Signs of a problem

The problem of floating revs looks as if the car owner easily presses and releases the gas pedal (and no one actually presses the accelerator): that is, the revs are high or normal, then they drop (the engine may even stall), and then the engine picks up again ", the turnover is growing. The cycle is repeated several times.

Often the problem of floating speed is combined with difficult starting, increased fuel consumption, and failures in engine operation. There may be jerking during acceleration and vibration during idle.

For diesel engines, a typical picture is when the speed on the tachometer fluctuates when the car is moving.

Checking the flow meter and XX regulator

The speed fluctuates on a cold engine, which means we start the diagnosis by checking the mass air flow sensor. The reasons indicating its malfunction immediately make themselves felt: floating operation of a cold engine and its interruptions, the engine is very difficult to start or does not start at all, as well as significant excess fuel consumption. In order to verify that the sensor is faulty, we will use a tester. The working sensor will show a value of about 1 V. Otherwise, it will need to be replaced.

One of the main reasons causing the engine to float is a breakdown of the engine idle control. This regulator is capable of reducing, or vice versa, increasing the amount of fuel supplied, which is regulated by the operation of a rod with a special needle. To the main faults

regulators include:

Power drop

, or rather, engine speed, can be observed during the operation of some consumers, for example, headlights. If these signs are present, the regulator must be replaced.

The main reasons for floating speed on a diesel engine

Let's look at some of the most typical situations why the speed may fluctuate on diesel engines.

DMRV malfunction

Most often, the problem with floating speed on modern internal combustion engines is associated with the mass air flow sensor.

Previously, the mass air flow sensor was installed only on gasoline cars. On modern diesel engines, mass air flow sensor appeared recently.

It works in conjunction with the EGR valve and gives the engine ECU information about how much air is in the intake, how much exhaust gas is entering the intake depending on the opening of the EGR. And on a turbo diesel engine, the air flow sensor limits “smoke” so that fuel is supplied to the cylinders strictly based on data on how much air the engine consumed.

A faulty MAF sensor not only leads to floating speed and unstable operation of the diesel engine in transient conditions, but also to increased fuel consumption and loss of power. Various “cleaners” for sensors give only a temporary effect.

air leak

Often the reason for floating speed lies in airiness (suction of excess air) in the fuel supply system.

Air can enter the diesel fuel system from different places, it all depends on the conditions and operating life of the engine.

The main or return fuel supply lines may lose their tightness. The seals of connections, rubber fuel hoses and clamps may be damaged. It is also worth checking the connections between the fuel lines and the fuel filter. The tightness of the fuel line at the place where the fuel is drained back to the injectors is often broken.

To independently detect air leaks in the diesel fuel system, you need to check the tightness of the fuel supply system.

It is better to entrust further diagnostics of the condition of the fuel system to specialists.

For example, if during the procedure for independently checking the air vents associated with removing the fuel hose, even the smallest particles of debris get into it, the fuel injection pump may fail altogether.

malfunctions in the EGR exhaust gas recirculation system

The EGR valve is installed on diesel engines that comply with Euro 4 (and subsequent) requirements. The recirculation system partially removes exhaust gases from the exhaust manifold and redirects them to the intake manifold. This allows you to reduce the amount of nitrogen oxides in diesel exhaust.

A valve covered with soot does not work correctly; in a diesel internal combustion engine, untimely opening/closing of the valve leads to loss of power and rough, noisy operation.

You can assess the condition of the EGR valve visually. The resistance at the sensor connectors is checked with a multimeter.

For normal operation of the recirculation system, the EGR valve must be cleaned regularly.

corrosion/wear of fuel injection pump parts

Corrosion occurs due to water that may be present in diesel fuel. Moreover, in this case, the speed fluctuates not only on a cold, but also on a warm engine.

To solve the problem of corrosion on the fuel injection pump, it is better to use special cleaners that are poured into the fuel tank. But the advice to add a little motor oil to the fuel as a preventive measure against rust on the pump should not be followed. Modern diesel internal combustion engines simply will not withstand such experiments.

In addition to corrosion, the problem of floating speed may indicate that the fuel injection pump elements are worn out . It is not practical to repair the unit. In case of failure, the injection pump is replaced with a new one.

Fuel pumps and fuel injection pumps for diesel engines can be found in the catalog

Source

Why do the revs fluctuate on a cold diesel engine?

