Among all the variety of car parts, there is one on which the supply of oxygen to the vehicle’s power unit largely depends. This element is called the “throttle valve” and is part of the intake system of an internal combustion engine. In this article we will talk about adjusting the throttle, the method of “learning” it, and also try to understand the operation of the throttle sensor and the features of its settings.

Throttle position sensor: its functions and operating principle

The throttle (also known as the throttle valve), as a structural element of the intake system of gasoline engines, is designed to regulate the amount of air entering the power unit. Air is necessary to create a fuel-air mixture, which means the throttle valve itself is directly involved in this process. But its position sensor is largely responsible for the quality and stability of the operation of the named element.

Such a device is simply necessary for the system, otherwise accurate fuel dosing will be a problematic task. As soon as the throttle position sensor sends a signal, the controller determines the current throttle position, and based on the rate of change of the signal, the dynamics of pressing the accelerator pedal is monitored, which, in turn, is the main factor for accurate fuel dosage.

When the engine starts, the controller begins to monitor the angle of deflection of the throttle valve, and if it is open more than 75%, the engine purge mode is activated.

Based on the sensor signal indicating the extreme position of the throttle, the controller proceeds to control the idle speed regulator, thus providing additional air supply to the car engine, bypassing the closed damper.

The described sensor is a potentiometric type device that includes constant and single-turn variable resistors. The total resistance of these elements reaches about 8 kOhm. The controller supplies a reference voltage to one of the potentiometer terminals, and the other extreme terminal of the device is connected to ground. The middle pin is responsible for transmitting a signal about the current position of the throttle, which, passing through a resistor, goes to the controller. A signal value whose voltage is less than 0.7 V is regarded as an indicator of a completely closed damper, and if the voltage is equal to or exceeds 4V, then the control unit considers the throttle valve to be completely open.

The TPS is installed on the throttle body and connected to the axis of its rotation, which has a special groove that fits into the position sensor socket and is attached to it with two screws. Installation of the sensor in place should be carried out with some offset and through a protective ring gasket. Once it is in place, it must be turned until the mounting holes of the sensor itself and the holes on the damper body completely coincide, after which they are connected using fastening screws.

Setting the initial position of the sensor is easiest done directly on the car.

After installing it (with the ignition off), connect the sensor connector, then turn on the ignition and check the voltage at the signal terminal. The value should correspond to less than 0.7 V, and if the value is greater, then you need to orient the sensor to the value you need by loosening the mounting screws.

Throttle adjustment

To adjust the throttle valve, first turn off the car’s ignition, which will ensure its closure, disconnect the sensor connector, immediately checking for continuity between the terminals, and if there is none, then this means that the TPS should be adjusted and adjusted.

Now that the throttle is in the closed position, you should use the feeler gauge located between the lever and the screw (also where the throttle body gasket is located). Using an ohmmeter (or any other similar device), make sure that there is no voltage here either; otherwise, if the device shows its presence, then you can conclude that the sensor is faulty and replace it with a new device. When everything is good, the adjustment continues as usual: you need to turn the throttle drive until the value between the terminals is reached, which is indicated in the technical documentation of the vehicle.

After making the adjustment, check the tightness of the screws on the sensor, as during the work they could have loosened and become loose.

What is needed and how to adjust the throttle valve?

The importance of the throttle valve adjustment (or adaptation) procedure cannot be overestimated, however, not every driver knows what it is. Now we will try to understand this issue.

When the throttle assembly of any modern car operates, various types of contaminants gradually accumulate on the surface of the valve - be it dust, soot or technical lubricant. Over time, they all form a fairly decent layer of dirt, which reduces the air gap between the damper and the vehicle's air duct. The presence of a gap of the established norm is a very important point in the matter of the normal functioning of the power unit of the machine, because it is thanks to it that the idle speed can remain at the desired level.

When it decreases, the vehicle's ECU (electronic control unit) sends a command to open the damper slightly by introducing certain coefficients that take into account changes in its cross-section. For some time, the electronic unit manages to maintain the air gap at a constant level, but still, sooner or later, the throttle will have to be cleaned of accumulated dirt. After flushing the specified unit, you will see how the engine speed has increased, and all thanks to the fact that the cross-section of the throttle valve will be freed from the unnecessary layer and will become larger.

The procedure for returning the throttle valve to its initial (set by the manufacturer) position is usually called “adaptation” or “learning”.

