DIY diesel engine heater

Do you know about the fuel heater for diesel engines?

Have you heard how difficult it is to start a car with a diesel engine in cold weather? This problem discourages residents of cold regions from buying diesel cars, and certainly has a completely scientific basis, namely the physics of the processes occurring with diesel fuel at low temperatures.

Summer diesel in the cold

But, fortunately for you and me, technology does not stand still, and, thanks to various devices, we can experience all the advantages of diesel engines even if we are residents of the far north. We'll talk about these devices today.

Process Basics

Typically, the diesel fuel filter is heated by some kind of electrical device. The most effective is the overhead bandage heater.

- It is installed on a fine filter - the most vulnerable point of the machines in question.

- It resembles a clip.

- It is connected by wires to the battery.

- It is turned on by the driver before starting the engine.

Also find out why there are high idle speeds and idle speed adjustment on the VAZ 2107. Although there is another option for providing heat. For example, the fuel filter for a diesel engine is heated by a flow-through heater.

- It is installed directly into the fuel line immediately before the fine cleaning element.

- Looks like a pipe.

- Also connects to the battery.

There are also tape heaters with which the cleaning element is wrapped. They are also connected to the on-board electrical network. From the information provided it should be clear how filter heating works in diesel engines. It simply heats the fuel using miniature heating elements powered by battery electricity.

More precisely, here are instructions on how to use, for example, an overhead device.

- Turn on the device a few minutes before starting the engine, at least ten minutes.

- Start the engine after the fuel has warmed up.

- Turn off the device when the engine warms up.

- The service life of such a device should be about five years.

However, if you suddenly have doubts whether such a device works, is there a filter heating on the machine at all? In this case, we will list how to check the presence and operation of the fuel filter heating, point by point.

- Inspect the line near the purifier. Finding where the device is located is natural.

- Touch it with your hand to see if it’s warm, if it’s at least warm.

- Take an electrical tester, disconnect the power from the installation, check the power supply.

- Check the installation resistance, compare the value with the passport data.

This is the sequence.

My own master

Now let's look at how to heat a diesel filter on your car with your own hands. Let's first consider installing an overhead bandage heater. It must be purchased first. We think that there should be no questions about where to buy heating at all - you just need to visit a large auto store or online sales site.

But let's say it has already been purchased. What are we doing.

- We wrap the cleaning unit with a heating element, strengthen it with thermal insulation, and also with plastic brackets.

- We connect one wire to the ground (body) of the car.

- The second, in accordance with the diagram attached to the product, is carried out through the salon.

- We install the standard switch for the driver plus the relay from the kit according to the diagram.

- We connect the wire from the relay to the fuse, then to the positive terminal of the battery.

Please note that detailed instructions describing installation must be included inside the product packaging, among the accompanying documentation. Now let’s look at how to make heating exclusively with your own hands, without store-bought equipment. For this method we will take the following materials:

- nichrome in the form of wire, 10 m;

- standard button;

- fiberglass, sealant;

- standard fuse;

- two universal clamps;

- soldering iron with soldering accessories.

Let's start installation.

- We apply sealant to the fiberglass fabric, glue the fiberglass fabric to the cleaning element, and let it dry.

- We wind the nichrome wire onto the body wrapped in fiberglass, and attach clamps to the ends of the wire.

- We wrap it again in fiberglass coated with sealant and let it dry.

- Solder the wires to the clamps.

- We connect these electrical terminals to the car network according to the diagram described above, namely, we connect one wire to ground, that is, we connect it to a convenient place on the body, and we connect the second to the electrical network.

- More precisely, first we attach a button to its output in the cabin, near the driver, which we attach to the instrument panel.

- Then we take the wire from the button to the fuse. The latter can be installed in a standard unit if there is space.

- We lead the wire from the fuse to the positive pole of the battery.

This completes the installation.

This method, if anything is unclear, can be studied online by simply typing a search query like this - heating the fuel filter with your own hands. You can watch the video.

And if you pay

Next, we will consider the possibility of modifying the diesel fuel filter by combining it with heating at specialized car services. More precisely, we will determine the cost of installing the system in major cities of Russia. By using the services of various well-known companies, you can spend considerable sums. These, along with the company names, are listed in the following table. This table is in front of you.

