- Purpose and principle of operation

- The main symptoms of a TPS malfunction

- Checking the throttle sensor

- Instructions for replacing the sensor on a VAZ-2114

- Useful video

- Conclusion

The VAZ-2114 model received a fundamentally new algorithm for the operation of all the most important systems. This is due to the fact that the car is equipped with an injection engine. For efficient and productive operation of the power unit, the “fourteenth” system uses a large number of various sensors and automated devices that read information and transmit the processed data to the ECU.

The VAZ-2114 throttle position sensor is one of those mechanisms without which it is not possible to operate the car. On what principle does the device work, how to replace the TPS in case of urgent need?

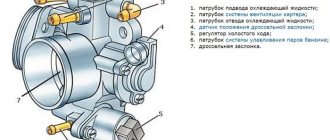

Purpose and principle of operation

In the “fourteenth”, the gasoline supply is adjusted in a radically different way than in earlier models. Under the hood of this car, the driver will not be able to detect the thrust of the mechanical accelerator drive, since electronics are responsible for the fuel supply.

All regulatory processes are controlled by the control unit. The ECU receives data read by various sensors. The throttle sensor on the VAZ-2114 is installed on the same axis as the throttle valve itself. This principle eliminates the connection between the accelerator and the throttle valve.

The manufacturer guarantees a minimum sensor service life of 50 thousand km. Currently, contactless mechanisms are on sale, the design of which excludes the presence of a movable slider. Such devices can operate for an unlimited amount of time.

How does this device work? Everything is extremely simple. The sensor itself is a variable resistor. The mechanism is connected to the ECU by a connector from which three wires come, followed by connecting them to two fixed and one moving contacts of the potentiometer.

There is also provision for connecting one fixed contact to ground, and the second one carries voltage. The operation of the TPS is closely coupled with the idle sensor to control the operation of the engine at idle speed. How to determine the performance of the device and eliminate any deviations in its operation?

What types of throttle position sensor are there?

This sensor comes in two types: film-resistor and non-contact, working on the magnetic resistor effect. Film-resistor ones are installed by the VAZ manufacturer and, as a rule, their service life is short (50 thousand km). The cause is mainly damage to the resistive field that the slider comes into contact with when the shutter position changes. The contact is broken, the signal does not go to the controller, thereby causing unstable operation of the automation.

Non-contact throttle sensors

Non-contact units are an order of magnitude more expensive than the previous version, but are highly efficient in operation and complex in design. The electronic version does not have a gas pedal cable. The role of the cable is played by a special block that transmits a signal through a sensor system. The device operates on the magnetoresistive principle. It includes a rotor and a stator. At the base of the rotor is a magnet. The stator is necessary to capture the electromagnetic field. A device of this category is intended for installation in electrical control units. There is an opinion that the absence of such an important component as a cable reduces the response of the gas pedal, but the reliability is undeniable. Cars with an electronic unit must have an on-board computer, which contains all the information about the engine tasks being performed. It is difficult to determine any breakdowns of this mechanism without special equipment.

Film resistor throttle sensors

Film-resistor components installed on the VAZ 2114, as well as on other VAZ representatives, especially during long-term use, can cause unstable idling, and when changing gears, the engine stops. When the first signs of malfunctions appear, diagnostics will rule out, as an option, a breakdown of the XX sensor, air flow sensor, or detonation, since in this case the symptoms are similar. When the XX regulator is not working, for example, the damper also opens significantly. The entry of a large amount of air into the chamber leads to rapid combustion of the fuel-air mixture. The revolutions increase and the engine power decreases.

The cause of failure of the 2114 throttle sensor itself may be oxidation of the contacts and, as a result, burnt contacts. In the first case, they can be restored by applying an anti-corrosion lubricant, but in the latter, only radical actions are required.

The main symptoms of a TPS malfunction

It is worth considering that different sensors in the VAZ-2114 car system sometimes exhibit the same symptoms. If any deviations occur in the operation of the power unit, it is necessary to comprehensively check all kinds of mechanisms for their operability.

The main painful symptoms characteristic of the VAZ-2114 TPD include:

- Instability of speed during idle.

- Jerking of the car in a certain accelerator position.

- Complete absence of idle.

