20.09.2019

| (Votes: 2, Rating: 5) |

Issues discussed in the material:

- How to correctly diagnose valve knocking in an engine

- Why do valves knock in a cold, hot, or accelerating engine?

- What to do if engine valves are knocking

- What do car owners think about why engine valves knock?

The engines of new cars are so quiet that they are almost inaudible. Even under intense acceleration, only a faint, noble rumble comes from under the hood. However, with mileage the situation begins to change. Sooner or later, the sound of a running engine becomes unpleasant. Such a change in engine operation is evidence of valve wear. In this article we will look at why engine valves knock and what can be done in such a situation.

How to correctly diagnose valve knocking in an engine

Inexperienced motorists have difficulty identifying the source of the noise by ear. That is, there are a lot of components and mechanisms in the car, and only an experienced driver can determine which of them is the cause of the unusual sound. However, the knocking of valves still has its own characteristic features - namely, a ringing sound, as if metal is knocking on metal. The source in this case is located near the timing mechanism. Moreover, changing engine speed does not affect the sound in any way.

But even if it is possible to determine that the knocking comes specifically from the valves, then only very experienced car owners can accurately identify the cause of the malfunction. However, there is a certain diagnostic algorithm with which you can more accurately determine the cause of the problems that have arisen. You need to do the following:

- Open the hood and unscrew the engine oil filler cap.

- Listen carefully to the running engine. An increase in the volume of the sound without the cap is a clear indication that the valves are the source of the problem.

- A stethoscope, which should be placed closer to the suspected faulty part, will help determine the source of the noise even more accurately.

The main reasons why engine valves knock

Every self-respecting car enthusiast should know the reason for incorrect valve operation. Below we list the main ones:

- The size of the gap between the pushers and valves has changed . When assembling the machine, this gap is precisely adjusted. If for some reason it changes, then metallic tapping will definitely appear.

- Saving on fuel, that is, refueling at a cheaper price than indicated in the car’s passport . This is fraught with engine detonation, which will certainly affect the condition of the valves.

- There are situations when valve noise is heard only when accelerating or driving at high speed . This is how low oil pressure manifests itself in the engine lubrication system.

- If a knocking noise appears after replacing the timing belt, it means it was installed incorrectly . Also, the position of the belt may become confused and thereby disrupt the operation of the valves.

- One of the main causes of knocking is the normal wear of valves during engine operation . It can only be eliminated by replacing them.

Let's look at some of the reasons in more detail.

The main reason for knocking is an increase in the gap between the cams on the camshaft and the levers. Violation of the standard value of the gap leads to knocking of the cam on the rocker. As a result, a metallic clatter is clearly heard. The gap increases, and operation in this mode leads to accelerated wear and serious engine damage. The gap size is set at the factory. Some machine models have the same gap size, while for others this parameter is unique.

At the same time, reducing the gap also has a detrimental effect on the operation of the valve. That is, in this case it is likely to be clamped, and over time, incomplete closure will become permanent. Operating the engine with clamped or poorly closing valves entails an inevitable decrease in compression, as well as overheating of the power unit. There is a possibility of complete failure of the cylinders - from one to all. To prevent such developments, it is necessary to periodically adjust the gaps. It is optimal to do this type of maintenance once every 10–15 thousand kilometers.

However, it is not only incorrect valve adjustment that can cause a metallic knock in the power unit. During detonation, the external manifestations are very similar. Detonation is a miniature explosion inside a cylinder. When this happens, the shock blast wave affects the inner surface of the cylinders and other elements of the piston system. As a result, valve knocking may occur. In addition, during detonation, black smoke comes out of the exhaust pipe, engine power drops significantly, and it quickly overheats.

Many motorists are perplexed: why valves knock only on a hot engine. In this option, a combination of factors - high speeds with insufficient oil pressure - leads to incorrect operation of the valves. Typically, low oil pressure is caused by worn parts and large gaps between them.

For what specific reason the valves knocked in your case, this list will help you find out:

- Be sure to check the engine intake and exhaust valves. Make sure the oil pressure is correct.

- Why do valves knock on a cold engine? This is a sign of a worn tappet. If the tappets are dirty or leaking, the result is that the oil is not supplied to the valves in sufficient quantities. The consequence will be overheating of the motor and metallic knocking.