Frost and sun are not the most wonderful day for a diesel engine

To understand a problem, you need to get to the bottom of it. And it is hidden not in the engine and its components, but in the fuel on which it runs.

Let's figure out what happens to diesel fuel at sub-zero temperatures. As you probably know, diesel fuel is essentially a waste product from the production of gasoline and other lighter petroleum fractions. This fact imposes some features on the chemical composition of diesel and its physical properties.

The fact is that even with a slight frost, paraffin crystals begin to form in this type of fuel, and with a further drop in temperature to deep minuses, it becomes generally viscous and thick, even if you cut it with a knife. But now we are talking about a relatively small “minus”.

For example, summer varieties of diesel fuel begin to behave poorly already at -5 C, winter varieties - at -20 C, but Arctic varieties at -35 C.

And of course, when the fuel thickens, there can be no talk of any engine operation; it won’t even start. There is only one way out - to warm it up.

Ways to prevent diesel fuel from solidifying in the tank

The summer grade of fuel or its inadequate quality are the prerequisites for future problems. There are three types of energy carrier: summer (operation down to -5°C), winter (up to -30°C) and arctic (pour point is -50°C). Before the cold season, it is recommended to replace the combustible material with a winter or arctic type.

If a mixture of two types occurs, and cold weather is coming, there are two solutions: using anti-gel additives or diluting the mixture with kerosene (or gasoline). But these are extreme measures. Their use is short-term.

The best way is to install a heating system for the fuel system. Naturally, if there is no standard heating of diesel fuel in the tank.

Diesel engine fuel heater

Let's say right away that many modern cars with diesel units have heating systems already installed from the factory, and their happy owners are unlikely to have to worry about their four-wheeled friend not starting in the cold or stalling on the road.

However, manufacturers may underestimate the severity of our winters, or the car may not be equipped with anything like that at all, since it was imported from countries with a warm climate.

In this case, you need to think about installing special heaters. And here a logical question arises: on which of the fuel system components is it best to mount these devices?

Everything is like in the well-known proverb - where it is thin, it breaks. The most vulnerable from the point of view of freezing and the influence of paraffin crystals are: fine filter, separator filter, fuel line and tank.

Today we will briefly look at the diesel fuel heater and several types of such heaters, namely:

- flow-through;

- bandage;

- tape;

- heated nozzle.

Let's start in order.

Flow-through fuel heater for diesel engines

The flow-through type is used to heat fuel lines and is usually installed in a section of the fuel line in front of the fine filter.

It is worth noting that this type is an auxiliary heater, since it is most useful only while the car is moving.

In-line diesel fuel heater

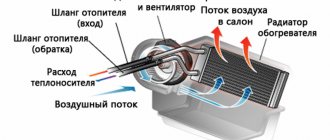

Flow-through heaters can be either electric or use hot liquid from the engine cooling system.

Bandage fuel heater for diesel engines

To eradicate the problem of fuel freezing in the bud, it is necessary to use several types of heaters. One of the most vulnerable elements of diesel engines is the fine filter.

It is he who has a hard time when paraffin crystals begin to form in the frozen diesel fuel. To solve this issue, it is recommended to insulate it first, and for this there are so-called bandage heaters.

They are pads with electric thermoelements that are mounted on top of the filter and secured with ties.

Diesel Fuel Heater

Tape heater

Another useful type of heaters are tape heaters. These are flexible elements that perform their role well in various sections of the fuel line. They can work both while driving and before starting the engine.

Diesel Fuel Belt Heater

Heated nozzle

Well, the last type that we will consider today. Heated nozzles are special devices with a heating element that are installed directly on the fuel intakes. Thanks to them, in severe frosts there is no fear of diesel fuel thickening at the point where fuel is taken from the tank.

Heated fuel intake nozzles

It must be said that there are complex systems that include most of the above types of heaters. They can be controlled either manually or automatically based on temperature sensors overboard, in the engine compartment and along the fuel route.

So, dear readers, we have found out that you should not be afraid of buying a car with a diesel engine, even if you live in a region with a harsh climate.

Modern technologies make it possible to almost completely solve problems with starting and operating diesel engines in cold weather.

