April 03, 2021 Category: Useful information.

After starting, the engine may vibrate slightly, especially in cold weather. Diesel engines are more susceptible to this problem than gasoline engines due to their design features.

Idle speed, when the clutch is disengaged and torque is not transmitted from the engine to the wheels, averages 680-780 rpm . Even with a serviceable, but not warmed-up engine, strong vibration at idle is possible. The main thing is that by the time the internal combustion engine reaches operating temperatures, which is an average of 3-5 minutes of warming up the engine, it disappears. There should also be no misfires, jerking or other extraneous sounds during engine operation.

If the vibrations are strong and prolonged

This situation can be caused by many reasons. But it is important to look for the cause, because increased vibration is detrimental to the internal combustion engine and is fraught with problems - from increased fuel consumption to early wear of CPG parts.

Usually the problem of vibration at idle is associated with malfunctions of the fuel system, internal combustion engine tripping, and problems with engine mounting. And you have to perform a number of checks to make sure that all components and assemblies that are related to the stable operation of the engine are in good working order.

Engine vibration at idle - what can be adjusted?

To adjust the idle speed, several components and assemblies installed in the car are used. First of all, it is the injector or carburetor that is part of the fuel system, producing a mixture of fuel and air. In addition, the fuel pump is adjusted, mechanical or electronic sensors, the fuel pressure regulator and other engine components are checked.

It should be remembered that the number of revolutions depends on the degree of opening of the throttle valve, which regulates the air supply, as well as on the action of the idle air valve, which supplies air independently of the throttle. The idle speed can be increased using the accelerator pedal.

Any vibration, including at idle, is very harmful to the car . It not only causes discomfort to the driver and passengers, but also negatively affects the general condition of the car. Gradually, cracks appear in the body, characterizing structural fatigue, and spontaneous loosening of bolts and nuts may occur. Such malfunctions often lead to unpredictable consequences and cause emergency situations.

Idling and vibration of a diesel engine – AvtoDIZEL

Idle speed for most diesel engines is around 680-780 rpm. Gasoline units may have a higher rate. Vibration at idle is noticeably felt in the steering wheel of a fully functional engine, especially while the car is warming up. After reaching operating temperature, the engine should start running absolutely smoothly. Also, vibration should decrease significantly or completely disappear with increasing speed on both a cold and warm engine.

Causes of diesel vibrations

If this does not happen, then diesel vibration at idle can be caused by a number of reasons, the most common of which are:

- Malfunction of the CPG or timing belt in one cylinder;

- Large differences in compression in the cylinders;

- Damage to engine mounts;

- Faulty injection pump or diesel injectors;

- Errors when setting timing belt marks;

- Incorrectly set injection advance angle;

In some cases, a diesel engine vibrates intensely at idle without any significant signs of malfunction, allowing the vehicle to be operated normally under load. In case of more serious problems, the diesel engine openly idles and smokes, does not develop power under load, and the consumption of diesel fuel and engine oil increases.

Diesel engine mounting pads

This malfunction should be determined by analyzing the vibration intensity at idle before and after warming up, as well as during diesel operation under load. Often, a diesel engine shakes due to the fault of the airbags, regardless of the temperature of the internal combustion engine. Vibrations appear not only at idle, but noticeably decrease at medium speeds. Diagnose the problem as follows. The hood is opened, the driver starts the car, moving forward, then repeats a similar movement back. This is necessary for rocking the internal combustion engine on cushions. At this time, an assistant stands nearby and evaluates the motor displacement. It is necessary to identify possible deviations when rocking back and forth on the pillows. If the motor noticeably moves forward, but moves less backwards and vice versa, and also falls sharply when jerking to one side or the other instead of a smooth return movement, then the engine mounts need to be replaced. It should be noted that the outwardly serviceable appearance of the pillow cannot be guaranteed to indicate the absence of malfunctions of this element.

Stopping the operation of one of the cylinders

In this case, the diesel engine vibrates much more strongly at idle (troit). There can be many reasons, ranging from air in the fuel supply system, a stuck diesel injector, or a failed glow plug to a burnt-out piston or valve. The problem of an inoperative cylinder may go away after the diesel engine warms up, and may appear during further driving. For a more accurate determination, it is necessary to check the presence of fuel supply to the cylinder, and also check the compression by measuring the pressure inside the cylinder.

Compression range

During operation, the motor wears out unevenly. Different compression in the cylinders of a diesel engine can cause vibrations during idle. All cylinders are working, but ignition of the mixture can occur either advanced or delayed. This leads to an imbalance, especially noticeable at idle during warm-up. After the engine reaches operating temperature and under load, vibrations decrease or disappear, since an increase in thermal clearances with heating of the internal combustion engine increases compression in the cylinders. To determine the malfunction, it is necessary to measure compression in each cylinder and compare the indicators with acceptable standards.