- If the oil pressure is normal, check the valve clearances. This is done using a specialized tool - a probe. To measure the gap, you need to place a feeler gauge of the required thickness in the gap between the rocker arm and the rod, the cam and the pusher. The exact measurement location depends on the motor design.

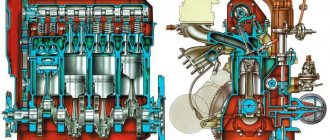

Brief description and principle of operation

The valves in the internal combustion engine serve to supply a mixture of fuel and air, as well as to release exhaust gases. The valve consists of a rod and a plate. The elements are located in the cylinder head. There may be two (sometimes four) valves in total. Inlet and outlet. For better filling of the cylinders, the diameter of the first is always larger. The valve opens thanks to the camshaft cams.

The latter rotates from the crankshaft via a chain or belt. Also, modern internal combustion engines use hydraulic compensators, which provide optimal performance in all positions. This ensures smooth operation and less noise.

Why do engine valves knock during acceleration?

The engine may knock while driving. If this happens, it is hardly possible to deal with it locally. The first thing to do is check the oil level in the power unit. Insufficient oil level may well be the cause of damage that causes the knocking noise. It is necessary to replenish the oil level to normal as soon as possible. It is likely that this simple action will help eliminate knocking in the power unit.

Then you need to find out whether the knocking occurs under load, that is, when the car is moving. Listen to how much it grows when the car accelerates. If both symptoms are present, then the likely culprit is the crankshaft bearings. You should not operate a car with such a defect, otherwise you can provoke a complete engine failure. Which will ultimately result in expensive repairs.

We recommend

“How to properly turn off a car engine: some useful tips” Read more

Often, knocking in the engine occurs due to refueling with low-quality fuel. This knock will fade over time. It is unlikely to be dangerous to the engine. If the knocking does not die out, you need to listen more carefully to the sound of the engine. The most dangerous thing is when the intensity of the knocking increases - in this case, further operation of the machine can definitely result in serious damage.

Why do hydraulic compensators fail?

This can happen for several reasons:

- Natural wear and tear. Typically, such elements become unusable after a mileage of 200 thousand kilometers.

- Using poor quality oil or oil of improper viscosity. Such a product must meet all standards. Otherwise, valve knocking may occur, since the hydraulic compensator will not cope with its task.

- Clogged plunger head or oil passages. This happens when the oil filter is not replaced in a timely manner. As a result, the pressure decreases, lubricant does not enter the system, sometimes the plunger gets jammed in the body and the hydraulic compensator stops working completely. This problem can be solved by

What to do if engine valves are knocking

The easiest and fastest way is to have it repaired by professionals. However, not everyone can afford to pay for their services. Therefore, you have to figure it out and solve the issue yourself. There are motorists who are interested in repairing their car with their own hands. There are also people who accumulate experience in self-repair for some purpose.

If valve knocking is a problem in your car and you have to repair it yourself, be prepared to do some serious work. Seriously and carefully, because if you make a mistake, the sound will only become stronger. Therefore, it is not recommended for a novice motorist to eliminate valve knocking. The sequence of actions is of great importance in this type of repair. First of all, it is recommended to study the repair manual for a specific car brand. Next you need to follow the algorithm:

- Engine oil is drained.

- The cylinder head plug is unscrewed. This will clear the way to the valves.

- The camshaft must be rotated until the mark on the pulley and the unit match.

- Determine the gap between the rods and valves by touch. The size of the gap can be changed using an adjusting washer.

- Depending on the specific car model, you need to turn the washer the required number of revolutions.

- Reassemble everything in reverse order and then check if the valve knocking has gone away.

Each car model has its own operating characteristics. But on average, every 25 thousand kilometers you need to adjust the valve clearances. The number of valves directly affects the noise level when they knock. The more valves, the louder the noise will be in the event of a malfunction. There is an engineering solution to the problem - some cars use hydraulic pushers to accurately maintain valve clearances.

Timing valves require preventive maintenance. It consists of periodically cleaning their surface from the deposits that have formed. Carbon deposits can reach a thickness that makes it difficult for the valves to operate properly. Therefore, you should not forget about their periodic cleaning and grinding. Careful implementation of preventive maintenance will extend the life of the engine and even slightly reduce fuel consumption.