By the way, don’t forget to subscribe to the blog to receive new articles and give links to it to your friends.

And I, in turn, will try to publish only the most interesting materials for you.

In winter, starting a frozen power plant causes many problems for car owners. Thickened oil, poor fuel volatility, and increased resistance in the battery make the power unit very reluctant to start. But there is a solution to this problem - install and use pre-heaters. These devices allow you to warm up engine fluids, providing relatively easy engine starting in severe frost.

Heating of the coarse filter

The filter heating circuit can be implemented and diesel fuel fluidity can be ensured by the following modifications: the drain valve is replaced with a glow plug or the heating element is mounted in the body of the fitting through which fuel is supplied. In the process of implementing these schemes, you will need special equipment in the form of a lathe or contact specialists who can produce handicraft parts.

Please note that removing the drain valve will not allow you to subsequently remove excess water from the fuel supply system that may be present in the diesel fuel. You should resort to this heating method only if you are completely confident in the quality of the diesel fuel being filled.

To carry out the work, the coarse filter (separator) is removed. After this, you need to machine a sleeve from steel, which will act as a substitute for the drain cap. Next, a thread is cut to securely attach the element to the filter housing. After this, a hole is drilled in the bushing and an internal thread is cut with a tap, through which the stud will be attached.

Then the glow plug is screwed in, the positive wire is fed to the heating element, the negative wire is fed to the stud. The finished solution is screwed into the separator body. All work related to the implementation of the electrical circuit implies the same requirements that were put forward when creating heating of the fuel intake from the on-board network of a diesel vehicle.

We also recommend reading the article on how to increase the power of a diesel engine. From this article you will learn about how you can increase the efficiency of the engine by installing a special tuning box and the main advantages compared to chip tuning.

There is also a simplified method for installing a glow plug, which does not require recessing individual additional elements. To install a glow plug in the valve fitting, you need to drill a hole, cut a thread in it and screw in the glow plug. The power supply is connected in the same way. It should be added that the second scheme is similar to factory solutions for heating diesel fuel.

Some nuances

A few details about the features of using both types of heaters. If you take a regular passenger car, the volume of lubricant and coolant is not much different (on average, 3.5 liters of oil are poured, and 4.5 liters of antifreeze). That is, theoretically, approximately the same energy will be required to heat both liquids. But there is one nuance - the oil is in one place - the pan, and the antifreeze is located throughout the system. Therefore, in the case of using a device for heating the coolant, circulation is required, but when heating the oil this is not necessary.

And one more thing - the antifreeze needs to be heated quite strongly (at least to 50-60 degrees), but the oil does not require this; you can only slightly increase its temperature to increase fluidity.

Due to these features, it is not advisable to use a 12-volt heater to heat antifreeze, since proper heating will require a lot of energy. Therefore, autonomous devices are mainly used to influence the lubricant, but those operating from a 220 V network are installed in the cooling system.

Next, we’ll look at how to make a pre-heater with your own hands for a VAZ or any other car. Note that there are a lot of variations of homemade devices, but we will describe only two devices that are relatively easy to manufacture.

Types of diesel fuel heaters in a standard tank: modern and vintage designs

Relevance of the idea

It makes sense for residents and guests of the northern regions to equip a diesel fuel tank heating system with their own hands. At forty-degree frosts, even paraffins fall out of the winter diesel fuel and the insulation of the filter is powerless: the intake will not be able to take at least a small fraction of the required portion due to the diesel fuel reaching its pour point.

An ordinary headlight bulb was previously regarded as the only way out of this situation. A sufficiently powerful thermal field from the lamp is able to melt the precipitated paraffins and ensure a flow of fuel into the coarse filter element, and there the fuel filter heater does its job. In a truck driver’s glove compartment, even now you can find a simple electrical circuit consisting of a light bulb, a fuse and a toggle switch - just in case.

Modern designs

A current way to protect the fuel system from sudden loss of performance in severe frost is a heated nozzle on the fuel intake. Those who are fond of solving problems using proprietary tools will benefit from developments from Nomakon:

- NTP 101/301 – for passenger cars (4,500/10,000 rubles).

- NTP 102/302 – for trucks (4,500/10,000 rubles).