True, the need for such an operation, which involves bringing high idle speeds to a standard value, is not limited to just after the flushing period of the specified unit, but is also required in a number of other cases. For example, after the car’s battery is completely discharged; after removing or replacing the accelerator pedal; after replacing or reconnecting the vehicle's ECU.

The most characteristic signs indicating that urgent throttle adjustment is required are the following phenomena: a whistle is heard when changing the throttle; At idle, the engine behaves inappropriately, or the power drops for no reason.

Before you start “learning” the throttle valve, you should fulfill several mandatory requirements:

– warm up the engine well by driving the car for 10 minutes;

– ensure that the battery voltage, in idle mode, is at least 12.9 V;

Throttle valve device

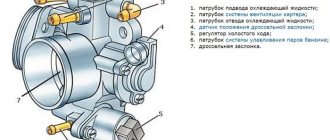

The design of the throttle body is not as simple as it might seem at first glance. Among other things, it is also part of the engine cooling system. It has channels for coolant circulation. It is also equipped with pipes, one of which is connected to the engine crankcase ventilation system, and the second to the gasoline vapor recovery system.

Idle speed control

The idle air control is an electromechanical device whose task is to maintain a certain crankshaft speed when the throttle valve is fully closed. For example, while the engine is warming up or the load changes, when additional equipment is turned on. The design of the idle speed controller is as follows: inside the housing there is a stepper electric motor, to which a spring-loaded conical needle is connected. When the engine is idling, the needle, moving back and forth, adjusts the cross-sectional area of the bypass air channel through which air passes when the damper is fully closed.

The throttle valve can have two types of drive:

- mechanical, like VAZ-2109, VAZ-2110, VAZ-2114;

- electric, which is used on most modern cars.

Mechanical drive

For the VAZ-2109, VAZ-2110 and other outdated models of the Volzhsky Automobile Plant, the throttle valve is connected to the gas pedal via a steel cable. The mechanical drive has a very simple design and low cost, so it is still used on many inexpensive cars.

Electric

If the throttle valve is equipped with an electric drive, then there is no direct connection between it and the gas pedal. The principle of operation of an electric damper does not change, but its design is much more complex. Simplified, such a node works as follows. The force of pressing the gas pedal is recorded by a special sensor, which transmits this information to the engine control unit, the throttle opening angle is determined by the throttle position sensor, and also transmits the corresponding signals to the control unit. The controller constantly compares these values and sends commands to the electric motor to increase or decrease the damper opening angle.

Throttle position at idle speed

What should be the readings of the DS position at idle speed?

Different! Why?

This parameter is more relevant to ardent fanatics of cleaning the throttle valve every week, or even every other day.

There are two main ways to control idle speed using the IAC (idle speed controller). Just control the speed xx! And don’t maintain the speed xx! It is very important!

So here it is:

- Using the idle speed controller installed in the bypass channel

- Using an idle air control that directly controls the throttle valve

Both systems are found on different cars. Even the Chevrolet Lacetti uses a different way to adjust the idle speed. On 1.4L and 1.6L engines the second method is used, and on 1.8 engines the first method is used.

This parameter in diagnostics is called “IAC Steps” or “DZ Position Step”. We will look at this in more detail in one of the future articles, but now I will briefly explain what the fundamental difference between these two methods is. This is necessary to understand throttle position diagnostics.

As we already know, all processes in the engine begin with air supply. By supplying air, we can regulate engine speed in different modes. The same thing happens when adjusting the idle speed. By supplying a certain mass of air, we regulate the speed xx within the required limits.

Note! The idle speed regulator performs a rough adjustment of the idle speed (about +/- 50 rpm. After this, the idle speed is more precisely regulated by changing the speed limit. But this is the topic of another article and now it is not so important.

So, in the first case, the damper is completely closed, and the air required for idling is supplied bypassing the throttle valve through a special channel. This channel contains a special valve-regulator that regulates the mass of air passing through this channel.

And in the second case, the air supply is carried out through the throttle valve itself. The damper is opened/closed using an electric motor and the necessary air mass passes through it to allow the engine to idle.

That is, it is obvious that in the first case, when the engine is running in idle mode, the correct values of the DS position will be equal to zero! Since the air does not flow through the throttle valve, but through a special IAC channel.

