Every car owner wants to modify his car so that it is perfect in every way. But a car should be ideal not only externally, but also internally. The engine also requires improvements. If you tune the engine, then there is no way to do it without a zero-resistance filter.

It is absolutely impossible to do without installing such a device, since a new injection and a reworked intake and exhaust system significantly increase the power indicators of the power plant, which requires more air to operate as smoothly as possible.

If in such a situation you do not install a zero resistance filter, then the motor will simply “suffocate”. It will shake and twitch, since the mixture will not be enriched at all. In addition, such filters can be purchased at any auto parts store. The so-called “nulevik” very easily replaces the standard one. The fasteners are interchangeable. It is also necessary to note the aesthetic side of the new filter. It will give the engine a sporty look.

What are the disadvantages of installing a zero resistance filter?

Let's look at the disadvantages of this element.

- It is wrong to think that if you remove the filter altogether, the car will go faster. When designing the motor, engineers took into account that part of its power would be used to overcome the filter resistance. Even the “nulevik” has resistance, there’s no escape from it. Therefore, there is a filter, otherwise you risk damaging the engine with abrasive dust.

- Due to the fact that this part has low resistance, there is an increased risk of penetration of small particles, which adversely affect the life expectancy of the engine.

- This part is typically used in sports cars for driving on closed racing circuits. If such a filter is used on a regular car, we recommend using additional protection, since in city traffic conditions this element will not perform its functions well.

As you can see, the pros and cons are equal. Therefore, it’s up to you to decide whether to buy this part or not.

The principle of operation of the filter, its features

The operating principle of the “nulevik” is based on two factors:

- high-quality cleaning of the flow entering the motor;

- minimum air resistance.

The effectiveness of the zero resistance filter is due to its unique design and the use of cotton (rather than paper) material.

The incoming flow is filtered from dust without causing any significant contamination to the product. Thanks to special impregnation, particles entering through the filter settle on the surface and do not interfere with the flow of air to the combustion chamber.

As a result, a sufficient volume of air enters the intake manifold, and the power of the power unit increases.

Why is the regular one so bad?

Low-profile tires: pros and cons

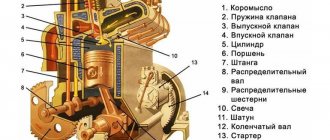

Again, everything is simple - as you and I know, an internal combustion unit has only 4 strokes, these are intake, compression, ignition, and exhaust gases. The engine, on the intake stroke, sucks the air-fuel mixture into the engine cylinders; if gasoline flows through its own line, then air is sucked in from the environment. If there were no filter, it would be sucked in with everything that came across (midges, dust, etc.), but the filter protects against this - however, it is a kind of plug that prevents the air from passing through normally, that is, resistance is encountered.

The standard filter element has a significant resistance coefficient, often taking away 5 - 7% from the engine power. This is understandable, it practically does not allow dust particles to pass through, and is made of special paper.

This element is far from ideal, it seems like everything is simple, but damn there is no solution and that’s it! Or is there?

Why is such a filter needed in an engine?

It is believed that the zero filter increases engine power. This is true and noticeable on powerful racing cars such as Formula 1, but does it make sense to install it on a simple car such as a Renault Duster?

Let's try to figure out what a zero-resistance filter actually does. Its main task, like any other similar device, is to clean the air entering the fuel system. Thanks to this, midges, dust and other contaminants do not get into the engine, fuel mixture, injector and carburetor of the car. By using a filter, the service life of the motor increases up to 10 times, since it prevents sand and other harmful solid particles from getting inside, which can cause damage to the mechanism.

What's wrong with a standard filter?

The zero resistance filter has quite opposite reviews. Before deciding whether to install it on your car or not, you should study the advantages and disadvantages of this type. Unlike a standard element, whose resistance coefficient is about 7%, a zero element has almost no such resistance. This value is close to zero. What does it mean? In simple terms, the nulevik is made of another paper or other material; it does not create resistance when the motor is running, that is, the power is directed to operating the engine, and not overcoming some obstacles in order to force the air mixture to move.