Intakes with a tube diameter of 10/12 mm can be equipped with a primitive 101 or 102 model. 301 and 302 products are universal + trained to dynamically change heating power. The choice is made based on the maximum consumption of diesel fuel through the heater, the voltage of the on-board network and the design features of the intake element.

The design diagram is extremely simple. The heating element is built into a metal case and is controlled from the on-board network via a cabin button. When current is applied, the heater creates a local thermal field and warms up the diesel fuel around itself. The manufacturer already recommends equipping vehicles with such a system when operating at an average ambient temperature of -15°C.

Antifreeze heater 220 V

The first will be an antifreeze heater operating from a 220 V network. To manufacture it you will need:

- heating element;

- Pipe sections;

- Plumbing fittings, tees, adapters;

- Materials for sealing connections;

- Clamps;

- Cable with plug;

- Insulating materials;

Below are the plumbing items that will be required for assembly:

Regarding the heating element. It is best to purchase a heating element for a water heater (for example, “Ariston”), equipped with a thermostat. Installing it in a homemade device will not be difficult, and in addition it will be possible to adjust the heating range. As for power, a heating element of 1.2-1.5 kW is suitable for a passenger car.

The diameter of the pipe and its length should be selected based on the size of the heating element and its mounting thread. The pipe itself should be thick-walled.

To assemble the device you will not need many tools:

- Bench vice;

- Taps and dies for threading;

- A set of keys;

- Angle grinder with cutting wheel (“grinder”).

Having prepared everything, you can start working. Assembling the pre-heater is done as follows:

- We take the pipe and make the necessary measurements, taking into account the existing bends and tees;

- In plumbing tees, the threads are usually already made, so you can immediately screw the heating element into it using sealing materials;

- We cut threads on a piece of pipe (external on one side, internal on the other);

- Screw the prepared section into the tee;

- On the other side, screw the adapter into the pipe;

- We screw another adapter into the third terminal of the tee;

- We connect the cable to the heating element and isolate the connections;

After assembly you should get a device like this:

As you can see, assembling an antifreeze heater is very simple. It is only important that all connections are well processed in terms of sealing, since even the slightest leakage of antifreeze is not allowed. Therefore, after assembly, you should carefully check the device before installing it on the car.

Additionally, you can weld a mounting bracket to the pipe. Installing an engine heater yourself is also not difficult. It can be mounted using either a sequential circuit (embed the device into the antifreeze supply pipe into the interior heater) or parallel (organize the supply from the cylinder block, and the drain into the pipe leading from the main radiator).

It is up to the car owner to decide which circuit to use, but the device must be installed correctly. In both cases, you need to correctly determine where the supply outlet is and where the drain outlet is. The adapter screwed into the end of the pipe is a supply adapter; it is through it that antifreeze will be supplied to the heater. The second outlet (from the tee) is a drain. The device must be installed so that the drain outlet faces upward.

Using a parallel circuit for installation, we place the heater below the intake point (usually this is the drain hole of the cylinder block, into which a fitting is screwed instead of a plug).

Also, some include electric water pumps from a GAZelle car in the scheme. In this case, forced circulation is ensured. Moreover, this pump can be powered either from the car battery or from a 220 V network. But in the second case, you will have to additionally use a step-down transformer.

Refinement of the fine filter

The fine filter loses its throughput even with a relatively small degree of paraffinization of diesel fuel. This does not allow the engine to start and can lead to malfunctions of the fuel injection pump, the fuel chamber of which is not supplied with fuel. Among the methods for heating diesel fuel with your own hands, heating this fine filter element stands out.

To make your own fine filter heater, you will need about 10 meters of copper wire, which has varnish insulation. You also need to have tools and materials for soldering (soldering iron, some tin and rosin), as well as insulating tape. Additionally, you will need to have a relay, a 10 or 15 A fuse, and a switch button.

Copper wire is wound in frequent turns around the body of the filter element. Contacts for supplying current are connected to its ends. The negative wire is supplied from the battery, a relay and a power button are installed on the positive one. It is optimal to make the positive contact from the ignition switch in order to avoid discharging the battery if the driver forgets to turn off the heating himself.