And in the second case, when the engine is idling, the correct values of the DS position will be equal to several percent (degrees). The readings cannot be zero, because if the damper closes completely, then the engine will stall.

We already have our first conclusion. That's the essence of it.

To properly diagnose throttle position, the first step is to determine how the idle speed is adjusted on that particular vehicle. If according to the first method, then the position of the DS at idle should be equal to 0%! And if using the second method - then a few percent!

Note: There are exceptions in all areas of our lives. Here too. For example, the Lacetti 1.8 LDA with the MR-140 control unit, although it has a separate idle speed regulator, but the throttle position at idle is 10-12%

In the first case, everything is simple and clear. If the values are different from zero, it means either the throttle valve cannot close tightly due to dirt or something else, or the throttle position sensor is not showing the truth, which means it is worn out and broken.

But in the second case, not everything is so simple.

There is an opinion that if the opening of the shutter is more than 5%, then mandatory cleaning of this very damper is necessary. This is true, but with many nuances.

And the most important of them are those that we have already talked about above:

- The idle speed regulator does not maintain idle speed, but regulates it

- The load on the engine is calculated by air flow (manifold pressure). The greater the mass of air consumed, the greater the load. Conversely, the greater the load on the engine, the more air it needs.

Throttle position sensor

This sensor is a potentiometer. When you press the gas pedal, the position of the damper and the voltage supplied to the controller changes. When closed, the voltage is 0.7V, when fully open it is 4V. In accordance with these data, the sensor controls the fuel supply.

If a malfunction of the position sensor occurs, the controller will not be able to correctly determine the position of the damper. This results in the following malfunctions:

- in all engine operating modes, the speed begins to fluctuate; at idle, the speed will be increased;

- when you switch off the gear (neutral) while driving, the engine may stall;

- Sometimes the CHECK light may come on.

To check the functionality of the position sensor, you can use a multimeter. With the ignition on, the probes are connected to connectors B and C. Changing the position of the damper should lead to a change in voltage.

» alt=»»>

Rice. 3 Errors associated with the throttle position sensor: P0122 - low signal level of the throttle position sensor If such an error is in the memory of the control unit, then there is no doubt that the output wire of the sensor is somehow connected to the ground of the battery, or the wire 5V sensor power supply is connected to ground. In the latter case, the same error should be accompanied by malfunctions in both the temperature sensor and the mass air flow sensor. In Russian-made sensors, this error often occurs due to a breakdown of the sensor itself - the internal resistive layer is broken, there is no contact inside the sensor. The malfunction most likely lies in the connecting connectors of the sensor and control unit (for example, moisture ingress). P0123 – high signal level of the throttle position sensor This fault code occurs when the common wire (ground) of the sensor harness is broken. It is necessary to ring the harness from the sensor connector to the block. The throttle position sensor circuits are checked using the ID-2 sensor simulator (see Fig. 4).

Rice. 4 Another unlikely reason is that the control unit is faulty. When permanent fault codes P0122, P0123 appear, the engine switches to standby mode. The throttle position is restored based on the current air flow (cyclic air filling). The stepper motor is in the maximum open position. It is possible to travel by car to a service station. Malfunction - the speed is not reset (slowly reset) when the throttle pedal is released. The throttle position when the pedal is released remains 1-2%. The system does not enter idle mode or the transition occurs late (0% throttle appears much later than the pedal is released). A sharp “over-throttle” helps to slow down. It is necessary: check the tension of the throttle pedal cable, check the throttle valve for internal contamination, check the operation of the spring mechanism of the throttle pipe, the supply voltage of the sensor should be + 5.00 V. Unclear malfunctions: - the throttle valve assembly is poorly designed - the locking screw prevents the sensor from accurately determining zero position - sensor is faulty. The fit on the throttle valve shaft does not allow it to accurately determine the zero position in the closed position - the supply voltage of the sensor is more than 5.01V. The voltage is determined by the internal source of the control unit. Measure the voltage by disconnecting the terminals from the temperature and mass air flow sensors; the control unit may be faulty. Malfunction - the vehicle does not achieve sufficient power. Throttle level does not reach 100% - a floor mat has gotten under the pedal and it does not have full travel (or a similar reason), check the throttle valve travel. The malfunction is sudden jerks and dips when pressing the throttle pedal. If jerks and dips appear due to the throttle sensor, this means that the resistive layer is slightly damaged in the middle throttle positions. Code P0122 should appear. Check: When opening the throttle slowly, make sure that the Throttle Position parameter accepts all values from 0.00 to 100.00%.

