Why are hydraulic compensators knocking?

A hydraulic compensator is a device responsible for automatically adjusting the thermal gap in a separate valve. Thanks to their use, engine operation becomes easier. The reason is that you don’t have to adjust the valves manually. They also increase the service life of the gas distribution mechanism. It functions more evenly because the thermal gap is always within the tolerances -stuchat-gidrokompensatori-prichini-i-ustranenie_0.jpg" class="aligncenter" width="644″ height="368″[/img]

But it happens that the hydraulic compensator starts knocking. Over time, the knocking becomes stronger and becomes impossible to ignore. Often there are three reasons.

- Severe natural wear and tear or manufacturing defects in design.

- The engine lubrication system operates intermittently.

- The engine oil is not compatible with the engine, or it has been used for too long, as a result of which it has lost its original properties.

The driver must remember that the compensator is capable of knocking not only constantly, but also in a certain engine operating mode.

In the cold

If the hydraulic lifters start knocking when cold, check which of the following is true.

- The oil is too thick. If the engine is not brought to the operating temperature range, the lubricant will begin to poorly penetrate into the cavities of the hydraulic compensator. To ensure that the cavity collects enough oil, you need to wait a little.

- The timing valve contains too much dirt. Solid particles appear if the engine oil has too many harmful impurities, or the owner delays the timing of lubricant changes. Also, the presence of debris indicates the release of wear products from some engine parts.

- Plunger jamming or severe mechanical wear. Most often, the cause is the penetration of abrasive particles into the oil structure.

Hot

Sometimes owners notice how hydraulic compensators begin to knock when hot when the engine is brought to operating temperature. There are also three reasons.

- The plunger pair of the hydraulic compensator is jammed. Loss of performance occurs due to dirt or natural wear and tear. Due to the appearance of scoring, the plunger stops moving fully. The thermal gap cannot be adjusted, so the hydraulic compensator begins to knock.

- Insufficient viscosity of oil heated to engine temperature. It begins to seep through the gaps of the plunger pair faster than when supplied by an oil pump. Lubricant from an unknown manufacturer, or incorrect selection taking into account the manufacturer’s recommendations leads to severe liquefaction. Leakage occurs along technological gaps.

- Exceeding the recommended engine oil level. This causes it to foam as the crankshaft forces the lubricant to circulate. This process is enhanced when water enters the engine. The driver needs to check the oil level. If possible, it is worth installing a new filter, first adding new lubricant.

Why do new hydraulic compensators knock?

The problem does not always go away after replacing hydraulic compensators. Especially if the engine has new elements installed and fresh oil is added. There are several options.

- Incorrect oil selected.

- The old filter is too clogged, you need to install a new one instead.

- The cleanliness of the lubrication system leaves much to be desired.

- The oil pump has failed.

- Oil supply channels are clogged.

As a rule, knocking has to be treated by flushing the cylinder head. If this does not help, then you need to replace the new oil pump. This behavior indicates significant natural wear and tear. Troubleshooting in this way is a rare occurrence, because in 90% of cases the problem is eliminated after changing the selected oil and washing the hydraulic compensators.

Can hydraulic compensators knock due to oil?

Yes it is possible. Moreover, the reasons do not always lie only in the poor condition of the lubricant. The correct operation of hydraulic compensators is also affected by viscosity and the concentration of harmful additives in its structure.

Even if the problem is not related to the lubricant, the driver must choose it based on the requirements of the car manufacturer. They are given in the service documentation.

This is interesting: Design of the MTZ-82 front axle - design diagram

Hydraulic compensators and malfunctions in them

Let's immediately determine that the knocking of the hydraulic compensator is a problem that occurs in 90% of cases not on new cars, although exceptions are possible if a low-quality part was installed at the factory.

But this is also unlikely, since the hydraulic compensator belongs to the power unit, and factories producing engines have much more stringent requirements regarding the quality of components supplied by suppliers. Problems with knocking hydraulic compensators can arise over time on a car of any make, year and country of manufacture.

There are also many options for the malfunction to manifest itself - on a cold engine, on a warm one (as they say, “hydraulic compensators knock when cold or hot,” respectively), while standing still and while driving.

There are a number of ways to eliminate annoying sound, each of which should be used in a specific situation.

