The Chevrolet Niva SUV (VAZ 2123) has established itself as a reliable car, especially in our off-road conditions. The basic equipment is provided by engines from two manufacturers: Opel Z18XE (1.8) and VAZ-2123 (1.6). There were no particular complaints about the Opel engine, which, unfortunately, cannot be said about the domestic one.

Thanks to increased modernization, the new Chevrolet Niva engine received, instead of standard adjusting screws and bushings, so-called “guide bushings” - plunger pairs of hydraulic compensators built into the cylinder head.

On Chevrolet Niva cars, hydraulic compensators (HC) of the SOHC type are installed on the engines.

It happens that on domestic engines, hydraulic compensators begin to work intermittently, thereby causing a lot of trouble to their owners.

Why do they replace hydraulic compensators with bolts on a Chevrolet Niva?

By replacing the adjusting supports in the Chevrolet Niva engine with hydraulic compensators, the engineers hoped to eliminate all the problems with adjusting the thermal clearances of the valves and reduce the noise level ; in fact, it did not work out as desired. The quality of hydraulic compensators is so unstable that out of a dozen parts, only one or two can work tolerably and according to the parameters. Naturally, this affects the operation of the engine - constant knocking under the valve cover, the engine trembles, constant failures and difficult starting.

Hydraulic compensator and adjusting bolt.

And that's not so bad. An inaccurately executed hydraulic compensator can bite and prevent the valve from closing in time . If this happens at high speeds, the valve inevitably meets the piston. What this threatens is clear - at least a bent valve, which means loss of compression and misfires. The controller immediately sees the malfunction and simply turns off the injector to save the catalyst. The engine stalls, seemingly for no apparent reason. Even in those engines where there are grooves in the piston bottom and the meeting of the valve with the cylinder is theoretically impossible, the valve does not close completely, its edges burn over time and the story with compression repeats itself.

Video about the difference between engine operation on hydraulic compensators and bolts

Reasons for replacing hydraulic compensators with bolts in a Chevrolet Niva

When the design features replaced the adjusting support in the Niva Chevrolet engine with a hydraulic compensator, the engineers were tasked with adjusting the thermal clearances of the valves, which at the same time should reduce the noise level. In the end, the result was not as expected. The quality indicators of hydraulic compensators turned out to be unstable. And this feature affects the operation of the motor. Alarm signals include: knocking under the valve cover, engine tripping, failures, difficulty starting the car engine.

On top of this, inaccurate installation work leads to such a problem that the valve cannot close in time. If this happens at high speeds, the valve inevitably meets the piston. And this leads to valve deformation, which in turn causes loss of compression and the risk of melting. The control system sees the error and turns off the injector to save the catalyst. The motor system begins to trip for no reason. In some engines, there is a surface area at the bottom of the piston that prevents the valve from meeting the cylinder. The valve stops closing completely, its edges burn, and over time the pressure in the cylinder returns. Bolts instead of hydraulic compensators are the most suitable option for the Niva.

If a characteristic valve knock is observed when the engine is warm, then an ordinary oil change is not enough. The work ahead involves removing the “head” and camshaft with further cleaning of the channels. If this work does not bring positive results, the hydraulic compensators will need to be replaced.

What is needed for replacement

The most unpleasant stories happened with hydraulics before July 2008. Then the plant began installing imported compensators, but also changed the head design to accommodate them.

It is not possible to install new compensators in old heads.

There is only one way out - replacing the hydraulic compensators with the good old classic adjusting bolts, the same as on classic VAZs. So to replace we need this classic set :

- locking plates , 4 pieces, article number 2101-1007078 ;

- eight adjusting bolts with article number 2101-1007075 ;

- nuts and bushings should be included with the bolts ( 2101-1007076 and 2101-1007077 );

- load springs , 8 pieces, article number 2101-1007117 .

Set of adjusting bolts with springs and locking plates.

In addition, you will have to buy the old-style 213 camshaft, article number 21213-1006008 . This shaft has a different form of working cams, which is designed to work with supports. In addition, with it the engine will become a little more responsive. And to adjust the thermal gap you will need a 0.15 mm feeler gauge . The tools that will come in handy are the emergency kit and nothing else.

