How to increase the power of a diesel engine with your own hands?

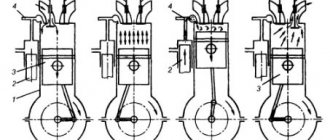

The compression at which fuel is introduced into the combustion chamber directly affects engine performance. As the compression ratio increases, the pressure increases. This contributes to more efficient combustion of the fuel mixture, releasing maximum useful energy and increasing engine power.

To increase compression, you need to adjust the power system, which regulates the time, pressure and proportions of the fuel mixture supplied to the combustion chamber. There are two power systems:

- Mechanical injection system - installed in older models of engines used before 2008. The mass of injected fuel is determined by the injection pump, from which fuel is pumped to the injector. The frequency with which the crankshaft rotates determines the injection power;

- Electronic injection system - installed in all modern cars. Fuel is pumped into the rail, electromagnetic injectors provide injection, and the electronic control unit regulates mass, compression and injection time.

By changing the power system with an electronic injection system, it is possible to improve the factory performance of an internal combustion engine.

Please note that some of the methods described below are not suitable for a mechanical power system.

Increasing engine power on high-pressure diesel engines

Improved engine performance is achieved by installing a special unit that replaces the operating modes of the fuel pump (HPF). Suitable for some engines equipped with older pumps (manufactured before 2008) under the brand BOSCHVP 44. Such installations are characterized by the fact that high pressure is accumulated in the pump, and not in the HP ramp.

An increase in diesel engine power is achieved by lowering the values shown by the fuel pressure indicator. And this causes an increase in pressure in the pump (in its body). All the work is done by the solenoid valve (it controls the pressure). Moreover, it operates outside the nominal modes, which leads to a decrease in the life of the high-pressure pump.

The described increase in diesel engine power has the following advantages:

- quick installation;

- there is no direct impact on the volume of emissions of harmful elements;

- the service life of the cylinder block is not reduced;

- the element base is inexpensive and objectively simple.

This block, of course, is not without its drawbacks:

- smoke is detected from the exhaust pipe (it is called after operational);

- the resources of the electromagnetic injector and fuel injection pump are reduced;

- floating engine speeds are observed.

Ways to increase diesel power.

1. One of the most common methods for increasing the power of a diesel engine is the use of a Common Rail system. This system has long been used by diesel owners. The essence of the work of the considered set is as follows. The system supplies the composition to the combustion chamber, regardless of the speed and power of the engine. In the standard engine configuration, compression is carried out in the intake manifold, while when using the CR system, pressure is created at the moment the composition is supplied to the combustion compartment. In this regard, this combination makes it possible to formulate the fuel composition and combustion indicators specifically for a specific cylinder.

According to the manufacturer, the system successfully increases motor performance by up to 30%. Performance indicators for any engine depend on the pressure under which fuel is supplied to the combustion site. The modern Common-Rail system is one of the most effective means of increasing the operating power of a diesel engine.

2. Another popular and no less effective way to increase engine operating power is turbocharging. Turbocharging supplies air flow into the cylinder, thus increasing the supply of the fuel mixture. This process allows you to achieve greater engine performance. As you know, turbocharging is successfully used on both gasoline and diesel engines. At the same time, the use of turbocharging for a diesel engine has some subtleties. When upgrading a vehicle with this device, it must be taken into account that the pressure in the exhaust system of a gasoline engine is almost two times lower than that of a diesel engine.

Turbocharging helps prevent engine failure when you press the car's stop pedal. Therefore, for a diesel engine, the turbine is one of the most important elements. The turbine requires proper care and timely maintenance. This element can significantly increase the technical characteristics of the vehicle, but at the first symptoms of a turbine malfunction, it is necessary to promptly begin diagnostics.

3. One of the most modern ways to increase the power of a gasoline or diesel engine is chip tuning. The essence of tuning is to install an electronic controller that is capable of changing the pressure characteristics in the fuel system. Also, the installed chip monitors the fuel mixture supply time and increases engine performance. A modern chip allows you to significantly increase the efficiency of the motor. Manufacturers of this equipment have managed to increase the performance of a diesel engine equipped with a turbine by 30%. At the same time, installing a chip allows you to make the engine more economical.

Doing chip tuning yourself is quite difficult. Installing the controller requires special skills. Each installation of the controller is accompanied by additional adjustment to the propulsion system of a particular vehicle. Before installing a chip that increases the power of a car, it is imperative to carry out a detailed diagnosis of the propulsion system. Since this method requires special skills and certain experience, it is recommended to turn to professionals to obtain the desired result.