We recommend

“Cleaning fuel system injectors: choosing products for gasoline and diesel” More details

If self-adjustment of the valves does not give a positive result, then it is better to contact a professional service station. Setting the gap yourself in this case is hardly possible. Sometimes the cause of valve knocking is completely different faults. But it is also possible that the valve clearances are set incorrectly.

Other causes of engine knocking

- The gasoline pump drive may make a loud metallic noise . It can easily be mistaken for the sound of faulty valves.

- Diesel engines have a fuel pump that creates high fuel pressure . Its knock is also loud, but half as often as one engine revolution.

- Connecting rods can also knock due to worn bearings . Each car model will sound unique. You can accurately determine a faulty connecting rod by turning off the cylinders one by one. If the sound disappears when one of the cylinders is turned off, the problem is in the connecting rod. Often, the knocking of connecting rods only appears when the engine speed decreases. This malfunction can only be eliminated by overhauling the engine.

- Subaru and Toyota cars are characterized by weakening of the crankshaft pulley . The reason for this is the loosening of the fastening nut. This defect is almost always manifested by oil leakage.

- After engine repair, a knocking sound may also appear.. This is often due to a poorly fitting cylinder block gasket. Its protruding edges prevent the piston from making its stroke. Naturally, this knock does not depend on the speed. It is barely visible against the background of the engine.

- There is another reason for knocking with a frequency that is half the engine speed . These are hydraulic compensators. When the lubrication system is clogged, the oil is dirty or does not meet the required characteristics, a knocking noise appears on a cold engine. As the power unit warms up, it disappears.

- Diesel units have another source of knocking - plunger pairs . However, this type of knock is not dangerous; the car can be operated with it.

We can conclude that there are many reasons for engine knocking. After all, this is a complex mechanical system. As soon as one setting goes wrong, the gap is broken, the geometry of the part changes, and uncharacteristic sounds may appear. This is why it is so difficult to independently determine the cause of knocking in the power unit. For example: why do engine valves knock only under load.

Knowledge of the principles of operation of a car engine and the results of engine observations help to establish the exact cause of the malfunction. Let’s assume what the thermal state of the engine is at the time of knocking, whether there is a load, what the speed was when extraneous noise occurred. Every nuance plays a role in determining the technical condition of the engine.

Car owners about why engine valves knock

Question 1:

“This happened to me: the valves were slightly pinched, due to my carelessness. After this, a noise appeared, barely audible. I decided to fix this and loosened the gaps to the required size. As a result, on a cold engine the knocking has almost gone away. On a hot engine, the central valves knock very clearly. The gap was adjusted using a feeler gauge. The gap was set so that it was difficult to insert the probe into it.

I now suspect that when heated, the cylinder head or camshaft bed changes its size. As a result, the valve clearances also change. After all, there is no knocking on a cold engine. Random pinching of the valves helped to identify the optimal gap size for those valves that, after increasing the gap, on the contrary, rattled. Has anyone encountered anything like this?

How to Replace a Worn Rod Seal

It is often possible to replace worn rod seals without removing the cylinder head.

Some shops fill the combustion chamber with compressed air to hold the valve in place while replacing seals. You may not have compressed air at home, but you can use a flex cable or similar soft, thick cord instead.

- Place the transmission in Park (automatic) or Neutral (manual), and set the emergency brakes (Handbrake).

- Remove the spark plug from the cylinder you need to work on.

- Rotate the piston you will be working on to BDC (bottom dead center). Rotate the crankshaft using the socket and jumper on the front crankshaft bolt. If necessary, remove all spark plugs to make it easier to turn the crankshaft.

- Fill the cylinder with about 5 feet of cord. Use a large screwdriver to push the wire through the spark plug hole. The end of the cord should hang in the spark plug hole after filling the cylinder so that it can be pulled out later.

- Raise the piston to TDC (top dead center) by turning the crankshaft by hand. This allows the cord to press against the valve and hold it in place.

- You can now use a spring compressor to replace the valve seal.

- Install a new seal.

- Reinstall the remaining components.

- Turn the piston towards bottom dead center and remove the cable.

If necessary, consult your vehicle's repair manual.

A dirty spark plug due to oil leaks can cause a misfire.