The appearance of at least one of these signs indicates that it is necessary to check the throttle sensor. You can determine the functionality of the device yourself, without resorting to the services of specialists. A few minutes of time is enough for this; the work of diagnosing and replacing takes an experienced driver less than one hour.

Beginner drivers may face some difficulties, but they are surmountable. For correct diagnosis, you must have some knowledge of electrical engineering. It is also necessary to equip yourself with certain instruments for measuring readings.

Diagnostics

You can do it yourself. However, checking the VAZ-2114 throttle position sensor should be carried out using a special device - a multimeter. It needs to be switched to voltage measurement mode and connected to ground. The red probe should be connected to the positive terminal “A”. It is located on the housing of the TPS connector. Please note that measurements are taken with the ignition on. Otherwise the value will always be zero. Turning on the ignition, look at the results. The voltage at the terminal should be five volts. A slight error of around 0.3 V is allowed. If the voltage is less than 4.7 V, the element is faulty and must be replaced.

If the multimeter shows zero when the ignition is on, there may be an open circuit and the voltage simply does not reach the sensor. But if everything is in order with the wires, then the VAZ-2114 throttle position sensor controller itself has failed. Signs of its malfunction are a complete absence of voltage at the TPS terminals.

Checking the throttle sensor

To carry out diagnostics, you must have a tester and a voltmeter on hand.

The procedure then boils down to the following steps:

- Open the hood and find the TPS.

- Disconnect the connectors.

- Set the voltmeter to voltage measurement mode.

Connect the “negative” probe to the car body, and connect the “positive” probe to the terminal on the block marked with the symbol “A”. If the voltage reading is close to zero, then we can conclude that the TPS is working, and the fault may lie in the circuit itself. If the voltage is 5 V, then we can judge that the sensor itself is faulty.

If the TPS is broken, you should not try to repair it. It’s easier to buy a new copy and forget about the breakdown. Otherwise, you will have to spend an incredible amount of free time and money, and there is no guarantee that the device will work properly in the future.

It is also a good idea to check the resistance of the potentiometer if you have an ohmmeter at hand. To do this, you need to release the TPS connectors and connect the probes of the device to any of the contacts. A sudden change in readings, so-called jumps, will indicate that the device is not working correctly. In most cases, the throttle sensor 2114 cannot be replaced, since the most common cause of its failure is a break in the conductive layer.

HOW TO CHECK ITS WORK INDEPENDENTLY

You already know the signs of a malfunctioning throttle position sensor, let's try to check its functionality ourselves. A sequenced test cycle will help you check how to check the throttle position sensor. To perform this, you need to have a tester, a multimeter or a simple voltmeter with a scale of 15-20 volts.

The verification procedure will be as follows:

- You need to open the hood and find the TPS. Look for it near the throttle valve;

- To check, a connector from this sensor is required, so it is disconnected from the TPS;

- Now a voltmeter or other devices are connected to work in voltage measurement mode. The “minus” of the device is connected to the “ground” of the car, and the voltage will be checked with the second probe. Carefully examine the connector body and find the terminal marked with the letter “A”.

- With the ignition on, check for voltage at this terminal. It should be equal to 5 volts. If there is power, then the TPS is out of order and must be repaired or replaced. If the voltage is significantly lower than 5 volts or is absent at all, it is necessary to check the entire electrical circuit of its power supply. If everything is fine with it, the controller may fail.

You can check the operation without disconnecting the connector from the TPS. Let's look at this technique in action, how to check the TPS without disconnecting it from the power supply. The purpose of the test remains the same, this is to check the presence of supply voltage at the TPS. With the ignition on and a voltmeter connected, the device should show a smooth voltage change from 0.7 to 4 V if you smoothly turn the plastic throttle sector. The TPS connector must be connected, and the supply voltage is checked by calcining the wire with the probe of the measuring device.

Article on the topic: Let's figure out why the low beam lamps in the VAZ 2114 do not light up: instructions for car enthusiasts

If you have an ohmmeter, you can check the resistance of the sensor potentiometer. In this case, the connector is disconnected from the TPS, and the ohmmeter probes must be connected to any fixed and moving contacts. When the sector rotates, the meter needle should move smoothly. Jerking or jerking movement of the instrument needle is evidence of its malfunction.

