Device

Modern cars use a disc brake system. However, on budget class cars, it is installed only at the front. The rear wheels are driven by drums. To actuate the pads, the rear brake cylinder is used. The VAZ-2110 is also equipped with it.

The brake system of this car itself includes the following elements:

- Front calipers.

- Hoses and tubes.

- Rear brake slave and master cylinder.

2110 and other VAZ models include a vacuum booster. It is controlled using the brake pedal. Pressure is created from the cylinder pistons, which acts on the pads.

System design and principle of operation

The main thing in the braking system of any car is the brake mechanisms and their drives. The hydraulic brake drive used on passenger cars consists of:

- pedals in the cabin;

- working brake cylinders of front and rear wheels;

- vacuum booster;

- pipeline (brake pipes);

- master brake cylinder with reservoir.

The principle of operation is as follows: the driver presses the brake pedal, driving the piston of the brake master cylinder. The piston squeezes fluid into the pipelines to the brake mechanisms, which in one way or another create resistance to the rotation of the wheels, and thus braking occurs.

When the brake pedal is released, the piston returns via a return spring, and the fluid flows back into the master cylinder - the wheels are released.

On domestic rear-wheel drive cars, the brake system design provides for a separate supply of fluid from the master cylinder to the front and rear wheels.

On foreign cars and front-wheel drive VAZs, the pipeline circuit diagram “left front – right rear” and “right front – left rear” is used.

Characteristics and manufacturers

On VAZ cars, the rear brake cylinder is a device containing 2 pistons inside. The body itself is made of metal. But sometimes it cracks. Most often due to marriage. Today there are several original manufacturers of these elements:

- "Craft".

- "Basalt".

Among foreign ones it is necessary to note:

- "Phoenox".

- "AND THOSE".

- "Lucas".

How much do VAZ rear brake cylinders cost? The price of a new element ranges from 300 to 500 rubles. The most expensive is a vacuum booster. Its cost varies from 1.5 to 2 thousand rubles for domestic cars.

Rear cylinder design

Replacing the rear brake cylinder of a VAZ 2109

In turn, the cylinder consists of:

- Brake fluid reservoir. A special sensor regulates the liquid level;

Note: The brake fluid reservoir does not have to be installed on the actual cylinder. It can be installed in another location if it is more convenient. It is important that it is connected to the cylinder cavity through tubes.

- The housing in which the pistons and return springs are concentrated;

- Return springs, allowing the pistons to return to their original position after pressing the brake;

Replacing the rear brake cylinder on a VAZ 2109

- Sealing cuffs that create the correct pressure in the tank;

- Pistons with pushers;

- Differential pressure sensor.

Note: with its help, the driver learns about the loss of tightness in one of the circuits.

How it all works

Replacing the rear brake cylinders of a VAZ 2109

As a rule, in normal condition and under optimal environmental conditions, the cylinder works like this:

- To slow down, the driver needs to press the brake. After this, the force is transmitted along the rod to the piston. This rod moves forward, helping to close the compensation hole. Thus, the brake fluid pressure begins to increase.

Note: the same thing happens in the front cylinder, which helps the car brake quickly.

- After the car has been stopped, the driver stops pressing the pedal. As a result, the pistons return to their original positions. In addition, the pistons begin to act together with the reservoir. This helps the pressure in the second level out and become similar to atmospheric pressure. In addition, the wheels also return to their original position.

Note: If the front or rear cylinder fails, the second one will operate with less force.

Symptoms of a problem

How to determine that an element requires replacement? First of all, a breakdown can be detected by the level of hydraulic fluid, which has begun to disappear in the master cylinder reservoir. The latter is located under the hood, near the vacuum brake booster. It is worth noting that when the pedal is operated, the liquid always decreases from the reservoir. But as soon as you release it, the pistons will return to their original position and the level will resume. If this does not happen, look for the problem.

Leaks can also come from the cylinder itself. In this case, the rear drum will be wet. Well, the last sign is the behavior of the car when braking. The pedal begins to “grab” at the very end, sometimes you have to press several times to create the required pressure. These signs indicate that the car needs to replace the rear brake cylinder. Don't put off repairs until later - it's for your safety.

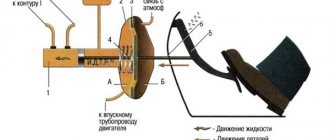

Working principle of the brake master cylinder

When braking, the brake booster rod pushes the first piston. When moving along the cylinder, the piston closes the compensation hole. The pressure in the primary circuit begins to rise. Under the influence of this pressure, the second circuit moves, and the pressure in the second circuit also begins to increase. The voids formed during the movement of the pistons are filled with brake fluid through the bypass hole. Each piston moves as long as the return spring allows. At the same time, maximum pressure is created in the circuits, ensuring the activation of the brake mechanisms.

When braking is completed, the pistons return to their original position under the action of return springs. When the piston passes through the compensation hole, the pressure in the circuit is equalized with atmospheric pressure. Even if the brake pedal is released abruptly, no vacuum is created in the operating circuits. This is prevented by brake fluid filling the cavities behind the pistons. As the piston moves, this liquid smoothly returns (bypasses) to the reservoir through the bypass hole.

If one circuit leaks brake fluid, the other circuit will continue to operate. For example, if there is a leak in the primary circuit, the first piston can move freely along the cylinder until it comes into contact with the second piston. The second piston begins to move, ensuring the activation of the brake mechanisms in the second circuit.

