Idle speed instability (IDL) is a more serious problem than many drivers realize. The fact is that it leads to the following negative consequences:

- at extremely low speeds, engine wear increases, in addition, increased vibration loads negatively affect other parts of the car;

- the engine may stall at the wrong moment, for example at a traffic light or when driving in neutral;

- Fuel consumption increases, since the driver has to “help” the engine so that it does not stall by pressing the gas pedal. In addition, for various reasons, revolutions can “bounce” on their own;

- increased vibrations in the car bother the driver and passengers;

- The dynamics of the car worsen, since unstable idle operation is most often a symptom of malfunctions in the ignition or fuel supply systems. As a result, engine power is reduced.

Therefore, if you notice that the idle speed is floating, you must immediately begin to search for and eliminate the causes, which is what we will do next.

Unstable idling of the engine with carburetor 2108 Solex and 2105, 2107 Ozone

Unstable idling of a car engine with a carburetor 2108, 21081, 21083 Solex or 2105, 2107 Ozone is one of the most common malfunctions.

In addition to the discomfort of operating a car with a shaking engine that is about to stall, a car owner faced with such a problem must be prepared for a rapid decrease in its service life, an increase in fuel appetite, loss of power, throttle response, etc. Very often, unstable idle speed appears from -for problems with the ignition system (2108, 2109, 21099 or 2105-2107), malfunction of the fuel system before entering the carburetor, fuel pump, or the engine itself. In this article we will look at the reasons for unstable idling of a car engine associated with a malfunction of the carburetor (2108, 21081, 21083 Solex, 2105, 2107 Ozone).

It should be noted right away that these reasons are typical for a warm car engine idling with the air damper fully open and the throttles closed. Unstable engine operation in other modes may have other reasons and will be discussed in a separate article.

Symptoms of a problem

— The engine is unstable at idle. It vibrates, “troits”, there may be popping noises in the muffler or carburetor. You can hear cylinder misfires and possible black smoke from the muffler. Shooting at the muffler indicates that the fuel mixture is too rich at idle, and shooting at the carburetor indicates that it is too lean. An over-rich or over-lean fuel mixture entering the engine cylinders at idle is at the root of all the causes of unstable idle speed. This is what we will start from when diagnosing and eliminating this malfunction.

— Idle speed spontaneously, then decreases, then increases (“floats”) . Typically, this phenomenon is observed when a separate piece of debris gets into the channels or jets of the CXX or the “suction” of foreign air into the carburetor. Periods of deterioration in idle performance may alternate with periods of stable operation. As a bonus, glow ignition can be added to unstable idle speeds - that is, the engine continues to run for some time after the ignition is turned off.

Causes of unstable idle

The engine idle speed control is broken

Most likely, for some reason the adjustment was made towards a leaner fuel mixture at idle. Adjust the idle speed using the “quantity” and “quality” screws of the fuel mixture, available on both the Solex and Ozone carburetors. For 2108, 21081, 21083 Solex normal idle speed is 750-800 rpm, for 2105, 2107 Ozone 850-900 rpm.

Adjusting screws for the “quantity” and “quality” of the fuel mixture of carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone

How to correctly and quickly adjust idle speed is described in the articles:

Carburetor solenoid valve faulty

The valve itself or the EPH system is faulty. If the valve fails completely, its needle will block the hole for supplying fuel to the idle system, and the engine will stall. At idle, it will only operate with the choke pulled out. If the solenoid valve shows signs of life, then idling is possible, but it will be unstable.

Solenoid valves for carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone

Check the valve's condition. Turn on the ignition and remove the wire from it. You should hear a click when it fires. If there is no click, connect the valve terminal and the battery plus with a piece of insulated wire. There is no click, change the valve. There is a click, we check the EPH system. It turns off the fuel supply to the idle system when the idle speed increases above 1200 rpm and at forced idle; the carburetor solenoid valve is part of it. Articles on the topic: “Checking and repairing the EPH system of carburetor 2108, 21081, 21083 Solex”, “Checking and repairing the EPH system of carburetor 2105, 2107 Ozone”.

The channels and (or) jets of the carburetor idle system are clogged

The fuel mixture becomes lean. Unscrew the solenoid valve or the idle air system fuel nozzle holder installed in its place. Remove the idle air system fuel nozzle from it. Clean it, rinse with gasoline, blow with compressed air. If it is deformed or its markings are not correct, replace it. Check the integrity and presence of its rubber sealing ring.