It makes no sense to repair it, since the reasons for the malfunction of the VAZ 2114 TPS almost always lie in the breakage of the conductive layer. Easier to replace with a new one.

Manufacturers guarantee its normal operation for approximately 50 thousand kilometers. Currently, TPS from the city of Kaluga have appeared. They are a contactless device that does not have a moving slide, and the contact does not wear out. The service life of such a device is unlimited.

When the TPS on a car is being replaced, this is a favorable moment to repair the throttle valve. Repair will be said loudly, since in most cases everything is limited to cleaning and washing this unit.

Use any liquid to clean carburetors, do not miss a single channel when cleaning and everything will work out.

Sometimes the question arises about how to test a new throttle position sensor. This can be done using an ohmometer as described above.

Instructions for replacing the sensor on a VAZ-2114

Both an experienced driver and a beginner can easily replace the mechanism. To carry out all the work, it is enough to have only a screwdriver on hand.

The process of replacing a device boils down to doing the following:

- first of all, you need to turn off the power to the car, remove the negative terminals;

- then disconnect the sensor connectors;

- loosen two screws and dismantle the mechanism itself;

- reconnect all connectors;

- return the battery terminals to their original position.

At this point, the installation of a new throttle sensor on the VAZ-2114 is considered complete. Experts recommend immediately checking the new mechanism. To do this, immediately after installing the new device, press the gas pedal. If this is not possible, you should change the location of the TPS.

When installing a new unit, it is advisable to change the foam rubber gasket, which acts as a seal between the pipes and the device. As a rule, a new gasket comes with a new sensor. You must first clean the area of the old gasket and then install a new one.

How does the throttle position sensor work?

When the engine is idling, the valve is closed, air enters the power unit through a separate channel, and for proper idling, a signal is sent to indicate the supply of gasoline.

- If you measure the voltage at the output, the value will be no more than 0.5 volts.

- By pressing the gas pedal, which is connected directly to the controller, the resistance in the electrical circuit changes and the damper opens slightly.

- The voltage in the electrical circuit increases, is recorded by the microprocessor and information about the state and position of the bypass valve is sent to the engine control unit.

- Its function is to dose the incoming air into the internal combustion engine and control the proportions of air and fuel.

- When checking the output voltage when the damper is open, the voltmeter shows about 5 volts, this is the maximum value.

Throttle valve malfunctions VAZ 2114

The mechanism itself is not a complex structure and is designed for the entire service life of the engine. However, some design features of the motor and a number of external negative factors, over time, create obstacles to its normal operation. In most cases, problems with the damper are the result of simple contamination. The reasons for the appearance may be the following:

- untimely replacement of the air filter, resulting in the entry of dusty, unpurified air;

- the presence of defects and cracks in the air system and its elements (for example, a defective air filter, a torn pipe), the result is the same - contamination of the air flow;

- the appearance of carbon deposits and oil residues on the inner walls of the throttle assembly and valve.

The result of the above reasons is the incorrect operation of the unit; the damper may not fully open or close, which directly negatively affects the operation of the engine. Although the filtration and air flow purification process can be controlled, it will not be possible to completely get rid of carbon deposits. Therefore, automakers recommend periodic cleaning of the unit from contamination every 25 thousand kilometers. We believe that this recommendation is completely justified in the conditions of Russian reality, the quality of fuel and the condition of the road surface.

Troubleshooting

Before taking any action, you need to check the VAZ 2114 throttle valve for possible problems.

In order to accurately diagnose a malfunction or incorrect operation of the throttle, there are characteristic signs inherent to it. These are:

- Instability of engine speed at idle, their unreasonable increase;

- Periodically stalling engine;

- Jerking while moving;

- The discrepancy between the effort when squeezing the gas pedal and the final result (the proper reaction from the engine does not occur, power does not increase, the car does not pick up speed or does it late).

- Noticeable increase in fuel consumption in standard driving mode.

Please note that the causes of problems can be caused by: - A malfunction of the TPS sensor, as a result of which fuel is supplied to the system in the wrong amount. — Malfunction of the idle speed controller. Therefore, sometimes it is advisable to check these important elements of the system.