resident Evil

Every five years, new environmental standards are adopted in Europe. As luck would have it, the greatest tightening concerns those emissions that are more typical for diesel - we are talking about nitrogen oxides and particulate matter. From Euro-3 to Euro-6, the permissible level was reduced eight and ten times, respectively.

Even with normal combustion of diesel fuel, the formation of particulate matter - soot - is inevitable. And there are plenty of incomplete combustion modes, and in each, soot emissions increase many times over. The notorious nitrogen oxides are formed in the combustion chamber at high temperatures and a large excess of air in the air-fuel mixture, on which, in fact, the diesel engine operates. Because of this same excess air, the usual neutralizer is not able to neutralize them.

To begin with, engineers had to implement an exhaust gas recirculation (EGR) system, which sends some of it back to the intake. Many people think that this is needed simply to burn off exhaust gases. This is partly true, but the main task is to reduce the amount of oxygen in the fresh fuel-air mixture and reduce the combustion temperature in the cylinder. Sometimes gasoline engines are also equipped with a recirculation system. For a diesel engine, it consists of a control valve, a gas flow cooler and an inlet shut-off valve.

The EGR control valve is installed on the exhaust side and diverts exhaust gases (EG) back to the intake. Its operation is controlled by the engine control module. A position sensor is also built into the valve. A self-cleaning function is provided: when the engine is turned off, the valve opens and closes several times. If the EGR system fails, it remains closed. However, it is not uncommon for soot deposits and corrosion to cause the valve to stick open over time. A diesel engine is already not distinguished by internal cleanliness; in addition, a full portion of exhaust gas will constantly return to the intake, which will reduce the service life of engine elements and its power.

The EGR cooler acts as an intercooler in supercharging systems. Cooled gases have a higher density, which means they require more flow. Additionally, they further reduce the combustion temperature in the cylinder. In some engine modes, such intense recirculation is harmful: it leads to incomplete combustion of fuel - for example, during startup and in warm-up mode. To avoid this, a valve is built into the system that directs gases bypassing the cooler and additionally protects it from condensation deposits due to too low a temperature.

The intake shut-off valve is nothing more than a throttle valve that is located in the intake tract in front of the exhaust gas supply channel. If necessary, it closes almost halfway, reducing the cross-section of the intake pipe. Due to this, a vacuum is created in the intake manifold and the intensity of exhaust gas recirculation increases. In fact, it is not used to operate the engine itself, except for the moment of its softer stop, when the damper closes completely and stops the air supply. A diesel engine has high-quality regulation of the air-fuel mixture, that is, only the fuel injection parameters change. In case of failure, the damper opens completely. The self-cleaning function is activated after the engine is turned off, when the throttle is fully opened and closed several times.

A malfunction of the exhaust gas recirculation system is indicated by the Check lamp. Diagnostics are carried out mainly using a computer. The good health of the system and the engine itself will be extended by periodic trips outside the city without traffic jams in order to clean them a little from carbon deposits, as well as the use of recommended motor oil and refueling at proven gas stations. The combustion products of questionable diesel fuel and cheap oil will boomerang back into the engine.

Advantages and disadvantages of a diesel engine

Now we should say a few words about all the pros and cons of such structures. Let's start with the positive aspects. Motors of this type operate on almost any fuel, so there are no serious requirements for the quality of the latter; moreover, with an increase in its mass and content of carbon atoms, the calorific value of the engine increases, and, consequently, its efficiency. Its efficiency sometimes exceeds 50%.

Cars with such engines are more “responsive”, and all thanks to the high torque at low speeds . Therefore, such a unit is welcome on sports car models, where you can’t help but rev your heart out. By the way, it was this factor that contributed to the widespread use of this type of engine in large trucks. And the amount of CO in the exhaust gases of diesel engines is significantly lower than that of gasoline engines, which is also an undoubted advantage. In addition, they are much more economical, and even before the cost of fuel was much lower than gasoline, although today their prices are almost equal.

