Compression in engine cylinders

Signs of engine wear include high oil consumption and poor starting in cold weather. In this case, the lubricant is consumed more than 150 g per 1000 km. If these signs are detected, then the compression in the cylinders is first checked. It helps to more accurately determine the performance of the power unit: valves, pistons and cylinders. To carry out diagnostics, it is enough to buy a special pressure gauge. It is not at all necessary to contact a car service.

Variable compression ratio: why is it needed?

Sometimes this indicator is confused with compression, despite the fact that the difference between them is huge. After all, the characteristics mentioned above, although interconnected, are essentially completely different. As even their size indicates. The compression ratio is a ratio, for example 10:1 or simply 10, and has no units of measurement. That is, it is measured in “times”. Compression shows the maximum pressure of the mixture in the cylinder before ignition and is measured in kg/cm2. Thus, the compression of an internal combustion engine with a compression ratio of 10:1 should be no more than 15.8 kg/cm2. You can say what the compression ratio is in another way. This is the ratio of the volume above the piston at bottom dead center to the volume of the combustion chamber. The combustion chamber is the space above the piston that has reached top dead center.

What should the compression be?

To identify the point of maximum wear of engine parts, you need to know the permissible pressure values. It is related to the degree of compression in direct proportion - the more, the higher the pressure.

Today you can find 3 types of engines in operation with different characteristics:

- Old engines with a low compression ratio - up to 8.5.

- Modern gasoline engines in which the air-fuel mixture is reduced in volume by up to 9-11 times.

- Diesel engines capable of compressing the fuel mixture from 16 to 24 times.

The combustion chamber of an engine running on diesel fuel is characterized by a small volume. Therefore, the motor does not require an electric spark, just strong compression.

The amount of compression is influenced by various factors:

- tightness of valve seating;

- cracks in valve seats;

- presence of lubricant in the cylinders;

- ring wear;

- wear of parts of the cylinder-piston group.

Norm and minimum

Through testing, data on the optimal pressure in the cylinders for different types of engines was obtained. When the engine has reached operating temperature and the battery is fully charged, the compression should be:

- On older engines equipped with carburetors, the lowest value is 1 megapascal. In old units - 10 bar. If the engine is new, the pressure can reach 13 bar.

- The optimal pressure in a gasoline engine is 1.5 megapascals. The minimum level is 1.1 MPa.

- For a diesel engine, the normal value is 2.4-3 MPa.

It is important to know! Analysis of parameter measurements allows us to establish a pattern that a compression ratio with a coefficient of 1.5 gives the optimal pressure in the cylinders.

If we more accurately determine the indicated coefficient, then for 4-stroke gasoline engines it is in the range of 1.2-1.3, for diesel engines - 1.7-2.

Signs of poor compression

Identification of the lower compression limit indicates increased engine wear. Friction occurs between the piston rings and the cylinder, which increases the gap between the parts. For this reason, compression is reduced.

The following signs can indicate that the compression is insufficient:

- There is a lot of smoke coming out of the breather. This is a valve that serves to remove crankcase gases from injection and carburetor engines.

- Reduced power of the power unit, especially noticeable on small engines.

- A lot of smoke comes out of the exhaust pipe as the engine oil burns in large quantities.

- High oil consumption due to wear of oil scraper rings and caps.

If at least one of these signs is noticed, then there is a reason to conduct a full engine diagnostics.

This will allow timely measures to be taken to restore its functionality. If we consider the reasons for the decrease in compression, we can highlight the main ones:

- Operating a car with a cold engine, thermostat failure.

- Overheating of the power unit.

- Use of low quality lubricant.

- Maintenance and oil changes are not carried out in a timely manner.

- The service life of the engine has expired.

If the head gasket is burned out or the valves are damaged, then changing the lubricant will not help. In these cases, engine repair will be required with replacement of piston group parts and other elements.

Permissible compression difference in cylinders

If the measured compression differs between cylinders, this complicates matters. The engine will have to be disassembled and overhauled. Not only will it be necessary to replace rings, valves and sealing caps.

Compression less than the minimum value in one cylinder means that there are defects in the piston or cylinder. In this case, all elements of the cylinder-piston group are usually changed, otherwise the difference in compression will remain and the problem will not go away.

The normal value is considered to be a pressure of 10-12 bar, depending on the car model and engine. But the permissible difference in compression in different cylinders has also been established. For example, in cylinders 2 and 3 this value may be 0.5 bar lower, which is quite acceptable. It depends on the load on the pistons - where there is more, there is more wear.

