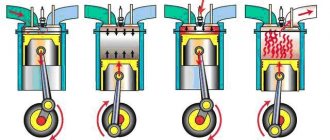

The first stroke is intake.

Modern engine structure

car, design of systems and mechanisms

The piston moves from TDC to BDC, and purified air enters the cylinder through the open intake valve (due to the vacuum created by the piston). The air is mixed with a small amount of exhaust gases remaining from the previous cycle, the temperature rises and at the end of the intake stroke reaches 300-320 K, and the pressure 0.08-0.09 MPa. The cylinder filling coefficient is 0.9 or higher, i.e. more than that of a carburetor engine.

Diesel engine: design and operation diagram

The diesel engine is an internal combustion engine invented by Rudolf Diesel in 1897. The design of the diesel engine of those years made it possible to use oil, rapeseed oil, and solid types of flammable substances as fuel. For example, coal dust.

The operating principle of a modern diesel engine has not changed. However, engines have become more technologically advanced and demanding of fuel quality. Today, only high-quality diesel fuel is used in diesel engines.

Diesel engines are characterized by fuel efficiency and good traction at low crankshaft speeds, so they are widely used in trucks, ships and trains.

Since the problem of high speeds was solved (old diesel engines quickly broke down when used frequently at high speeds), the engines in question began to be often installed in passenger cars. Diesels intended for high-speed driving received a turbocharging system.

The second stroke is compression.

How does a simple engine work?

Engine design for children

The piston moves from BDC to TDC, the intake and exhaust valves are closed. The air pressure and temperature increase and at the end of the stroke are 3-5 MPa and 800-900 K, respectively. The compression ratio is regulated by the serviceability of the crankshaft parts and is equal to 17-21.

Operating principle of a diesel engine

The operating principle of a diesel engine differs from gasoline engines. There are no spark plugs, and fuel is supplied to the cylinders separately from air.

The operating cycle of such a power unit can be represented as follows:

- a portion of air is supplied to the diesel combustion chamber;

- the piston rises, compressing the air;

- from compression the air is heated to a temperature of about 800˚C;

- fuel is injected into the cylinder;

- The diesel fuel ignites, which leads to the lowering of the piston and the execution of the working stroke;

- combustion products are removed by blowing through exhaust windows.

How a diesel engine operates determines its efficiency. A working unit uses a lean mixture, which saves the amount of fuel in the tank.

The third stroke is the working stroke.

At the end of the compression stroke (20-30 degrees of rotation angle of the crankshaft before the piston reaches TDC), a portion of fuel is injected in a finely atomized form through a nozzle into the cylinder under high pressure (15-20 MPa) using a pump. Fuel evaporates when it comes into contact with heated air, its vapors mix with the heated air and ignite. When fuel burns, due to the supply of a large amount of heat, the depletion and temperature of the resulting gases sharply increase. At the beginning of the expansion stroke, the gas pressure is 7-8 MPa. and the temperature is 2100-2300 K. Under the influence of pressure, the piston moves from TDC to BDC, performing useful work. The volume of the cylinder increases, the pressure and temperature of the gases decrease and when the piston approaches BDC they are 0.2-0.4 MPa.

How does a four stroke engine work?

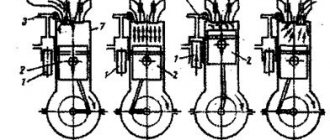

Structurally, the working cycle of a typical four-stroke unit is ensured by the operation of the following elements:

- cylinder;

- piston - performs reciprocating movements inside the cylinder;

- intake valve – controls the process of supplying the air-fuel mixture to the combustion chamber;

- exhaust valve – controls the process of exhaust gases expelling from the cylinder;

- spark plug – ignites the resulting air-fuel mixture;

- crankshaft;

- camshaft - controls the opening and closing of valves;

- belt or chain drive;

- crank mechanism - translates the movement of the piston into rotation of the crankshaft.

Duty cycle of a four-stroke engine

The working cycle of such a mechanism consists of four cycles, during which the following processes are implemented:

- Intake (fuel and air injection). At the beginning of the cycle, the piston is at TDC. At the moment when the crankshaft begins to rotate, it acts on the piston and moves it to BDC. This leads to the formation of vacuum in the cylinder chamber. The camshaft acts on the intake valve, gradually opening it. When the piston is in its extreme position, the valve is completely open, resulting in intense injection of fuel and air into the cylinder chamber.

- Compression (increasing the pressure of the combustible mixture). In the second stage, the piston begins to move back to the top dead center of the compression stroke. The crankshaft makes another turn and both valves are completely closed. The internal pressure increases to 1.8 MPa and the temperature of the combustible mixture rises to 600 C°.

- Expansion (working stroke). When the piston reaches the top position in the combustion chamber, the maximum compression is set to 5 MPa and the spark plug is fired. This leads to combustion of the mixture and an increase in temperature to 2500 C°. Pressure and temperature lead to an intense impact on the piston, and it begins to move back to BDC. The crankshaft makes another turn, and thus the thermal energy is converted into useful work. The camshaft opens the exhaust valve, and when the piston reaches BDC, it is fully open. As a result, the exhaust gases begin to gradually leave the chamber, and the pressure and temperature decrease.