The lack of resistance is good, but you have to pay for it with the poor filtering ability of the element, which is why the motor gets dirty much faster. This is the main disadvantage of a zero filter: it is not able to protect the internal systems of the car from small solid particles, such as grains of sand and solid impurities.

Zero resistance

The throughput of such a device is much higher, so the nulevik allows you to increase engine power without significantly affecting fuel consumption. A special feature of the structure is large pores and a minimal amount of paper in the structure. The zero-resistance air filter retains almost no air. As a rule, cotton fabric and aluminum screen are used as the base.

Pros and cons: is there any sense in nulevik?

CVT pros and cons

In reality, the difference with and without a filter is noticed only on a dynamometer stand. The benefit of reducing the resistance of only one element of the intake system appears exclusively in the “full throttle” mode at high speeds; in the standard city driving cycle, the effect of the “zero filter” is exactly zero.

Even for forced engines, reducing intake resistance gives a penny of benefit. Let's take for example a graph taken on a dyno with a Nissan Skyline ECR33, whose RB25DET engine has already moved away from the standard configuration:

The result is not bad - 250 horsepower at the wheels. But, if we remove the air filter altogether - to ensure a reduction in intake resistance even greater than that of a high-quality "zero" - we will get the second graph:

The drop in power after the 5000 rpm peak has become smoother, but the difference in numbers is negligible: its increase without a filter is only 8 horsepower. With 250 hp, which is already there, it is impossible to notice anywhere except on the track, when hundredths of a second count.

And you have to pay for these pennies by complicating maintenance and deteriorating air purification.

In addition, the oil impregnation of “zero” vehicles itself can cause problems on engines equipped with mass fuel flow sensors. The air flow, passing through the filter, carries along microparticles of oil, which then settle on the walls of the inlet pipes and directly on the surface of the sensing element of the mass air flow sensor. Because of this layer, which acts as a heat insulator, the mass air flow sensor begins to “lie”, giving an incorrect signal to the injection computer. And here, based on the “outdated” composition of the air-fuel mixture, the conversation will not be about a microscopic increase in peak power, but about a noticeable drop.

In some cases, the installation of the Federal Tax Service itself can even reduce the maximum engine power. When installing a fashionable cotton “cone” or a foam “mushroom”, you have to dismantle the standard air filter box and air intake. If the layout of the engine compartment is unsuccessful, after this “anti-tuning” the engine does not receive air that is close to atmospheric temperature, but air that is already heated, passing through the radiator. An increase in air temperature for every 10 degrees Celsius gives a loss in density of 0.04 kg/m3 - and an average atmospheric two-liter engine, revved up to 5000 rpm, drives 35 - 40 cubic meters through itself per minute! As a result, an engine with a zero-resistance air filter receives less air mass than with a standard, supposedly “stifled” intake.

An inevitable harm from using zero air filters is accelerated wear of the cylinder-piston group. Even the air purification results of these filters declared by the world's leading manufacturers (for example, K&N) do not exceed 99% under ideal conditions and using expensive branded impregnation oil. The paper curtain air filter is capable of filtering out 99.5 to 99.9 percent of dust. It would seem that the difference is small - but after several tens of thousands of kilometers we will already be talking about the difference in whole grams of dust that gets into the engine cylinders. Moreover, as the paper filter gets dirty, it only increases the degree of filtration: dust, clogging the pores, reduces the flow area, and they become capable of trapping smaller particles, although at the cost of increasing resistance.

In “zero” filters, contamination on the surface of the pores reduces the likelihood of new particles adhering, and the cross section of the pores remains larger than the size of the filtered particles; as contamination increases, the degree of purification decreases with little change in resistance. Previously used contact-oil air filters suffered from the same thing, where oil soaked the fishing line stuffed inside (designs familiar, for example, from old Soviet trucks and motorcycles). “Nuleviks” have become a more compact and lighter version of these filters, which have long been replaced by paper filters.