But in order to understand why the hydraulic compensator is knocking and the reason for its failure, you first need to understand what kind of mechanism it is, what it consists of, and how it functions. And in general, what can such a knock lead to, and what will happen if it is not eliminated in a timely manner.

How to recognize

The engine itself is a noisy unit, how can you determine that it is the hydraulic compensator that is knocking? If the compensator malfunctions, a sharp knocking or chirping sound appears. The frequency of which is half the speed of the motor.

A knock is considered a malfunction when it does not disappear after two to three minutes after starting the engine. Either it appears hot, after

warming up the engine. It may not be heard from inside the car, but you will hear it when you are outside the car, without even opening the hood.

What is the danger of knocking? This is the first sign of gas distribution problems.

The knocking may be due to a damaged valve spring, or due to excessively large valve clearances. Therefore the following check needs to be done:

- Inspect the condition of the springs (if they are broken) and check the dimensions of the valve clearances.

- If necessary, adjust the gaps.

- After this, you should turn the crankshaft so that the valve suspected of knocking opens slightly.

- Now turn the spring slightly, the valve will turn automatically behind it.

- Start the engine, the knocking noise may disappear.

- If not, try checking and adjusting the gaps again.

A persistent knock after such an adjustment means that the hydraulic compensator is broken.

Features of the operation of hydraulic compensators

Conclusion

As practice shows, the most common cause of noisy operation of hydraulic compensators is the use of bad oil

- either low quality, or old (used), or not recommended by the engine manufacturer.

Therefore, in most cases, the problem of noisy operation of expansion joints is solved already at the first stage, by changing the oil and filter, as well as flushing the engine, during which the expansion joints should also be washed. And the knocking of hydraulic valves due to wear or damage occurs much less frequently.

Camshaft location

Modern cars most often use a mechanism with an overhead camshaft, which has reduced the metal consumption of the structure and, as a result, increased reliability.

Since metal expands when heated, and the valves are constantly in a high-temperature zone, to prevent it from being pressed in, as a result of which it does not fit tightly into the seat, a thermal gap is provided between the valve stem and the camshaft cam.

In this case, the thermal gap has a certain value to ensure the maximum possible opening of the valve, eliminating its tightening.

Previously, on engines with an overhead camshaft, the thermal clearance was adjusted by placing shims of a certain thickness between the valve stem and the camshaft cam.

The disadvantage of using these washers was the need to periodically check the gap and adjust it by selecting washers.

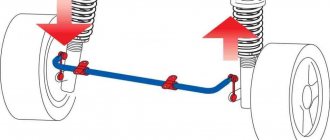

Nowadays, to ensure thermal clearance, hydraulic compensators are increasingly being used, popularly known as hydraulic compensators, the use of which eliminated the need to adjust the gap, and all because the gap is adjusted by oil pressure.

Hydraulic compensators, like shims, are located between the valve stem and the camshaft cam.

Externally, the hydraulics look like a small piston, so the head has seats for them.

Design and operating principle

The design of the hydraulic compensator itself is simple. It consists of a cylindrical piston, the bottom of which receives the force from the camshaft cam.

Inside this piston, a plunger is installed in its seat, through which force is transmitted through the piston from the cam to the valve stem (see photo above).

The plunger moves freely in its seat, providing a thermal gap.

The hydraulic valve works like this: when the engine is running, the cam runs up against the bottom of the hydraulic compensator piston and moves it down. While moving, the piston presses on the valve through a plunger, and it opens.

The gap is adjusted using oil.

The oil pump supplies working fluid to the head under pressure. In the hydraulics, it enters the space below the plunger and displaces the plunger inside the seat.

The higher the oil pressure, the more it will put pressure on the plunger and the more it will come out of its seat.

When the pressure decreases, the plunger enters the seat again. Thus, the thermal gap between the plunger and the valve stem is independently regulated and depends on the pressure in the lubrication system.

To prevent oil from flowing out of the hydraulic valve after stopping the engine, ball valves are installed in the oil supply channels in the cylinder head.

Having the advantage of no need for adjustment, the hydraulic compensator also has one significant drawback - high sensitivity to engine oil.

Is it possible to drive with knocking hydraulic lifters?