Solenoid valve of the 2108 Solex carburetor and the CXX fuel jet removed from it

It is possible to clean the CXX without removing the carburetor from the engine. Set the crankshaft speed within 3000 rpm. Unscrew the valve or holder a couple of turns. Apply the throttle by hand rotating the lever on the throttle axis of the first chamber. Screw the valve back on. Repeat the operation several times until stable idle speed appears. In this simple way we increase the vacuum in the CXX channels. It will carry all the deposits there into the cylinders. Before cleaning, you can pour a little acetone into the hole under the valve and wait until the deposits loosen.

Methodology for finding problems on domestic carburetor systems

Before you start troubleshooting, you need to check that the carburetor is adjusted correctly. The manufacturer sets the settings for ideal operating conditions - the amount of oxygen in the atmosphere of flat terrain and gasoline that complies with GOST. And this is on a new car.

In reality, periodic adjustment of all 4-5 carburetor adjustment screws is required. At least two of them are responsible for stable idle operation. The adjustment is made with the engine running using a simple screwdriver.

The procedure is described in the owner's manual, and differs slightly depending on the carburetor model. The main condition for correct tuning is the absence of leaks, a clean air filter, and high-quality gasoline. The amount of oxygen in the air corresponds to daily use. That is, if you live on a plain, there is no point in adjusting the carburetor while climbing a mountain serpentine to an altitude of 800 meters above sea level.

- Warm up the engine to a temperature of 90°C. If there is no thermometer, the degree of heating can be easily determined by the opening of the cooling system thermostat;

- We start the engine, give a small load - turn on the headlights and the climate system (without air conditioning). Each type of carburetor has its own idle speed, let’s take 750-800 rpm as a basis, as on Solex. The idle speed is controlled by the “quantity” and “quality” screws of the mixture. It will not be possible to establish normal speed with wine alone;

- The forced choke lever (choke) is closed;

- Using the “quality” screw, we adjust the speed to the maximum possible value. As a rule, the screw is fixed at the factory and closed with a plug. It needs to be removed;

- Next, using a standard (on the dashboard) or remote tachometer, set the speed to 900, turning only the “quantity” screw;

- Then use the “quality” screw to set the required value: 750-800 rpm.

Afterwards, you need to start the engine in normal mode, make a test drive, and accelerate in neutral several times to the maximum speed. Then turn off the engine, and after a couple of minutes start it again and check the number of revolutions at idle with a load (high beam + heater). If necessary, repeat the adjustment process.

Disassembling and cleaning the unit

The tools for disassembling the carburetor will be the same as for dismantling. We perform the procedure in the following order:

- Place the product on a clean surface, unscrew the fasteners of the top cover and remove it.

It is not recommended to clean the jets with metal objects (wire, awl, etc.), since the passage hole can be damaged.

Table: calibration data for DAAZ 2107 jets

| Carburetor designation | Fuel main system | Air main system | Fuel idle | Air idle | Accelerator pump nozzle | |||||

| I Kam. | II Kam. | I Kam. | II Kam. | I Kam. | II Kam. | I Kam. | II Kam. | fuel | bypass | |

| 2107–1107010; 2107–1107010–20 | 112 | 150 | 150 | 150 | 50 | 60 | 170 | 70 | 40 | 40 |

| 2107–1107010–10 | 125 | 150 | 190 | 150 | 50 | 60 | 170 | 70 | 40 | 40 |

To clean the float chamber from dirt, you need to use a medical bulb. It is used to collect remaining fuel and debris at the bottom. It is not recommended to use rags, as lint can get into the jets and clog them.

Cleaning the carburetor without disassembling

The most common way to remove contaminants from inside a product involves disassembling it piece by piece, which not every car enthusiast can do. There is also a simpler option for cleaning the unit without disassembling it using special aerosols. The most popular are ABRO and Mannol.

Washing is carried out as follows:

- With the engine turned off and cooled down, dismantle the air filter housing and unscrew the solenoid valve.

Before you start repairing or adjusting the carburetor, you need to be sure that it is the problem. In addition, the unit must be periodically inspected and cleaned of contaminants that form both outside and inside the mechanism, which step-by-step instructions will help you with.

How to adjust idle speed

The speed can be adjusted using screws. They are available on carburetors specifically designed for VAZ. A floating idle may occur if there is a malfunction in the mass air flow sensor.