What does it affect?

SSD directly determines the amount of work produced by the internal combustion engine. The higher the compression ratio is initially calculated, the more productive the ignition will be. The output of the motor will increase proportionally. Let us remember how developers in the 90s tried to increase this figure without completely modernizing the engine. In this way, they competed with each other, making the units more powerful without spending a lot of money. But what’s most interesting is that the engines in this case did not consume more fuel, and even became more economical.

However, there is a limit to everything, and as mentioned above, too high a coefficient leads to a decrease in the life of the internal combustion engine. Why is this happening? The fact is that with significant compression, the fuel mixture begins to spontaneously detonate and explode. This especially affects gasoline-powered units, so here this coefficient has a strict limitation.

Remember that the use of low-octane fuel causes detonation on units with increased SSD. Conversely, high-octane fuel may not allow the engine to fully open if used in units with a low compression ratio. For this reason, both parameters must match. More details in the table below.

How is compression measured?

The main engine parameter, which is indicated in the operating manual, is the compression ratio. It determines how many times the fuel mixture is compressed before combustion. The cylinder volume divided by the piston stroke is the compression ratio. It does not change if the car owner has not tuned the engine, for example, bored the cylinders or installed a different crankshaft.

But this characteristic should not be confused with compression, which means piston pressure. It is determined by rotating the crankshaft with the starter.

Compression decreases over time due to wear of parts. Its units of measurement can be:

- Bar.

- Atmosphere (atm).

- Megapascal (MPa).

- Kilogram*force per square centimeter (kgf/cm2).

The most modern unit of measurement is the Megapascal, which is equal to 9.9 atmospheres.

Comparison results

Ultimately, what is the difference between compression ratio and compression ratio? Analyzing these two terms, you can notice a significant difference. The compression ratio is a dimensionless quantity. It can be changed, but only by interfering with the engine design.

Compression can vary during the operation of the vehicle. In addition, this parameter largely depends on the compression ratio. After all, the pressure in a smaller volume will always be greater.

In other words, if the compression ratio increases, then the compression also increases.

How to measure compression

To assess the technical condition of the cylinders and piston group elements, a special device is used - a compression meter.

It includes the following elements:

- Pointer pressure gauge with scale graduation from 0 to 2.4 MPa. For a diesel engine, you will need a device with a scale of up to 4 megapascals.

- Flexible hose with a tip for connecting to the spark plug hole.

- Check valve.

- Pressure relief device.

- Adapter nozzles for different threads in spark plug holes.

A simple configuration of the device is a pressure gauge equipped with a check valve and a conical rubber nozzle. When measuring, you do not need to screw it in, just press it firmly with your hand.

The pressure gauge is used to measure pressure. The check valve is designed to retain air in the device until maximum pressure is reached. It occurs within 5-10 working cycles. Next, the readings are set to “0” by releasing the pressure with a special button. In a diesel engine, compression is measured through the injector holes, which may have different threads. That's why the kit includes adapters.

Checking without a device

There is a simple way to measure compression without special devices. If you need to find out which cylinder is faulty, you can unscrew the spark plugs and rotate the engine with the starter. In this case, the hole is closed with a finger and the release and intake of air is checked. If the malfunction is serious, for example, a burnt valve, then the air in the cylinder will be pushed out and sucked in less easily.

Oil check

If diagnostics reveal a low compression value, then you can find out what the specific reason is. 30 ml of engine oil is poured into all cylinders and the pressure is measured again.

- If the compression has increased to a normal value, then the problem is the wear of the pistons and cylinders, or the piston rings.

- If, after adding oil, the pressure is poor only in some cylinders, then rings may break, valves or pistons may burn out.

More accurate diagnostics can only be done with a compression meter.

What is compression ratio and how does it differ from compression?

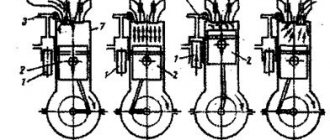

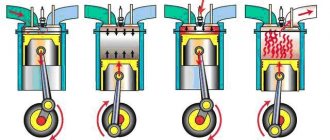

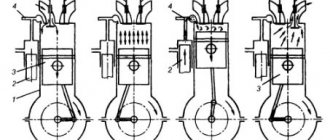

Each internal combustion engine operates due to the fact that gases are formed in its cylinders when burning the fuel mixture, which drive the pistons, and they, in turn, drive the crankshaft. Thus, the combustion energy is converted into mechanical energy, a torque arises, due to which the car moves.