Why is it necessary to modernize the throttle valve on VAZ-2109, 2110, 2115

Spare parts stores sell throttle assemblies with valves of increased diameter (52, 54 and 56 mm) for VAZ-2109, 2110 or 2115 cars. According to the sellers, by installing such a valve instead of the standard 46 mm one, the car owner will receive significant advantages: the car becomes more responsive to the gas pedal, problems with idle speed disappear, the car's dynamics improve, and this is especially noticeable if you replace the standard air filter with a zero-resistance filter. The main argument that they try to convince car owners is that the engine requires more air to operate efficiently, for which it is necessary to replace the standard throttle assembly with an improved one. They even give figures: the diameter of the VAZ-2109 or VAZ-2110 receiver is 53 mm, and a damper with a diameter of 46 mm allegedly “strangles” the engine.

Many VAZ-2109 and VAZ-2110 owners succumb to persuasion and replace the standard device with an improved one. After this, indeed, the engine works better and the car drives more dynamically. The reason for the improvements actually turns out to be much more prosaic: instead of the old, dirty throttle body, which had long been in need of thorough cleaning, the owner installed a new one. As a result, the engine returned to normal operation, which is perceived by the owners as the promised responsiveness and agility of the car.

In order for the car to work properly and not appear at the service station for as long as possible, except for maintenance cases, you must treat it carefully. One of the important components of the iron horse is the throttle valve. This mechanism plays an important role in the operation of a diesel or gasoline engine. And it doesn’t matter whether the power plant is carburetor or injection. The remote control can be either mechanically or electronically driven. In the latter case, sometimes it becomes necessary to adapt the throttle valve. How to do it? Let's try to figure it out, and at the same time take a closer look at the types of this node. We will also find out whether this needs to be done, and what could happen otherwise.

Purpose of the throttle valve

Not a single car in the world can do without such a unit as a throttle valve. The mechanism is a transverse channel regulator that changes the amount of flowing liquid or gas. That is, at its core, the damper is an air valve. When it is closed, the pressure in the intake system is equal to vacuum, and when it is open, it is compared to external atmospheric pressure.

By pressing the accelerator pedal, the degree of opening of the damper is adjusted. Accordingly, how much air enters the engine cylinders depends on this. Almost every modern car is equipped with an injection engine, where all important responsibilities are assumed by the electronic control unit (ECU).

As some car enthusiasts know, the optimal ratio of gasoline to air is 1:14.7. By detecting the throttle position and the amount of air using sensors, the ECU regulates the operation of the injectors and fuel pump. This knowledge will be useful in deciding how to adapt the throttle valve.

In other words, the computer commands how much fuel needs to be supplied to the engine in order to maintain optimal proportions.

Causes of throttle valve malfunction

The problems described above are usually caused by malfunctions of one or another part of the throttle assembly. Let's consider these phenomena in more detail.

The IAC is designed to supply air to the engine intake manifold when idling (that is, at the moment when the throttle valve is closed). If the functioning of the regulator is disrupted or completely stopped, the engine at idle speed begins to operate unstably until it stops completely.

Another common cause of throttle failure is problems with the throttle position sensor (TPS). The sensor records the throttle position and transmits the corresponding information to the electronic control unit (ECU). The block, in turn, selects the engine operating mode, determines the amount of air and fuel supplied, and adjusts the ignition timing.

A faulty sensor does not send information to the ECU or transmits incorrect data. In this regard, the control unit selects the wrong operating mode or switches it to emergency operating conditions. The fact that the DPSD has failed is indicated by the Check Engine warning light on the dashboard lighting up.

In electronic throttle valves, which are the majority today, control drive sensors are susceptible to breakdowns, which, together with the DPSD, transmit commands on the throttle position to the ECU.

If one or another sensor fails, problems in the “behavior” of the car arise that are listed at the very beginning of our article - a weak response to pressing the gas pedal, a decrease in the number of engine revolutions per minute (not higher than 1500 rpm), their instability at idle etc.

In rare cases, the damper drive motor breaks down. If this happens, the damper is locked in one position and the control unit puts the machine into emergency mode.