Starting a diesel engine in frosty weather is often complicated by the fact that diesel fuel has a higher thickening point than gasoline, so often in severe frosts it is simply difficult to pump through the fuel system. And accordingly, after starting, there may also be problems with the normal operation of the engine in different engine operating modes, including floating idle speed.

Other reasons why the idle speed of a diesel engine fluctuates when cold:

- Partial failure of the high pressure fuel pump (HPF). However, it is worth noting here that if the specified pump breaks down, the speed will fluctuate not only “cold”, but also “hot”. Usually the pump simply wears out, or is subject to corrosion or mechanical damage.

- Crankcase gas recirculation (EGR) system. If the USR valve is clogged, it may jam, which will automatically lead to a decrease in engine power and unstable engine idling.

- Malfunction of engine sensors, in particular, we are talking about the mass air flow sensor. As with gasoline engines, when the sensor fails, it transmits incorrect information to the ECU, and therefore the control device cannot set constant speed, including at idle.

- Air leak in the fuel supply system. In turn, this occurs due to depressurization of the fuel lines, for example, at the joints, damage to the seals, and so on. Due to the airiness of the fuel system, the high-pressure pump cannot pump up the pressure necessary for normal engine operation, and the speed begins to “float”, especially at idle, when its value is low. When the engine speed increases (in particular, after the engine warms up), the operation of the power unit improves.

- Clogged air filter. In such a situation, the engine will not have enough air, and accordingly, at low speeds the engine will operate unstably, both “cold” and “hot”.

Conclusion

Usually, increased and even floating speeds when starting the engine “cold” are allowed during the first few seconds of engine operation. If so, there is nothing to worry about. However, if the revolutions fluctuate for a long enough time and at the same time the car (engine) also vibrates, then this is a reason to perform diagnostics. First of all, you need to start by checking for ECU errors, and if there are any, check those components and assemblies with which they are connected. Also perform several manipulations to identify possible air leaks.

Source

What to do if the idle speed of a diesel engine is floating?

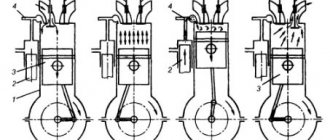

Stable operation of the engine depends on the supply of fuel, air, high-quality spark formation, and exhaust gas removal. In addition, the accuracy of valve clearances and ignition timing directly determine the uninterrupted and smooth operation of the engine.

After starting, the power unit begins to warm up. As this process progresses, the tachometer needle drops from 2500 to 800 rpm and remains at that level. If this does not happen, then you need to look for reasons and correct the situation.

Suction of unaccounted air

Most often, jumps in engine speed at idle are associated with the suction of unaccounted air into the intake manifold. The engine control unit regulates the opening time of the injectors, relying on the readings of the mass flow sensor (MAF) or absolute pressure sensor (ABP) paired with an air temperature sensor (ATS). The ECU (Engine Control Module) fuel maps contain the desired idle speed, which is maintained using the idle speed controller (IAC) or an electrically driven throttle valve.

In an injection power system with a flow meter, any leakage in the intake tract after the mass air flow sensor will cause unstable engine speed at idle. The actual amount of air entering the cylinders will be greater than the calculated values, which are based on the MAF readings. Also, a lean mixture error often occurs, since the ECU registers unaccounted air only after the fact, based on the readings of the oxygen sensor (lambda probe).

As more air enters the engine, the speed rises, causing a mismatch in the ECU between the desired crankshaft speed and the actual crankshaft speed. Wanting to equalize these values, the controller closes/opens the idle air control or throttle valve, if the IAC is not provided structurally. But due to unaccounted air, it is impossible to set the speed; they begin to rise and fall, which the driver notices by the twitching tachometer needle.

Diagnosis of main faults

The most common causes of floating speed in a modern engine are the mass air flow sensor, throttle position sensor, idle speed control and speed sensor. For self-diagnosis, you must use the exclusion method.

As for the speed sensor, this device is mounted on the gearbox and transmits signals to the controller at a certain frequency. This way the ECU understands how fast the car is moving. The internal combustion engine control unit limits the fuel supply, and the idle speed controller initiates the supply of air bypassing the throttle. Additionally, during the diagnostic process, it is necessary to clean the throttle valve area and check the functionality of the throttle position sensor.

