Many must have noticed that recently more and more cars that run on diesel fuel have begun to appear on the roads.

The reason for this is simple - more optimal use of fuel, because its consumption, most often, in a diesel engine is noticeably less than in a gasoline engine.

But practice shows that diesel engines are usually inferior in power to their gasoline counterparts. That is why the turbo timer for diesel began to gain popularity - a fairly simple device that helps the engine continue to operate even at idle speed.

But is it needed at all? We will try to figure this out in our article.

What is a turbo timer?

It is important to know The turbo timer in the “signal” with feedback ensures gradual cooling of the diesel engine without sudden temperature changes.

The device supports the operation of the internal combustion engine after the ignition is turned off for 2-3 minutes. The device supports the operation of the internal combustion engine after the ignition is turned off for 2-3 minutes.

Principle of operation

The principle of operation of the turbo timer on car security systems B92, B94, A 39, A61 and other versions:

- Thanks to the use of the device, the driver will be able to turn off the ignition system and leave the car with the engine running. At this moment, you can turn on the security mode, and the engine will idle for some time.

- While the engine is running at idle speed, air continues to circulate inside the turbocharged unit, which allows the device to cool.

- After the engine temperature drops or the timer expires, the power unit will stop.

Pros and cons of a turbo timer

The main advantages of turbo timers on Starline B6, B92, B94 and other versions of alarms:

- saving time thanks to the timer operating on diesel and gasoline in automatic mode;

- reducing the likelihood of malfunctions in the operation of a turbocharged unit;

- ease of installation and connection - the turbo timer can be configured to turn on and off by a user without experience in installing anti-theft systems.

Disadvantages characteristic of turbo timers:

- Reduced security level. While the engine continues to idle, there is an excellent opportunity for criminals to steal the car.

- The appearance of a conflict between the device and security alarm systems. In the simplest and most standard CAN alarms with auto start on a car with 12V or 24V, the running engine stalls after switching to security mode. Therefore, when installing a turbo timer, it is necessary to either replace the alarm completely or use special interfaces for interaction between systems.

- Unauthorized installation of the device entails a violation of the terms of the warranty and is a reason for refusal of free repair and service work.

Varieties

There are two types of turbo timers for cars:

- Autonomous systems. Such devices are manufactured in the form of a module mounted on or under the center console of the car. The unit is purchased as an addition to the anti-theft system and is connected using programmable channels. The alarm key fob has buttons that allow you to set the turbo timer and control the system.

- Built-in. Such turbo timers are built into the control unit of the security complex and are considered an additional option. The module is installed hidden under the center console.

Turbo timer. An extremely important element or a completely useless thing?

Car manufacturers are constantly offering consumers new products. This article will focus on the turbo timer

, intended for installation on

turbocharged cars

. Is this device really necessary, or is it completely possible to do without it? Let's figure it out.

Turbo timer: what is it, what is it for?

Technological progress cannot be stopped. Representatives of the auto industry prove this constantly. Safety, efficiency, and environmental performance of vehicles are improving. Driving characteristics are improved. A reasonable question arises: are innovations really useful? Maybe additional options are needed solely to make gullible customers of car dealerships pay more money?

Description of the gadget

Car enthusiasts eager to increase the speed capabilities of their iron horses should:

- thoroughly study the technical characteristics of various turbine models;

- choose reliable, most efficient equipment.

Otherwise you won't be able to understand:

- how long will the turbocharger work properly;

- Will it be possible to significantly increase the potential of the unit?

Experts advise paying attention to the turbo timer, which is an electronic sensor (not much larger in size than a matchbox). The device is located under the dashboard. Power is supplied through wires connected to the ignition switch terminals.

Device efficiency

We have not yet decided on the efficiency of the turbo timer. The main reason is the specificity of the turbine operation

. It functions for a certain time, although the power unit is already turned off. Those who drive turbocharged cars know very well: after rushing along the highway at high speeds, you need to wait for some time and not immediately turn off the engine. Why?:

- bearings rotate;

- oil does not flow and burns on metal surfaces;

- The oil line is partially blocked.

The result is a breakdown of the unit. Moreover, its restoration is an expensive undertaking.

Turbines for Audi, BMW, Volkswagen, Mercedes, Renault, Peugeot, and other brands equipped with a timer do not wear out so quickly. When the vehicle stops, the driver safely turns off the ignition, and the device operates until the engine stops.

Customers of auto repair shops are interested in whether everyone needs to install a gadget. It is not possible to answer the question unambiguously. It's better to analyze your driving style. For constantly rushing car owners who do not want to waste precious time waiting for the turbine running at idle to cool down, it is preferable to equip the car with a smart device.

People who often sit in traffic jams and adhere to the speed limit probably do not need to spend money on buying a turbo timer.