A fairly common cause of unstable operation of the internal combustion engine is depressurization in the intake tract.

Air leaks can occur in the following areas and components:

- Places where the damper is pressed against the body

- Cold start jet

- Connecting corrugated tube behind the DPZD

- The junction of the crankcase gas cleaner pipe and the corrugation

- Injector sealing

- Conclusions for gasoline vapors

- Vacuum brake booster pipe

- Throttle body seal

Contamination can also be considered a fault. The throttle body in a car engine is directly connected to the crankcase ventilation system. This is why oily deposits accumulate on the body and axle over time.

Typical signs of a dirty throttle valve are a lack of smooth operation, frequent jamming and jamming. As a result, the engine begins to operate unstably, and corresponding errors are formed in the electronic control unit.

Source

Mechanical throttle

Currently, a mechanically driven damper can only be found in budget car configurations. In such a mechanism, the damper is connected to the accelerator pedal via a metal cable, fixed to the shaft and placed in a housing on which sensors are also located:

All this looks like a separate block. Various pipes also lead to it; coolant is supplied and discharged through one, and through others the crankcase is ventilated and fuel vapors are captured.

Thanks to the IAC, the required number of crankshaft revolutions is maintained when the damper is closed. The regulator itself consists of a stepper motor and a special valve. Together they regulate the amount of air, regardless of what position the throttle valve is in. Usually there are no problems regarding how to adapt the throttle valve in the case of a mechanical drive.

Electronic throttle device

The electronic throttle assembly consists of the following elements:

electronic control unit;

an electric motor that controls the throttle valve drive;

a mechanism consisting of a body, an axis and a damper;

gas pedal position sensor;

throttle position sensor.

The position sensor is installed on the damper body. Its signal changes when the position of the gear mounted on the end of the axle changes. The data is recorded and a signal, whose voltage varies depending on the position, is transmitted to the control unit. During processing, the signal voltage is converted into percentages: from 0 to 100%. 0% – damper is closed, 100% – completely open.

Like many other innovations, electronic throttle control first found its way into the world of sports. Using an electric drive, the problem of controlling multiple throttles was solved

A sensor installed on the gas pedal detects changes in its position and transmits data to the control unit. The data is processed, and depending on the position of the pedal, the damper drive is started, opening or closing it. There is also feedback. The position of the damper is monitored by a sensor and the control unit, receiving a signal, compares the angle of the open damper with the position of the gas pedal. Thanks to this connection, the electronic control maintains engine idle speed by controlling the optimal throttle position according to the specified parameters.

Electromagnetic throttle valve

The electronic analog, unlike a mechanical unit, allows you to achieve the optimal torque value in any engine operating mode. The level of fuel consumption is reduced, and driving such a car is comfortable and safe. The main distinctive features (and in this case, advantages) are the following:

- idle speed is controlled by moving the throttle valve;

- there is no mechanical connection between the pedal and the damper.

Due to the fact that there is no mechanical connection, torque can be controlled electronically instead of the gas pedal. The damper module itself consists of the following elements:

- housings;

- the damper itself;

- electric drive;

- return spring mechanism;

- damper position sensors.

Installing not one, but two damper position sensors in the module will improve reliability. For this purpose, magnetoresistive devices or potentiometers with sliding contacts can be used. It is precisely because of the breakdown of these elements that it is necessary to decide how to adapt the throttle valve on many cars.

If a malfunction occurs in the electric drive, the damper is brought to the emergency position due to the return spring mechanism. In this case, the module itself must be replaced, which can only be done as an assembly.

Types and operating modes of the throttle valve

The type of throttle drive determines its design, operating mode and control. It can be mechanical or electrical (electronic).

Mechanical drive device

Older and budget car models have a mechanical valve drive, in which the gas pedal is directly connected to the bypass valve using a special cable. The mechanical drive for the throttle valve consists of the following elements:

- accelerator (gas pedal);

- rods and swing arms;

- steel rope.

Pressing the gas pedal moves a mechanical system of levers, rods and cables, which causes the valve to rotate (open). As a result, air begins to enter the system and an air-fuel mixture is formed. The more air is supplied, the more fuel will be supplied and, accordingly, the speed will increase. When the accelerator is in the inactive position, the throttle returns to the closed state. In addition to the main mode, mechanical systems can also include manual control of the throttle position using a special knob.