Increasing engine power is a very important operation, during which it is worth taking into account the characteristics, as well as the level of wear of the fuel and engine systems. To maintain engine performance, regularly maintain your car and perform preventative maintenance according to the manufacturer's recommendations.

Happy modernization!

Increasing diesel engine power

Engine power is directly affected by compression of the fuel supply to the combustion chamber. Increased pressure will greatly contribute to more efficient combustion of fuel. This releases more energy and increases power.

An increase in compression can be achieved by adjusting the power supply systems, which regulates the proportion of fuel entering the chamber. The following power systems are distinguished:

- Mechanical injection.

Now practically not used. Installed in engines that were produced before 2008. In this case, the fuel mass is determined by the fuel pump. The crankshaft rotation speed is determined by the injection force.

- Electronic injection.

Used on almost all modern machines. This is where fuel is pumped into the ramp. The injection itself is carried out using magnetic injectors. The injection time and compression are adjusted using an electronic unit. The technical characteristics of the motor can be improved if some changes are made to the power system.

The following will describe methods for improving motor performance that are only suitable for an electronic power system.

How to improve the performance of a diesel engine?

An article about how you can improve the performance of a diesel engine - tips, recommendations, description of necessary actions. A strong engine means speed, and who doesn’t like driving fast! Many car enthusiasts are susceptible to the idea of creating a more powerful engine. Refinement of the engine will increase its dynamics and reduce fuel consumption. Increased dynamics gives the driver confidence behind the wheel. The ride becomes more comfortable, and the driver’s actions when overtaking appear decisive.

One of the main advantages of increasing engine dynamics is a sharp start and rapid acceleration.

If you approach this procedure competently, you can reveal the hidden capabilities of the automobile “heart”.

There are several ways to increase engine power. Some of them have a low level of difficulty and can be completed by every car enthusiast; others will be very problematic to carry out without the intervention of specialists.

Increasing car engine power with your own hands

Increasing engine power is a type of tuning. Outwardly invisible to the human eye, but noticeably improves the dynamics and quality of the car.

There are 6 ways to increase power:

1. Installation of a wide-phase camshaft instead of a standard mechanism.

A convenient and budget option for increasing power with your own hands. They hire an experienced minder as an assistant. It can be done without the use of special equipment.

Installation of an improved camshaft allows for maximum filling of the cylinder chambers at high speeds. Excellent price-to-result ratio.

2. Reducing the friction force.

Reducing mechanical losses while reducing friction forces allows you to achieve positive dynamics in increasing power. The emphasis is on reducing the friction force of the pistons on the cylinder walls.

There are several ways:

- reducing the thickness of the piston rings;

- reduction of the piston skirt;

- making changes to the connection of the connecting rod to the piston by moving it into the piston bosses.

3. Reducing the weight of the piston group.

To increase engine power, standard engine components are replaced with lightweight versions. The effectiveness of the method is questioned by experts. Today it has not been proven that changing the weight of the piston group increases engine power.

4. Boring of cylinders.

An effective but costly method. Increases engine power. Boring the cylinders increases their volume. It turns out to be a good gain over standard power. Among the disadvantages is the increased “appetite” of the car, expressed in increased fuel consumption. The cost of using the machine increases.

5. Engine chip tuning.

Many motor manufacturers include a power reserve when creating them. In normal condition it is not used. Designed to maintain stable engine operation. Power is limited due to electronic blocking.

Software, straight hands and a laptop can unlock the hidden reserves of the motor. You can achieve an increase in power. Among the disadvantages of the engine tuning method is a reduction in service life.

6. Direct-flow muffler.

Installing a direct-flow muffler gives a slight increase in power. Resistance to exhaust gas pressure is reduced due to a special design. Among the disadvantages, there is an increase in noise when driving. Causes complaints from the traffic police.

The above methods are used carefully so as not to damage the engine. A reasonable approach and competent execution of the work are required.

Increasing the compression ratio

The efficiency of fuel combustion directly depends on the compression ratio. The lower the fuel level required to achieve power, the higher the compression ratio will be. The high efficiency of a diesel engine compared to a gasoline engine depends on the compression ratio used in them. For diesel engines, the compression ratios are from 18:1 to 22:1. These advantages are fully realized due to the fact that diesel engines do not have a throttle valve. Let's say the power increases to 2% if you increase the compression ratio by just one.

It is worth noting that by increasing the compression ratio it is not always possible to achieve an increase in power. As the compression ratio increases, engine reliability and power may deteriorate if the compression ratio is close to the detonation limit of a given fuel type.