Important point

Do not forget: a turbo timer is a tool that significantly complicates the task of car thieves. Until the engine cools down and the device turns off, the car will not move. By means of a timer, the control is blocked and the siren is turned on. The price of a turbine add-on (depending on the model) varies from sixty to one hundred and fifty conventional units.

Conclusion

Everyone decides for themselves whether to upgrade the turbine or not. You can get additional information by contacting consultants by phone. Consultations are provided free of charge. The information received will certainly be useful.

How the turbo timer works

Instructions on how to turn on and off the turbo timer on a starline alarm and troubleshooting.

A car’s turbocharger operates at a high rotation speed, which can reach one hundred and fifty thousand revolutions per minute. Since the turbine has a single lubrication system with the engine, after turning off the ignition, oil stops flowing to the turbocharger, which continues to rotate by inertia. This leads to the fact that the remaining lubricant in the bearings quickly burns out, and the wear of almost all parts of the turbocharger increases sharply. If you let the engine idle for one or two minutes before turning off the ignition, the turbine parts have time to cool and the service life of the turbocharger increases significantly. It is for this purpose that a turbo timer is installed. In modern cars with a turbocharger, this function is already included as standard, but when installing a non-standard alarm system, a specialist must take into account the presence of an ignition turn-off delay system.

After you remove the ignition key from the lock, the engine with the installed turbo timer continues to run for the specified time and then turns off on its own. In this case, the car can be set to alarm as normal and go about your business.

Simple DIY turbo timer

A turbo timer is a simple device that allows you to extend the life of the engine, no matter whether it runs on gasoline or diesel. If your car has a turbocharged engine, then you cannot do without a turbo timer.

You can immediately guess why it is needed if you understand the turbocharging system, the heart of which is the turbine.

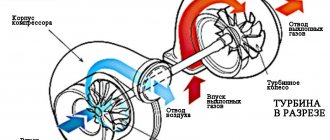

Not everyone has had the opportunity to see the turbine structure in person. Therefore, let’s take a few minutes and describe the turbine design in one or two sentences.

A turbine is a high-tech device, the body of which resembles a snail; impellers are installed inside the body and rotate at a speed of more than 50,000 rpm. Now I think it’s clear why it is so important to ensure continuous lubrication of rubbing parts and optimal temperature of turbine components.

Well, we understand everything about the principle of operation: there are blades on the shaft, and the shaft rests on bearings. Everything is clear, the only thing that is not clear is the reason why it is necessary to install a turbo timer on turbocharged engines .

But your doubts and questions will immediately disappear if you remember the structure of the oil pump, or rather, what drives it. That's right - the oil pump shaft is connected through gears to the crankshaft.

And now everything falls into place: if the engine stops, then the oil pump will stop, and lubricant will stop flowing to the rubbing parts and components, but the turbine DOES NOT STOPE! It physically cannot drop the speed from 50,000 thousand to zero in a second, and for some time it will rotate due to inertia, accordingly, the inner race of the bearing will rotate and oil starvation occurs. In this case, the wear of the rubbing parts will be greater the higher the temperature of the rubbing parts.

Therefore, after the trip, it is necessary to let the engine run at low speeds, which will allow the turbine and the engine to cool. If this is not done, then after a few years the clearances in the bearing will increase and lubricating oil will enter the combustion chamber, and combustion products, that is, carbon deposits will settle on the surface of the exhaust system and the sensors that are installed there.

We have figured out the reason, now let’s move directly to options for implementing a delay (turbo timer) before turning off the engine. There are three ways to solve this problem:

1 Sit in the car and wait a couple of minutes and then turn off the engine yourself, but this does not look very respectable;

Operation logic

Self-refurbishment of diesel injectors (common rail system)

The turbo timer allows the engine to continue idling after the key has been removed from the ignition. The device is used in internal combustion engines equipped with turbocharging. It does not matter whether gasoline or diesel is used as fuel. Under heavy loads and prolonged operation at high speeds, the turbocharger becomes very hot. During operation, engine oil is used for cooling, and in some turbines, coolant is used. Once the engine is stopped, oil circulation stops. Therefore, if the temperature in the channels is too high, the oil burns, which leads to the formation of carbon deposits. When the turbine resumes operation, the burnt oil will act as an abrasive, grinding down the surfaces of the rubbing parts. In addition, deposits reduce the cross-section of the oil channels, thereby impairing the supply of lubricant. The logic of the turbo timer is to let the engine run for a few more minutes after stopping in order to cool the turbine. At the same time, you can safely lock your car and go about your business. The engine will stop after the programmed time.