The combustion of the fuel mixture occurs in the cylinders, and before ignition, the pistons compress it to a certain volume. It is the ratio of the total volume of the cylinder to the volume of the combustion chamber that is called the compression ratio of the internal combustion engine. This quantity has no dimension and is expressed by a simple ratio. For most modern gasoline internal combustion engines it ranges from 8:1 to 12:1, and for diesel engines - from 11:1 to 14:1.

Compression refers to the maximum value of pressure that occurs in the combustion chamber at the very end of the compression stroke of the fuel mixture.

How to properly check engine compression

Before checking the compression, you need to fully charge the battery and make sure the starter is working properly. Otherwise, the measurement will be inaccurate and the readings will be underestimated. As a result of the error, you can begin to repair the motor, although you need to look for other reasons.

Doctors use different diagnostic methods:

- on a cold engine;

- on a warm engine;

- with closed or open throttle.

The most accurate data is provided by diagnostics on a warm engine, which is carried out in the following order:

- Start the engine and warm it up to a temperature of 70 degrees.

- On a diesel engine, unscrew the injectors; on a gasoline engine, remove the high voltage wires and unscrew the spark plugs.

- Disconnect the wire plug from the injectors or turn off the gasoline pump by removing the corresponding fuse.

- Install the compression gauge nozzle on cylinder 1.

- Press the gas pedal to open the throttle.

- Turn the engine 5-10 revolutions with the starter.

- Record the compression readings and repeat the procedure on the other cylinders.

Attention! The injector plugs may not be disconnected, but when measuring compression, a little gasoline will penetrate into the crankcase. This does not affect the accuracy of measurements.

The fuel supply on a diesel power unit with a mechanical fuel pump is turned off with a shut-off lever.

WHAT IS ENGINE COMPRESSION RATIO AND COMPRESSION?

Good afternoon, today we will learn what automotive indicators of an internal combustion engine are, such as the compression ratio and compression of the power plant, and how they differ from each other. In addition, we will define the concepts of compression and compression ratio, talk about the main features of these engine indicators, and also establish why the values of these parameters are so important for a particular vehicle engine. In conclusion, we will talk about how the final compression values of the power plant influence the identification of possible engine malfunctions, and also why the compression ratio directly affects the power parameter of the car’s engine.

In order to understand why the compression indicators and compression ratio of an internal combustion engine are needed, as well as how they differ from each other, it is necessary to know their definitions, to understand the importance of each parameter that directly or indirectly affects the durability of the vehicle’s power plant. We will discuss these issues in our story in order to get a comprehensive understanding of the compression ratio and compression ratio of the engine, and also why there is no need to confuse these somewhat similar indicators for measuring engine performance. In addition, let's consider a frequently asked question by many car enthusiasts: “How do the parameters of the compression ratio and engine compression differ from each other, and also which indicator is most important?”

1

.

Compression ratio.

Concept and features of an automobile indicator The compression ratio of a power plant is the ratio of the volume of the working area of the cylinder to the volume of the combustion chamber of the fuel-air mixture. On a gasoline engine, depending on the specific task, the compression ratio can be in a different range of values from 7 to 11 points. As for diesel power plants, due to certain design features of the device, their compression ratio significantly exceeds gasoline ones and averages from 13 to 19 points.

Today, the engine compression ratio or indicator is indicated on almost all modern vehicles. Based on this parameter, the manufacturer in the documentation and also, as a rule, on the gas tank flap of a particular vehicle indicates the fuel recommended for refueling; for example, if the vehicle is equipped with a gasoline engine, there will be an indication of the brand of gasoline AI-92 or AI-95.

In order to imagine in more detail how and where the compression ratio is created in a car engine, you first need to imagine the cylinder block and the pistons that move in it. The fact is that each piston has, so to speak, its own “dead spots” in the cylinder block. This point is called the upper plane of the block, when the fuel is compressed to the limit and is waiting for the moment to ignite. The lowest point is the plane where the piston goes down, and the space is filled with a new portion of the fuel mixture or, conversely, is already filled with gases that have expanded from ignition.

How often to check compression

For prevention, diagnostics are carried out when replacing spark plugs. This procedure should be carried out every 25-50 thousand km.

In addition, emergency diagnosis is carried out for the following signs:

- The engine consumes a lot of oil - more than 200 ml per 1000 km.

- Blue smoke comes out of the exhaust pipe.

- The car has become harder to start in winter.

- Unstable idle, vibration.