Chimney sweep

Then environmentalists began to strongly press engine workers regarding soot emissions. For this purpose, the oxidation neutralizer, which combats CO and CH emissions, was supplemented with a diesel particulate filter (DPF). More often they are combined in one building, but there are also separate designs.

The DPF filter resembles a regular neutralizer. The difference is that it accumulates soot particles and performs their afterburning - regeneration. The process requires a temperature of about 600 degrees. Under normal conditions, the temperature of diesel exhaust gases is from 150 to 300 ºС, and by influencing the engine control it can only be raised to five hundred. The problem is solved in two ways. Following the first, the filter channels are coated with platinum. This catalytic layer reduces the soot combustion temperature to the required 500º and speeds up the process itself. The second way is to use a fuel additive as a catalyst, for which a small additional tank is provided.

After regeneration, ash residues remain, which fill the filter. They are formed from motor oil and fuel; it is impossible to convert them into anything. The useful volume of the filter is reduced, and regeneration intervals are shortened. A filter that is completely clogged is replaced.

The filter with a catalytic layer is complemented by a pressure difference sensor, exhaust gas temperature sensors and a lambda probe. The pressure sensor detects the difference in exhaust pressure before and after the DPF filter. The amount of accumulated soot is determined by the pressure difference: the greater it is, the more clogged the filter is. The condition of the filter itself is assessed using the same parameter. The engine “brain” interprets too much pressure difference as a clogged filter, lights up the Check lamp and goes into emergency mode. It will behave similarly if the differential is too low, attributing it to damage to the filter. The sensor signal also serves to monitor the regeneration process.

Depending on the complexity of the system, two to three exhaust gas temperature sensors are used, located on the filter housing. A front sensor at the inlet of the oxidation converter determines whether its operating temperature has been reached. The middle one - at the input of the DPF filter - signals the temperature required for regeneration. The rear one (not used in simpler systems) is placed at the outlet to control the temperature of the exhaust gases during the process. Based on the readings, the amount of burned soot is calculated.

The lambda probe is located behind the particulate filter; its readings are needed to more accurately determine the amount of burned soot.

The system with a fuel additive is designed and operates on a similar principle. It does not have a lambda probe and only one exhaust temperature sensor. Depending on the fuel level, an additive is injected from an additional tank (about a couple of liters) into the main tank. When the engine is running, it is deposited on soot particles in the DPF filter and its channels, acting as a catalyst. The engine control unit is responsible for regeneration. When the level of soot accumulation exceeds 60%, the “brain” begins to look for suitable driving conditions. Typically this is a speed of 40 km/h at rpm above 2000. Under such conditions, by various means (usually additional injection and closing the EGR control valve), the exhaust temperature rises to 500º. The running process is controlled by pressure and temperature sensors, since heating above 1000º can damage the DPF filter.

Under ideal conditions, complete regeneration takes 15 minutes. (Don’t panic if white smoke suddenly comes out of the exhaust pipe, and then just as suddenly disappears: this is a kind of side effect.) There are no typical intervals for this, since each car is used in its own way.

However, in real conditions everything is more complicated. Constantly driving in traffic jams over short distances interferes with normal regeneration. It can start repeatedly and never finish. Sooner or later the system starts asking for help.

When the soot accumulation reaches 80%, the DPF warning light comes on. In this case, there is still hope for the process to proceed automatically if you drive for a long time outside of traffic jams. When 100% full, the lamp begins to blink continuously. The error is stored in the engine control unit and it goes into emergency mode with fuel injection limited. In this case, you should go to a service center, where they will perform manual regeneration using a diagnostic computer. But if you ignore this warning too... When soot accumulation reaches 140%, the Check light comes on - the engine is even more strangled, but forced regeneration can still be performed. At 200% the filter can no longer be saved. But its price reaches 100,000 rubles...

You cannot diagnose the system without a computer. For its normal operation, it requires high-quality fuel with low sulfur content and periodic driving outside of traffic jams. Any metal-containing additives lead to increased ash formation in the particulate filter and shorter regeneration intervals.

