screwdriver, and pliers. Depending on the location of this filter, other means may also be required. If it is snap-on, you will only need pliers to remove it. If it is located on the fuel line, then it has 2 fasteners, and the fuel filter assembly is also secured with a bracket. First, before removing the filter, you need to relieve the pressure to prevent fuel spillage. This can be done by pulling out the pump fuse, after which you need to wait until the engine stalls. After you have disconnected the fuel line, remove the filter by removing it from the bracket.

After completing the above steps, you can install a new fuel filter. It is important to install it correctly; to do this, you need to look at the case where the arrows are located to determine the correct installation direction. It is recommended to remember how the previous filter was installed and install the new one as well. This will ensure correct installation. The filter must be secured to the bracket, and then the fuel line must be connected using new fasteners that come with the filter. It is also recommended to check the integrity of the fuel lines. After this, insert the pump fuse and start the engine.