12.02.2021

| (Votes: 1, Rating: 5) |

Issues discussed in the material:

- Actions of drivers that lead to steering rack failure

- Signs of a broken steering rack

- Diagnosis of steering rack faults

- Possible actions if the steering rack breaks

- Change or repair the steering rack

- What car enthusiasts say about steering rack failures

A situation where the steering rack breaks in a car is not uncommon, but an even more common scenario is the failure of adjacent parts. Therefore, it is necessary to conduct a thorough diagnosis to find the true cause of the problems.

Once it turns out that the rack is definitely to blame, the car owner has two options: repair or replacement. In our article we will tell you what is the most appropriate thing to do, and also analyze the causes and signs of a broken steering rack.

Actions of drivers that lead to steering rack failure

When the vehicle is running, the steering rack experiences significant stress. By 100,000 kilometers, you can expect the first faults to appear in it, which can be eliminated by replacing or restoring the corresponding parts. Such problems can be prevented by knowing and following the operating rules of the machine, avoiding common misconceptions that lead to steering rack failure. Let us carefully analyze the causes of problems with this unit.

- Incorrect and incorrect service

Not every car owner knows about the need to service the steering rack. Paying attention to the brake pads and promptly changing the engine and transmission oil, they completely lose sight of the steering rack. Meanwhile, you should have it repaired immediately if turning the steering wheel is accompanied by a hum or knocking noise.

Good care of the rack is difficult to achieve in a garage, so we recommend using the services of specialized organizations. It is short-sighted to spare money on quality service, because troubleshooting and restoring the steering rack, or even a complete replacement, will require much greater costs.

- Control of smudges

The functioning of the steering rack is impossible without a special hydraulic fluid that serves to lubricate the moving parts and create operating pressure. If oil smudges are found under the car in the appropriate place, this is a signal that the steering rack is probably broken. Therefore, you need to periodically inspect the place where you park your car. If oily traces are detected, it is wise to contact a service station as soon as possible to diagnose and repair the steering rack.

While operating the car, you should listen carefully to see if any extraneous sounds appear. The presence of knocks when overcoming bumps or a hum when turning are signs of the need for repairs. It is not recommended to postpone the latter, because using a machine with faults only increases the cost of further repairs, as well as its complexity.

- Parking with wheels turned

A dangerous habit of drivers is to leave a car in a parking lot with misaligned wheels. If the vehicle is left in this position for a long time, the hydraulic power steering and steering rack are damaged due to high pressure in the system. During frosts, the negative impact of such parking increases. Low temperatures cause hydraulic oil to thicken. During subsequent driving, the steering rack is poorly lubricated, which significantly reduces its service life.

Hence the recommendation for drivers to leave the car in the parking lot only with its wheels aligned. This is a good measure to prevent damage to the steering rack. A simple technique that can reduce the number of malfunctions with the machine and allow you to save on expensive repairs.

According to the experience of experienced motorists, the steering rack does not like dynamic starts and strong vibration. If you need to drive on bumpy roads, you should do it at low speed, this is the only way to minimize the likelihood of a malfunction of the steering and suspension system. When starting abruptly, all components of the car, including the transmission and engine, suspension, CV joints and steering rack, experience increased loads.

Defective parts

The parts of the disassembled rack must be wiped of oil, cleaned of deposits and carefully inspected. Repair kits usually include only rubber seals and fluoroplastic bushings with rings. This may not be sufficient for every case.

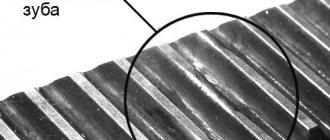

Carefully inspect the surface of the gear rod - there should be no damage or signs of wear. Pay special attention to the working area - the teeth and the part of the rod that comes into contact with the rings, seals and bushings. Any damage, corrosion, risks and scuffing will lead to rapid wear of the seals and rack leakage.

Deep corrosion of the rack rod. Such a detail cannot be installed.

There should be no cracks, nicks, chips or deep wear on the helical teeth of the drive shaft gear. It is dangerous to install a shaft with such damage - the rack may jam in motion.

A common cause of knocking noises in the rack is wear of the pressure bushing. The working surface of the part must be smooth, without signs of pressing or scoring. The pressure bushing is usually not included in the rack repair kit, but for many cars it can be purchased separately.