Many drivers are interested in the question of whether it is possible to drive with knocking hydraulic compensators and what consequences this can lead to. Let's answer it right away - it is possible, but it is not advisable, since the car will be plagued by a number of problems . In particular:

- loss of power;

- loss of control elasticity (the car will respond worse to steering);

- unenvironmental friendliness (unhealthy exhaust plume from the rear);

- excessive fuel consumption may occur;

- increased vibration;

- additional noise under the hood.

Accordingly, during the operation of a faulty engine there is a chance to “finish off” it completely. Therefore, it is strictly not recommended to drive with faulty engine components. After all, sooner or later it will fail. And the sooner you start repair work, the cheaper and easier it will cost you.

Main manufacturers

Of course, original parts and consumables, those installed at the manufacturer, are of higher quality and more reliable. Therefore, we must strive to maintain their performance. However, sometimes analogues are superior to the original.

Hydraulic compensators are manufactured by a variety of companies. But the Germans succeeded most in this. Hydraulic compensators from INA, SWAG, FEBI have proven themselves in reliable and long-term operation of a wide variety of engines. These parts are also produced by AE and AJUSA - they are also European, but, according to reviews, they have low quality workmanship. Elements can start knocking after just a few thousand kilometers. The main problem for all such parts is the danger of defects or low-quality raw materials. As a result, the friction surfaces quickly wear out - the hydraulic compensator knocks on cold and hot. Driving with such a malfunction is highly not recommended.

This is interesting: The cooling radiator is leaking - what to do, how to fix it

Knock is different, because the consequences are different.

How are these devices convenient? Because they perform their functions without requiring maintenance or special care.

You don’t have to think about them until you hear a certain, specific knocking sound from the hydraulic compensators.

Moreover, it can appear only at startup and disappear as it warms up, or it can continue all the time.

What happens when hydraulic compensators knock:

- the functioning of the plunger pair stops;

- the dynamic load on timing parts and components increases;

- fuel consumption increases;

- valve heads burn out with subsequent damage to the block head;

- noise occurs in the engine, making general diagnostics difficult;

- Acceleration dynamics deteriorate.

If you hear a knocking sound from the hydraulic compensators when cold, that is, immediately after starting and continues until the engine warms up, then the probable causes may be the following:

- The plunger valve allows oil to pass through when the engine is off.

- Narrowing of oil-conducting channels by pollutants. At the moment of start-up, the oil has a high viscosity and does not enter the plunger, which is why the hydraulic compensators knock when cold. When heated, the viscosity decreases and its penetrating ability increases.

- High oil viscosity. The knocking noise disappears as fluidity increases.

This phenomenon is not very critical, although it should not be ignored.

Often hydraulic valves knock only at the moment of start-up. This occurs because when stopping, some of the engine valves freeze in the open position and the plunger valve “bleeds” some oil. Well, what if the hydraulic compensators knock when they’re hot? Although the question is posed somewhat incorrectly. Let's figure out why the knocking appears when the engine starts and does not stop as it warms up. In this case, as in the previous one, there are several probable reasons:

- Poor quality oil initially or has not been changed for a long time. The knocking noise most often stops after an oil change.

- Malfunction of the hydraulic compensator itself.

- Oil filter dirty.

- The knocking of hydraulic compensators when hot occurs if the oil pump does not develop the required pressure.

There is another reason that, for some reason, appears on the Priora. A knocking sound in the compensators appears after replacing 5W40 oil with 0W40.

Troubleshooting methods

In specialized services, the cause of the knocking is determined using acoustic diagnostics. The same method allows you to identify a faulty hydraulic compensator, and there is always one. So is it possible to find it without resorting to the help of professionals?

Acoustic engine diagnostics

It is possible if you disassemble the motor. Of course, it does not need to be completely disassembled. It is enough just to remove the valve cover and try to push through each device. When pressing on the working hydraulic compensator, you have to apply some force. The faulty piston is the one that retracts when pressed lightly. There is no other way to identify a knocking hydraulic compensator.

It should be noted that if extraneous noise appears while the engine is warming up, it is not recommended to operate the vehicle. In this case, it is necessary to entrust the iron horse to the caring hands of professionals. If this is not possible, you can try to fix the problem yourself.

To do this, perform the following operations:

- the oil and oil filter are changed;

- The channels are washed to remove old lubricating fluid.