12V oil heater

Now let's look at how to make a 12 volt engine heater with your own hands. In this case, the device will be used to heat the lubricant. It will be located in the pallet. Moreover, for this you do not need to make any holes in it, since the oil heater will be screwed in instead of the drain plug.

To make it you will need:

- Small diameter tube;

- Nichrome wire 0.6 mm, total length 2 m (in the form of a spiral);

- Ceramic insulators;

- Textolite washers and bushings;

- Small connecting elements (bolts and nuts for them);

- Drain plug;

Do-it-yourself additional heating of a factory diesel fuel tank: step-by-step instructions

It is recommended to start making your own installation if you have a desire to invent something. There are no particular difficulties in the process of designing the product: no special skills are needed, but knowledge of electricity from a school physics course will not hurt - this is enough to correctly connect a homemade invention to the on-board network.

Components

You can construct a diesel fuel heater in a tank using available materials. The basis of the heating device is the heating element. It is unlikely that you will be able to find a heater for direct use - you will have to be smart. The following can serve as a converter of electric current into heat:

- Flexible heating element for 12 or 24 V.

- Nichrome wire.

- 12 V car boiler.

To connect to the electrical network, you will need a standard set of elements, consisting of a four-pin 30 A relay and a socket for it, a switch button, a 30 A fuse and a wire of the required length with a cross-section of at least 2.5 mm2. A visual indication of the heater operating modes, which is provided by an LED, will not be superfluous. Plastic ties and heat shrink casing should also be available.

For your information. A timer or thermal relay will help automate the control process.

Heating based on a boiler

Simplicity is the main criterion for the perfection of a homemade product. Using a car boiler as a heating element means taking the path of least resistance. In this situation, there is no need to invent anything - it is enough to purchase an accessory and the components necessary for assembling the electrical circuit at the auto store.

From the boiler itself, only a heater is needed - the plastic cover along with the cigarette lighter cord are removed. Further actions are carried out in accordance with the instructions:

- A hole is drilled in the fuel intake cover for the “+” terminal.

- The heating element is attached to the fuel intake using plastic ties.

- Wiring is connected to the boiler: ground goes to the nearest screw, “+” – from the interior. It is advisable to solder the twist and protect it with heat shrink.

- Seal the hole in the lid with sealant.

- Connect the “+” relay from the boiler, the button and the LED, ground. Take the positive contact from the battery through a 30 A fuse.

When installing a purchased or home-made fuel tank intake heating system on a diesel engine with your own hands, you encounter one problem area - the hole in the fuel intake cover. It is better to close it with some kind of plastic plug. Regular sealant and hot melt adhesive will not work: over time they will dissolve in diesel fuel. Liquid rubber has the required qualities: being in a liquid state, it completely clogs the technological hole and eventually turns into a solid state.

For your information. Liquid rubber is a one-component polyurethane sealant. Found on sale in small quantities. One example is Sikaflex-221.

Heater based on nichrome wire

The main characteristic of a nichrome product is resistivity. It depends on the geometric characteristics of the conductor: cross-section and length. The resistance value determines the power characteristics of the installation, which affect the amount of heat generated when a current of a certain strength passes.

general characteristics

Such a device is certainly a necessity in the climatic conditions of Russia. After all, most of the year our weather is not the most favorable for operating a car. Starting the engine often becomes problematic. Therefore, thanks to the heater, the service life of the diesel unit increases along with ease of use.

It's quite easy to use. The car enthusiast can only choose the appropriate option, and this is the only thing that can be difficult, since there are already many manufacturers of this device and choosing the right model from the whole variety sometimes becomes a difficult task.

Air heater or diesel engine preheater?

If a car enthusiast wants to get into a car that has already been warmed up, then he cannot do without an air device. Often the car is warmed up with the engine running. However, this method cannot be called the best. And fuel consumption with this approach will increase significantly. Therefore, air heaters are part of the standard equipment of many large vehicles. But the device can also be beneficial for passenger cars.

Advantages of an air heater

The advantages of using a heater are the following:

- improved visibility;

- comfort;

- increasing safety and quality during operation;

- fuel economy.

In addition to saving fuel and lubricants, it is possible to prevent rapid wear of the engine and reduce funds for its repair and maintenance.