Feasibility of installation

A turbo timer is most often installed on a diesel engine only due to the more frequent use of turbochargers in conjunction with the internal combustion engine of the Diesel cycle. In what cases is it advisable to install this accessory:

- a turbocharged diesel engine is installed on an SUV that is used for its intended purpose or on a car that constantly drives loaded. In both cases, the engine operates under increased loads, and when driving off-road, there is also no normal cooling by the incoming air flow;

- you yourself equipped the engine with a turbine and/or you simply cannot imagine your trips without constant dynamic acceleration.

But even in this case, strong arguments can be made against installing a turbo timer:

- a diesel or gasoline engine is used for measured city driving with infrequent loads. Even if from time to time you have to actively pedal, then a quiet ride at up to 2000 rpm, even 1 minute before stopping, is enough to cool the turbocharger of a modern car. It would be useful to remind you of the high requirements for motor oil, which should be poured into turbocharged engines;

- The car has an alarm system with a turbo timer function. In this case, installing a separate device will be a waste of money. The alarm functionality can be viewed on the official website of the security system.

DIY installation

Please note that installing a turbo timer on a car equipped with a standard alarm system, with control over the main components via a CAN bus, and also equipped with a modern security system, will be an extremely difficult task. You will need skills in reading electrical diagrams, as well as understanding the logic of the operation of the main electronic systems of a car.

For the design of the device, it does not matter whether the turbo timer is installed on a diesel or gasoline engine. The difference in connection will largely concern only the power supply for the service functions of the device

The connection logic will differ depending on the specific car model and turbo timer. When purchasing a device from reputable manufacturers (HKS, Apexi, Greddy, TT, Blitz, TTX), in most cases you receive:

- Control block;

- module with a screen for demonstrating time reporting and other service functions;

- wires and connectors for connection;

- instructions.

Installation

To install the kit on your car, you will need:

- pliers that can be used to cut the wire and crimp the terminals;

- male-female terminals. You will also need a bolt terminal for ground, if one is not provided in the kit;

- heat shrink for reliable insulation of joints;

- clamps for fixing wires;

- screwdrivers and other tools necessary for assembling/disassembling the interior.

Do-it-yourself installation begins with de-energizing the on-board network (disconnect the negative terminal of the battery). You need to remove the interior plastic blocking access to the ignition switch contact group. To install a turbo timer on diesel/gasoline, you need to “cut” into the wires coming from the ignition switch. The module, which is often supplied with double-sided tape, can be secured in a convenient place near the device. The same method is suitable for mounting the control unit, which can be located inside the dashboard. If possible, it is better to additionally secure the block and wires with ties to avoid further extraneous noise when driving over uneven surfaces.

Turbo timer installation options

If the driver himself does not want to act as a turbo timer, that is, sit in the car for several minutes waiting for the temperature to drop, then you can order the installation of the device on the car. There are two versions:

- Installation of a turbo timer as a separate unit;

- Turbo timer combined with car alarm.

In both cases, the device is placed under the dashboard (hidden from the eyes of the driver and passengers), so that it will not break out of the interior. The turbo timer is connected to the wires that come from the ignition switch.

Purpose and principle of operation of the turbo timer.

Tire sealant: how to choose and use the product

The opinions of car owners regarding the use of turbo timers are divided - some consider the device necessary for cars equipped with turbocharged engines, opponents consider it unacceptable to pay for a device that is not necessary for operation by reducing the level of safety.

The main argument is the operating principle of a car turbocharger.

How a turbine works, the purpose of a turbo timer.

In the design of a turbocharger, the main role is played by the turbine and discharge (compressor) wheels mounted on a common shaft.

The first is driven into rotation by the flow of exhaust gases coming from the exhaust manifold. The rotation is transmitted to the compressor, which compresses the air taken from the air filter and forces it into the intake manifold. This leads to an increase in the concentration of oxygen in the fuel-air mixture, more complete combustion of fuel, improved traction characteristics of the engine, and a decrease in the content of toxic gases in the exhaust.

At the same time, the temperature in the working volume of the internal combustion engine and, accordingly, the exhaust gases increases (in modern turbocharged engines it can exceed 800 degrees). The turbine wheel operates under conditions of severe thermal loads; high rotation speeds of the turbocharger (in some models over 200 thousand revolutions per minute) additionally lead to an increase in heat losses in the bearings (regardless of the type or design).

The cooling functions are performed by the engine oil supplied to the unit during engine operation. When the power unit is stopped or the ignition is turned off, the oil circulation stops. If the turbine was previously operated in modes close to the maximum, there is a danger of overheating.

Possible consequences include:

- violation of the structure of materials;

- deformation of nodes;

- burning of the oil remaining in the channels, coking of the system, blockage of gases, failure.

Manufacturers in their operating instructions began to draw attention to the inadmissibility of stopping an engine equipped with a turbocharger immediately after intensive use. For a car owner, failure to follow recommendations often costs thousands of rubles to repair or replace the turbine.