Method No. 2. Power increasing blocks

The popularity of using blocks to increase the power of a diesel engine is explained by their versatility, quick installation and ability to significantly save fuel.

Among the disadvantages, it is worth noting a decrease in the service life of the cylinder block, injectors and injection pump and the rapid depletion of the particulate filter. Also, the modular method, in contrast to properly carried out chip tuning, increases the emission of harmful substances.

The unit is included in the high-pressure fuel system and its computing module controls engine operation, bypassing the ECU, without underestimating sensor readings. By diagnosing the pressure in the fuel system, and when it increases, it sends a command to the control unit to increase the injector timing within the permissible range.

Installing the module allows you to control and change injector control pulses. The module is connected to the injector wire gap and regulates the operation of the fuel injector by changing the opening time of the injector needle. As a result, the fuel injection angle changes and combustion efficiency increases.

Installed on diesel engines with a mechanical injection system. The block increases the power of a diesel engine due to changes in the functioning of the fuel pump. The module adjusts the fuel sensor data to lower values. As a result, pressure increases in the fuel pump housing using a solenoid valve.

The positive aspects of this method include inexpensive equipment and ease of installation. The disadvantages include floating engine speeds and reduced fuel injection pump life.

The equipment connects to the wires of the rail pressure sensor and sends data about a decrease in compression in the fuel rail to the electronic control unit. The ECU changes the intensity of the injectors, the power of the internal combustion engine increases, and fuel consumption decreases.

The fuel pump is responsible for regulating the pressure level in the fuel accumulator. By installing an additional unit in the electronic circuit of the fuel system, information about the loss of fuel injection pump power is supplied to the ECU. The ECU will give a command to increase the injection timing.

Method number 3. Turbocharging

Engine performance is increased by installing a turbine, which supplies a large amount of air into the combustion chamber. The fuel system control unit gives a command to increase fuel injection and engine power increases.

The disadvantage of this method is the increase in fuel consumption and the short service life of the turbine. At the same time, turbocharging prevents the engine from stalling when you press the car's stop pedal.

Cleaning the intake valves from carbon deposits

This is necessary so that the compression is better.

We buy a can of Wynn's Diesel EGR 3,

We remove the pipe going from the intercooler to the intake manifold and, with the engine running, GRADUALLY and A LITTLE LITTLE splash into the manifold. Very, very neat. The liquid is very caustic and also flammable. It is necessary to ensure that the motor does not catch a hydraulic shock, and that a very huge piece of carbon deposits falling off the valve stem does not jam the motor. In general, you need to spray and gradually add gas so that you spray out this cylinder no faster than in 30 minutes.

After this, it is advisable, without turning off the engine, to put on the pipe from the intercooler to the manifold and go for a drive in third speed. So to speak, let the engine “fuck off.”

What does motor power depend on?

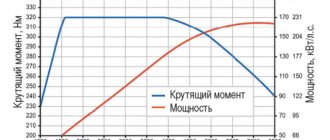

Car engine power is a value obtained by multiplying engine speed by torque. Power is a constant value for a particular car. To increase power, you need to increase the speed. In fact, not everything is as simple as it might seem at first glance.

There is a mechanism for changing the valve timing. It plays the role of a regulator in the motor power system and is a stumbling block on the path to increasing engine power.

The main task of the gas distribution mechanism in the engine is to ensure uniform filling of the cylinders with the fuel-air mixture. The gas distribution mechanism shows different results depending on the operating ranges of the engine.

Low speeds do not contribute to the complete filling of the engine cylinder chambers. The power build-up is slow and sluggish. To fully fill the chambers, the engine speed should approach 3000 thousand. Excessive use of a sharp increase in speed and an increase in speed at the start is fraught with rapid wear of the clutch.

Manufacturers of power plants have learned to overcome the limitations associated with the gas distribution mechanism. The electronic system automatically regulates the phase change conditions depending on the driving style. Allows for efficient filling of the cylinder chambers with the fuel-air mixture without the threat of clutch failure.

Most of the cars driving on the country's roads cannot be classified as new. Almost 80% of the car fleet is represented by used cars with various mileage levels.

The prevailing motors are not equipped with a complex electronic control system. The fuel-air mixture is used inefficiently. Cars can and should be upgraded to increase engine power.

Basic methods for increasing engine power

In practice, you can increase the power of both gasoline and diesel engines. To achieve the best result, it is recommended to use the entire range of measures.

Increasing cylinder volume and compression ratio

Changing engine size is a fairly common and simple method. It can be implemented by several solutions at once:

- Boring of cylinders followed by installation of larger diameter pistons. It is very important that all cylinders are bored equally.