And errors during filter maintenance only increase the wear rate. Some people manage not to saturate the filters, while others use cheap aerosols or oils that are completely unsuitable for impregnation. Try rubbing a drop of the brand's impregnation oil between your fingers: it's so sticky that it's hard to even wipe it off your fingers. Other oil will not provide any noticeable improvement in cleaning compared to a filter that is not impregnated at all.

The only advantage for engines that have not undergone serious tuning from installing “nuleviks” can be considered the absence of the need for regular replacement: you need to wash and re-impregnate the same filter on time.

Service issue

If you decide to install a zero filter instead of a standard type air filter, then you will have to take extra care of it. The essence of care is cleaning and periodic impregnation with solutions. Moreover, during care, a certain technology is strictly observed.

If you don’t do this, your car’s fuel consumption will increase significantly, power will drop, and the car will begin to react poorly to increased speed when you press the gas pedal.

- remove the filter;

- clean dirt with a soft brush;

- remove dirt from the seat;

- rinse the filter with water;

- shake several times rather than dry;

- apply cleaning agent on both sides;

- install in place.

If the car is operated in fairly harsh conditions, then such preventive maintenance is carried out at least every 8 thousand kilometers. For normal conditions, 10-12 thousand km is enough. One zero can be washed up to 20 times. Then a mandatory replacement.

What can be said about such zero-resistance filters? They look impressive in the photo, are expensive and, in theory, have important advantages over standard filters. But when applied to production cars they are useless. It is a fact.

It is important to install nuleviks on powerful sports engines and engines that are subject to serious technical tuning. The filter itself will not improve the weather on engines whose power does not exceed 120-150 horsepower.

What do you think about this? Is there any sense in nuleviks, or is it a useless waste of money? Write your opinion in the comments.

That's all I have. Thanks to everyone who is with us! Subscribe, ask questions and invite your friends to join us!

(No ratings yet)

Excellent radar detector for the money SoundQuest 420

Ceramic car coating, pros and cons

The SoundQuest 420 radar detector is suitable for car enthusiasts looking for an inexpensive and reliable device. At a cost of approximately $50, this radar detector has all the necessary characteristics:

- detects all ranges of radar systems in Russia and the CIS countries: X, Ka, K, short-pulse signals Ultra-X and K, as well as the POR range; the laser receiver detects light rays in a complete circle;

- a new system for filtering false alarms and impulses in the Ka range is preinstalled - Smart-Filter;

- protection from detection by VG-2 radar detectors.

The miniature body will not clutter up the interior, much less block the view of the road; the device is attached using suction cups and a bracket to the windshield, or glued to the front dashboard with double-sided adhesive tape. Even a novice driver can install and connect. The device operates from the car's network, the connection is made to the cigarette lighter, a 12-15 Volt adapter is included. If something is unclear, you can use the self-learning function; the radar detector will demonstrate the basic principles of operation. The kit includes detailed instructions in Russian.

Having detected a pulse from a police radar, the device will issue an individual signal corresponding to the frequency of the received wave, and an icon corresponding to the range will light up on the LED screen. As you approach the traffic police post, the intensity of the beepper will increase. If desired, you can set the signal muting mode or adjust the comfortable volume level. There are also 4 levels of display brightness.

When starting the engine, you do not have to turn on and configure the radar detector every time; all previously entered settings are saved in memory. When driving outside the city, the sensitivity level is adjusted by simply switching between City/Highway modes.

There are few reviews about the SoundQuest 420 radar detector. The advantages include a good reception range, especially outside the city. There are also a lot of disadvantages, and they are all standard: increased sensitivity to extraneous impulses, frequent malfunctions, cannot be left in the car overnight in winter - it will turn on at least half an hour after starting the engine.

ravid.ru

Why KN is SPECIAL

Upon external inspection of the filter, large holes are visible in the filter material - this is the main reason for the high air flow capacity. The filter is made of layers of surgical cotton gauze impregnated with oil, sandwiched between an aluminum mesh.