If there is a leak in the second circuit, the operation of the brake master cylinder occurs somewhat differently. The movement of the first piston involves the movement of the second piston, which does not encounter obstacles in its path. It moves until the stop reaches the end of the cylinder body. After which the pressure in the primary circuit begins to increase, providing braking of the car.

Despite the fact that the brake pedal travel increases slightly when there is a fluid leak, braking will be quite effective.

Why is this happening?

In most cases, failure of this element occurs due to natural wear and tear. The rear brake cylinder is a very reliable part, and its service life is about 200 thousand kilometers. If the car has not yet reached this mileage, the cuffs are most likely damaged. This happens when you neglect to replace the brake fluid or mix it with other brands. It absorbs moisture well, which makes it ineffective. And the water begins to corrode all metal parts. Therefore, the fluid must be changed every two years, regardless of the mileage of the car. Also, the rear brake cylinder fails due to squeezed out pistons. This happens when the rear pads are not replaced in a timely manner. Sometimes the pistons simply jam, causing the car to constantly slow down while driving or slow down a little. At the same time, the drum begins to get very hot.

The next thing you need to pay attention to is brake bleeding technology. When performing this work, do not break off the fitting on the cylinder. If it gets stuck (which often happens), purchase a repair kit so that in case of deformation you can replace the damaged element. Some motorists tap the body around the fitting with light blows of a hammer and spray WD-40. In some cases this helps. Next, we will look at how to remove the old rear brake cylinder and install a new one in its place.

Replacement

To do this, we need a jack, a balloon, a hammer and a set of wrenches (if it’s a VAZ, then two for 10 and 12). First we put the car in gear. The handbrake cannot be used as it uses our cylinders. Next we remove the bolts on the rear wheel. Raise the car on a jack. Remove the wheel and unscrew the bolts on the drum using a 12mm wrench. We take the last one out. If it has become stuck, you can “stir” it with blows of a hammer. In order not to damage the drum (since such actions can crack it), we use a wooden block as a lining. After that, remove the pads and use a 10mm wrench to unscrew the brake hoses.

Be careful - when dismantling, liquid will flow from them. Wear rubber gloves. To prevent the liquid from splashing on the floor, prepare a container (for example, a plastic bottle). To remove the rear cylinder, use the same wrench to unscrew the two mounting bolts. At this stage, dismantling is complete. Now we fasten the new part into place. Installation is in the reverse order. After assembling the system, be sure to bleed the brakes. This operation is also performed when replacing pads and any elements of the system, be it a tube or a vacuum booster.

How to upgrade

To completely remove air from the system, you will need an assistant. The latter must press the brake pedal on command. You will also need a container into which the airy liquid will be released. It is best for it to be transparent. A regular mineral water bottle will do. You will also need a hose through which the liquid will flow from the fitting into the container. This can be any rubber or silicone tube. It is desirable that it is also transparent.

So, how to properly bleed the brakes after replacing the rear cylinder? First, add fluid to the plastic reservoir of the master cylinder to the required level. Then we connect the hose with one end to the unscrewed fitting, and lower the other into the bottle. The assistant should press the brake pedal 4-5 times and press it “to the floor” at the last time. As you press, hydraulic fluid will begin to exit the system. The first time it contains many small air bubbles. It would seem that it was possible not to pump. But they are the ones that interfere with effective braking. The compressive force of air is much lighter than that of liquid, which results in greater heating.

When to finish the procedure? After each pumping step, the amount of air, namely bubbles, will decrease. This is done until they completely disappear from the liquid. To determine this, use only clear tubes and a container. After this, screw the fitting back and check the fluid level in the master cylinder reservoir. It should decrease. Top up again to the maximum level. Remember that the brand of the substance used for topping up must be the same as what is currently used in the car.

Adviсe

After this work, it is necessary to check the serviceability of the new element. To do this, press the brake pedal and lock it in this position (it is advisable to have an assistant). Next you need to spin the wheel. It must be in hanging condition. The drum should not rotate. If this happens, or when you press the pedal, liquid flows out of the fittings, check that the part is installed correctly.

It would be a good idea to check the serviceability on the go. Do this at low speed, because after bleeding the pressure in the system drops, and the first time you press the pedal, usually nothing happens. The car should brake well and hold the handbrake.

Car brake system care

As one of the most important components, the car's braking system requires constant attention and care. Here, literally any malfunction can lead to unpredictable consequences on the road.

Some diagnoses can be made based on the behavior of the brake pedal. Thus, an increased stroke or a “soft” pedal most likely indicates that air has entered the hydraulic drive system as a result of a brake fluid leak. Therefore, it is necessary to periodically monitor the liquid level in the tank.

Its increased consumption may be a consequence of damage to hydraulic hoses and tubes, as well as ordinary evaporation over time. This causes air to enter the system and cause brake failure.

Parts that have become unusable must be replaced, and the system will have to be pumped by bleeding air from each working cylinder on the wheels and adding fluid. The process is long and tedious. ” alt=””> When the car pulls to the side when braking, it indicates a possible failure of one of the working cylinders or excessive wear of the linings on a particular wheel. If the brake mechanisms are dirty, a characteristic noise may occur when you press the pedal.

All these malfunctions can be easily fixed independently or by contacting a service center. And to minimize the troubles described above, take care of your brakes and use engine braking more often, especially on steep and long descents. Prolonged activation of the main working system leads to overheating of parts and causes various breakdowns.