Of course, the car enthusiast begins to think about purchasing a diesel engine preheater primarily in order to increase ease of use. But an air heater is also quite suitable for this purpose. But if you also want the service life of engine parts to increase, then you should think about the option under consideration. And manufacturers are ready to offer a wide selection of devices.

Advantages of a preheater

It can be activated remotely and is capable of warming up the engine to 25 degrees. At the same time, the interior of the car will also become warm, which will significantly increase ease of use.

Among the most important advantages of the device are the following:

- The engine always starts without problems. The car owner will save a lot of his nerves and save fuel. Regular and stable starting will increase the service life of engine parts. In addition, the load on the battery will be reduced and the amount of harmful emissions will be reduced.

- Warm interior. This will increase the convenience for the car owner and protect him, since in this case the risk of diseases will be reduced.

- Clean glasses. An excellent overview will be provided from the very beginning of the trip.

Thanks to all these components, diesel engine preheaters become universal devices for car owners.

Various models of preheaters are characterized by different features with their own advantages and disadvantages.

Difficult choice

To answer the question of which diesel engine preheater is best to purchase, you need to take into account various nuances. This includes the frequency of use of the vehicle, the characteristics of the vehicle itself, as well as the conditions of its operation and the service life of the engine.

If the climatic conditions are satisfactory, then there is no particular need for the device. Also, if the car is in a heated garage most of the time, then a heater is unlikely to be needed. It’s another matter if the car is operated in a harsh climate, where winters are usually long and frosty. Then the preheater will be truly in demand.

Electric heater

Electric pre-heaters for diesel engines operate from a 220V network. This device is distinguished by its relative simplicity and low price. It will be the best option for those cars that are part of the time in the garage, and sometimes parked on the street. It is clear that it requires power from the network. Therefore, such a device is not the most convenient, since it will have to be connected to the network before starting the engine. Some models of such heaters have a fan that allows you to heat the interior.

The device is shaped like a regular boiler with antifreeze in the cooling system. This option is the most budget-friendly. You can find cheap domestically produced models with minimal functionality.

Foreign-made heaters that are protected from overheating will cost more. And some choose devices that have many functions, including battery charging and a start timer.

We heat the fuel from the engine cooling system

A composition heated in a tank or separator can easily lose fluidity when passing along the entire highway, and even at high vehicle speeds. In this case, the car enthusiast can choose and make with his own hands any layout of the diesel fuel heater using simple technologies:

- basic insulation of the fuel line with building materials;

- installation of an electric flexible heater by winding or applying it to the surface of the unit;

- installation of a heat exchanger in front of the fine filter element.

The last method is to make a part that has two independent contours. The simplest example of such a device consists of two tubes of different diameters. The thinner tube is welded and centered inside the larger one. The outer circuit consists of pipes for passing diesel fuel. The small circle of the cooling system is connected to the indoor unit. Variations of this design are possible, where the circuits intended for diesel fuel and hot antifreeze can be swapped. More complex specimens contain an internal block made of a spiral type. High reliability of diesel starting in winter conditions can be ensured only with comprehensive modernization. Its essence lies in the use of several of the methods described above, which heat the components of the fuel system.

On frosty winter days, owners of diesel vehicles may encounter operational problems. Remains of summer fuel or a sharp drop in ambient temperature can become a serious problem.

In this case, the car may easily not start due to the solidification of the energy carrier. Even worse is if the fuel line freezes while driving. Then the car may stall while driving. The closer you live to the north, the better you need to take care of heating the car tank. It's better to be prepared for trouble than to suddenly get stuck on a deserted highway.

Standalone devices

Unlike those described above, these devices do not require an electrical connection. In order for autonomous devices to work, the presence of fuel in the car is sufficient, with the help of which they function. Diesel fuel forces coolant to circulate over a small radius.

The small arc includes the interior stove. Therefore, as a result of the operation of the device, the car becomes completely warm. The equipment provides expanded functionality, as well as overheating protection.

If you constantly use your car in extreme conditions, it is, of course, better to purchase this type of device. Taking into account the features of the engine and choosing a model from a trusted manufacturer, the car enthusiast will ensure a comfortable ride from the very start of the engine, slow down the wear of parts and eliminate unforeseen situations when the engine simply does not work, "Binar" and "Kamaz"

Since 1995, the companies Teplostar and Advers have been producing diesel engine pre-heaters jointly. Among the models you can find both liquid and air devices.