A turbo timer is an electronic device that prevents the occurrence of such emergency situations by maintaining idle speed of the internal combustion engine for a specified time after turning off the ignition. This ensures that the turbocharger elements are cooled to a safe level. Upon completion of the process, the engine ignition system is automatically turned off.

Running in a diesel engine

Before reading this article, we strongly recommend that you read the article on what break-in is and why it is needed. In this article we will look at the features of running in modern diesel engines equipped with a common rail system.

Today it is no secret that modern diesel engines are more economical and efficient than gasoline ones. A diesel engine is more efficient than a gasoline engine. And that is why it is used in commercial vehicles, construction equipment, generators and even military equipment. But nothing happens for nothing, and you will have to pay for it with a more complex technical device, greater weight and less reliability.

Modern diesel engines are equipped with an electronic common rail injection system

One of the main differences between modern diesel engines is the presence of a complex and expensive fuel system. Common Rail - translated as “Common Ramp”, which means The Common Rail system resembles the fuel injection system of a conventional injection engine with two differences: very high pressure and fuel injection directly into the cylinder.

This system makes it possible to make a diesel engine more flexible (high-torque) and economical. Also, many have probably noticed that modern trucks practically do not emit clouds of black smoke during acceleration, which cannot be said about some old Kamaz.

Also, the Common Rail system made it possible to increase the power of a diesel engine by 25% compared to an engine of the same volume equipped with a mechanical injection pump.

Presence of turbocharging

Most engines are equipped with turbocharging, which increases the efficiency of a diesel engine. At speeds above 3000 rpm, a diesel engine that is not equipped with a turbocharger is no longer able to suck in enough air. In order for the engine to be more economical and closer in power and torque curves to its gasoline counterparts, it is equipped with a turbocharger.

By the way, an interesting fact - the main wear and tear on the turbine of any internal combustion engine occurs when starting and stopping the engine. Because When starting, there is no oil pressure in the engine - oil does not enter the turbine, and at the time of the first outbreaks in the combustion chambers, it spins up to 20,000 rpm. And at such speeds, “dry” friction occurs in the plain bearing of the turbine shaft. And when it stops, the turbine, heated to 300-400 degrees Celsius, stops and the oil circulation through the plain bearing stops. As a result of high temperatures and lack of cooling by oil flow, the bearing is covered with a layer of soot.

EGR system

Translated from English, Exhaust Gas Recirculation means crankcase gas recirculation system. The function of this system is to direct part of the exhaust gases back into the engine. Thanks to this system, combustion chambers become overgrown with carbon deposits faster. Almost every modern engine has this system.

This is what the EGR valve itself looks like. It is not difficult to guess that all the resulting plaque adds soot to the engine power system. The only sure way to avoid this is to disable the EGR valve either programmatically or mechanically, depending on its type. This will also add thrust to the engine, due to the fact that at low speeds more exhaust gases will pass through the turbine, and therefore more air will enter the engine.

Connecting a turbo timer

The degree of difficulty of connecting it yourself depends on the specific turbo timer model, as well as the electrical equipment of your car. The main catch is to deceive the comfort unit, if there is one in the design of your car. It will not allow you to arm the car with the engine running.

The diesel turbo timer has the following standard connection pins:

- constant “+” from the battery;

- a pin responsible for powering certain devices when the ignition is not turned on. “+” appears on the output when the ignition key is turned to ACC mode;

- pin on which “+” appears when the key is turned to the ON position;

- pin for connecting to the handbrake;

- the negative terminal, called “ground”.

To install a turbo timer with your own hands, you need a contact group diagram. If you wish, you can use a multimeter in DC current mode. This way you can identify the wire on which the “+” is used for life support of the motor (usually with the largest cross-section and red color) or appears only after turning the key to the ACC position. Power is supplied to the handbrake terminals only when the parking brake lever is raised. The ground can be connected to any bolt adjacent to the car body.

There is no need to cut the standard wiring to connect the wires. The ideal option is to remove the wires you need from the blocks, insert the wires from the turbo timer there, and then re-crimp them into the terminal and install them back into the block. Often, due to inconvenient access, it is extremely difficult to perform such manipulations when installing a turbo timer on a diesel engine. Therefore, a slightly “barbaric” method is used - a small section of insulation is exposed, onto which the wire from the turbo timer is wound. The twist is additionally soldered and carefully insulated.