- Replacing the cylinder head gasket with a thinner one.

- Grinding the cylinder head.

Any plumbing work to change motor parameters should be carried out only by an experienced specialist. It should also be understood that such procedures, one way or another, are an intervention in the design and affect the operation and service life of the engine.

Replacing motor parts

Installing lightweight parts instead of factory ones allows the engine to run faster, and therefore efficiency increases. As a rule, the flywheel, pistons and rings are replaced. The lighter flywheel spins faster and increases power by up to 4% of original power. The other side of the coin is unstable idle. The light flywheel lacks inertia. Lightweight pistons and rings are one-piece forged designs that not only make the engine run faster, but are also more durable.

Method number 1. Chip tuning

Chip tuning is reprogramming the factory settings of an electronic control unit. The ECU is the most important part of the engine, receiving information about the engine's condition from sensors. Using this information, the ECU determines the optimal crankshaft speed, fuel delivery and air volume. The settings set in the ECU at the factory are designed for average performance and saving engine life.

Reflashing the ECU allows you to build in your own data processing system. Pulses coming from the sensors are converted using special programs and form an automatic control system for injection mechanisms, which improves many characteristics.

There are two options for chip tuning: reconfiguring the factory ROM chip or replacing it with further firmware. You need to choose a chip tuning option and prepare:

- Buy a scanner to diagnose your car brand;

- Carefully select the firmware version;

- Install a firmware editing program on your laptop that is suitable for the machine’s ECU;

- Purchase a microcircuit if you decide to change it (ROM 27S256 or ROM 27S512);

- ECU programmer. Buy, rent, do it yourself;

- Find a K-Line adapter to connect to the car port.

Procedure:

- Using a diagnostic scanner, check for errors and, if any, reset them;

- Disconnect the battery;

- Remove the panel and take out the control unit;

- Replace the ROM chip;

- Put the control unit in place;

- Connect the battery;

- Connect the laptop to the diagnostic port. The laptop must be fully charged, or better yet connected to power;

- Turn on the ignition;

- Launch the program to reconfigure the engine;

- After installing the software, turn off the ignition and disconnect the cable.

Advantages of chip tuning:

- Increased dynamics;

- Economical fuel consumption;

- No maximum speed limit;

- Changing cold start and running modes.

Chip tuning will have the greatest effect in diesel cars with a turbine by optimizing the switching system and pressure. Torque increases by almost half, and power by a third.

Disadvantages of chip tuning:

- With a significant increase in power, the service life of the engine will be shortened;

- Revocation of warranty;

- There is a risk of engine damage.

Incorrect firmware can lead to engine detonation.

Thus, we see that replacing the chip significantly increases the efficiency of the engine. However, in order to competently reprogram the ECU, special skills are required, and not every car owner can do this with his own hands.

What you need to know about chip tuning

Chip tuning means changing the standard control program of an internal combustion engine in order to increase its power. As the reader probably guessed, you will have to pay something to improve the performance of the motor. We'll talk about this a little later, when we talk about the disadvantages of chip tuning. For now, let's try to highlight the advantages

"firmware". These usually include:

- Relatively cheap. The chip tuning procedure is much cheaper than the simultaneous purchase and installation of engine supercharging units, new exhaust system elements, zero-resistance filters, etc.;

- Improved power performance. The standard engine power is slightly reduced relative to the potential maximum that can realistically be achieved. We will also examine this point in more detail;

- “Tailoring” the car to the owner. Thanks to chip tuning, you can modify the car for specific operating conditions and, if necessary, roll back the changes.

As owners of cars with a chipped engine note, after the modification they began to clearly feel the difference between 95 and 98 gasoline. In a sense, engines became more economical. The reason lies in more efficient use of fuel - consumption is almost the same, but the output power is slightly higher. But what about the cons? They are:

- Reduced fuel efficiency with an aggressive driving style and when using “aggressive” firmware;

- Accelerated consumption of engine and transmission life and, accordingly, reduction of intervals between repairs of units, replacement of certain consumables, etc.

The reader may think that automobile concerns deliberately create programs and set calibration coefficients that are unfavorable for the car owner in order to underestimate the power ratings of engines. In fact, this is not entirely true. Power density is not

a key factor in the design and production of engines. Units must comply with environmental standards. A small operational resource is unacceptable. Don’t forget that the taxes levied on transport are not the same. They also depend on the type, volume and power of the power unit. Sometimes the operation of engines is tightly controlled by a program to ensure that the driver fills the car with a specific brand of gasoline. Chip tuning allows you to remove, albeit artificial, but not without reason, restrictions. After its implementation, powerful indicators will increase by the following amounts:

- Atmospheric engines: a stable increase of 3-7%, in some cases up to 15% (depending on the model of the unit);

- Engines with a supercharging system: a stable increase of 20-25%, in some cases up to 40-50% (applies to both diesel and gasoline).

