The engine speed begins to fluctuate, the engine does not operate stably at idle, but the car can drive and will start. Often, owners of such Nissans or repairmen may think that there is a malfunction behind this - some kind of breakdown, defect, or something incorrectly assembled. But in reality there is no malfunction, and all components of the car are assembled correctly. The whole problem lies in the failure of the electronics, namely the need to teach the throttle valve to operate correctly and idle. The training procedure itself does not require any equipment and adaptation (training) of the throttle on a Nissan is accessible to anyone. But in the procedure itself, the accuracy of all points must be observed. But even the availability of information about the learning process does not make the procedure simple. Diagnostic equipment, when the throttle valve is mismatched and when the idle speed of the engine increases, does not detect any defects. And very often, even repairmen cannot explain the reason for the suddenly increased idle speed. After proper training, the motor operates in the range of 700-800 rpm. The electronic throttle is very sensitive to dirt deposits and resins that are deposited on it during operation of the machine. Because of this, the idle speed of the engine begins to float or freeze. The engine response to the gas pedal during acceleration is also less sensitive. Therefore, cleaning the throttle is mandatory. But if the throttle is very dirty, after cleaning it, throttle mismatch occurs - and as a result, floating and incorrect revolutions. It is impossible not to clean the throttle - in the end the engine will not work correctly. If you have the opportunity, clean the electronic throttle valve on time - once every 15,000 km. If for any reason you have removed the connector from the electronic throttle, battery, or Nissan engine control unit, you will have to carry out the throttle valve adaptation procedure.

When is the damper adaptation performed?

The need for such an operation, which involves bringing high idle speeds to a standard value, arises not only after flushing the throttle assembly, but also in other cases, in particular in the following:

- after the vehicle battery is completely discharged;

- after replacing or removing the accelerator pedal;

- after replacing or reconnecting the vehicle's electronic control unit.

Undoubted signs indicating that the damper needs to be trained immediately are the following phenomena:

- whistling when revving;

- inadequate behavior of the engine at idle;

- lack of power at idle or failures.

Conditions for carrying out the idle speed adaptation process

Before starting training, a number of prerequisites must be met:

- travel by car for 10 minutes;

- ensure that the battery voltage at idle is at least 12.9 V;

- warm up the gearbox;

- The wheels of the vehicle must be straight, the steering wheel must be in the middle position;

- engine temperature – 70–95 °C;

- all devices that put a load on the car’s electrical network (heated windows, headlights, etc.) should be turned off;

- The automatic transmission selector is set to N or P.

Adaptation of air flow at idle speed

Now you can proceed directly to learning how to idle, “armed” with a stopwatch and a little bit of patience. The procedure is performed like this:

- The engine starts and warms up to standard operating temperature.

- The ignition is turned off and no action is performed for 10 seconds.

- The ignition turns on (the accelerator pedal is in the released position), wait 3 seconds.

- The following actions are performed five times in a row: the accelerator pedal is fully depressed and fully released.

- After 7 seconds, the pedal is pressed again (fully) and maintained in this state for 20 seconds.

- The pedal is released completely (and without delay) at the moment when the malfunction indicator on the panel stops flashing (it should be lit steadily).

- Then immediately, without touching the accelerator pedal, you need to start the engine so that it can idle.

- We wait about 20 seconds.

After all the announced actions, we accelerate the engine (2-3 times) and make sure that the ignition timing and idle speed standards comply with the standards. At this point, the damper adaptation procedure can be considered complete.

Adaptation and training of the electronic throttle valve of Nissan cars

New Nissan vehicles are equipped with electronic throttles. The electronic throttle valve determines the air supply necessary for optimal engine operation. The electronic throttle also regulates idle speed and warm-up engine speed. Usually, after removing the battery terminal, or some kind of repair associated with disconnecting the engine electrical wiring or flushing, cleaning the electronic throttle valve, or with a breakdown of the engine injection control system, problems associated with idle speed appear.