What is the temperature of the exhaust manifold?

Is it critical to control this parameter or at a similar pressure the mixture should not become critically lean with a live stock pump? Is it better to install - not to install a sensor “three hundred bucks is not extra…”? Last edited by FlyHol; 01/25/2006 at 14:29.

- 01/25/2006 14:31 #6 For 300 bucks you can check the mixture using a broadband lambda and if it’s poor, buy a fuel controller and adjust it... I would do that.

- 01/25/2006 15:16 #7 And then the air temperature changed, the quality of gasoline changed, the injector went haywire, etc. And we’ve already spent a lot of money to adjust the lambda once;) At least one of the critical parameters (and EGT is not the worst candidate) must be in front of your eyes constantly, and it’s better if with a warning.

Re: What is the temperature of the exhaust manifold? August 19, 2015 at 16:40 Branches https://youtu.be/TmN_Q4YS55g everything turns red if you are very worried, wrap it with thermal tape as advised for release, you can hold on with your hand. 15 meters 2.5cm wide costs $40 Re: What is the temperature of the exhaust manifold? August 20, 2015 at 08:10 Branches I don’t agree with the video. The car is tuned, and the fuel may also burn out in the muffler. The option of wrapping tape around the manifold or hoses is fine, you can also protect the hoses with fiberglass... But the question about the temperature of the exhaust gas is still interesting)) Re: What is the temperature of the exhaust manifold? August 20, 2015 at 08:46 By Vetvyami And what is the actual problem with looking at the temperature? A regular Bluetooth scanner ELM327 shows the lambda probe temperature parameter on most cars without any problems...

Triple sheepskin coat

When additional fuel is supplied during the regeneration process, it enters the engine oil, causing it to dilute. Therefore, on the oil dipstick of a diesel engine you can sometimes see three marks: the usual two (minimum and maximum) and another mark for the maximum dilution level.

The engine control module is capable of calculating the dilution level based on the duration and intervals of regeneration. Once a certain threshold is reached, one or another indication appears on the dashboard.

You should not completely rely on electronics; you need to periodically monitor the level using the dipstick. Even before reaching the dilution limit, the oil noticeably loses its effective properties, and its combustion products additionally clog the particulate filter. Don't wait until the last minute and change your oil early. If you have a DPF, you need to use oil with a low ash content, otherwise the regeneration intervals will shorten with increasing consumption, and the oil, therefore, will lose density even faster.

Refueling and maintenance are the two most important aspects of use.

First of all, when purchasing a diesel power unit, you need to choose a normal refueling location. We are talking not only about the quality brand of the gas station, but also about the quality of the diesel fuel, which does not always coincide. Take advantage of the recommendations of experts and check the quality of diesel fuel using simple tests. The fuel should not freeze or become cloudy and should be clean under all conditions. It is also worth following the maintenance recommendations:

- For a diesel power unit, many manufacturers set a slightly shorter service interval than for gasoline engines, but this is not always the case;

- You must one hundred percent comply with all service conditions set by the car manufacturer, use only original materials during the service;

- when buying an unknown oil, you can say goodbye to the engine after 10-20 thousand kilometers; filters are also worth buying original and very high quality;

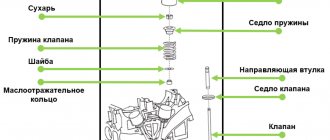

- special attention should be paid to diagnosing equipment during service - this will help avoid the most unpleasant problems associated with the injection pump and the cylinder head;

- Diesel engine repairs should be carried out immediately after the car shows a problem; this will help maintain a certain quality and the desired properties of the installation.

If a gasoline engine is sometimes operated successfully and with problems, then this idea will not work in diesel power units. It is necessary to use the services of a professional service to service the Common Rail, turbine, injection pump and cylinder head. It is these parts that most often fail and cause certain troubles during operation. A breakdown can completely disable the unit.