Operating principle of the electronic drive

Electronic throttle device

The second and more modern type of damper is the electronic throttle (electrically driven and electronically controlled). Its priority differences are:

- There is no direct mechanical interaction between the pedal and the damper. Instead, electronic control is used, which also allows you to change the engine torque without having to press the pedal.

- Engine idle speed is controlled automatically by moving the throttle.

The electronic system includes:

- gas pedal and throttle position sensors;

- electronic engine control unit (ECU);

- electric drive.

Graphs of output signals of throttle position sensors

When you press the accelerator, the gas pedal position sensor, consisting of two independent potentiometers, changes the resistance in the circuit, which is a signal to the electronic control unit. The latter transmits the corresponding command to the electric drive (motor) and turns the throttle valve. Its position, in turn, is controlled by appropriate sensors. They send feedback information about the new valve position to the ECU.

The current throttle position sensor is a multi-directional potentiometer with a total resistance of 8 kOhm. It is located on its body and reacts to the rotation of the axis, converting the valve opening angle into DC voltage.

In the closed position of the valve, the voltage will be about 0.7V, and in the fully open position it will be about 4V. The controller receives this signal, thus learning the percentage of throttle opening. Based on this, the amount of fuel supplied is calculated.

Signs of a clogged damper

When the throttle valve becomes clogged, the engine begins to operate in an unstable mode. Typical signs of a malfunction in this case are:

- increased idle speed;

- delayed engine response to pressing the accelerator pedal;

- while the car is moving, jerks are observed, and sometimes the vehicle changes speed independently, without the driver’s participation;

- abruptly releasing the gas pedal causes the power plant to stop.

In some cases, the CHECK indicator on the instrument panel will light up. Sometimes tar deposits settle on the throttle shaft, causing it to seize. Then the gas pedal is pressed with noticeable force.

Before moving on to solving the problem of how to adapt the throttle valve on a Skoda or any other car, you need to make sure that the diagnosis is accurate by conducting a visual inspection of the mechanism. To do this, you need to remove everything that is possible in order to open access to the module. Be careful not to accidentally disconnect the cooling system pipes.

Cleaning the remote control

If the cause of unstable engine operation is a dirty damper, you should move on to cleaning it. To do this, you can contact a reliable service station. Among the large number of workshops, you can find one that specializes in specific brands (Audi, Volkswagen, Toyota, Mercedes and others). However, the owner can do all the work himself, since much experience and skills are not required in this matter.

At service stations, the cost of the procedure may depend on a number of factors:

- complexity of the work - for some cars, access to the remote control will require the dismantling of many parts;

- service station service level - as a rule, the larger the organization, the more expensive it is;

- location – in large cities you can leave more money than in the periphery.

Cleaning the throttle valve is a simple procedure, after which you usually need to think about how to adapt the throttle valve on a Nissan or any other car.

Any car owner can perform this procedure independently. No special knowledge or skills are required here. All you need to get to the damper are tools and rags (preferably soft ones). You also cannot do without a special product - mainly the carburetor cleaner “Carb Cleaner” is used.

Need for maintenance

The prophylaxis procedure should not be carried out in the absence of obvious reasons. Before starting, you need to carefully evaluate the condition of the throttle valve. If there are no obvious signs of tar deposits and areas of coking, then the reason for unstable operation may lie elsewhere.

Also consider the mileage of the car. Experts recommend resorting to flushing no earlier than after 100 thousand km. But on some cars, for example, a Ford Focus, it may be necessary to flush it after 30 thousand kilometers.

You should know how to clean your throttle body to achieve the desired result. This requires a special carburetor cleaning solution, for example, Abro Carb & Choke Cleaner or similar products. The assembly must be dismantled; only in this case can the maximum effect be achieved, otherwise carbon deposits will remain inside the tubes. Disconnect all pipes from the throttle valve to gain good access to the inlet part of the assembly.

Self-cleansing procedure

If the damper is electronically actuated, then it is better to remove the negative terminal of the battery. Next, you can do everything according to simple instructions:

- dismantle the air filter by unscrewing the pipe clamp;

- disconnect all connectors of the throttle module and other pipes;

- move the air filter receiver to the side so that it does not interfere, and begin cleaning the damper;

- upon completion, reassemble the damper module in reverse order, checking that everything is in place;

- After assembly, start the engine and check the idle speed.