Niva hydraulic compensators, a bit of theory

What exactly is a hydraulic compensator and why is it needed in the engine? The valves have a thermal gap. You can “choose” it in two ways. The first way is mechanical adjustment. Either with washers, as on the “eight”, or bolts, as on the “classic”. The second way is to install a hydraulic compensator between the camshaft cam and the valve.

Oil is supplied to the hydraulic chamber under pressure, and thereby the valve clearance is selected. But there is one thing, BUT. For high-quality operation of hydraulic compensators, a certain oil pressure is required. According to German documentation, at least 1.5 kg at idle. On our classic engine, normal pressure at idle is 1.2-1.5 kg.

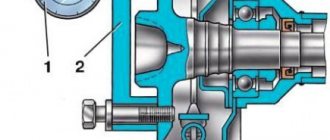

But we hung a hydraulic chain tensioner and eight hydraulic compensators on our oil pump. The system is working at its limit. Let me remind you that the design of the pump remains from a penny and has a performance designed for a 1.2 liter engine. Shown in the photo. 1 – old-style hydraulic support, 2 – new-style hydraulic support, 3 – new-style hydraulic support cup.

old and new hydraulic guides

Scheme of a 5-speed gear shift mechanism VAZ-2123

At the factory, modern Niva cars are equipped with a five-speed gearbox, made according to the three-shaft type.

Gearbox design:

The main elements of the box body are the clutch dome, the gearbox housing itself and the rear cover. The production of frame parts is carried out at the plant from a modern aluminum alloy with chemical additives.

Heat removal from heated rubbing parts is realized by manufacturing a multi-fin structure on the surface of the crankcase and also to protect the speed selection unit from overheating and exceeding excess pressure, a breather is present in the design.

The tightness of body connections is ensured through the use of pressed shaped gaskets. In case of repair of the gear selector assembly, it is also possible to use a liquid gasket former. The lower part of the gearbox housing is covered with a stamped steel protection with a gasket.

In a modern design, the gearbox housing and synchronizer clutches are reliable and adapted to operating conditions on Russian roads.

The factory crankcase protection on the Chevrolet Niva copes with its function quite well. For safe travel on rural roads and off-road, you can consider installing additional combined protection for the gearbox and transfer case. There are many different options and designs offered on the Internet, where you can choose the option you like, both in price and in terms of configuration and quality of metal.

Over time, any mechanism wears out, sooner or later it will be necessary to carry out maintenance and adjust the gear mechanism. There are quite a lot of companies on the spare parts market that produce any components, parts and related materials for both old and new Chevrolet modifications.

Interesting! According to reviews from the owners of these cars, you can carry out maintenance and repair of the gear shift mechanism on a Chevrolet with your own hands at home.

Location of control and drainage holes:

- a control hole is made for ease of oil change in the upper left part of the crankcase housing;

- the technological hole for draining used oil remains unchanged at the bottom of the frame.

It is equipped with a screw-on magnetic plug to collect small metal shavings. Lubrication of rubbing surfaces is carried out by spraying. Domestic oil seals are installed in the housing at the output of the primary and secondary shafts. The axis of the gearbox speed gear is fixed on the rear cover of the gearbox housing.

The rotation of the input shaft is carried out through 2 ball bearings. For the industrial shaft, the design of the unit includes double-row ball roller bearings.

A breather is installed in the upper part of the housing (near the clutch). If the breather malfunctions (cap failure), transmission oil may be squeezed out through the seals and housing connections.

The gearbox uses a three-shaft system. At the moment of turning on any of the speeds, except the fifth, the intermediate shaft transmits torque to the secondary one.

The arrangement of the shaft gears is implemented in the following sequence:

- toothed gear of constant mesh with the input shaft;

- III;

- II;

- I.

Advice! The manual transmission of the VAZ 2123 is quite “gentle”; overloads should not be allowed; it is recommended to change the oil without waiting for a mileage of 45-50 thousand km.