The special oil composition contained in cotton gauze does not limit the throughput and at the same time provides high-quality filtration of the air flow. This is the basis of a unique filtration system! Dust particles in the air flow, attracted to the filter, have a negative charge and passing through the filter element (similar to the action of a magnet) are attracted and attached to the impregnated cotton gauze, which has a positive charge.

If there is a large accumulation of trapped particles on the outside of the filter, the holes in the gauze fabric remain open. This outer level of dust and sand becomes a secondary element for filtering incoming particles while providing high throughput. This simple but very effective secondary filter is the basis for a long filter life, in many cases up to 10 times longer than a conventional filter. The 100,000 mile filter requires no maintenance and is the 'norm'. Cleaning is carried out according to mileage or if the accumulated layer of contamination is 2mm - 3mm.

How is it different from other types of filters?

The main difference between the “nulevik” lies in its design. Classic filters installed on most cars are made of paper (more precisely, from compressed fibers).

The flow of air masses passes through small holes in the fibers, and then goes to the motor.

As soon as the fibers become clogged, the resistance also increases, because the air needs to find new ways to overcome the obstacle. If you do nothing, the engine power drops.

Taking into account existing standards, the paper filter must have a large thickness with maximum fiber compression. This design ensures high-quality cleaning, but the resistance is increased immediately after installation.

The design of the “nulevik” is based on the principle of reducing resistance.

The device is based on several layers of cotton, which effectively traps dust and dirt. In this case, the retained particles essentially become part of the product.

Thanks to this, the efficiency of the filter element is higher and one square centimeter of surface accepts more dust than its predecessor.

Cotton fabric is sandwiched in an aluminum screen, which increases the filter surface. The developers claim that the working part of the “nulevik” is 4-5 times larger than in a classic filter, which ensures a long service life and lower resistance of the product.

This is achieved thanks to another factor - the presence of a special coating (oil) on the cotton, which traps dirt without harming the flow.

The best zero resistance filter

| Metering | Received maximum power, kW/hp. | Change in power,% from initial value | Brand, model, filter type | Retail price, c.u. |

| 1 | 69,2/94,11 | — | Standard VAZ | 6,45 |

| 2 | 71,6/97,363 | + 3,76 | Pipercross PK003, universal cone | 55 |

| 3 | 73,3/99,68 | + 6,23 | Pipercross PK003VR, cone with internal diffuser | 75 |

| 4 | 73,9/100,5 | + 7,1 | K&N RC2600, universal cone | 60 |

| 5 | 74,4/101,84 | + 7,8 | JR CR07301, universal cone | 40 |

| 6 | 73,3/99,68 | + 6,23 | Green K370, universal cone | 60 |

| 7 | 75,2/102,27 | + 8,9 | Pro Sport, cone with internal diffuser | 85 |

| 8 | 74,1/100,77 | + 7,3 | Without a filter | — |

| 9 | 73,5/99,96 | + 6,5 | Pipercross PP43, cased, in standard case | 40 |

- “Torque” characteristics of the VAZ-2111 engine with various air filters.

- Dependence of filter resistance on crankshaft speed.

- Change in air flow depending on the crankshaft speed.

- Estimation of engine power increase at 7000 rpm depending on the type of air filter.

- Which 0-wheeler did you choose?

- By what criteria did you choose the nulevik?

xn--2111-43da1a8c.xn--p1ai

Advantages and disadvantages of the design

Like any new tuning product, the “zero” filter exhibits pros and cons in operation. Most reviews from tuning enthusiasts who installed the “nulevik” consider the only drawback of the design to be the high price of a high-quality filter.

The main advantages of the sports filter are recognized:

- Increased engine power.

- Improved cleaning (for high-quality models).

- Easy to install (no intervention required by auto mechanics).

- Possibility of self-service.

- Repeated use of the filter (up to 20 washes).

- A small increase in power (by 3-5 hp for a hundred-horsepower engine) when installing a “zero” filter in the standard place of mass models.