The last symptom indicates a failure of the ignition system or several spark plugs. Before measuring compression, these faults must be eliminated. On diesel engines, wear of valves, pistons and cylinders shows the same signs. Cold starts are especially noticeable - diesel fuel cannot ignite.

What is compression and compression ratio of a car engine?

Engine compression ratio

is the ratio of the total volume of the cylinder to the volume of the combustion chamber.

On a gasoline engine, depending on the specific task, the compression ratio can vary significantly, reaching values of 8 to 12. On diesel engines, due to their design features, the compression ratio is much higher and ranges from 14 to 18 units.

For gasoline engines, the higher the compression ratio, the higher the specific power. But if you greatly increase the compression ratio, the service life may decrease and the risk of engine problems when refueling with low-quality fuel increases sharply.

Compression

- this is the maximum air pressure in the combustion chamber at the end of the compression stroke.

Compression is the pressure in the cylinder, and therefore it depends on the compression ratio (the pressure in a smaller volume will always be greater, i.e., as the compression ratio increases, the compression increases). By the amount of compression you can preliminary judge the condition of the engine. It is important to carry out the compression measurement procedure correctly. If the compression level decreases, it is necessary to find out the cause of the drop. It could be piston rings or problems in the valve mechanism, you can find out this way. 15-20 grams of motor oil are injected into the problem cylinders using a syringe. The measurement procedure is repeated. If the pressure gauge readings have increased, the reason for the drop is in the piston rings; if they remain at the same level, it is in the valves.

If you liked the article, like and subscribe to my channel.

Source

Methods for restoring compression

There are several ways to increase the pressure in the engine if the rings are stuck:

- Pour 100 ml of engine oil into each cylinder. It is necessary to give time for the rings to “throw away”. Periodically you need to turn the crankshaft.

- The second method is more effective. A mixture of kerosene, acetone and motor oil is prepared in a ratio of 1:1:1. 50 g is poured into each cylinder, the spark plugs are put in place, and the engine is left alone for 10 hours. Next, the spark plugs are removed, and the engine is cranked by the starter several revolutions. After installing the spark plugs, you need to start the engine and warm it up to 40 degrees. Then the oil is drained and the system is washed with a special product. All that remains is to add fresh oil and replace the filter.

In addition, special chemicals for normalizing compression can be found on sale. Such products contain additives that are poured into the engine. But their effectiveness is questionable, and responsibility for use lies with the car owner.

Compression ratio of internal combustion engine

However, it is necessary to understand that this is a geometric compression ratio, but the actual one is approximately equal to 12, since the engine operates on the Atkinson cycle, that is, the mixture begins to compress after the valves are closed late and is compressed 12 times.

The efficiency of such a motor in terms of power and torque is determined by such a concept as the expansion ratio, which is the inverse of the geometric compression ratio.

In the 1950s and 60s, one of the engine building trends, especially in North America, was to increase the compression ratio, which by the early 1970s on American engines often reached 11-13:1.

However, this required appropriate gasoline with a high octane number, which in those years could only be obtained by adding poisonous tetraethyl lead. The introduction of environmental standards in most countries in the early 1970s led to a halt in growth and even a reduction in compression ratios on production engines.

Engine compression ratio - what is it?

The ratio of the total volume of the cylinder to the volume of the combustion chamber is called the compression ratio - E.

(Compression ratio of the Lada Niva 4×4 engine is 9.3. (see here))

Everything is short and clear. But is that enough? The design of the power plant is only a method or system that converts the thermal energy of burned fuel into mechanical energy of the rotating parts of the engine. The concepts of “compression”, “expansion”, “working fluid” also oblige us to consider the physical and chemical processes occurring in the engine cylinders. And these processes are impossible without temperature, which, in turn, is determined by the degree of compression. The efficiency of using expanding gases depends on the degree of expansion. And so, when considering these processes in the most general form, it is possible and necessary to understand something. Everything is in order.

The compression ratio is one of the engine characteristics. It shows how many times the volume of the working mixture or air decreases when the piston moves from BDC to TDC. Using this characteristic, you can determine the type of fuel used in the engine; outdated or advanced engine model; This is a diesel engine with separate combustion chambers or a diesel engine with direct injection.

Increasing the compression ratio increases engine power and improves its efficiency. The possibility of increasing the compression ratio is determined mainly by the properties of the fuels, the toxicity of the exhaust gases and the load on engine parts; for gasoline car engines E = 6.5 -14, and for diesel engines E = 15-24.