How did I buy shnivy in Nizhny Novgorod, or sold the harness. main auto forum

prehistory

, the mother of one of my lady friends ordered shnivy for herself in Nizhny Novgorod. The act in itself is twice reckless - shnivy, and even in Nizhny Novgorod, brr))) but what’s done is done. Today they were invited to prepare documents and inspect the car. They called me - “just in case”, as a balanced person who understands cars and can protect them from selling any tripe. I’ll say in advance - they called me for a reason) I heard a lot of “good” things about this office - today I saw it personally.

Previously, we managed to find out that over the phone, ORAL!!! And a preliminary contract for the supply of a car was concluded in writing, in which this car itself was listed - without any “extras”.

arrived at the Sormovsky turn, to the sales consultant Anton Shirshitskikh. They asked to show the car - no problem, although it was not parked on the street, but in a darkened box. But they didn’t seem to find anything criminal. By the way, the car is absolutely “naked”, from the factory: no anticorrosive, no protection, nothing. Let's go register. But I must say that we decided to abandon the anticorrosive agent because we had to install a signaling system first, otherwise you’ll get covered in this shit. Well, they also found the religni cheaper, they are easy to install there, so there was no point in overpaying either. So the final list of extras that we were set on was protection and mats.

And this is where things started to get interesting. The order was printed out for us with a list of special features, for signature. Well, here I tell Anton that we will make some changes here right now, namely, we will eliminate everything except the rugs and protection.

Also interesting: Do-it-yourself Niva 2121 elevator: drawings, dimensions

him: Everything has already been written out, received from the warehouse, I can’t cancel anything. I: Why can’t you? return it to the warehouse. Nothing has been installed on the machine yet anyway - The machine is already in operation - but we haven’t ordered anything yet, how could it get into production? - you voiced over the phone that you also needed roof rails and anticorrosive - yes, you did, but we changed our minds, and now we only want protection and mats. Or we can stop wanting this too - you can’t sell a car without additional equipment - you can - that’s one thing, we take protection and mats - that’s two - why don’t you want roof rails and anti-corrosion? — because we will install the roof rails ourselves for less money than you, and we don’t see any point in doing anticorrosive yet. First, let's inspect the car - perhaps the factory one will be enough. - no, you don’t understand, you can’t do anticorrosive on a dirty car, it should only be done on a new one, before it’s covered in dirt, and if you drive it even a little, it will get dirty and you can’t do anticorrosive. — Anton, they wash it before anticorrosive treatment is done. - not a single company in NN (!!!) will do anticorrosive for you on a new car - thank you, we don’t need anticorrosive. - Why don’t you want railings? - because they cost too much for you.

in response, we are printed with a piece of paper in which the price for them is 8,500 instead of the original 9 thousand. - will it suit you? - no, it won’t suit me, I’ll buy these railings in the store for 6500, are you ready to sell them for that amount? - no, I’m not ready, they cost 8500 here - then we’ll cross them out too. - well, you promised!!! — where is the document in which this is recorded? - Here! you promised on the phone! Next time (bug, who will come to you again) we will formalize all agreements with you in writing!!!

These bagpipes started to stress me out. Please call his manager. It was promised that he would come right now. We sit. Anton is also sitting, calling the phone a couple of times, poking at the computer.

Me: - Well, where is the leader? he: - just a minute, he’ll come over now - Anton, let’s not do nonsense and waste your and our time. We take protection and mats, we don’t need anything else, start processing the documents.

Apparently realizing that there is nothing more to catch, he begins. True, having first asked, “Are there really no more changes?” - exactly!! apparently this time my word turned out to be more significant than the pieces of paper - again, without signing any documents with the buyer of the car, the manager got to work)

bottom line: if you want the seller to decide for you what you need and what you don’t, and also shame you by not keeping his promises - welcome to Nizhny Novgorod))

and I still have a second series waiting for me - acceptance of the car. So I think we need to demand that we put it on a lift - we need to check how well the protection is screwed on))

and then, when one local user gets a warranty repair on his car, and if he allows it, I’ll tell you about another wonderful NN dealer, the Sollers company, which also knows how to screw up its customers pretty well.