The most common of them were diesel engine pre-heaters “Binar” and “Teplostar”, as well as air devices “Planar”. They are all compact in size, easy to install and operate, and display temperature data very accurately.

Domestic models are distinguished by reasonable prices and decent quality. Sometimes such devices are purchased for installation on trucks. But for Kamaz they use special pre-heaters for the Kamaz diesel engine that have long proven themselves.

The battery with such a device will never run out, since the standard stove is constantly running. If you need to wait for loading/unloading, there is no need to heat up at idle, wasting a large amount of fuel. At the same time, the engine life will be saved by 400 kilometers each time (this is exactly how much is allocated for wear of parts during a cold start for Kamaz).

Improvement of fine filter elements

Quite often, at the final stage of fuel purification, the filter element becomes clogged with crystallized paraffin. As a result, the supply of diesel fuel to the working cavity of the high-pressure pump stops and the likelihood of its breakdown increases. To prevent this from happening, we will consider two options for organizing the heating of a fine filter, which can be implemented independently.

Option 1

To work you will need the following parts and equipment:

- about 6-10 meters of nichrome or copper wire with a cross-section of 0.5-1 mm;

- control button;

- fiberglass and heat-resistant sealant;

- fuse 10-15 A and relay;

- two plumbing clamps;

- tin, rosin and soldering iron.

The procedure for organizing this type of instantaneous diesel fuel heater with your own hands includes the following points:

- apply sealant to the fiberglass fabric and glue it to the element body (dry for about 24 hours);

- wind the wire in small increments onto the body of the part and secure the ends with clamps;

- apply fiberglass with sealant over the turns of wire and let dry;

- Solder the contacts for connecting the wiring onto the clamps and assemble the electrical circuit.

Useful recommendation! It is better to use a toggle switch and a relay through the positive line, and connect the negative line to the battery. In order not to forget the device is turned on, the “plus” should be taken from the ignition switch.

Option 2

The method relates to bandage-type heating. Suitable for its implementation:

- electric heated mirrors;

- heating film (similar to underfloor heating);

- flexible heater.

Webasto or Hydronic

Those who trust only foreign manufacturers should pay attention to diesel engine pre-heaters Webasto and Hydronic.

The first are represented by three models:

- E - for cars;

- C - for engines from 2200 cc;

- P - for SUVs, minivans and minibuses.

The advantages of the models include the presence of an automatic programmable timer and remote control. The disadvantages are the possible freezing of the liquid crystal screen and the high cost of the equipment.

The pre-heater for the Hydronic diesel engine is available in five modifications:

- 4 - for small cars with an engine capacity of up to two liters;

- 5 - for cars with an engine of more than two liters;

- МΙΙ - for trucks and special equipment - from 5.5 to 15 liters;

- ΙΙ Comfort – for engines from two liters;

- LΙΙ - for trucks and special equipment - over 15 liters.

The devices are capable of self-diagnosis, but their glow plugs can often become clogged, which will have to be replaced at your own expense.

Briefly about the main thing

The main reason for placing a diesel fuel heater in a car tank is to prevent diesel fuel from solidifying and becoming cloudy at the entrance to the fuel system. A secondary feature is the service life of the high-pressure pump: it is higher when working with warm diesel fuel.

You can invent a heating system based on a boiler, flexible heating element or nichrome wire. The optimal solution is a design based on an autoboiler. The cost of the accessory does not exceed 300 rubles, and the price of the branded offer from Nomakon starts from 4,500 rubles. The difference is noticeable, and independent work is not difficult.

DIY diesel engine preheater

Some car owners prefer to do everything themselves. Let's look at what a homemade heater is and how to make it.

The device includes a small chamber-boiler, into which a fuel-air mixture and a component for igniting it are supplied. Diesel fuel comes here directly from the fuel tank. The heater has a coolant circuit that heats up and releases heat into the space after switching to a small circuit.

To make this device you will need:

- a heater, which could be a coil from an electric kettle;

- fittings;

- tank;

- junction box.