In diesel engines, as the compression ratio E increases, the temperature and air pressure increase at the start of injection. As a result, ignition delays are reduced, the rate of pressure rise is reduced, and engine operation becomes smoother. However, at large E (due to higher pressures in the cylinder), it is necessary to increase the mass of parts of the crank mechanism to increase strength. This leads to an increase in mechanical losses. It must be remembered that as a result of combustion of the air-fuel mixture, the volume of the cylinder is filled with a mixture of nitrogen, carbon dioxide and water vapor, and that at high temperatures (over 2000°C) in the combustion chamber, water dissociates into hydrogen and oxygen, and carbon dioxide into carbon monoxide and oxygen. A significant amount of heat is spent on this - the increase in temperature of the working fluid is inhibited.

Increasing the compression ratio in gasoline engines is limited due to the possibility of detonation. Knocking combustion that continues for a period of time can cause engine damage.

The compression ratio is an engine characteristic specified by the designer. There is no need to check it, and only when repairing an engine must you strictly follow the technical conditions for assembling a particular engine.

Is the compression ratio constant? Or is the compression ratio a variable value?

If we assume that the compression ratio is a constant value, then we get two other constant values - temperature and pressure. But this cannot happen. It is impossible to consider the operation of an engine, taking into account only its design.

In order for temperature and pressure to appear, something needs to be compressed (compression ratio). This something is air or an air-fuel mixture (working fluid).

The engine load is regulated by throttling the air, which is an indispensable condition for maintaining an approximately constant composition of the air-fuel mixture in a gasoline engine. In a diesel engine, the load is controlled by changing the amount of fuel supplied to the combustion chamber.

In other words, we control engine power by changing the amount of working fluid in its cylinders.

Modern cars use electronic control systems that can quickly and accurately calculate the composition and quantity of the working fluid, supply it to the engine cylinders in a timely manner and in the right quantity, taking into account many factors affecting the operation of the power plant as a whole.

Let's remember some engine operating modes - idle, partial load and maximum load. For each of these engine operating modes, a certain amount of working fluid is required in accordance with the position of the fuel pedal.

For idle mode, a minimum amount of working fluid is required, for maximum load mode - a maximum.

If you fill the volume between the piston located at BDC and the block head with the maximum amount of working fluid (maximum load), and then move the piston to TDC, then the working fluid will be compressed to a certain density. After the calculations, we will obtain the actual degree of compression of the working fluid. This actual compression ratio cannot be higher (for naturally aspirated engines) than the compression ratio specified when the particular engine was designed.

How is engine compression ratio calculated?

Since it is very desirable that the internal combustion engine installed in a car has the highest possible compression ratio, it is necessary to be able to determine it. This is also important in order to avoid the danger of detonation, which can simply destroy the engine, when adjusting the power unit aimed at boosting it.

The standard formula by which the compression ratio of an internal combustion engine is calculated is as follows:

- CR=(V+C)/C,

- where CR is the engine compression ratio, V is the cylinder displacement, C is the combustion chamber volume.

In order to determine the value of this value for one cylinder, you must first divide the total working volume of the power unit by their number. In this way, the value of parameter V is determined from the above formula. Determining the volume of the combustion chamber (that is, the value of C) is somewhat more difficult, but quite possible. To do this, experienced motorists and mechanics specializing in the repair and adjustment of internal combustion engines use a burette, which is graduated in cubic centimeters. The simplest way is to pour liquid (for example, gasoline) into the combustion chamber, and then measure its volume using a burette. The obtained data must be substituted into the calculation formula.

In practice, the engine compression ratio is usually determined in the following cases:

- When boosting the power unit;

- When adapted to operate with fuel of a different octane number;

- After such an internal combustion engine repair, when adjustment of the compression ratio is required.

What is compression ratio

This degree is the ratio of the volume of the engine cylinder to the volume of the combustion chamber. Otherwise, we can say that the compression value is the ratio of the volume of free space above the piston when it is at bottom dead center to the same volume when the piston is at the top point.

It was mentioned above that compression and compression ratio are not synonymous. The difference also concerns the notation; if compression is measured in atmospheres, the compression ratio is written as a certain ratio, for example, 11:1, 10:1, and so on. Therefore, it is impossible to say exactly what the compression ratio in the engine is measured at - this is a “dimensionless” parameter that depends on other characteristics of the internal combustion engine.

Compression ratio

First, let's look at what should be understood by this term. The compression ratio is a geometric quantity that has no units of measurement. This is due to the fact that the parameters of the power unit are used to determine it. In other words, the compression ratio is the ratio of the entire volume of the cylinder to the volume of the combustion chamber.