Road to hell

Another order to reduce nitrogen oxide emissions forced engineers to further complicate the diesel engine. But some have already reached the limit of their ability to limit their formation in the engine cylinder. Meet Selective Catalytic Reduction (SCR). You can see it not only on trucks, but also, for example, on the Mazda CX-7 diesel crossover, intended for the European market. Another neutralizer-converter and a tank with an additive - carbamide (urea) - were added to the exhaust system. This AdBlue solution is injected into the converter and converts nitrogen oxides into harmless substances.

The converter consists of two parts: a zeolite neutralizer and a slip neutralizer. Zeolite is a catalytic coating that allows the reaction between urea and nitrogen oxides to occur. In this case, ammonia is released, which neutralizes the oxides. Sometimes unreacted ammonia passes on. To neutralize it, the second part is used - the slip neutralizer. The mixer in front of the SCR converter ensures an almost uniform distribution of urea in the exhaust gas stream and helps to evaporate it.

The NOx (nitrogen oxide) sensor monitors exhaust gas purification. It works similar to an oxygen sensor. Moreover, it is connected to a separate control module and forms a single unit with it.

The 15 liter AdBlue tank has a built-in pump and heater. The solution itself is harmless, but begins to freeze already at -11º. According to the regulations, it must be replenished and sometimes updated. The nozzle is located in front of the SCR converter and injects urea into the mixer. A separate module controls the operation of the system. The SCR indication is mainly due to a low amount of fluid. If there is a malfunction, it is supplemented with a “receipt”. In some cases, the engine may be blocked from starting.

As in other systems, diagnostics are entrusted to the computer. The system is very demanding on fuel quality, which is why most of the problems are caused by it.

So, the conclusion. Keep an eye on the lights on the dashboard, don’t skimp on fuel and oils, take the car out for a country walk from time to time and don’t be lazy to check the oil level - then your life together will last longer.

The amount and temperature of exhaust gases are under control!

Any failure of any engine of any vehicle causes a lot of thrills because it happens (in most cases) at the very moment when you demand maximum performance from it: take-off, climb, go-around... You might think that if in the moment of overtaking (this is about cars) the engine sneezes with a loss of power, then everyone will be wildly delighted...

So which is better? Should you put on pink driving glasses - “it’s a foreign car, what will happen to it...” or, having read the “Operation Manual” from “A” to “Z”, be prepared for a sudden failure? My opinion is that the second option is preferable, and the best option is to prevent refusal..... What is needed for this? — Competent operation with timely maintenance along with monitoring and diagnostics.

Failures of the crank mechanism and cylinder-piston group are the most dangerous due to the “suddenness” and severity of the consequences. The bulk of such failures are associated with disturbances in the combustion process. There is a need to control and understand this process.

Water dispenser?

Most diesel fuel filters have a built-in water level sensor. It enters the fuel in various ways and leads to corrosion of fuel equipment elements. The density of water is higher than the density of diesel fuel, so it accumulates at the bottom of the filter. The float sensor will notify you when it is overfilled. A bolt or cover is provided for drainage.

Some filters have a heater built into them. It can handle light waxing of diesel fuel in cold weather, but only if the fuel is originally winter grade.

Sometimes on the filter housing you will find a hand pump for bleeding the system that has taken in air.

Hydrogen sulfide H2S

The effects of this gas on organic life are not yet entirely clear to science, but it is known that it can cause severe poisoning in humans. In severe cases, there is a risk of suffocation, loss of consciousness and paralysis of the central nervous system. In chronic poisoning, irritation of the mucous membranes of the eyes and respiratory tract is noted. The smell of hydrogen sulfide is felt already at a concentration in the air of 0.025 ml/m3.

Hydrogen sulfide in exhaust gases occurs under certain conditions, even despite the presence of a catalyst, and depends on the sulfur content in the fuel.

Universal hair dryer

Most diesel engines are supercharged. The turbines in them are quite tricky: each manufacturer sees their variable geometry in their own way.