Regular aspirated

with a volume of 1.5 liters it is usually possible to “invigorate” a maximum of 10 hp. At the same time, units with KE-Jetronic injector and mono-injector are not tuned in this way. Another thing is supercharged engines, which can be boosted by paying for it with operational resources. Power indicators can be increased both with and without additional mechanical modifications. There are several levels (stages, from the English Stage) depending on the number of purely mechanical modifications:

- Stage Option for cars with factory equipment. Gives a stable, but not the greatest increase in power;

- Stage Suitable for vehicles with a removed catalyst and particulate filter, modified intake and more efficient intercooler. It is also advisable to install a sports exhaust. The increase in power is more significant;

- Stage This level can be completed after Stage 2. Installation of a more powerful turbine/supercharger is recommended. The increase in power is very noticeable and is often equal to two-thirds of the standard indicators.

Properly carried out chip tuning will not greatly affect the service life of the engine. But an incorrectly selected program can greatly harm the same gearbox. Here's how it works: we have a conventional box designed for a torque of 250 N*m

, and after tuning the torque increases to

300 N*m

. The unit will work for some time without breakdowns, but sooner or later they will definitely happen. By the way, after chip tuning, the car owner in most cases loses the factory warranty. Special centers engaged in such tuning will insist that software changes will not be noticed during warranty service, but there is still a possibility of such an outcome.

Types of chip boxes

Power increase modules can be divided into several groups according to their operating principle

1

Changing injector control pulses

Devices operating on the first principle provide direct intervention in the operation of the fuel system, blocking several of its important stages. This changes the fuel injection angle and seriously reduces the overall engine lifespan. Until recently, this was the most common way to increase the power of an internal combustion engine.

2

Replacing fuel injection pump operating modes

Power increasing units with replacement of fuel injection pump operating modes do not have a negative impact on the engine cylinder block. They stimulate an increase in pressure in this unit, changing the readings of the corresponding sensors. As a rule, they are used in diesel internal combustion engines produced before 2008.

3

Changing fuel pressure sensor readings

The third type of power increase unit works, as the name suggests, as follows: it changes the readings of fuel sensors (but not below the nominal value) in the data channel without disturbing the optimal operating conditions of the engine. As a result, the time interval for fuel injection (injector opening period), calculated by the ECU, undergoes changes in the direction of increasing it.

4

Gas pedal booster

This is a trick that makes the engine ECU think that you pressed the gas pedal hard at the moment when you press it as usual. Positive changes noted by all those who have installed such a device are the disappearance of turbo lag, faster acceleration. Of course, consumption increases slightly, but not enough to pay attention to it.

What parameters change

After chip tuning (stage 1 and beyond), a number of calibration parameters stored in the ECU memory will be subject to change. The number of changes can reach 20, and in the case of certain firmware versions it can be more. First of all, the following are corrected:

- Excess factor;

- Bypass valve operating parameters;

- Calibration factors;

- Valve timing.

To better understand the extent of the change in ECU memory, here is a partial

list of changes in diesel engine management. After stage 1 the following are changed:

- Gearbox switching time;

- Turbo limiters, turbine pressure and its duty cycle;

- Injection start time:

- Limiters of torque, temperature, smoke;

- Throttle valve opening parameters and sensitivity;

- Lambda probe monitoring;

- Main pressure.

As stated in the previous section, after chip tuning the engine can be used to its fullest, which affects its service life. If high-quality, thoughtful tuning was carried out in accordance with the capabilities of the power unit and transmission, there is nothing to fear - the driver uses the full potential

engine in rare cases. For most of the operating period, the load on the unit is only partial. Usually, with incorrect chip tuning and attempts to squeeze the maximum out of the car, the gearbox is the first to suffer (the specified torque is inadequate), but the engine also suffers. Interesting fact: despite a small increase in power after flashing the naturally aspirated engine control unit, the car still becomes more “vigorous”. This is due to a significant increase in torque, which becomes especially noticeable in the zone up to 4000 rpm. The overall dynamics are also improving, but environmental performance is getting worse.

How is chip tuning done?