Injection pump and diesel injectors

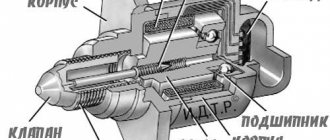

In idle mode, the injection pump is responsible for supplying fuel and maintaining idle speed. Insufficient amount or overfilling of diesel fuel will lead to vibrations at idle. Often, after the engine warms up, the increased vibrations disappear. If the motor shakes a lot or the shaking does not go away at operating temperatures, then the pump needs to be adjusted. Many high-pressure fuel pumps are designed with special adjusting screws. These screws determine the supplied volume of diesel fuel to maintain the idle speed of a particular engine specified by the internal combustion engine manufacturer. It should be noted that it is not recommended to independently adjust the speed without proper experience. Clogged or faulty fuel injectors can also cause your diesel to vibrate excessively when idling. In this case, the injection pump supplies a sufficient amount of diesel fuel to maintain idle speed, but the injector dispenses diesel fuel ineffectively.

Problems with valve timing

The appearance of vibrations in the diesel engine at idle speed after work has been carried out to replace the timing belt may indicate that the belt is incorrectly aligned. An error of one “tooth” leads to shaking of the motor. Larger displacement requires immediate engine shutdown to prevent serious consequences.

Other reasons

The list of possible reasons that lead to an increase in the intensity of diesel vibrations at idle includes:

- Difference in the weight of the pistons (often manifests itself after repair);

- Runout of the crankshaft or camshaft;

- Balance imbalance due to flywheel malfunctions;

Finally, it is worth adding that the operation of a diesel engine, which vibrates strongly at idle and other speeds, has a detrimental effect on the service life of the unit and attachments. Faults that cause strong vibrations require immediate repair.

Diesel engine vibration

A diesel engine is more susceptible to vibration than a gasoline engine, especially if the car is not warmed up properly. But, if the car is warmed up, and the vibration at idle is still quite noticeable, then this may indicate a malfunction that is better to identify and eliminate in order to avoid more serious and costly problems. Typically, normal engine vibration should only be felt by the driver with his hands on the steering wheel. If the vibration is increased, then passengers will also feel it, because the entire cabin and, in particular, the seats on which they sit will rattle. So, if you feel vibration at idle speed, then you should check the engine for malfunctions.

Causes of diesel engine vibration

It happens that a diesel engine vibrates at idle speed, but when it increases, the operation stabilizes, then there are no malfunctions. But sometimes it happens that the engine not only vibrates, but its efficiency deteriorates, it revs, smokes, loses power, and also begins to “eat” more engine oil and fuel. There may be several reasons for this:

Malfunctions in the operation of the piston group

There may be various reasons: a problem with the fuel supply, air getting into the fuel supply system, a clogged diesel injector, as well as problems with the valves, even burnout of the piston. To identify the problem, diagnostics are required with mandatory compression measurements and checking diesel injectors and valves.

Malfunctions in the operation of the gas distribution mechanism (GRM)

Sometimes engine vibration is observed immediately after replacing the timing belt. A shift of the belt marks even by one or two teeth can lead to a violation of the valve timing, which will unbalance the entire operating cycle of the engine. The result will be a drop in power, interruptions in the operation of the power unit and, of course, vibration.

Different compression ratios for cylinders

Different compression in the cylinders is very often the cause of engine vibration. At the same time, the engine works and does not stall, but due to untimely ignition of the fuel mixture (either delayed or advanced), an imbalance occurs and, as a result, strong vibration of the diesel engine at idle speed. Sometimes after warming up the situation improves, because compression in the cylinders increases due to increased thermal clearances. But this does not mean that there is no problem, so it is advisable to measure the compression in the cylinders.

Problems with injectors or high pressure fuel pump (HPF)

Vibration can also be caused by disturbances in the operation of the injectors, especially if they are heavily contaminated. Shaking can be felt during operation not only at idle, but also while driving. If there are interruptions in the operation of the high-pressure fuel pump, this can also lead to disturbances in the operation of the engine - the speed begins to fluctuate and vibration occurs.

For most pumps, it is possible to adjust the idle speed of a diesel engine using special screws designed for adjustment.

But here you need to be careful, because setting it incorrectly can only aggravate the situation and the engine will completely stop starting. Therefore, if you do not have experience in such work, then it is better to entrust it to specialists.

Violation of the integrity of the engine mounting

This malfunction can be identified by visually inspecting the pillow for damage or by influencing it with rocking. With constant vibration, the rubber seals of the cushion can wear out, which leads to even stronger vibration. And when a critical level is reached, if the problem is not corrected in time, the support will completely fail.

Other Possible Causes

There are other reasons why engine vibration may occur, but they are much less common. For example, imbalance (different weight) of pistons, imbalance of flywheel, crankshaft or camshaft. It is necessary to understand that vibration is not only a discomfort created while driving, but primarily a sign of a malfunction. And, if this malfunction is not eliminated, then sooner or later it will lead to even more serious problems, which will certainly cost much more. Moreover, vibration can lead not only to engine damage, but also to other equipment of the power unit.