You can verify this by finding out the voltage, which, as a rule, during normal operation is 0.99-1.00. To do this, the multimeter must be set to 20 V, and measurements are taken between two wires; they are easy to find - by the green and yellow colors when the car is running. If the multimeter produces different numbers, the sensor needs to be replaced. When the cause is a faulty wiring of the speed sensor, such a defect can be noticed visually. Wiring can:

- get damaged;

- oxidize;

- wear out.

In all cases, it needs to be replaced and the contacts cleaned, even if there is the slightest oxidation.

If the sensor responsible for the crankshaft position is faulty, the first thing to do is check the wires that go to it.

If no damage is noticed here, a multimeter should be connected to the sensor, and the crankshaft should be set so that it is in a position where the highest voltage is 200 mV. If you pass a screwdriver over the core and voltage surges are shown on the device screen, the sensor is in good condition and works normally.

What about the injector?

Everything is a little simpler here, since no adjustments are needed. The reason is that a smart on-board control system is responsible for everything. And specifically for idling - the regulator (IAC). Some may call it an idle speed sensor, but this concept is completely wrong. The fact is that there are two types of devices on injection cars - sensors (reading) and actuators. The idle air control is a stepper motor; it does not measure anything, but on the contrary, it opens and closes the air supply through a special channel.

A breakdown of the IAC can only be determined by external signs, and then only relatively. The fact is that the control lamp on the dashboard will not light up if the regulator suddenly fails. But if you feel unstable revolutions, or they have disappeared completely, and the engine jerks and stalls, then first of all, of course, it is worth checking the performance of the IAC. It is worth noting that sometimes the “Check” can light up when the IAC is faulty. This happens if the engine detonates. The knock sensor signals a malfunction to the electronic control unit.

Carrying out diagnostics

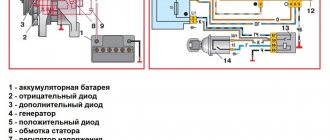

The simplest method is to measure the voltage at the block to which the regulator is connected. These are terminals D and A. When the ignition is turned on, a voltage of 12 V should be present on them. If the voltage is less than this value, it is worth looking at the battery and generator. It is quite possible that the battery is undercharged. In the same case, if there is no voltage at all, it is necessary to check the entire power circuit of the device and diagnose the ECU.

Set the multimeter to resistance measurement mode. Between pairs of terminals A and B, C and D, there should be a resistance of approximately 53 ohms. Remove the IAC and connect (with the ignition off) to the block. Then turn on the ignition and look at the behavior of the needle - it should extend completely when voltage is applied. If this does not happen, we can judge that the IAC is broken.

Sometimes simply cleaning the regulator helps. To do this, you can use sprays, of which there are sufficient quantities in stores. But in some cases, only replacing the device will help. Of course, this is not a DAAZ carburetor, the cost of the IAC will be many times lower, and there will be no problems with replacement. If, even after the replacement, the engine does not idle, it is necessary to fully diagnose the injector.

Specifications

Before we begin to describe the malfunctions, it is worth considering the engine options that were installed on the VAZ 2107 carburetor. The characteristics and design of the engine are quite simple. The engine has an in-line longitudinal arrangement of cylinders.

So, for the VAZ 2107 with carburetor versions of power units, engines marked 2103 and 2106 were installed.

VAZ 2103

| Name | Index |

| Volume | 1.5 liter (1452 cm3) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Power | 80 hp |

| Fuel | Gasoline with the possibility of installing gas cylinder equipment |

| Cooling | Liquid |

| Injection system | Carburetor |

| Fuel consumption | 6,7 |

| Cylinder diameter | 76 |

| Cylinder operating order | 1-3-4-2 |

VAZ 2106

| Name | Index |

| Volume | 1.6 liter (1569 cc) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Power | 75 hp |

| Fuel | Gasoline with the possibility of installing gas cylinder equipment |

| Injection system | Carburetor |

| Fuel consumption | 6,7 |

| Cylinder diameter | 79 mm |

| Cylinder operating order | 1-3-4-2 |

The engines were equipped with gearboxes manufactured by VAZ - 4-speed manual transmission and 5-speed manual transmission. Unlike new models, all power units have a timing chain instead of a belt. Unlike the “fives”, the seventh model of the Zhiguli has higher engine power and displacement.