In sports tuning, power can be increased by installing an enlarged throttle valve on a special cold air duct.

High-quality filter models use expensive cotton paper, which has a high air throughput with maximum filtration of dust and dirt particles. Foam filters are inferior to cotton filters in all respects. All other advantages appear with the correct choice and operation of the filter.

Differences between a standard filter and a “nulevik”

The standard filter material is paper impregnated with special oil. It traps the smallest fractions of dust, but at the same time creates significant air resistance.

“Nulevik” is made from a special material that has significantly greater porosity than paper.

Thanks to this, it does not interfere with the passage of air flow. Low resistance filters are made of multi-layer cotton fabric mounted on an aluminum frame.

Types of low resistance filters

There are two types of “nuleviks” on the auto parts market:

- Dry

(without impregnation) - the operating principle is more similar to standard filter elements. Just like standard solutions, they need to be changed every 10 - 15 thousand km. The maximum power increase that such filters provide is 5%. - With impregnation

- they are more “powerful” solutions, as they add up to 7% hp. Thanks to this, they are popular among owners of tuned cars.

Low-resistance filters with impregnation require additional maintenance every 3-5 thousand km, since small particles of dust (due to the applied composition) stick to the filter material and clog it. The car owner will have to disassemble, wash, dry the “nulevik”, then re-apply the impregnating composition and install the part back. Otherwise, the zero resistance filter will be 3-4 times worse than the standard one.

WHAT MAKES NOTHING FROM

The vast majority in two ways. Some use high-quality surgical gauze as a filter element, others use porous (foamed) polyurethane. The first gauze filters appeared almost 40 years ago in the USA, since then the concept of their production has hardly changed. Porous polyurethane began to be used a little later, about 30 years ago. It is believed that this material is less demanding in maintenance and more durable. However, in the end it all depends on the operating conditions. There is also a third option, also positioned as gauze, but in fact it is a kind of artificial material, very similar to pressed padding polyester. It is quite simple to distinguish it from “medical fabric”; it does not have a pronounced mesh structure inherent in noble fabric. The actual service life of such products is short, and the quality of filtration... But we will talk about the quality of filtration in the next issues. Here we will only touch on the impregnation procedure.

Selecting and installing a filter

Photo of VAZ 2110, on which the “zero” is installed

Without touching on the variety of designs (universal, sports, cone, cylindrical, open, closed), the main criterion for choosing a “zero” filter is cost. Filters from the best manufacturers (Venturi, K&N, Simota, JR, Pipercross, Green) can be purchased for 3,000 – 8,000 rubles. Some models for sports tuning are sold for 12,000 - 15,000 rubles. Domestic filters from the Pro Sport brand are cheaper (650-1000 rubles).

Car tuning enthusiasts have come up with several ways to install a “zero” filter on an engine. The simplest way to install it yourself is to dismantle the standard filter, in its place you can put a “zero filter”.

In engines of domestic carburetor models, the filter is installed on the carburetor and secured with a clamp to the inlet pipe. More complex methods use the removal of the filter to brackets in free engine compartments. A filter placed near the front air intake on a corrugated metal pipe works effectively. It must be taken into account that poor sealing of an extended air duct (dust entering through connections) reduces the efficiency of the “zero” filter.

K&N filter

The products of this manufacturer have firmly established themselves in the automotive market and have a huge number of admirers.

The K&N zero resistance filter was developed in California by the company of the same name to help increase power values. In terms of their characteristics, the products of this manufacturer are in many ways ahead of their analogues from competitive companies. According to the developers, installing it on the engine will increase power figures by as many as four “horses”. The element can be used for a long time, and when operating a car in normal urban conditions, it can be cleaned only after 80 thousand km of the car's mileage.

The K&N Zero Resistance Air Filter is made from the purest cotton.

The main parts of the element consist of several cotton layers, which are located between two aluminum plates. To increase the performance of the filter, it is impregnated with special oil, and its design features ensure durable and reliable operation on any engine.