This is interesting: EGR valve: what is it, principle of operation, main malfunctions

The engine speed begins to fluctuate, the engine does not operate stably at idle, but the car can drive and will start. Often, owners of such Nissans or repairmen may think that there is a malfunction behind this - some kind of breakdown, defect, or something incorrectly assembled. But in reality there is no malfunction, and all components of the car are assembled correctly. The whole problem lies in the failure of the electronics, namely the need to teach the throttle valve to operate correctly and idle. The training procedure itself does not require any equipment and adaptation (training) of the throttle on a Nissan is accessible to anyone. But in the procedure itself, the accuracy of all points must be observed. But even the availability of information about the learning process does not make the procedure simple. Diagnostic equipment, when the throttle valve is mismatched and when the idle speed of the engine increases, does not detect any defects. And very often, even repairmen cannot explain the reason for the suddenly increased idle speed. After proper training, the motor operates in the range of 700-800 rpm. The electronic throttle is very sensitive to dirt deposits and resins that are deposited on it during operation of the machine. Because of this, the idle speed of the engine begins to float or freeze. The engine response to the gas pedal during acceleration is also less sensitive. Therefore, cleaning the throttle is mandatory. But if the throttle is very dirty, after cleaning it, throttle mismatch occurs - and as a result, floating and incorrect revolutions. It is impossible not to clean the throttle - in the end the engine will not work correctly. If you have the opportunity, clean the electronic throttle valve on time - once every 15,000 km. If for any reason you have removed the connector from the electronic throttle, battery, or Nissan engine control unit, you will have to carry out the throttle valve adaptation procedure.

Replacing the mass air flow sensor

When replacing the mass fuel flow sensor on a Nissan QG18DE engine, you should follow the following sequence of actions:

- Disconnect the negative terminal from the battery.

- Unscrew the housing to check the condition of the filter element and, if necessary, read it.

- Disconnect the power connector and unscrew the mass air flow sensor.

- Install the new sensor in reverse order.

If you plan to replace the power supply, you will need to cut off the old one and connect a new one by twisting or soldering electrical conductors.

Throttle learning - what is the process?

When the throttle assembly of any modern vehicle operates, a lot of contaminants in the form of dust, soot, and oil gradually accumulate on the surface of the throttle. They form a layer of dirt, which makes the air gap between the damper and the car's air duct smaller than the established norm. This gap is important for the normal functioning of the “heart” of the car, since thanks to it the idle speed is maintained at the required level.

When it decreases, the vehicle's electronic control unit (car computer) slightly opens the damper by introducing coefficients that take into account changes in its cross-section. Up to a certain point, the ECU manages to maintain the air gap at a constant level, but sooner or later the throttle valve will still have to be cleaned of dirt. After flushing this unit, the engine speed will certainly increase due to the fact that the cross-section of the throttle, freed from the contaminant layer, will become larger.

This is interesting: Replacing lamps in Kia Sportage 3: photos, instructions

The procedure for returning to the initial (set by the manufacturer) position of the damper is usually called training or adaptation.

Other weak points of the Nissan 1.8 l engine (QG18DE)

Other problems occur quite often in a Nissan engine. For example, the head gasket often burns out. The seals that seal the spark plug channels leak in the plastic valve cover. The idle air valve gasket located next to the throttle valve leaks antifreeze, which drips directly onto the electronic engine control unit.

You can select and buy a contract Nissan 1.8 engine for Nissan Primera, Nissan Almera, Nissan Almera in our catalog.

Training procedure

1. First we must teach the accelerator pedal to release its position.

2. Make sure the accelerator pedal is fully released.

3. Turn the ignition to ON and wait at least 2 seconds

4. Turn the ignition key to OFF and wait at least 10 seconds

5. Turn the ignition to ON and wait at least 2 seconds

6. Turn the ignition key to OFF and wait at least 10 seconds

7. End

Teaching the damper to open

The purpose of this procedure is to teach the gas pedal to fully open the throttle. It must be performed every time the connector is disconnected from the gas pedal or from the ECM (ENGINE CONTROL SYSTEM i.e. engine control unit)

Procedure operations

- Make sure the accelerator pedal is completely released.