Full connection

Sometimes you can find a turbo timer installed on a diesel engine, in which the ground wire and the pin connecting to the handbrake are twisted and shorted to ground. The purpose of information about applying the parking brake is necessary for your own safety:

- If the turbo timer is installed correctly, the device will keep the engine idling only when the handbrake is activated. Removing the parking brake will stop the internal combustion engine. The function is largely positioned as anti-theft, but an experienced thief can leave the parking brake barely applied, which will not interfere with movement. In cars with automatic transmission, it is better to install a turbo timer in conjunction with the automatic transmission selector. The turbo timer should only work in position P, which will really increase the degree of protection;

- on a car with a manual transmission, when the engine is running in neutral gear, the effect of a hydraulic transmission is created. The rotation of the gears through the oil transmits, albeit small, force to the drive shafts (try hanging up one of the wheels of the drive axle and starting the engine; you will see that it will rotate). Therefore, running the engine without a parking brake and a driver inside is a potentially unsafe situation;

- Not all turbo timers are equipped with a forced shutdown function. If you were moving in a quiet mode before stopping, then there is no need to continue running the engine after stopping. By removing the key and then lifting, lowering and lifting the parking brake lever again, you can turn off the turbo timer yourself if you wish.

A diesel turbo timer installed as standard will perform a direct function and also show the voltage of the on-board network. Connecting pins for additional readings (for example, car speed, engine speed, speed shift indication, etc.) is described in the instructions for the device. There you will also find a guide for setting the motor operating time delay.

Alarm with built-in turbo timer and its selection

The function of a timer that keeps the engine running can be performed by a car alarm. Therefore, now, in 2015, few people purchase a turbo timer made as a separate device. Let’s say the instructions supplied with the equipment contain the following diagram:

Wiring the main connector of a car alarm

As you can see, there is a diode inside the main module. This means that it is included in the ignition circuit wire break. We are talking about a variant of the circuit designated by the letter “A” in chapter “1”.

Scheme “A” from “Chapter 1” has maximum versatility. For a car with two ignition circuits, it is suitable to the same extent as for all other cars. Well, the “minus” of the presence of a diode is the voltage drop, sometimes exceeding 1 Volt.

In the manual for the equipment of another model, everything looks different. Here is shown the wiring of a connector equipped with 6 terminals:

Power 6-pin alarm connector

The wire in green insulation allows current to pass, bypassing the lock terminals. At the same time it is a “control entrance”. The wire indicated in the diagram is connected in a T-shape, and the breaking points, if you do not take into account the presence of “blocking”, are completely absent here. None of the schemes presented in the first chapter can be implemented with such a signaling. It’s good if in this case they suggest using a “semi-automatic”, otherwise you will have to be content with the option discussed in “Chapter 3”.

Signaling models that allow you to implement any of the schemes discussed above also exist. True, they are accompanied by a separate relay, the power contacts of which must close the main circuit. This increases the complexity of installation and reduces overall reliability.

The APEXi 405 turbo timer is made in the form of a handle, it is compact and fits harmoniously into the interior of any car (the most compact turbo timer on the market). Ergonomics are also excellent - the timer is controlled thanks to a convenient 4-position joystick. Suitable for petrol and diesel cars!

The APEXi turbo timer package includes: an indication unit with a joystick, a control unit with built-in relays, a set of wires 0.7 m long, terminals for connection, instructions for connection and configuration.

The Japanese company APEXi is a recognized world leader in the production of tuning components, such as exhaust systems, intake and cooling systems, shock absorbers, turbines, and electronics. APEXi products are the standard of quality for many in the tuning world.

There are two connection options. The turbo timer is programmable and can itself calculate the delay time based on the lambda probe readings. Or it can simply work as a time relay (of course, you can manually set the time). In addition, the turbo timer is connected to the handbrake. This is a security element. If, for example, while the engine is running, someone gets into the car and tries to drive away, then by lowering the handbrake, the turbo timer will turn off the engine. The first simple option only requires connecting the power without a white wire. The second one is more complicated in the sense that, firstly, you need to go to the ECU and look for the lambda probe and ground wire, and secondly, we have a broadband lambda probe, and it has a completely different type of signal, and even more than one... so this connection option is no longer needed . If you have any thoughts, I'll be happy to listen. Now we connect the turbo timer itself. First, we will find a thick red wire in the harness behind the instrument cluster. This is +12V of the ignition switch. We connect the green turbo timer wire to it. We connect the red wire to the relay block in the legs, there you can find a good connection under the nut (check that it is constantly +12). The ground wire can be connected there to any good contact (be sure to check that there is ground and that +12 does not appear, for example, after turning on the ignition). There are two wires going to the handbrake switch. One is brown and white. We connect the gray turbo timer wire to it. I placed the block itself in the area of the relay block and secured it with plastic clamps, it turned out well. I placed the indicator block in the middle of the dashboard trim at the very top above the hazard warning button. I carefully disassembled the indicator block, filed it with a file where necessary, and ground off the place where the wire came out to hide it as much as possible. Drilled a hole in the cover and glued the block with double-sided tape. Installation is complete. With the simple option, the turbo timer does not need to be configured. It also shows the voltage of the on-board network.