The cost of high-quality flashing can reach $800-900. A special feature is custom firmware, which can cost up to several thousand and even more than ten (!!) thousand dollars. At the same time, specialists not only make changes to the program of a part of the control unit, but also conduct high-quality diagnostics in order to identify faults that may interfere with chipping. The normal algorithm for preparing a vehicle and flashing it looks like this:

- Diagnostics and troubleshooting;

- Removing speed indicators with standard ECU programs;

- Development of a suitable firmware version;

- Removing the electronic control unit;

- Reflashing and testing the car on the stand.

Typically, specialists do not conduct a test drive and limit themselves to checking at a stand.

, and the driver is asked to evaluate whether the desired result has been achieved. Note that steps 3-5 can be repeated up to 2-3 times. The firmware may be updated with new versions that take into account the shortcomings noted by specialists or the driver. A good tuning center will also give you a guarantee and even return the money spent if you are dissatisfied with the quality of the work performed.

Tuning without flashing

It is possible to improve the power performance of the engine and make it more responsive to manipulations with the gas pedal without making changes to the software of the standard ECU. Technically, some options also refer to chip tuning, but external, and not to a global change in the original control unit. There are 4 options to choose from:

- Gas pedal booster settings;

- Installation of an additional block with advanced capabilities (piggy-back);

- Complete replacement of the standard control unit (stand-alone);

- Using a tuning box (powerbox, chip box, tuning box).

The gas pedal booster is connected to the open circuit of the electronic gas pedal and increases the signal, giving the ECU other information. Simply put, the control unit perceives a signal of 20% pressing as if the driver is pressing up to 40%. This means that the pedal becomes sharp, but at the end of its travel there is almost no response from the engine. Booster doesn't give

increase in power.

An additional unit is installed both to improve the engine’s power performance and to maintain the normal operation of the on-board electronics and immobilizer. Usually it is connected through the main wiring connector, but there is an option to connect via a cable to the standard control unit. The compatibility of such devices with modern cars is questionable, but additional units for obsolete passenger vehicle models can still be found on sale.

advanced capabilities in its place

It’s not cheap, but it gives approximately the same result as high-quality type tuning.

This is a good option in cases where you want to quickly convert a city car into, for example, a rally vehicle category. At the same time, installing such units always

requires special knowledge and consultation with a specialist - many device models are potentially harmful to specific car models.

One of the simplest tuning options is the installation of a chip box, which intercepts and changes signals from sensors and sends them to the main control unit. It is correct to call such a device a multifunctional “cheat” that will help unlock the potential of the engine. Such boxes need to be selected wisely and consulted with a specialist. If you decide to install a unit that comes to hand by chance, then there is a possibility that the boost parameters will go beyond safe limits, almost one hundred percent exceed the limits of environmental standards, accelerated wear of the catalyst and particulate filter, an increase in fuel consumption (on average by 20%) and much more.

Air filter

It should be as large an area as possible and have a rigid metal mesh.

In our country, the filter must be changed every 5 thousand km. mileage, as well as engine oil. I recommend the air filter Bosch 0986AF2067. He is the notorious “original”

Do you see two stiffening ribs on the mesh? So that. The mesh just doesn't fit. There are also filters without a metal mesh at all - these CANNOT be installed!

Those. Here's a good filter:

But this is NOT possible:

Naturally, all four bolts connecting the air filter box must be tightened. If the threads are broken, then take longer bolts, put wide washers and install nuts.

When choosing a module, pay attention to the following characteristics:

- Brand and operating principles;

- Real results (graphs of bench measurements);

- Speed of microprocessors or their availability;

- Number of data processing channels (connection points);

- Ability to select programs;

- Tightness of execution;

- Reliability of connectors.

Advantages of chip tuning:

- More changeable parameters. They can be adjusted more accurately.

- The reliability of the engine is equal to the factory one.

- Great increase in power.

- Uniform increase in power and torque.

- Less fuel consumption during quiet driving.

- No additional devices.

- The engine life is higher than when using tuning boxes.

Advantages of the tuning box:

- The ability to independently restore factory settings.

- Easy to install.

- Easy to reinstall on another car with the same engine.

- Low price.

- Usage cannot be tracked.