For engines running on gasoline, this value can vary dramatically - in the range from 8 to 12. As for diesel power units, they have this characteristic even greater - 14-18 units. This is largely dictated by design features.

In search of an answer to the question of what is the difference between compression ratio and compression ratio, it is worth considering another point regarding gasoline engines. Here's the thing. The higher the compression ratio, the higher the power density. At the same time, a strong increase in this parameter will inevitably lead to a noticeable decrease in the service life of the motor. And on top of that, serious problems can arise if you fill your car with low-quality fuel.

Compression calculation

Let's look at how to find out the engine compression ratio.

It is calculated by the formula:

Here Vр means the working volume of an individual cylinder, and Vс is the value of the volume of the combustion chamber. The formula shows the importance of the chamber volume value: if, for example, it is reduced, the compression parameter will become larger. The same will happen if the volume of the cylinder increases.

To find out the displacement, you need to know the cylinder diameter and piston stroke. The indicator is calculated using the formula:

Here D is the diameter and S is the stroke of the piston.

Since the combustion chamber has a complex shape, its volume is usually measured by pouring liquid into it. Once you know how much water fits in the chamber, you can determine its volume. For determination, it is convenient to use water because of its specific gravity of 1 gram per cubic meter. cm - how many grams are poured, so many “cubes” in the cylinder.

An alternative way to determine the compression ratio of an engine is to refer to its documentation.

How to change engine compression ratio

In modern internal combustion engines, the compression ratio is changed both upward and downward. If it needs to be increased, then the cylinders are bored and pistons of larger diameter are installed. Another fairly common method is to reduce the volume of combustion chambers. To do this, where the cylinder head mates with the block, a layer of metal is removed. This operation is performed on a planing or milling machine.

If for one reason or another it is necessary to reduce the compression ratio of an internal combustion engine, then the easiest way to do this is to install an additional duralumin gasket between the cylinder block and the head. Another, more complex method is to remove a layer of metal from the bottom of the piston on a lathe.

What does the compression ratio affect?

It is important to understand what the engine compression ratio affects: compression and power directly depend on it. If you make the compression greater, the power unit will receive greater efficiency, since the specific fuel consumption will decrease.

The compression ratio of a gasoline engine determines the octane number of fuel it will consume. If the fuel is low octane, it will lead to the unpleasant phenomenon of detonation, and too high an octane number will cause a lack of power - an engine with low compression simply will not be able to provide the required compression.

Table of basic ratios of compression ratios and recommended fuels for gasoline internal combustion engines:

| Compression | Petrol |

| To 10 | 92 |

| 10.5-12 | 95 |

| From 12 | 98 |

Interesting: turbocharged gasoline engines operate on fuel with a higher octane number than similar naturally aspirated internal combustion engines, so their compression ratio is higher.

It is even greater for diesel engines. Since diesel internal combustion engines develop high pressures, this parameter will also be higher. The optimal compression ratio of a diesel engine ranges from 18:1 to 22:1, depending on the unit.

The influence of compression ratio on motor characteristics

The higher the compression ratio, the greater the compression of the internal combustion engine and its power (all other things being equal). By increasing the compression ratio, we also help increase engine efficiency by reducing specific fuel consumption. The compression ratio of the internal combustion engine determines the octane number of gasoline used to operate the engine. Thus, low-octane fuel will cause engine detonation with a high value of this coefficient. An excessively high octane number of fuel will not allow a power unit, the compression of which is low, to develop full power.

Initial data

Octane number of fuel used for gasoline engines with various compression ratios.

- 7.0–7.5 octane number 72–76.

- 7.5–8.5 octane number 76–85.

- 5.5–7 octane number 66–72.

- 10:1 octane number 92.

- From 10.5 to 12.5 octane number is 95.

- From 12 to 14.5 octane number is 98.

Aligning the interface between the head and the block by cutting off the metal layer leads to a reduction in the combustion chamber of the motor. This causes the compression ratio to increase by an average of 0.1 when the head thickness decreases by 0.25 mm. Having this data at your disposal, you can determine whether it will exceed the permissible limits after repairing the cylinder head. And shouldn't measures be taken to reduce it? Experience shows that when a layer of less than 0.3 mm is removed, the consequences may not be compensated.

Changing the compression ratio

Why change the degree?