Recommendations for choosing oil

The brand of motor oil must be selected following the recommendations of the plant where the car came off the assembly line. But the seasonality of operation must also be taken into account. When the engine heats up, the viscosity of the lubricant decreases. To ensure the same lubricant characteristics, a thicker liquid is poured in the warm season, and a thinner liquid in the cold season.

Recommendations for choosing engine lubricants

If the knocking does not stop after the engine warms up, you need to check the filter. Over time, the filter element becomes clogged with foreign particles, which prevent the lubricant from penetrating the hydraulic compensators. In this case, it is necessary to replace the filter.

Pistons can knock when cold if low-quality lubricant is used, which contributes to contamination of the channels. This problem can be eliminated by removing the expansion joints and washing them in gasoline. The devices must be removed one at a time and then installed in the same sequence.

How to replace an element

If all the previous methods have been applied, but the desired results are not achieved, the knocking hydraulic compensator must be replaced with a new one. To do this, remove the valve cover, the sprocket from the camshaft and check the tensioner. Then they remove the bed and take out the pushers, strictly observing the sequence. They take out the compensators and lay them out in the same way.

Now you can start cleaning the lubrication system and the piston installation sites. After cleaning, new elements are inserted there, using a torque wrench to screw in. The last step will be installing the remaining parts.

Location of hydraulic compensators

A simple way to eliminate the knocking of hydraulic compensators

A simple and effective method that helps in most cases is to add a special additive, Liqui Moly Hydro-Stossel-Additiv, to the oil. This allows you to flush the oil channels, remove contaminants and restore supply to the hydraulic compensators. In addition, the composition helps to thicken the oil fluid, thereby compensating for the natural wear of hydraulic compensators. The additive is added to warmed up engine oil; full effect occurs after approximately 200-500 kilometers.

How else can you eliminate the knocking of hydraulic compensators?

- Replacement of hydraulic compensators. Advantages: guaranteed results. Disadvantages: expensive and time-consuming. It should be taken into account that for some foreign cars you first need to order parts, wait until they arrive and sign up for repairs at a service center. On most engines, replacing hydraulic lifters will require additional costs for disposable parts, such as gaskets or sealant.

- Thorough flushing of the oil system with special flushes, for example: Liqui Moly Oil-Schlamm-Spulung. Advantages: relatively inexpensive. Disadvantages: in any case, it improves the performance of the propulsion system, but does not always completely eliminate the knock.

- In advanced cases, it may be necessary to replace the oil pump or clean the engine oil lines with partial or complete disassembly.

Identifying faulty hydraulic compensators

In principle, it is not difficult to identify a knocking hydraulic compensator. It is enough to remove the valve cover from the car to gain partial access to them, which will be enough for checking.

To check the hydraulics, it is enough to use a thin wooden block.

The check is carried out by pressing on the bottom of the hydraulic valve. When force is created, it will begin to sink into its seat. When checking, it is important that the camshaft cam does not act on the bottom of the hydraulic valve.

A jammed hydraulic compensator will simply not be recessed into the seat by the created force; human impact will not be enough to overcome the forces of the valve spring.

If there is no oil in it for any of the listed reasons, the hydraulic valve will be recessed into the seat with significantly less force than when working normally.

POPULAR WITH READERS: Different compression in cylinders, what to do

Using this method, you can calculate broken hydraulic compensators.

What to do if hydraulic lifters are noisy?

The article is about what measures need to be taken if hydraulic compensators are noisy - the reasons for the knocking, methods for eliminating the problem. At the end of the article there is a video about what to do if hydraulic lifters are knocking.

If the gaps are not adjusted properly, then the valves in the timing belt will also close incorrectly, as a result of which they will burn out and a knock will appear. In addition, the size of the gaps may change if the timing mechanisms are heavily worn during operation. Since adjusting valve thermal clearances is a rather complex and responsible task, hydraulic compensators began to be used instead of levers and washers that require complex adjustments.

A hydraulic compensator (hydraulic pusher) is a small mechanism that automatically adjusts the thermal clearances of timing valves

, without any additional settings. This miniature mechanism automatically changes the gaps to the desired size under the influence of a spring and engine oil pressure.

How to identify a faulty element

Identifying a failed hydraulic compensator is quite simple.

With the valve cover removed, press it firmly. A serviceable element will hold the load, but a worn element will fail even under slight pressure. In the same way, it will fail and not compensate for the gap when the engine is running. Extraneous sounds are inevitable here.