Sources

- https://koleso.temaretik.com/1699146910712989990/tri-sposoba-uvelicheniya-moschnosti-dizelnogo-dvigatelya/

- https://xn—-7sbfgyinmbd7aq0n.xn--p1ai/uvelichenie-moschnosti/blok-uvelicheniya-moschnosti-dvigatelya/

- https://zen.yandex.ru/media/id/5c7d2c2eeada0500b2d920cf/chiptiuning-chto-eto-kakovy-dostoinstva-i-nedostatki-5ec10a3738e7d258172a63e6

- https://eneosservice.ru/moduli-uvelicheniya-moshchnosti

- https://KrutiMotor.ru/chip-box-dizelya/

- https://spidertuning.ru/stati/tiuning-boks-protiv-chip-tiuninga/

Measures available to the average car owner

lighten the design of the car

The easiest way to add dynamics is to reduce the weight of the car, thereby reducing the load on the engine. And every ten kilos matter. It is no coincidence that new generations of the same cars boast of “losing weight” by 20-30-40 kilos due to aluminum body parts.

install a zero resistance air filter

This method reduces air resistance at the inlet - as a result, more air enters the chamber. The increase in power is minimal, about 0.5-2.5%, and on some engines it is not observed at all, but the availability of this method has made the installation of “nuleviks” popular. And the zero filter looks impressive, sporty.

True, you have to pay for reducing air resistance with worse filtration - with such a filter, the likelihood that small debris will get into the intake manifold is higher.

perform exhaust tuning

This point includes a whole range of measures.

You can replace the exhaust pipes with pipes with a different diameter, install a direct-flow muffler, remove the EGR valve and particulate filter, which programmatically “choke” the engine.

All these measures are aimed at reducing the resistance that is created during the release of exhaust gases and optimizing their movement through the exhaust manifold.

As a result, the diesel engine will pick up speed better and accelerate faster. Proper exhaust tuning can add up to 5% power to a diesel engine.

perform diesel chip tuning

Another method accessible to the average owner is to reflash the diesel control unit in such a way as to change important characteristics such as the composition of the air-fuel mixture and increasing torque.

Properly carried out chip tuning allows you to extract more power and torque from the engine, reduce the effect of turbo lag, increase the stability of the diesel engine at idle speed - and all this without the need to make changes to the engine design.

On the other hand, errors in chip tuning will cause engine malfunctions and significantly reduce its service life.

Reducing friction force

You can also quite well increase the number of “horses” if you reduce the friction force between the piston and the cylinder walls. Of course, there is motor oil for this, but as a rule it is not enough, so various additives are used. Can I recommend the Suprotec additive, about which there are a lot of rumors; some are not sure how it works. Someone says that it really works, we belong to the second type of people and recommend this additive. In principle, you don’t have to trust us and use some other additive from another manufacturer, it’s your choice.

Using this method, you can achieve about a 7% increase, and also improve the reliability of the engine due to the fact that the friction force of the piston on the cylinder walls will be less. There is also a rumor that this additive reduces fuel consumption, but we have not tested this and will not confirm this rumor.

Method No. 2. Power increasing blocks

The popularity of using blocks to increase the power of a diesel engine is explained by their versatility, quick installation and ability to significantly save fuel.

Among the disadvantages, it is worth noting a decrease in the service life of the cylinder block, injectors and injection pump and the rapid depletion of the particulate filter. Also, the modular method, in contrast to properly carried out chip tuning, increases the emission of harmful substances.

The unit is included in the high-pressure fuel system and its computing module controls engine operation, bypassing the ECU, without underestimating sensor readings. By diagnosing the pressure in the fuel system, and when it increases, it sends a command to the control unit to increase the injector timing within the permissible range.

Installing the module allows you to control and change injector control pulses. The module is connected to the injector wire gap and regulates the operation of the fuel injector by changing the opening time of the injector needle. As a result, the fuel injection angle changes and combustion efficiency increases.

Installed on diesel engines with a mechanical injection system. The block increases the power of a diesel engine due to changes in the functioning of the fuel pump. The module adjusts the fuel sensor data to lower values. As a result, pressure increases in the fuel pump housing using a solenoid valve.

The positive aspects of this method include inexpensive equipment and ease of installation. The disadvantages include floating engine speeds and reduced fuel injection pump life.

The equipment connects to the wires of the rail pressure sensor and sends data about a decrease in compression in the fuel rail to the electronic control unit. The ECU changes the intensity of the injectors, the power of the internal combustion engine increases, and fuel consumption decreases.

The fuel pump is responsible for regulating the pressure level in the fuel accumulator. By installing an additional unit in the electronic circuit of the fuel system, information about the loss of fuel injection pump power is supplied to the ECU. The ECU will give a command to increase the injection timing.

Method number 3. Turbocharging

Engine performance is increased by installing a turbine, which supplies a large amount of air into the combustion chamber. The fuel system control unit gives a command to increase fuel injection and engine power increases.