Wear of the pressure sleeve - the fluoroplastic insert is pressed through

Severely worn and damaged rack parts cannot be restored in a garage. If problems are found during troubleshooting, contact specialized service stations for help. There they can restore the rack shaft and rod using professional equipment.

Signs of a broken steering rack

Modern cars are equipped with electric power steering (EPS) or power steering (power steering). The steering rack in both mechanisms has similar problems, but there are also nuances. Therefore, we will pay attention to each mechanism.

- Power steering rack problems

Signs of a power steering rack failure are related to the hydraulics - the pump and the working fluid. How to understand that the steering rack is broken? The following signs will help with this:

- Increase in the required effort to drive a car. This is otherwise called a “heavy” steering wheel. That is, previously it was possible to turn the steering column with almost one finger, but now it requires more serious effort.

- Constant leakage of hydraulic fluid from the expansion tank. This can be determined both by the indicator glowing on the dashboard, and by oil stains where the car is parked, and traces of oil on parts under the hood.

- Movement with a thud. The noise is most pronounced when overcoming uneven sections of the road.

- Significant noise when turning the steering wheel. An increase in the angle of deviation of the wheels from the normal increases the hum, while the direction of rotation does not matter. Often, along with the noise, there is a slight vibration of the steering wheel.

- After turning, the steering wheel either does not return to its starting point at all or does so very slowly.

- When driving in a straight line, the front wheels do not maintain direction, which causes the car to wobble.

- Electric power steering rack defects

We recommend

“Knocking in the steering rack: looking for the cause, dealing with the consequences” More details An

electric power steering rack is subject to the same malfunctions as a hydraulic one. Only transmission oil leaks are impossible. A breakdown of a rack equipped with an ESD usually manifests itself as follows:

- knocking sound when turning the steering wheel;

- steering wheel jamming;

- the steering wheel rotates with unequal force;

- spontaneous rotation of the steering wheel;

- “red steering wheel” indication on the dashboard.

Thus, you can understand that the steering rack is broken based on general signs, regardless of the strengthening mechanism. EUR is especially afraid of contact with water. Moisture is dangerous if it gets on the rod or mechanism control unit.

Rail assembly

Assemble the rack in the reverse order of disassembly. Lubricate the parts with power steering oil before installation to prevent scoring on the bushings.

Insert fluoroplastic rings and bushings into the rack body carefully - the material is fragile and can burst from impacts or great force. For accurate pressing, you can use a socket head and an extension of a suitable size from a set of keys.

After installing the gear rod, center it according to the marks made before disassembly, then insert and screw the drive shaft.

Insert the pressure sleeve and washers into the socket, tighten the adjusting nut the required number of turns and turn the mechanism by hand several times from lock to lock (you need to rotate the drive shaft). If the rack is assembled correctly, the gear rod should move easily, without jamming. Tighten the adjusting mechanism locknut.

Tighten the tie rods and install the boots, crimp them with special clamps.

Important: do not use plastic ties instead of clamps, they do not provide reliable compression of the boot, moisture will get inside the rack, the rod will rust and damage the cuffs. The rail will leak.

Diagnosis of steering rack faults

It also happens that motorists turn to the service specifically to repair the steering rack after hearing a knock. However, diagnostics show that the cause of extraneous sounds and other symptoms of a malfunction lies in a completely different place. Namely, the defect may be in the ball joint, support bearings, steering rods and ends, suspension arms and other chassis elements. You can understand that it is the steering rack mount that has broken before calling the service using several tests:

- With the engine not running, open the hood, stand near the open driver's door and turn the steering wheel from one extreme position to the other, listening to sounds.

- Sit in the car and pull the steering wheel with both hands already closed, checking whether there is feedback to the control during a knock and how interconnected it is.

- With the engine running, turn the steering wheel to the extreme right position, then slowly move it to the left. The goal is to check the noise at extreme points or when changing the direction of the applied force.

- Assess whether there is knocking on the steering wheel when driving over small bumps. It may well turn out that they arise in another place. Such simple diagnostics may well help to identify imaginary damage to the steering rack and thereby save a lot of money.

- Inspect the steering rack mechanism for oil leaks, loose fasteners, pull the rods to determine the play.