You can quickly determine if a speed sensor is faulty by analyzing the speedometer readings. If the engine stalls at idle, and the needle on the device remains motionless as the speed increases, then it is worth checking the contact group and/or replacing the sensor.

The crankshaft position sensor acts as a synchronizing element for ignition and fuel supply. Its malfunction manifests itself in such a way that the engine simply does not start.

Floating speed on diesel

If the diesel engine speed fluctuates, then the problem may be that the moving blades of the fuel pump may be stuck. This phenomenon can be caused by rust. Corrosion occurs because diesel fuel often contains water. It is noteworthy that in such a case, the speed can fluctuate both on a cold and on a warm diesel engine.

Causes of improper idling

Wear of CPG parts is one of the common reasons why the speed fluctuates at idle. Or it could be wear and tear on the EGR exhaust system - Exhaust Gas Recirculation - this is an exhaust gas recirculation system (installed to reduce the toxicity of exhaust gases). Or it could be a problem with the ignition system. Or it could be blade corrosion.

If the EGR valve is clogged, repairs can be made by purging the system or replacing this valve.

If the diesel engine speed fluctuates, the reason may be corrosion of the pump or turbine blades.

If you add motor oil (100-200 grams) to the fuel tank of a diesel car, the pump blades will be lubricated and protected from wear.

Low compression is when the pistons, cylinders and oil rings are worn out, as well as burnt valves. It could also be a leak in the cylinder head. In this case, air leaks into the engine. Naturally, the operating mode of the motor will not be stable. To assemble the cylinder head and valve cover, you must use a sealant. There is a material about sealant - Valve cover sealant.

If the gasket under the head is broken, then when coolant gets into the cylinders, the engine may experience water hammer; this is the material used to clean the pistons.

In addition to the above parts, you also need to check the armored wires. These are the wires that go to the spark plugs. If they are broken, then the high-voltage voltage is not transmitted stably.

Checking the sensors

Unstable operation of a cold engine can also be affected by malfunctions of the speed and crankshaft operating position sensors. The speed sensor is located on the gearbox itself, which serves to transmit signals to the controller, thereby monitoring engine operation in idle mode.

Together with the XX regulator, the controller regulates the supply of air volume outside the throttle valve, and the frequency of the signal is directly proportional to the vehicle speed. In addition, thanks to this sensor, there is a significant saving in fuel consumption. If the sensor rod breaks, the speedometer needle will remain motionless until it is repaired.

The sensor responsible for the working position of the crankshaft is not only capable of influencing the floating operation of the engine, but also completely disabling it. It serves to synchronize the engine ignition systems and fuel supply system. If this sensor fails, the relationship between these systems is disrupted, i.e. it just won't start. You can determine its performance using a multimeter, and if the reason is still in it, then you need to hurry up with its replacement.

Engine idling

Engine idling is when the car is at neutral speed, no load is created on the engine, the engine operates according to the configured fuel supply mode at idle.

Sometimes it happens that everything seems to be in order, but no, the engine cannot start working stably. Stability in operation means that there is no sudden fuel supply or, conversely, a sharp limitation of it, engine vibration is at the same level, the noise is also the same.

That is, unstable engine operation is when the tachometer needle jumps from 500 to 1500 rpm. Moreover, a cold engine and a hot one can behave differently.

The simplest reason for such instability in operation is contamination of the candles, for example, flooded candles. I told you what to do in this case. Another reason could be a clogged air or oil filter or, even more complicated, wear of parts of the cylinder-piston group (CPG).

What speed should it be at idle?

Most car factories configure the engine to idle at 700-900 rpm.

In some cases, for example, if the starter or generator breaks down or if the battery is dead, you don’t need to turn off the engine, otherwise you won’t be able to start it later. Therefore, sometimes work at XX can last a long time.

Diagnosis of main faults

The most common causes of floating speed in a modern engine are the mass air flow sensor, throttle position sensor, idle speed control and speed sensor. For self-diagnosis, you must use the exclusion method.

As for the speed sensor, this device is mounted on the gearbox and transmits signals to the controller at a certain frequency. This way the ECU understands how fast the car is moving. The internal combustion engine control unit limits the fuel supply, and the idle speed controller initiates the supply of air bypassing the throttle. Additionally, during the diagnostic process, it is necessary to clean the throttle valve area and check the functionality of the throttle position sensor.