In practice, such a need arises rarely. You may need to change compression:

- if desired, boost the engine;

- if you need to adapt the power unit to operate on non-standard gasoline, with an octane number different from the recommended one. This is what, for example, Soviet car owners did, since there were no kits for converting a car to gas on sale, but there was a desire to save on gasoline;

- after an unsuccessful repair, in order to eliminate the consequences of incorrect intervention. This may be thermal deformation of the cylinder head, after which milling is required. After the compression ratio of the engine has been increased by removing a layer of metal, operation on the gasoline originally intended for it becomes impossible.

Sometimes the compression ratio is changed when converting cars to run on methane fuel. Methane has an octane number of 120, which requires increasing the compression for a number of gasoline cars, and lowering it for diesel engines (the coolant is in the range of 12-14).

Converting diesel to methane affects power and leads to some loss of power, which can be compensated for by turbocharging. A turbocharged engine requires an additional reduction in the compression ratio. It may be necessary to modify the electrics and sensors, replace diesel engine injectors with spark plugs, and a new set of cylinder-piston group.

Ways to change the compression ratio

With modern power units, this characteristic can be adjusted both up and down. If you need to increase the parameter, then the cylinders are bored and pistons with a larger diameter are installed. Anyone interested in understanding the differences in combustion engine compression and compression ratio will find this information helpful. After all, among car enthusiasts there are supporters of various types of tuning.

Another, no less effective way to change the compression ratio is to reduce the combustion chamber. In this case, a layer of metal is removed from the junction of the cylinder head with the engine block. This operation is carried out using a planing or milling machine.

If for some reason there is a need to lower the compression ratio, then, on the contrary, it is worth placing an alloy gasket between the cylinder block and the cylinder head. Another method is to remove a layer of metal from the piston bottom. However, it is more difficult to implement, since it will require certain efforts, skills and abilities. In addition, this procedure requires a lathe.

Engine boost

To produce more power or to be able to drive on cheaper types of fuel, the internal combustion engine can be boosted by changing the volume of the combustion chamber.

To obtain additional power, the engine should be boosted by increasing the compression ratio.

Important: a noticeable increase in power will only be on an engine that normally operates with a lower compression ratio. So, for example, if a 9:1 engine is tuned to 10:1, it will produce more additional horsepower than a stock 12:1 engine boosted to 13:1.

The following are possible methods for increasing the engine compression ratio:

- installation of a thin cylinder head gasket and modification of the cylinder head;

- cylinder boring.

By refining the cylinder head we mean milling its lower part in contact with the block itself. The cylinder head becomes shorter, which reduces the volume of the combustion chamber and increases the compression ratio. The same thing happens when installing a thinner gasket.

Important: these manipulations may also require the installation of new pistons with enlarged valve recesses, since in some cases there is a risk of the piston and valves meeting. The valve timing must be re-adjusted.

Boring the BC also leads to the installation of new pistons of the appropriate diameter. As a result, the working volume increases and the compression ratio becomes higher.

How to increase engine compression ratio

If you need to increase this indicator, use several methods:

- boring the block and installing pistons with a large diameter;

- reducing the volume of the combustion chamber by removing the metal layer at the cylinder head connection.

We must not forget that in some cases the installation of upgraded pistons will be required. This is done to eliminate such an undesirable consequence as the pistons meeting the valves. In particular, the valve recesses on the elements are increased. Also, the valve timing must be adjusted again.

Interestingly, Japanese manufacturers have revealed the potential of internal combustion engine compression ratios best of all. While European auto companies went the route of improving hybrid engines, the Japanese managed to increase the SSD to 14 units on gasoline power units, using a variable value. But how is this possible without detonation moments? Everything turned out to be simple. It turns out that you need to cool the chamber where the fire occurs. Then you can safely compress the mixture. And it is not at all necessary to use cool air for this: it is enough to modernize the exhaust system.

A technique that has long been known from racing engines. The exhaust channels are changed according to the 4-2-1 scheme. Portions of exhaust gases do not interfere here; they fly out one by one into the chimney. Thanks to such a clear exhaust system, the purging of the cylinders is improved, where less hot gases remain.

The secret of the Japanese formula, according to which you can safely compress a combustible mixture, has a strictly mathematical relationship. So, if the exhaust percentage is reduced by 2 times, the SSD can be raised by 3 units, but no more. If you also cool the air entering the cylinders, you can add one more unit.

However, to implement this method, it will be necessary to modernize the gas exchange by forking out for phase shifters of both camshafts. In addition, some aspects will need to be improved. For example, changing the length of the piston stroke through computer intervention.