In some cases, before you begin to adapt the throttle valve on a Toyota, Nissan or Skoda, it is necessary to remove the throttle itself, which allows you to completely clean the valve. To do this, you will need a 5 mm hexagon to unscrew the 4 fasteners. Removing the throttle should be done with great care, as there is a risk of damaging the gasket.

If, after cleaning the throttle body, increased idle speed is observed, it means that the damper needs to be adapted. What this is is further in the topic of the article.

How to clean the electronic throttle body without removing it from the car

Experts recommend servicing electronically controlled throttle valves at least once a year or every 20 thousand kilometers. It is better to perform the damper cleaning procedure before the onset of autumn rains, for which there is a logical explanation. The fact is that due to the increased humidity of the incoming air, dirt deposits on the drive parts, axle and damper soften. Because of this, the throttle sticks, which makes it impossible to control engine speed and can cause an accident.

On most foreign and domestic cars, the electronic gas pedal drive is installed directly in front of the intake manifold. The accessibility of the mechanism and the ease of its maintenance make it possible to carry out preventive maintenance in literally 15-20 minutes.

For this you will need:

- carburetor cleaner (replaced with gasoline, kerosene, diesel fuel, etc.);

- silicone lubricant in the form of a spray;

- rags;

- a screwdriver with a flat or Phillips blade (depending on the type of screws used to secure the air supply pipe);

- a brush with stiff bristles or a toothbrush;

- protective gloves.

It is better to do the work sequentially - this way you will avoid mistakes and be sure that you did everything correctly:

Using a screwdriver, loosen the clamps securing the air supply pipe and disconnect the corrugated hose from the body of the electronic accelerometer.

Press the throttle valve, turn it 90 degrees and conduct an external inspection. Dirt and grime on the walls of the case are sufficient reason to begin cleaning immediately. Tar and soot deposits primarily clog the gap required for the engine to idle. Because of this, the speed becomes unstable or the power unit completely stalls due to the loss of air supply. In addition, touching the valve to a thick layer of carbon deposits causes it to jam and contributes to increased wear of plastic gears and other drive parts.

Lock the throttle in the open position. To do this, place an object made of wood or plastic of suitable thickness between the damper and the inner wall of the case - for example, the handle of the same screwdriver.

When starting to clean the unit, generously moisten the inner walls and damper with detergent.

Pay special attention to those places in the throttle chamber through which the valve axis passes - the tar deposits accumulating there are precisely the reason for the rotation unit jamming. As a result, the throttle turns jerkily and makes driving uncomfortable.

After waiting 10-15 minutes to soften the blockages, they are removed with a brush

If necessary, the process is repeated many times, achieving complete cleaning of the throttle. Keep in mind that on some car models the throttle chamber walls are coated with a special molybdenum coating. The extremely smooth layer promotes laminar air flow in the channel and prevents soot from settling. Do not confuse this coating with carbon deposits and do not try to remove it. On the contrary, use gentle cleaning methods and abandon the hard brush in favor of a soft flannel cloth.

After achieving a soft, even shine from the walls of the inner chamber, clean the front and rear sides of the throttle valve. Wipe parts and surfaces dry with a rag. Additionally, blow out the assembly with compressed air.

After cleaning the throttle body to ensure that the electronic throttle pedal operates smoothly and smoothly, apply silicone lubricant to the axle, the throttle body and the part of the throttle chamber that it connects to.

Attach the air duct and tighten its fastening clamps.

After intervention in the unit, the throttle valve position parameters will change, so in some cases it is trained. If the idle speed begins to change spontaneously (“float”, as auto mechanics say), then reset the volatile memory of the controller by briefly disconnecting the “positive” terminal from the battery.

Something else useful for you:

And the last thing I would like to remind you: when starting for the first time, do not press the gas pedal until the engine warms up. By ensuring the engine operates at rated speed over a wide temperature range, you will allow the controller to adapt to changing conditions and set the optimal idle settings. In the future, this will make it possible to operate the car without any surprises from the throttle assembly.

The need to adapt remote sensing

This definition refers to the operation (or training) that is carried out so that the ECU “knows” what position the throttle valve is in relative to the degree of depression of the accelerator pedal. This procedure is simply necessary if the engine is unstable at idle.