The crankshaft position sensor acts as a synchronizing element for ignition and fuel supply. Its malfunction manifests itself in such a way that the engine simply does not start.

Floating speed on diesel

If the diesel engine speed fluctuates, then the problem may be that the moving blades of the fuel pump may be stuck. This phenomenon can be caused by rust. Corrosion occurs because diesel fuel often contains water. It is noteworthy that in such a case, the speed can fluctuate both on a cold and on a warm diesel engine.

Possible reasons

The list of potential causes of floating idle speed is quite wide. Among the main ones are:

- malfunction of the mass air flow sensor (air mass meter, mass air flow sensor);

- problems with the idle air control;

- failure of the speed sensor;

- malfunction of the crankshaft position sensor;

- The throttle position sensor (TPS) is faulty

- breakdown of the idle speed solenoid valve;

Clogged injection nozzles and malfunctions in the fuel supply system can lead to unstable readings on the tachometer. For a diesel engine, malfunctions in the injection pump fuel supply system in idle mode are common.

What else can cause malfunctions?

The module and spark plugs, as well as damaged high-voltage wires, can also cause unstable speed of a cold engine. Spark plugs must be changed after 25,000. km. mileage

At the same time, periodically checking them for functionality is also important. If the spark plugs are full of carbon deposits, or they are wet from fuel or oil, they also need to be replaced. To replace spark plugs, you need to get a special spark plug wrench.

Malfunctions of high-voltage wires include the reasons why electric current does not flow to the spark plugs. This can be caused by a break in the wire, if the integrity of the insulation is violated, which causes a breakdown of the current, too high resistance of the wires, as well as extremely poor operation of the contact group.

Malfunctions of high-voltage wires can lead to failure of some sensors and disruption of their operation, and ignition of the fuel mixture in the cylinders occurs untimely, which disrupts the synchronization of their operation.

Also, the speed fluctuates on a cold engine due to the failure of the solenoid valve, which is responsible for the idle speed of the engine. To check its operation, you need to remove the power supply from it, turn on the ignition and connect power to the contacts briefly. In this case, you can hear a characteristic sound, signaling its serviceability.

On a cold engine the speed fluctuates, what should I do?

Has the revs been fluctuating on a cold engine lately? Do not rush to conclusions - this type of malfunction can be caused by a number of reasons. In any case, the problem with unstable operation of the engine must be solved immediately, so that floating speed does not end in a complex disassembly and repair of the entire engine. And these are completely different prices.

Does the speed fluctuate on a cold engine, but the reason is not clear? Start with the mass air flow sensor, whose second name is the mass air flow sensor. The stable operation of the engine directly depends on how correct and proportionate the fuel mixture is.

It is known that the composition of the fuel mixture includes the fuel itself and the air mass. In order for its composition to be optimal, a flow meter is needed. He monitors the formation of the correct proportions and provides information to the car’s on-board computer. In addition to forming the mixture, the mass air flow sensor is responsible for the volume of air that saturates the cylinders, as well as for the timely start of the engine.

Does the rpm fluctuate after cleaning the throttle body?

Firstly, an error may have been made during connection. Secondly, calibration is necessary.

The system can be trained manually without special equipment. It consists of unscrewing the negative terminal from the battery for 10 minutes. This will reset the settings to factory settings. When the terminal is returned and the car is started, everything returns to normal. Adaptation algorithm without a PC:

After removing the battery, the speed fluctuates or the engine stalls - we suggest doing the following (on a warmed-up power unit): remove the “-” terminal from the battery and return it after 40 seconds, then set the right pedal at 2100 rpm. (+/- 100) and keep at this level for at least two minutes. If you carry out these manipulations “cold”, then hold in this position for at least ten minutes.

Unstable “heart” activity (the car jerks) of your iron friend when moving is dangerous, so it is important to quickly understand and fix the problem. Sources of failures:

Also, such factors lead to the car being difficult to start.

Source

The main reasons for floating speed on a diesel engine

Let's look at some of the most typical situations why the speed may fluctuate on diesel engines.

Most often, the problem with floating speed on modern internal combustion engines is associated with the mass air flow sensor.

Previously, the mass air flow sensor was installed only on gasoline cars. On modern diesel engines, mass air flow sensor appeared recently.