- Turn the ignition switch “ON” and wait at least 2 seconds.

- Turn the ignition switch “OFF” and wait at least 10 seconds.

- Turn the ignition switch “ON” and wait at least 2 seconds.

- Turn the ignition switch “OFF” and wait at least 10 seconds.

Teaching valve to closed position

The purpose of this operation is to learn the fully closed position of the valve lever, observe the output position sensor. This must be done every time the connector from the electrical linkage or ECM has been disconnected.

Procedure operations

- Make sure the accelerator pedal is fully released.

- Turn the ignition switch "ON".

- Turn the ignition switch “OFF” and wait at least 10 seconds.

- Make sure that the valve lever moves for more than 10 seconds, this should be confirmed by sound.

Training in air supply at XX speed

On engines 1.6 and 2.0 this process goes as follows:

- The battery charge must be at least 12.9 V.

- Warm transmission.

- Antifreeze temperature – at least 700.

- The gear selector lever is in position “P”.

- All electricity consumers are turned off.

We teach the gas pedal to the “released” position - this test is necessary to determine the output signal of the throttle position sensor, and is performed after each ECM cable disconnection. To do this you need the following:

- Turn the ignition key to the “ON” position and pause for at least two seconds.

- Turn off the ignition and wait for ten seconds.

- We repeat these two operations again.

We teach the throttle valve to the “closed” position - this is done for the same purpose as teaching the gas pedal to the released position. To do this, you need to use the key to turn the lock to the “ON” position and back to the “off” position and do not touch anything for ten seconds - you will hear the characteristic chirping of the motor returning the damper to the closed position.

Now the training article itself, for this you need a stopwatch to maintain the specified intervals accurate to the second:

- After warming up the engine, turn it off and pause for a few more than ten seconds.

- With the gas pedal fully released, without starting the engine, turn on the ignition and wait three seconds.

- Fully press and release the accelerator pedal 5 times within five seconds.

- After a seven-second pause, press and hold the accelerator pedal until the CHECK ENGINE light flashes amber and stays on continuously.

- Release the pedal after the CHECK ENGINE light comes on continuously after three seconds.

- Start the engine and wait twenty seconds, then sharply increase and decrease the speed 2-3 times to understand how the engine maintains idle speed (700 +50 rpm).

This is interesting: How to completely disable the alarm on a car: disabling a car alarm with or without your own hands with or without a key fob

A flashing yellow light means self-diagnosis mode - lower the accelerator pedal and read the code number; when there is no error, the light will blink forty times with an interval of 0000.

If the pedal is not lowered for ten seconds, the ECM memory goes to zero - settings and errors are reset. But if there is an error, it means that the throttle valve has not been trained.

Mass air flow sensor Nissan Almera N15

The Almera H16 mass air flow sensor is used to measure the volume of intake air. It is mounted before the air filter and secured with two self-tapping screws.

On the pre-restyling version of the Nissan Almera N16, the air flow sensor has the following pinout:

- 1 (green) – air flow signal;

- 2 (red) – feeding;

- 3 (black) – mass contact;

- 4 (white) – ignition power supply;

- 5 (yellow-black) – air temperature indicator.

Mass air flow sensor with part of the air duct

Signs of a malfunction of the mass air flow sensor:

- after starting the engine, after five minutes it stalls;

- complete or partial lack of reaction of the internal combustion engine to operating the pedal;

- increased fuel consumption.

You can install a sensor from a VAZ 2110, but then you will have to replace the chip.

Nissan mass air flow sensor

You can also use a BOSH mass air flow sensor with the article numbers:

- 0280218116 – with four wires;

- 0280218037 – with five wires.

It is better to buy a sensor without an air duct, it is cheaper.