A variable coefficient system is used on many Japanese engines, for example, for Inflniti. The ability to automatically change this compression ratio depending on the load can significantly increase the efficiency of the engine, especially a turbocharged one. Each portion of the mixture burns at the optimal compression at the moment. So, if the load on the engine is insignificant and the mixture is lean, maximum compression is turned on. Conversely, in loaded mode, the minimum degree is used, since a lot of gasoline is injected and detonation is possible.

Thus, the advanced system for changing the SSD makes it possible to halve the engine displacement, while maintaining power and dynamic characteristics.

A trend towards increasing the engine compression ratio was also observed in the mid-20th century in the USA. The bulk of American engines produced in the 70s were in the range of 11-13 units. But they only worked on very high-quality, high-octane fuel obtained by leading. After leading was banned, a decrease in the compression ratio was observed in serial samples of internal combustion engines.

It is important to know that the increase in power will be most noticeable on engines that normally operate at a low compression ratio. For example, engines with an indicator of 8 units, increased to 10, will produce more power than units with a stock parameter of 11 units, boosted to 12.

Deboosting for low octane fuel

This operation is carried out when the issue of power is secondary, and the main task is to adapt the engine to a different fuel. This is done by reducing the compression ratio, which allows the engine to run on low-octane gasoline without detonation. In addition, there are certain financial savings on the cost of fuel.

Interesting: a similar solution is often used for carburetor engines of old cars. For modern electronically controlled fuel injection engines, deforcing is highly not recommended.

The main way to reduce the engine compression ratio is to make the cylinder head gasket thicker. To do this, take two standard gaskets, between which an aluminum gasket insert is made. As a result, the volume of the combustion chamber and the height of the cylinder head increase.

Calculation of compression ratio

For any internal combustion engine, it is important that this parameter has the maximum possible value. However, if you need to force the engine, you should know how this characteristic can be calculated. This is necessary in order to avoid detonation, which can cause the engine to simply fail.

The formula used for the calculation is as follows:

where CR is the compression ratio, V is the working volume of the cylinder, C is the volume of the combustion chamber.

The car enthusiast who wants to know the difference between compression and compression ratio will be interested in such calculations. Perhaps this will be useful to him in practice.

To determine this parameter for only one cylinder, the total engine displacement should be divided by the number of “glasses”. As a result, we obtain the value of V from the formula above.

But determining the C indicator is much more difficult, but still possible. To do this, experienced motorists and mechanics involved in engine repairs have the right tool in mind - a burette. It is graduated in cubic centimeters. The easiest way is to pour gasoline into the combustion chamber, and then measure its volume with a burette. All that remains is to enter the obtained data into the formula.

Some interesting facts

Methanol race car engines have a compression ratio of over 15:1. By comparison, a standard carbureted engine consuming unleaded gasoline has a maximum compression of 1.1:1.

Of the production models of gasoline engines with 14:1 compression, there are models on the market from Mazda (Skyactiv-G series), installed, for example, on the CX-5. But their actual coolant is within 12, since these engines use the so-called “Atkinson cycle”, when the mixture is compressed 12 times after the valves are closed late. The efficiency of such engines is measured not by compression, but by expansion ratio.

In the middle of the 20th century, in the global engine industry, especially in the USA, there was a tendency to increase the compression ratio. Thus, by the 70s, the bulk of American automobile industry samples had a coolant ratio from 11 to 13:1. But the normal operation of such internal combustion engines required the use of high-octane gasoline, which at that time could only be produced by the ethylation process - by adding tetraethyl lead, a highly toxic component. When new environmental standards appeared in the 1970s, leaded lead was banned, and this led to the opposite trend - a decrease in coolant in production engines.

Modern engines have an automatic ignition angle control system, which allows the internal combustion engine to operate on “non-native” fuel - for example, 92 instead of 95, and vice versa. The OZ control system helps to avoid detonation and other unpleasant phenomena. If it is not there, then, for example, if you fill an engine with high-octane gasoline that is not designed for such fuel, you can lose power and even fill the spark plugs, since the ignition will be late. The situation can be corrected by manually setting the OZ according to the instructions for a specific car model.

4.File compression ratio

Compression of information in archive files is achieved by eliminating redundancy in various ways, for example by simplifying the codes, eliminating constant bits from them, or representing repeated characters or a repeating sequence of characters in terms of a repetition factor and corresponding characters. Algorithms for such information compression are implemented in special archiver programs (the most famous of which are arj/arjfolder, pkzip/pkunzip/winzip, rar/winrar) certain ones are used. Both one and several files can be compressed, which in a compressed form are placed in the so-called archive file or archive.