If the knock does not reach the steering wheel, the fault should not be found in the rack. The absence of knocking at the end points of wheel rotation also indicates the absence of damage to the rack. However, the possibilities for independent troubleshooting of this unit are very modest. And when contacting the service, the driver in most cases will still hear that the problem is in the rack. After which the mechanics will begin to diagnose and repair it. This is due to the high cost of this type of repair, which leads to a certain abuse.

Mechanism repair

Since the steering rack has a complex structure, auto repairmen rarely disassemble it and repair it. It is much easier to buy an assembled spare part and install it on the car.

Today on the market there are original auto parts and cheaper analogues. Car manufacturers recommend installing only original parts, as they fit perfectly into all car systems. But the experience of car enthusiasts says that similar spare parts also last a long time. The main thing is to choose a good manufacturer. This can be done by reading reviews on the Internet or asking advice from an experienced car enthusiast.

Do not forget to periodically change consumables - bushings, oil seals, boots. Periodically inspect the bottom of the car; if there are cracks or leaks, immediately buy a repair kit. This will extend the life of the entire device.

A thrifty and careful driver may not even think about the steering rack throughout the entire period of owning the car. Therefore, it is worth following simple operating rules: avoid potholes, slow down before bumps, and if you have the first symptoms of breakdowns, immediately contact a car service center. Then the device will serve you for a long time.

Steering malfunctions in most cases should only be repaired by specialists, since careful adjustment of the control unit is required. According to traffic rules, operating a car with a faulty steering wheel is prohibited. And there are few brave souls who dare to drive an uncontrollable car.

Possible actions if the steering rack breaks

Most steering rack repairs occur in specialized workshops. After all, even dismantling this unit is not easy. But it is quite possible to eliminate some minor defects on your own. Among them:

- Replace damaged rubber boot. If detected early, when a seal leak has not yet led to a malfunction of the steering rack, it is quite possible to replace it yourself. All you need is a garage with a pit. It is recommended to thoroughly clean the parts under the rubber from dirt.

- Remove hydraulic fluid leaks. To do this, you need to drain the power steering oil and change the hoses, preferably all at once.

- Replace tie rod ends. The wear of the ball pins in them resembles the symptoms of a problem with the steering rack - knocking and play in the steering wheel.

- Replace the worn-out crosspiece on the steering column shaft.

- Adjust the tension or replace the hydraulic pump drive belt. Slipping of this belt negatively affects the operation of the power steering and makes it difficult to rotate the control.

The rack is designed in such a way that it allows adjustment of the gaps between the gears in the transmission unit. Therefore, minor wear can be eliminated by simply adjusting the adjusting screws. But you shouldn’t do this yourself. The operation requires precision; you need to leave at least minimal gaps, otherwise you will only speed up the moment when the steering rack breaks.

If the source of the knock is located inside the rack housing, it is unlikely that you will be able to solve the problem on your own. Of course, unless you are a professional auto mechanic. The most common problems that occur inside the steering rack are:

- wear of the teeth of the steering shaft or gear;

- bearing wobble;

- leakage of seals;

- ring production of cylinders and bushings;

- a change in the geometry of the shaft or rack as a result of an impact or a wheel falling into a deep hole.

Some of these faults can be eliminated using repair kits using the services of a service station. But it is better not to change the parts of the gear mechanism separately, but simply install a new steering rack.

Choosing the right master

A good master is the key to a long service life of the repair rack. You shouldn’t go to untested guys who seem to be doing the repairs, but apparently not! Even with high-quality spare parts, there is no guarantee that the rack will last long after they are repaired.

It is advisable to go to certified service stations, or to those who are classified as only repairing racks. As a rule, in large cities there are about a dozen such firms.

NECESSARILY! We ask for a guarantee on the work before repairs, if they don’t give it, or they give it for a week or two, then we simply refuse! The warranty should be at least 6 months, preferably more. At serious stations they will offer you repair kits that they have been working with for a long time.

I WILL SAY THIS - the longevity of your unit depends on the right technician, because if you install even one oil seal incorrectly, the rack will begin to leak within a few days. So don’t see yourself doing handicraft work, it will come out sideways.