- Exhaust (removal of exhaust gases). The engine crankshaft turns and the piston begins to move to the top point. This leads to the expulsion of exhaust gases and an even greater decrease in temperature and a decrease in pressure to 0.1 MPa. Next, a new cycle begins, during which these processes are repeated again.

During each stroke, the engine crankshaft rotates 180°. During a full working cycle, the crankshaft rotates 720°.

The four-stroke engine has become widespread. It can work with both gasoline and diesel fuel. The difference between the operating cycle for a diesel engine is that the ignition of the air-fuel mixture does not occur from a spark, but from high pressure and temperature at the end point of the compression stroke.

The fourth measure is release.

The piston moves from BDC to TDC. Through the open exhaust valve, the exhaust gases are pushed out through the exhaust pipe into the environment. At the end of the exhaust stroke, the gas pressure is 0.11 -0.12 MPa, the temperature is 850-1200. After this, the diesel operating cycle is repeated. In two-stroke engines, the time allotted for the working cycle is used more fully, since the exhaust and intake processes are combined in time with the compression and power stroke processes. The operating cycle occurs over 360 degrees (one revolution of the crankshaft).

Internal combustion engines. Diesel cycle.

The compression ratio ε in the cycle can be increased if you compress not the combustible mixture, but clean air, and then, after the compression process is completed, fuel is introduced into the cylinder. It is on this principle that the Diesel cycle is based (named after the German engineer R. Diesel, who built an engine operating on this cycle in 1897). The diagram of an engine operating on the Diesel cycle and the indicator diagram of this engine are presented in the figure below. In process a-1, clean atmospheric air is sucked into the engine cylinder; in process 1-2, this air is adiabatically compressed to pressure p2 (the compression ratio in engines with the Diesel cycle usually reaches ε = 15÷16). Then the process of air expansion begins and at the same time fuel (kerosene, diesel oil) is injected through a special nozzle. Due to the high temperature of the compressed air, the fuel ignites and burns at constant pressure, which is ensured by the expansion of gas from v2 to v3 at constant pressure. Therefore, the Diesel cycle is called a constant-pressure combustion cycle.

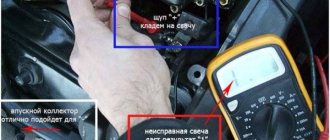

Turbocharged diesel engine

The principle of operation of a turbine on a diesel engine is practically no different from that on gasoline engines. The idea is to pump additional air into the cylinders, which naturally increases the amount of incoming fuel. Due to this, there is a serious increase in engine power.

The turbine design of a diesel engine also does not differ significantly from its gasoline counterpart. The device consists of two impellers, rigidly connected to each other, and a body that looks like a snail. The turbocharger housing has 2 inlets and 2 outlets. One part of the mechanism is built into the exhaust manifold, the second into the intake manifold.

Turbojam

During operation, the turbine can make up to 200 thousand revolutions per minute. It is instantly impossible to spin it up to the required rotation speed. This leads to the appearance of the so-called. turbo lags, when some time passes from the moment you press the gas pedal until intense acceleration begins (1-2 seconds).

The problem is solved by modifying the turbine mechanism and installing several impellers of different sizes. In this case, small impellers spin up instantly, after which they are overtaken by large elements. This approach allows you to almost completely eliminate turbo lag.

Variable geometry turbines, VNT (Variable Nozzle Turbine), are also produced to solve the same problems. Currently, there are a large number of modifications of this type of turbine. Geometry correction also successfully copes with the opposite situation, when there are too many revolutions and air and it is necessary to slow down the impeller speed.

Intercooler

It was noticed that if cold air is used during mixture formation, engine efficiency increases to 20%. This discovery led to the development of the intercooler, an additional element of turbines that increases operating efficiency.

After air is sucked in, it passes through the radiator and, when cooled, enters the intake manifold. We have already published an article in which you can familiarize yourself in detail with the intercooler operation diagram.

The turbine of a modern car must be properly maintained. The mechanism is extremely sensitive to the quality of engine oil and overheating. Therefore, it is recommended to change the lubricant at least every 5-7 thousand kilometers.

In addition, after stopping the car, you should leave the internal combustion engine on for 1-2 minutes. This allows the turbine to cool down (if the oil circulation suddenly stops, it overheats). Unfortunately, even with proper operation, the compressor resource rarely exceeds 150 thousand kilometers.

Note: the optimal solution to the problem of turbine overheating on diesel engines is to install a turbo timer. The device leaves the engine running for the required time after the ignition is turned off. After the required period has ended, the electronics itself turns off the power unit.

The structure and principle of operation of the diesel engine make it an indispensable unit for heavy vehicles that require good traction at the bottom. Modern diesel engines work equally well in passenger cars, the main requirement for which is throttle response and acceleration time.

Difficult maintenance of a diesel engine is compensated by durability, efficiency and reliability in all situations.

Source