For most Toyota, Lexus, Mercedes, Nissan, and Audi cars, it is necessary to adapt the throttle valve, as this allows you to eliminate the malfunction. The procedure is performed in the following cases:

- in the event of a critical drop in the voltage of the on-board network (the battery is switched off or completely discharged);

- the ECU was replaced;

- the valve was cleaned and the throttle was removed;

- when replacing the throttle module itself;

- the accelerator pedal was replaced, usually with an electronic one.

It is worth noting that due to the layer of dirt, the gap between the damper and the body changes, and after cleaning the damper, its position has changed. But the ECU “has no idea” about this and continues to control the fuel supply according to previous indications (before the cleaning operation). Adaptation will completely eliminate this gap and restore engine performance.

The simplest way to carry out adaptation

Now the question of whether it is necessary to adapt the throttle valve after cleaning should definitely not arise if there were still doubts. The easiest way to carry out the operation is to simply reset the battery terminal. Just to begin with, it is worth warming up the engine well to operating temperature, for which you should take a short trip. Then, turning off the engine, disconnect the negative terminal of the battery and wait. Depending on the brand of car, the waiting time can be 10-30 seconds or 15-20 minutes.

During this period, all ECU parameters should return to the original (factory) settings. Next, all that remains is to connect the terminal and start the engine - the speed should return to normal.

Adaptation using the example of some cars

Another method, which we will consider using the example of one well-known German brand, also involves adaptation without a computer. Here you should warm up the engine to a temperature of approximately 70-99°C. The battery voltage must be at least 12.9 Volts when the engine is not running. The action plan for how to adapt the throttle valve on a Volkswagen will be something like this:

- After warming up and turning off the engine, you should wait a short period (5-10 seconds).

- With the gas pedal released, turn on the ignition and wait 3 seconds.

- After 3 seconds, you need to press the accelerator pedal all the way 5 times and release it back. Act quickly, as you only have 5 seconds to do this.

- After the 5th exercise, you should wait a pause.

- After 7 seconds, press the pedal all the way again and hold it in this position until the “CHEK” indicator starts flashing (≈ 10 sec.), then it should remain on continuously (≈ 20 sec.).

- When the indicator lights up constantly, count to three and only then release the pedal.

- Start the engine (repeat if necessary), wait 20 seconds, then lightly accelerate (2000-3500). If the tachometer shows 700 rpm at XX (+- 50), it means that the adaptation was successful.

In this case, it is necessary to strictly adhere to the time intervals of each setting step. This is the only way the ECU training will go smoothly. But before that, it’s worth studying the adaptation features and the possibility of a manual procedure for your car. Perhaps only service station specialists can help.

Throttle learning idle

After flushing the unit or reflashing the ECU, the throttle valve should be trained to idle. To do this, fulfill the following conditions:

- check the voltage on the battery with the engine off, it should be at least 12.9 V;

- the coolant temperature should be in the range from 70 to 100 degrees;

- the steering wheel must be in a neutral position;

- The gearbox oil must be warmed up;

- all electrical consumers are turned off;

- automatic transmission handle in position P.

Failure to comply with the above requirements will lead to incorrect operation of the engine, so they must be followed. After warming up the engine, you must:

- turn off the ignition for 10 seconds;

- make sure that the accelerator pedal is in the up position;

- turn the key to the ON position for 3 seconds (do not start the engine);

- Press the gas pedal all the way 5 times within 5 seconds and release it for the last time;

- after 7 seconds, press the gas pedal all the way and wait until the “CHESK ENGINE” display lights up continuously;

- After pausing for 3 seconds, release the gas pedal.

Try to start the car, the attempt can be repeated several times. During stable operation, rev the throttle several times and the idle speed should return to the acceptable range.

The procedure for learning the throttle using a PC and car programs has its own specifics, depending on the brand of car, etc. Therefore, it makes no sense to describe the entire process in detail. But first you need to install special software on your PC, for example, VAG-COM for a VAG car group (or other) and drivers. The following is the standard connection order for all:

- turning on the ignition;

- connecting the PC to the car diagnostic connector with an information wire;

- launching software on a PC;

- conducting a test;

- receiving information about readiness for further work - the inscription: “The adapter is ready for work.”

Following a special algorithm, you will be able to coordinate the remote control and the ECU in the “throttle fully open/fully closed” modes for cars with both an electronic and mechanical gas pedal. In this case, the throttle valve training is carried out when the car is warm and the above requirements are met.