Maintenance of the VAZ 2107 engine is quite simple. So, the engine requires scheduled maintenance every 10,000 km. Many motorists are wondering what kind of oil to pour into the engine? Considering the design of the engine, the most suitable option is “semi-synthetic”.

Many car enthusiasts argue that it is better to pour “mineral water” or “synthetic” in general. Of course, an engine with high-quality oil will run longer, but in the case of the “seven” even the manufacturer recommends using “semi-synthetic”. But for power units equipped with an injector rather than a carburetor, it is already recommended to use a higher criterion motor oil - “synthetic”.

Checking the EPHH needle valve.

We also remove the hose from the side outlet (fitting “2”) of the electro-pneumatic valve and connect this hose to the economizer. We start the engine. If the economizer valve is working properly, the engine should run at low speed. If the engine stalls at idle, the valve diaphragm may rupture.

To change the valve, disconnect the wires from the microswitch terminals.

2. Using a screwdriver, unscrew the two screws securing the economizer housing to the carburetor.

3. Remove the bracket with the microswitch...

4. ...as well as the economizer assembly.

5. Remove the gasket from the economizer.

6. Unscrew the two bolts holding the body and economizer cover together...

7. We halve the economizer and check the condition of the diaphragm.

If the diaphragm is defective or the needle and seat are worn, we replace the economizer assembly.

On older models it was possible to change parts individually.

We install the new economizer in the reverse order.

Irregularities in the operation of the VAZ 2107 engine at idle speed are a fairly common phenomenon. And if we are talking about a power unit with distributed injection, then very often the cause of such problems is a malfunction of the idle air regulator (IAC). We will talk about it in this article.

How to adjust the VAZ 2107 carburetor to idle?

Now comes the most important part. A tachometer is required here. After checking all systems, their serviceability and correct settings, you can begin adjusting the speed xx. To do this, the car is installed on a flat surface, the quality and quantity screws are tightened all the way and unscrewed four turns, this is how they are adjusted from the factory.

You need to set up the starting device in advance and remove it completely. The engine must be warmed up to operating temperature. If there is a need for a cold start, remove the choke and remove it as soon as the engine warms up. But don't touch the gas pedal.

Set the speed to

800 rpm, tightening the air-fuel mixture quantity screw. After this, you need to unscrew or tighten the quality screw so that the speed becomes the maximum possible. Take your time to make the setup process more accurate.

Tighten the quantity screw again to

800 rpm Now you need to adjust the quality screw until the engine begins to shake a little. This moment will be the most acceptable in terms of fuel economy and acceleration dynamics.

There is another method, which consists of cyclically raising the speed using a quality screw. This process can be continued for a very long time, until the engine simply stalls. The most important thing is that the speed does not drop below

750 rpm, but did not exceed 900. Otherwise, the engine will operate unstably or consume too much fuel. It will become more difficult to configure it.

If high idle speeds are adjusted, they will noticeably reduce engine life, however, in winter, adjustment at idle speed up to

1000 rpm when the carb is frozen and needs additional mixture. After this, the next adjustment will need to be adjusted in the spring to reduce the speed.

VAZ 2107 carburetor idle speed floats

There may be several reasons for this unpleasant problem:

The IAC idle speed controller is malfunctioning

The idle speed of the engine changes by itself and it may even stop; often the engine does not want to start without pressing the gas pedal. And the “Check Engine” lamp may not light up. At medium and high speeds, the engine keeps its speed evenly, and no loss of power is noticeable.

Problems with the mass air flow sensor (mass air flow sensor)

If the mass air flow sensor is faulty, the speed may change not only at idle speed, but also at any other throttle opening, even when driving under load. A car can put its owner in a very dangerous situation by suddenly losing traction while overtaking. The check engine light is usually on. If you notice these signs, you will need to replace the faulty sensor. Read how to do this here

Optimal operating mode of power units

Many car owners think about what engine speed is the most economical. It must be said that for each engine the optimal speed indicator may vary.

- For example, diesel engines provide excellent pickup from the very bottom. Therefore, the best efficiency will be achieved at speeds of 2000 per minute.

- Whereas gasoline engines, especially turbocharged ones and those with a small volume, show the best traction at high speeds. For them, the optimal performance will be at around 3500-4000 rpm.

- If the car is equipped with an automatic transmission, the computer control unit itself will select the optimal engine speed. If you are using a manual car, you should keep the engine speed in the range from 2000 to 4000 rpm. In this mode of operation, the motor will be more economical, and you will be spared from various breakdowns.