It works in conjunction with the EGR valve and gives the engine ECU information about how much air is in the intake, how much exhaust gas is entering the intake depending on the opening of the EGR. And on a turbo diesel engine, the air flow sensor limits “smoke” so that fuel is supplied to the cylinders strictly based on data on how much air the engine consumed.

To check the mass air flow sensor, you need to test it with a multimeter. The normal voltage of the sensor is about 1V. Other sensors are checked in a similar way.

It is also necessary to pay attention to the integrity of the wires, terminals, and chips. If you suspect, replace the MAF sensor with a new one.

A faulty MAF sensor not only leads to floating speed and unstable operation of the diesel engine in transient conditions, but also to increased fuel consumption and loss of power. Various “cleaners” for sensors give only a temporary effect.

air leak

Often the reason for floating speed lies in airiness (suction of excess air) in the fuel supply system.

Air can enter the diesel fuel system from different places, it all depends on the conditions and operating life of the engine.

The main or return fuel supply lines may lose their tightness. The seals of connections, rubber fuel hoses and clamps may be damaged. It is also worth checking the connections between the fuel lines and the fuel filter. The tightness of the fuel line at the place where the fuel is drained back to the injectors is often broken.

To independently detect air leaks in the diesel fuel system, you need to check the tightness of the fuel supply system.

You need to start with a visual inspection of the engine compartment and the bottom of the car - there should be no noticeable cracks or other pipeline defects, fuel leaks or stains.

It is better to entrust further diagnostics of the condition of the fuel system to specialists.

For example, if during the procedure for independently checking the air vents associated with removing the fuel hose, even the smallest particles of debris get into it, the fuel injection pump may fail altogether.

The EGR valve is installed on diesel engines that comply with Euro 4 (and subsequent) requirements. The recirculation system partially removes exhaust gases from the exhaust manifold and redirects them to the intake manifold. This allows you to reduce the amount of nitrogen oxides in diesel exhaust.

The most common reason why the EGR system fails is the formation of carbon deposits on the EGR valve seat or plate due to poor fuel quality.

A valve covered with soot does not work correctly; in a diesel internal combustion engine, untimely opening/closing of the valve leads to loss of power and rough, noisy operation.

You can assess the condition of the EGR valve visually. The resistance at the sensor connectors is checked with a multimeter.

Also, when diagnosing the recirculation system, the inlet pressure is checked. If it is not standard, increased air consumption is likely - exhaust gases enter the intake manifold in excess, the fuel-air mixture is formed incorrectly, which causes unstable diesel speed.

For normal operation of the recirculation system, the EGR valve must be cleaned regularly.

On diesel engines, the problem of floating speed is often caused by the fact that the moving blades of the high-pressure fuel pump (HPF) jam when moving. The reason is the formation of rust on these blades.

Corrosion occurs due to water that may be present in diesel fuel. Moreover, in this case, the speed fluctuates not only on a cold, but also on a warm engine.

To solve the problem of corrosion on the fuel injection pump, it is better to use special cleaners that are poured into the fuel tank. But the advice to add a little motor oil to the fuel as a preventive measure against rust on the pump should not be followed. Modern diesel internal combustion engines simply will not withstand such experiments.

In addition to corrosion, the problem of floating speed may indicate that the fuel injection pump elements are worn out. It is not practical to repair the unit. In case of failure, the injection pump is replaced with a new one.

Fuel pumps and fuel injection pumps for diesel engines can be found in the catalog

When considering why engine speeds fluctuate, it is worth considering the general reasons:

What else could cause a failure?

Unstable speed when cold can be caused by damaged wires, faulty spark plugs and module. Do not forget that spark plugs are changed every 20-25 thousand km (they can change less often - it all depends on the specific model of spark plugs). It is equally important to periodically check the spark plugs for functionality. For example, if you notice that they are covered with soot, very wet, and traces of fuel or oil are visible, it’s time to think about buying new spark plugs. You can make the replacement yourself, without resorting to the help of service station specialists. But for this you will need to purchase a special spark plug wrench.

Returning to the topic of faulty high-voltage wires, you need to find out the reasons why the current does not reach the spark plugs. In most cases, this is due to a wire break or insulation failure. A strong breakdown occurs, the resistance grows to prohibitive values, the contact group does not work well.