The turbo timer is necessary to protect the turbocharged engine from premature wear and damage due to thermal shock. After the ignition is turned off, the turbo timer keeps the engine idling until the turbine temperature drops to a safe level. A turbo timer is installed on cars with a turbocharged engine.

At high engine loads, the turbocharger rotor (shaft with compressor and turbine impellers) develops at hundreds of thousands of revolutions per minute. If the motor is suddenly stopped, the rotor rotates by inertia. But the oil pump no longer works, and the remaining oil burns out in the hot sliding bearings. They wear out faster, the gaps increase - oil is sucked into the cylinders, the engine smokes, the pistons and rings become overgrown with carbon deposits, control system sensors fail... Troubles can be avoided if you allow the engine to run at minimum idle speed for at least a minute before stopping. During this time, the rotor will have time to reduce speed to a minimum, the bearings will cool down - and the motor will stop painlessly.

Main features of the turbo timer

- Supports engine operation after turning off the ignition

Automatic determination of the time required for the turbine to cool down

Setting the base turbine cooling time

Training of signals and logical levels of engine sensors, as well as idle speed

Disabling certain car alarm sensors and engine immobilizers while the turbo timer is running

Installed in cars with gasoline and diesel engines equipped with automatic or manual gearboxes (as well as in cars not equipped with a tachometer sensor)

Programming operating modes

Operating mode indication

Device and principle of operation.

After driving a car, you, as always, take out the key from the ignition, get out of the car and go about your business, and in the meantime, thanks to the installed turbo timer, the car continues to work for another 1-3 minutes, cooling the turbine. After the set time, the turbo timer will turn off the engine.

With an aggressive driving style, the engine and turbine operate in extreme conditions and the oil temperature is higher than usual, therefore, to extend the life of the engine and turbine, it is necessary to allow the car to “cool” for some time. To do this, you can either not turn off the car after stopping for 2-5 minutes, or install a turbo timer that will do the same thing, only automatically, when you have already removed the ignition key, locked the car and are sitting at home. At the same time, the Apex Auto Timer turbo timer can itself determine the required time for the car to cool down, or you can set the time manually. It is also possible to display data from the lambda probe and display the battery charge.

The turbo timer can be purchased and installed at our installation center

Increasing the service life of turbocharging is the natural desire of every conscious car owner. Let's look at how to install a turbo timer yourself and whether it is worth installing it on a diesel engine at all.

Recommended option for cars with one ignition circuit

Two schemes have been considered, and now another one will appear. It shows how to connect a semi-automatic timer:

Connecting a semi-automatic timer

The relay shown in the diagram can be placed by the manufacturer together with the turbo timer electronics in the same housing. Then the connection diagram will look simpler (Fig. on the right). The switch that switches the “zero potential” is a micro-button for the handbrake or a separate button in the cabin. Its presence is mandatory.

Let's consider the algorithm of operation of semi-automatic timers:

- As soon as the key is turned to the IGN position, the relay is activated and the corresponding indicator on the console lights up;

- To open the relay contacts, you need to activate the countdown. This action is performed by closing the microbutton contacts.

Let's imagine a non-standard situation: the handbrake is applied, the driver turns the key to the IGN position and then turns off the ignition again. Then, after the time preset in the settings has elapsed, the relay contacts should open. In general, during the operation of the “semi-automatic”, no situations will arise that lead to unexpected consequences. But it is recommended to remain attentive.

Self-installation and setup of a turbo timer

The reliability of the system and the safety of the vehicle depend on a correctly installed turbo timer, so it is recommended to follow the instructions below:

- disassemble the lower part of the torpedo;

- connect the turbo timer according to the image below;

Turbo timer connection diagram - perform a test run and configure the device;

- make sure it works;

- secure all removed elements in place.

In addition to the timer, you will need some tools for installation. Using pliers and screwdrivers, you can disassemble and reassemble elements of the car interior. Since the operation of the machine is accompanied by increased vibration, all wires must be secured with clamps, and the connections must be insulated using heat shrink.

The move away from naturally aspirated engines brought its own peculiarities to the operation of iron horses. The installed timer will allow you to take care of the car without wasting time on cooling the turbine, and combination with the security system will protect the car from theft.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

Feasibility of installation

It is most advisable to install a turbo timer in the following cases:

- A turbocharged diesel engine is installed in an all-terrain vehicle, primarily used in off-road applications. The operating mode is predominantly harsh. Often you have to drive with the maximum permissible load and with no cooling by the oncoming air flow;

- The decision to install a turbine on an atmospheric engine was made independently.

Installing a turbo timer seems less relevant in the following cases:

- Gasoline or diesel engines are used in a gentle mode. Movement occurs mainly around the city. The driving style is far from dynamic. Before stopping, the speed rarely exceeds 2000. The power plant uses high-quality oil;

- The car already has a car alarm with a turbo timer, for example, Starline. Installing an additional device will be unnecessary;

- The car is under warranty and installing additional equipment will lead to its loss. In this case, you need to get advice from a car dealership about the possibility of installing the device.