To confirm the need to replace the mass air flow sensor, we will perform diagnostics. Using a multimeter, measure the voltage at the first contact with the green wire. Take measurements with the engine stopped but the ignition on. Confirmation of a sensor malfunction will be a voltage level of more than 1.07 Volts.

How to clean the throttle body

When the engine does not want to start right away, but does so after several attempts, dips occur at idle and the car is felt “twitching” at low speed - this means it’s time to clean the throttle mechanism from oil dust and deposits from the action of crankcase gases.

After all, the air, passing from the filter through the mass flow sensor, penetrates the throttle mechanism and from there into the manifold. The condition of the throttle valve is very important: if deposits and dirt have accumulated on it, it means that less fuel assemblies goes into the cylinders and you have to press more on the pedal.

The damper needs to be cleaned every 30 thousand kilometers traveled. The sequence of work is as follows:

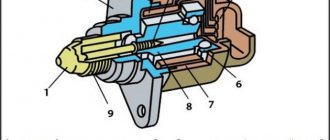

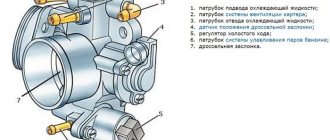

- We remove the corrugated pipeline of the air filter and the holder of the crankcase gas tube, disconnect the hoses of the adsorber and cooling fluid. (photo 004-01)

- Remove the throttle assembly by unscrewing the four screws. Remove the cable from the gas pedal and remove the throttle mechanism. (photo 004-02)

- Remove the throttle body gasket and inspect its integrity. (photo 004-03)

- At the same time, we clean the idle speed control and throttle position sensor.

- It is recommended to clean the throttle assembly with a soft brush using carburetor or brake cleaner. (photo 004-00)

- Having cleaned the throttle valve assembly, we put it in place, connect the throttle cable, all the hoses and the corrugation of the filter element.

When the engine starts, white smoke may come out - this is not dangerous, as the product used to clean the throttle assembly burns out.

After cleaning, it is necessary to undergo adaptation of the throttle valve.

Cleaning the Qashqai Reservoir

To remove the damper, you will need to unscrew the 4 bolts that secure it to the edges of the housing. Then disconnect the plug from the absorber purge valve. To clean the engine, you can use carburetor cleaner.

It is better to wipe off the plaque with a clean cloth, so with minimal contamination it will not be very noticeable, and as a result, the light fabric will turn black. It is recommended to clean the outside of the case first and then thoroughly wipe the inside.

To make cleaning the Qashqai throttle valve easier, you need to fix its body by bending it in the desired direction. During the internal cleaning process, it is recommended to bend the petals of the mechanism, as well as remove and wipe the grille. Don't forget about the smallest details and hard-to-reach places.

After the Qashqai throttle valve has been completely cleaned, it is assembled in the opposite order. If you do everything in the same way, without disconnecting other connectors, then adaptation of the remote control will not be required.

Repair instructions

Having examined the resulting mechanical picture from all sides, it is necessary to clean and rinse off dirt from the throttle valve with a carb cleaner.

cleaning needs to be done

Now wipe the clean throttle body with a clean cloth. If necessary, it is recommended to carry out cleaning several more times in a row. For better results, you can gently press the flap from above with your finger, opening it slightly for better penetration of the carb cleaner inside.

After reassembly is carried out in the reverse order, it is necessary to carry out adaptation measures for the throttle in order to increase the amount of flammable vapors inside it, washed out by the cab cleaner and to avoid engine idling.

Now we should consider in detail the process of learning the throttle grid. It must be remembered that to begin training XX, the following conditions must be met:

- the engine is warmed up to a temperature of at least 70 degrees (maximum 95);

- if the gearbox is automatic, then you need to put it in P;

- turning off the heated rear window in particular and the stove - in general - immediately before the start of training;

- if there is no “daylight” light, the light switch must be set to OFF. If there is such a light, use the side lights.