The disadvantage of this method is the increase in fuel consumption and the short service life of the turbine. At the same time, turbocharging prevents the engine from stalling when you press the car's stop pedal.

Fuel supply and return hoses

We buy a couple of meters of Gates 3225-00053 and replace, without looking or thinking, pieces of hoses from the fuel intake of the tank to the fuel line on the frame and from the fuel line on the frame to the injection pump and the return distributor (located on the fuel filter ramp).

I strongly recommend using spring clamps to connect hoses. In the “original” they are exactly what is on the car.

In general, I recommend using spring clamps everywhere. On all hoses. Why? Google to the rescue.

Injectors

Naturally, due to our poverty, we cannot completely replace the nozzles, but we are obliged to change the nozzles.

Currently the only atomizer manufacturer that makes sane atomizers is Monark. For turbo engines, number 039305176 (SD314), for naturally aspirated engines, number 039305120 (SD261).

The nozzles must be set to the maximum possible pressure: for turyuo 145 bvr, for aspirated 120 bar. You can add 5 bars to the plus for spite. The higher the pressure, the better the atomization, the smaller the droplets and the better the combustion.

Washers for injectors are DISPOSABLE. Therefore, we stock up on Elring heat sink washers in advance. 693.758.

Where is the best place to refurbish?

Advertisements about increasing the power of a car can often be found on billboards, in newspapers, and on car service websites. Many small workshops offer to change the engine, but quite often there is a situation where they do not have the necessary tools or qualifications. Experienced craftsmen will rarely work in small workshops that have a minimum of equipment.

We also recommend reading our specialist’s article, which talks about how to install gas equipment on a car.

When contacting the service, you need to pay attention to some factors:

- the car service must have a license to carry out repair work;

- You should study reviews about the auto center, as well as find out the qualifications of the technicians and the equipment of the service;

- Self-respecting service stations provide a guarantee for all work performed.

Sometimes auto center technicians can tell you where to buy this or that spare part at a good price.

Through certified services, you can order original parts with a warranty from the manufacturer.

The durability and reliability of the motor depends on how reliable the center and qualified technician were chosen. Incorrect boring or installation of incompatible parts can lead to complete failure of the unit.

Using turbocharging

The use of a turbine leads to a significant increase in the power of a diesel engine. The cylinder begins to receive air in a large volume. And the fuel volume is increased using electronics. Exhaust gases begin to spin the turbine at lower engine speeds, which leads to an increase in thrust.

One of the features of diesel engines is that they do not have a throttle.

Thanks to this, air quickly enters the cylinders without any control systems. To prevent the engine from overheating, you should install an intercooler that cools the air entering the cylinders.

The positive aspects of turbocharging:

- More efficient fuel combustion occurs.

- Motor power increases.

Negative aspects of turbocharging:

- The work period is very limited.

- Fuel consumption increases slightly.

- Only expensive oil should be used.

- The turbine itself is also not cheap.

All the methods described above can help make the car faster. The most popular method among drivers is the installation of additional units. But we must not forget that increasing the engine power will certainly lead to a reduction in its service life.

In addition, increasing vehicle speed always comes with additional costs associated with installing a more efficient braking system. Therefore, you should think carefully before deciding to tune your car.

Video on how to increase the power of a diesel engine:

Source

Installation of lightweight pistons and connecting rods

Reducing the weight of the crank mechanism parts helps reduce inertia and promotes faster spin-up of the crankshaft and flywheel. For sports cars, connecting rods, pistons, and flywheels are lightened manually; excess metal is removed:

- on the flywheel - by drilling holes in a circle;

- on connecting rods - by cutting off metal from the connecting rod caps, from the I-section;

- on the pistons - by shortening the skirt, removing aluminum from the bosses.

When modifying it manually, you need to remember that the different weight of the pistons plus connecting rods (P+W) leads to an imbalance of the motor, and if the flywheel is lightened, then you need to balance it on a special machine. At the factory, the crankshafts are balanced as an assembly with the flywheel and clutch, but before that, each of the crankshaft parts undergoes this procedure separately. To adjust connecting rods, piston pins and pistons, electronic scales are needed; first, the connecting rods are adjusted by weight, then the pistons separately. Afterwards, the parts of the cylinder-piston group are assembled, and each P+Sh is hung separately.

As a rule, pins have a minimal difference in weight, and they are not always modified; the difference between any parts for each cylinder, as well as the assembled weight, should not exceed 1.5 g (ideally, no more than 0.5 g). There are still many different nuances here; some car owners, in order not to bother with fitting (the process is quite tedious), buy ready-made tuning kits.