Change or repair the steering rack

Replacing the steering system from official dealers is very expensive. Therefore, many car owners prefer to install this unit from third-party manufacturers. They are attracted by the significantly lower cost. At the same time, such non-original spare parts from some manufacturers are made of quite high quality. They have a service life comparable to the original steering racks.

Some, in pursuit of savings, choose the cheapest or refurbished mechanisms, but such a steering rack can break after 3-6 months of use.

Also on sale is a repair kit consisting of a set of anthers, oil seals, bushings and other parts.

It is more rational, of course, to delegate the restoration of the steering rack to a well-established service station. After all, performing such work requires the skills and experience of the performers. A significant contribution to the reliability of the steering rack in the future is made by the quality of the repair kit that is planned to be installed.

What is included in the repair kit and what is its cost?

A repair kit or repair kit is a set of oil seals , guides, plugs, plastic parts, etc., it can differ significantly from the model and device. For example, a repair kit for an electric power steering differs significantly from a power steering; there are generally few seals in the electric booster, because practically no oil is used there. A short video.

The cost also varies significantly, from 1,500 rubles to 5,000 rubles. It all depends on the manufacturer and quality. I would like to warn you against low-quality Chinese spare parts - I personally saw when a repair kit could be bought for 500 rubles, I don’t know who the manufacturer is, I think the quality is appropriate! Thus, after repair, such spare parts will not work for long, and you will again need to go to the service station and spend money on removal and assembly - disassembly, remember - the stingy pays twice. Therefore, you need to take only high-quality spare parts (repair kits); sometimes it is better to look towards original parts.

Separately, it is worth thinking about the shafts or rods; if they are badly damaged by corrosion, then they need to either be completely changed or sent for grooving in order to “stuff” the so-called mirror. However, the masters must be of a high level.

What car enthusiasts say about steering rack failures

- Symptoms of the malfunction “The knocking sound of the rack is heard when driving on a road with small potholes and only when the music is turned off. I drove 40 thousand kilometers with such a rack, it would have continued to work, but I replaced it due to the expiration of the warranty.”

- Replacement or Repair

“The original rack is also unpredictable. If it has been in a warehouse for a long time, then there is a high probability of leaks. That's why I'm in favor of repairs. A year ago I turned to a good professional service to replace the bushing and seals. After the repair everything works without problems.” - Consequences of ignoring the problem

“No special troubles can be expected. Only over time the knocking will intensify. Eventually you’ll get tired of listening to it, and you’ll repair or replace the steering rack.”We recommend

“Tie rod knocking: causes, diagnosis, replacement” Read more

- About the need for urgent repairs

“I encountered a knocking sound in the rack, but the steering wheels and tips did not cause any complaints. I had to take it apart many times. I determined that the knocking came from the rack and steering shafts. I tried to remove the gap between the splines, change the position of the rack, and tighten the locknuts too much. But I did not achieve a positive result. I bought a “contract” mechanism at a car disassembly, and it turned out to be a knock too!” - Service intervals

“Once every 30,000 km, the fasteners need to be tightened or adjusted. Without such care, the rack will wear the most when the steering wheel is in a straight position. If it suddenly starts knocking when the wheels are in a straight position, the problem can be eliminated by tightening it. But in extreme turning positions the steering wheel will bite. With periodic maintenance, snacking can be avoided.”

Is it possible to buy a used rack and get by at low cost?

Another option for a potentially inexpensive solution to the problem is to purchase a used mechanism from disassembly. This makes sense if you have a good friend at the disassembly who will not let you down. There can be a lot of problems in this case, and we should not forget about the entrepreneurial spirit of Russian sellers of spare parts, especially in the used segment. The more you try to save, the more potential difficulties you will attract into your life. And this is also important to remember, otherwise there will be problems in operating the machine.

So, used steering racks have a number of problems:

- they are often tightened using simple methods to demonstrate to the buyer that there is nothing knocking or play in the device; after a couple of kilometers the knocking and other troubles will return;

- cars that have traveled more than 350,000 km and are at the end of their useful life are being dismantled; in this case, the steering mechanism is already on its last legs and can die at any inopportune moment;

- often the device lay in a warehouse for a long time or stood together with the machine on the street, which caused corrosive changes, drying out of seals and other defects in the equipment;

- it is quite possible that they are selling you a poorly restored rack; many sellers of used spare parts buy old mechanisms, restore them using cheap spare parts and sell them;

- It is almost impossible to check the device at the time of purchase; this increases the chance of purchasing low-quality equipment, which will soon require replacement.