Some build guide vanes into the housing, which can change the flow area of the exhaust channel in front of the turbine wheel. This results in constant boost pressure over a wide speed range. Others went even further, building two turbines - high and low pressure - into one large housing.

In a diesel engine, the turbine is thermally less loaded than in a gasoline engine. But the gasoline rules for extending the life of this unit also work here. Do not turn off the engine immediately after stopping. If before this there was driving with a high load or regeneration was in full swing, then the exhaust temperature can be very high. By the way, you can install a turbo timer and entrust it with the care.

How they checked

All measurements were taken on a Volkswagen Polo 1.6 MPI with a manual transmission. Each time, parts and assemblies were measured at the same points (in some cases, a shift of just a few centimeters gave completely different numbers). Each point was measured several times to ensure repeatability of the result. It was entered into the table.

Measurements were carried out using a non-contact thermometer HW600. At one time, we already explained why the figures obtained using such devices cannot be considered 100% reliable. All bodies emit radiation in the infrared range of electromagnetic waves. By measuring the power of this radiation, the surface temperature can be obtained. But different bodies have different emissivity. In a non-contact thermometer, the coefficient is set by the manufacturer and is unchanged, so an error of several degrees is inevitable. But this is if we measure the temperature of different objects. If we take the same surface, then as it warms up or cools down, we can record the difference in temperature, and this is exactly what we need!

Candlestick

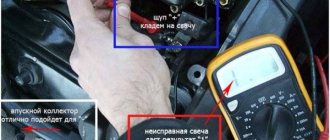

To make starting easier in cold weather, pre-heating is used. Special spark plugs heat the combustion chamber to 1000º in a couple of seconds. This makes it easier for the fuel to evaporate and ignite the mixture. But, unfortunately, a malfunction of even one of them can put an end to a successful launch.

Currently, spark plugs operate in three modes: the usual preheating, accompanying and DPF regeneration mode. The accompanying mode is used when the engine is cold and lasts about four minutes. It is needed mainly to reduce harmful emissions. In regeneration mode, the spark plugs can further increase the exhaust temperature. It is not in our power to extend their life, and therefore we will only advise you not to rush to start the engine right away: it is better to wait a few seconds after their indication on the dashboard goes out.

Exhaust temperature

- 01/27/2006 07:01 #18 I read it, good article. If I have time today, I’ll translate it and post it here.

- 01/27/2006 07:46 #19 Does anyone have any reliable information about how long a thermocouple lasts, in months or kilometers? Otherwise you often come across that they say it will burn out if it is close to the head, and where to put it, for example, on a four-wheel drive engine, here The manifold length to the turbo is 10 cm in total.

GT-T 5MTGarrett Edition

01/27/2006 08:02 #20 where is the correct place to put it before the turbo or after the turbo? S15 spec R https://www.brn-gt-club.ru https://www.kels.ru Return to the list of topics Sale of GT car Toyota Altezza 1998 RUB 320,000 Toyota Celica 2000 RUR 355,000 Toyota Celica 1998 RUR 333,000

GT flea market NEW.

Tricky oiler

The indication of high oil dilution depends on the specific vehicle. This could be a DPF light, a familiar oiler, or a specific text warning. Some machines have separate high and low oil level sensors. When the indication has already appeared, the engine can go into emergency operation mode with power limitation.

After each oil change, you should use a computer to inform the engine “brain” about this by reconfiguring the dilution calculation

Diesel engine: soot and crap

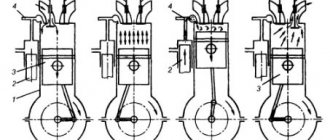

Combustion pressure limitation

In diesel engines, due to the fact that the evaporated fuel mixed with air burns sharply under strong compression during the ignition process, we will talk about “hard” or “noisy” combustion. The high peak pressures that will result from this require fairly robust engines. The forces generated during combustion cause periodically changing loads on engine parts and, based on their size and service life, these parts impose restrictions on combustion pressure.