What options exist for correctly installing a turbo timer?

This process can be carried out with the help of professional service staff, or you can do it yourself. At the moment, there are two main ways to quickly and correctly install this element:

1) installation as a separate unit;

2) carrying out installation along with alarm systems for cars.

In both the first and second cases, the main location of the mechanism is the lower part of the instrument panel.

What are the disadvantages of a diesel turbo timer?

It goes without saying that everything cannot be so rosy and attractive, and there will definitely be something that is designed to spoil the existing positive impression and will make you think again.

Today on the market you can find an alarm system with a turbo timer for a diesel engine.

Installing a turbo timer is no exception. The thing is that combining the device with a standard alarm system causes some difficulties. It is not possible to carry out this work correctly. This is due to the fact that as soon as the key is removed from the ignition switch, the engine immediately stops. To prevent this from happening, an additional channel is needed, and it can only be taken from an additional alarm. This means that the car owner will be forced to spend money not only on a turbo timer, but also on a new security system. However, again the coin has two sides. The purchase of such a non-standard alarm makes it possible to install an autostart system that has a number of very useful and pleasant functions in everyday life. It will come in handy if you love comfort and are not used to wasting precious minutes of your time, including warming up the car.

Among other things, there is a possibility of some kind of conflict with the car dealership where the iron friend was purchased. Many car manufacturers have an extremely negative attitude towards installing turbo timers due to the fact that these devices are not original spare parts. Thus, installing a turbo timer may be a reason to remove the car from warranty.

Connection, configuration, disconnection

Let's consider the connection using the example of StarLine A93 - since this alarm is based on a common modular platform, in other modern models the functioning and settings of the turbo timer are similar.

After turning on the circuits, all that remains is to configure the alarm functions. They are configured via the main key fob:

- Disarm the vehicle and quickly press the Valet service button five times.

- Turn on the ignition.

- The key fob screen will display AF (alarm settings).

- Enter the AF menu by pressing button 3 long until the beep, then briefly.

- Further presses on button 3 will move to function 14, which by default is set to 14-1.

- By pressing button 1, set the new function value: 14-4. Channel 2 is now configured to control the turbo timer.

- Long and short press button 3 again to exit to the main menu.

- Press 3 to select the SF (autorun functions) menu.

- Enter this menu by long and short pressing 3 again.

- Go to function 1 and set it to 1-1. Otherwise, the turbo timer will not turn on.

- Go to function 11 to set the principle of monitoring the operation of the engine (if, after turning on the turbo timer, the alarm does not detect that the engine is running, then the ignition duplication will stop). This only needs to be configured with an analog connection, if the alarm is not connected to the vehicle's CAN bus or does not read engine speed from it. Option 11-1 sets control by voltage in the on-board network and is available without additional connections, in options 11-2 and 11-3 connect to the signal output of the generator, 11-4 sets control by tacho signal (connection to an analog tachometer or to injectors).

- Go to function 12 to set how the turbo timer is activated. In option 1, ignition interception occurs every time the driver pulls the handbrake and turns off the ignition. This method does not always work, since there is a short pause between turning off the ignition and turning on the turbo timer - the engine may stall before the turbo timer turns on. In this case, use option 12-3: ignition interception will occur immediately when the handbrake is pulled if the engine is running. In option 12-2, activate the turbo timer manually by pressing button 2 on the key fob until the engine is turned off. This is more convenient in winter - you don’t have to leave the car on the handbrake, risking it freezing. In option 12-4, ignition interception will be disabled and the turbo timer will not be operational.

- If the turbo timer requires an immobilizer bypass to operate, go to function 13 and set it to option 13-3.

- Turn off the ignition.

Something else useful for you:

To activate or deactivate its operation, enter the cursor menu:

Please note that when activated, the countdown will start from 6 - the time specified in the settings will begin to count down as soon as you arm the car. Manufacturers of modern cars, in order to increase engine power and reduce emissions of combustion products into the atmosphere, are increasingly using turbocharged technology

The main disadvantage of the development is the clogging of gases and oils in the turbine as a result of its overheating during operation. Connecting a turbo timer helps to avoid costly repairs

Manufacturers of modern cars, in order to increase engine power and reduce emissions of combustion products into the atmosphere, are increasingly using turbocharging technology. The main disadvantage of the development is the clogging of gases and oils in the turbine as a result of its overheating during operation. Connecting a turbo timer helps to avoid costly repairs.

A turbo timer is understood as a certain device or function as part of a car alarm that keeps a turbocharged engine running at idle speed after the car's ignition is turned off. When the optimum temperature is reached, the engine automatically stops.