If you decide to save radically, then it is better to simply change the car in which the rack is knocking. Of course, if we are talking about a budget car from AvtoVAZ, you can buy a new device from the factory and drive it another 90-100 thousand km without problems. The cost of domestic slats is not so high as to save money on them and risk your safety. But for any foreign cars the cost of such equipment will be very high. So you will have to make some informed decision and spend money, or sell the car to buy another.

Steering components

Automakers use a standard steering design that has remained largely unchanged since 1898. The differences lie in the location of the steering wheel (right or left) and the type of power steering used (electric or hydraulic). The production of cars with an “empty” steering rack, not equipped with a power steering, has practically ceased, and also recently, automakers have been moving away from the practice of using power steering, preferring an easier-to-maintain and more economical electric power steering.

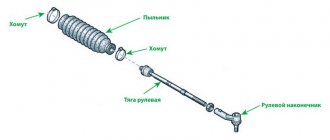

The steering system consists of the following components:

- steering wheel. Most cars are equipped with an airbag;

- steering column. Depending on the brand of the machine, it can be adjusted both in height and in offset;

- steering rack. Equipped with either hydraulic booster or electric booster;

- steering rods. Connecting elements between the rail and the tips;

- steering tips. They connect wheels and rods and are consumables.

About company

Any instruction or specification for a car states that the service life of the steering rack is 200,000-250,000 kilometers. However, repairs to this important part may be required much sooner. The main reasons are most often: violation of vehicle operating rules, aggressive driving style and, of course, the road surface, which leaves much to be desired within the Russian Federation; all this can lead to premature wear of the steering rack. If you want to check the serviceability of your car’s steering rack or, due to any signs, you think that diagnostics and repairs are necessary, then it’s time to contact the professionals of our technical center. It will not be difficult for the 60/24 team to identify the cause of the defect and eliminate it in the shortest possible time.

Typical signs of a faulty steering rack

It will not be difficult for an experienced driver, who has long been accustomed to his own iron horse, to feel changes in the car’s performance. The sooner you find out about a malfunction, the cheaper it will cost you to fix it; in this case, it is extremely rare that you have to completely replace the unit. First of all, we recommend paying close attention to the following signs of a faulty steering rack:

- Backlash in the rack

- Unusual sounds when rocking the steering wheel of an unstarted car

- Tight self-return and steering movement, as well as squeaks in the extreme position

- Steering wheel sticking

- Tapping on the rail

- Leak in the rack

Repair of steering racks and gearboxes in our technical center

The quality of work performed by the craftsmen of our technical center is guaranteed by extensive experience in repairing the steering gear of cars of various brands. If necessary, the following actions will be taken:

- Computer diagnostics of steering

- Determining steering defects

- Replacing the repair kit

- Steering rack restoration

- Testing the correct operation of the steering system

- Camber adjustment

- Repair of power steering, in particular its pumps

- Replacing the boot

- Replacing the tip, etc.

The technical center specialists provide the client with an exact list of work to eliminate the malfunction. We take into account all wishes and guarantee a minimum execution time. How is a steering rack repaired?

To determine the cause of the malfunction, the vehicle will be inspected on a lift, all signs of malfunction indicated by the client will be carefully checked. Sometimes at this stage, collateral defects in the steering are identified that require elimination, for example, replacing seals and oil seals or grinding rack shafts or making bushings. It may also be necessary to involve technical equipment from special factories in Moscow. Upon completion of work, control testing is required on a simulator stand. When dismantling a faulty part, tests are carried out on a special stand, where, by simulating real operating conditions of hydraulic and mechanical systems, specialists will determine the cause of the defect in the operation of the unit. For various types of malfunctions, either partial or complete disassembly of the steering rack may be required. The shafts will be checked for corrosion, and the gear clutches, oil seals and seals will be carefully inspected.

At the request of the client, any segment can be replaced with a new one or restored. When replacing the steering rack with a restored one, the client will be offered to pay for dismantling and installation work, as well as the difference in the cost of the unit. The technical center provides a written guarantee for all work and units.

Source: rul-reika.ru