Setting up the turbo timer

Setting up the Starline turbo timer functions is implemented by selecting two parameters:

- engine idle time;

- dependence on the temperature of the turbo mechanism.

Early versions of Starline did not have the ability to set a specified operating time using the key fob. In later versions, for example, A93, it is possible to set the engine operating time after removing the ignition key from 1 to 60 seconds. The longest time allows you to set A63. It allows the engine to run for 240 seconds after the owner leaves the salon.

Magicar has a working algorithm similar to Starline. The main difference is the ability to set the engine to run for 5 minutes after a trip. Some Agicar models have several preset modes to simplify user setup.

Understanding the ignition switch terminals

It would seem that if you can implement an automatic timer option, then why talk about “semi-automatic machines” at all? In fact, a semi-automatic timer can be easily connected to any car, but the same cannot be said about an “automatic” one. Look at the diagrams below:

Connecting a turbo timer in different cars

Here we show you exactly how to connect an automatic timer. Let's say that the presence of two ignition circuits (IGN and IGN2) is not provided for in the car circuit. Then you can’t do without installing a diode. The diode itself, shown in diagram “A,” must pass a significant amount of current, while the voltage drop across it should preferably be kept to a minimum. In practice, selecting such a part is not easy.

The ignition switch terminals are usually designated as follows:

- 30 – contact to which voltage is applied all the time;

- 2 – terminal connected to pin “30” when the key is in the ACC or IGN position. Through terminal “2” the current flows into the power supply circuit of the accessories;

- 50 – starter contact, receiving the potential “+12 Volts” when the key is brought to the START mark;

- 15 – terminal of the main ignition circuit. It closes with contact 30 when the key is turned to the following marks: IGN, START;

- 15/2 – terminal of the second ignition circuit. The positive potential is located on it when the key is turned to the IGN mark, but not START.

Everything should be clear here.

Problems encountered with the device

Reasons why the turbo timer does not work:

- incorrect connection to the engine starting circuit;

- incorrect settings;

- the handbrake is not engaged;

- the selector is not in parking mode;

- On the key fob, the turbo mode is inactive.

You should start diagnosing the problem by checking the settings. If activation still does not occur, you should pay attention to the connection diagram. It is necessary to check the reliability of the cables and the absence of breaks in the conductors going to the timer.

What is a turbo timer and why is it needed?

A turbo timer is a very small electronic gadget that can significantly increase the service life of a car turbine. In essence, it is a small specialized controller that independently turns off the engine some time after the ignition key is removed from the lock. During this entire period, the power unit continues to operate at idle speed. The turbo timer is installed directly under the car's dashboard and connected to the ignition switch.

What does an installed turbo timer look like?

The essence of the turbo timer is to allow the turbine to gradually cool down after operating at very high temperatures. The fact is that it is cooled by machine oil, which is supplied to it by the engine oil pump. If the motor stops working, then the supply of lubricant (which is also a coolant) stops. This can lead to failure of parts such as turbine bearings.

Experienced drivers, who often operate the turbocharged engines of their cars at high speeds and thereby heat the turbines to very high temperatures, before turning off the engines, leave them idling for a certain time, and only then turn off the ignition. Thus, the turbine has time to cool down and is provided with normal cooling. If you use a turbo timer, then you don’t need to wait this period while sitting in the car. You can remove the key from the waiting lock and go about your business, and the “smart” electronics will turn off the engine itself a little later.

It should be noted that if someone breaks into a car with a working turbo timer when the owner has already left the car, he will not be able to steal it. The fact is that this device blocks control of the car and, moreover, when an attacker tries to drive away in it, it turns on the alarm.

When to install a turbo timer

From what the driver actually sees, there is only a small part of the device in the cabin, which can be seen in the photo of the diesel turbo timer.

Let's start with the fact that the turbo timer can be installed not only on a diesel engine, but also on a gasoline one. The only condition is the presence of turbocharging, without which this device simply will not work.

When driving at high speeds, the turbocharger begins to heat up, quite strongly, which is quite normal.

The problem is different - that after a relatively quick stop, if you turn off the engine, the turbine will also cool down, quite quickly, by the way.

Practice shows that there is nothing good in this process. Why? Everything is quite simple - in traffic jams and similar situations, drivers often turn off the engine, because letting it burn through fuel in an hour-long traffic jam is not very wise.

But you can’t know for sure when the traffic jam will begin to move, even minimally, and therefore at any moment you may need to turn on the engine and start moving.

If you drive at high speeds, heat up all the turbine components, then stop quite quickly, and then after a minute or two, for example, start moving again, there will be a huge load on the turbines.

This problem can be solved by installing a turbo timer on a diesel engine, which in this case is needed only to ensure that the turbines do not cool down during short engine stops.