All products from this manufacturer have a warranty period, which, according to the company's engineers, is one million miles.

Replacing the air filter on a VAZ 2101-VAZ 2107

Note! To replace the air filter, you only need one “10” wrench and it is advisable to stock up on a clean rag in order to wipe the dirt off the inside of the air filter housing!

- Replacing the air filter

- Additional video clip

Where is the air filter located?

Immediately after opening the hood of the car, of course, you will not be able to find the air filter, but why? Yes, because it is located inside the case, which you see in the photo below. To clearly see the filter, you will first have to remove the cover of this housing and only then remove it. (For information about the procedure for removing the cover and replacing the filter, read in the same article just below)

When should you change the air filter?

- Firstly, as a rule, there is no such frequency for replacing the air filter! And all because it must be replaced if it is heavily soiled or if it is severely deformed.

- Your memory will help you understand when you need to check the filter status, but why do you ask? Yes, because if the filter is heavily contaminated, the car’s consumption increases by “0.5-1” liters, and since the classics do not have an on-board computer that measures consumption, in this case, use only your memory.

Note! Well, you still look into the engine from time to time to check the condition of the filter and replace it if necessary!

How to replace the air filter on a VAZ 2101-VAZ 2107?

Removal: 1) First, unscrew all the nuts that secure the air filter cover.

2) Then remove the cover from the air filter.

3) Next, remove the air filter from the housing.

4) And then cover the carburetor neck with a clean rag to prevent dirt from getting into it.

5) Next, wipe the inner air filter housing and covers with a rag.

Installation: 1) Install the new air filter in the reverse order of removal.

Important! 1) Make sure that no dirt gets into the carburetor neck when replacing the filter!

2) On some cars there are marks on the air filter cover, according to which the cover must be aligned:

- When the outside temperature is +5 and above, the red mark (indicated by the letter “A”) should be located near the warm air supply pipe, which is indicated by the letter “G”.

- When the outside temperature is -5 and below, the red mark should be located near the air intake pipe, which is indicated by the letter “B”.

Note! 1

If there are no such marks on the filter cover, then pay attention to the fixed damper with a seal, it replaces the red mark! (For information about where the damper with seal is located, see the very bottom of the article, in the “For Beginners!” section)

2. If there is no sealing flap on the air filter cover, then install the air filter cover as you wish!

For newbies! Question: Where is the air filter cover seal located? Answer:

Additional video: In order for you to better understand how to properly replace the air filter on a classic car, watch the added video below, after watching it you will understand everything clearly and clearly.

Vaz-Russia.ru

Feasibility of application

In addition to the maintenance advantages, the zero-resistance filter has other advantages:

- if you replace only the standard filter on the engine with a “nulevik” one, this will give approximately 2-5% increase in power, which in itself is not significant, that is, its use without other engine tuning is not very effective in terms of boosting;

- There will be more induction noise under the hood of the car, that is, the engine will sound a little more aggressive;

- At low and medium speeds the torque will increase significantly.

( 2 ratings, average 5 out of 5 )

Service

To carry out maintenance you will need a special composition (oil). The service order is as follows:

- Remove the filter and clean it with a soft brush to remove external and large contaminants. You cannot use compressed air, gasoline, or kerosene for these purposes - this can damage the filter elements.

- Treat the filter with a special compound, wait about 10 minutes for the oil to soak in. To service large models, it is more convenient to use a container of appropriate size filled with a special composition. The filter must be rotated while immersing it in the solution. This gives the greatest coverage of all sections of the element for processing.

- Next, you need to rinse under running water.

- After the “water procedure”, you need to remove excess water and dry the filter at room temperature. It is prohibited to use any heaters for these purposes.

- Carry out an external inspection. If light spots are detected, impregnation must be repeated.

- Install the filter on the car.

Keeping it in good condition

Like any other element, this filter needs to be cleaned. To do this, you need to dismantle it and carefully clean all surfaces of the element using a special brush. Next, you need to apply a special cleaning agent to the surface of the filter and leave for ten minutes until it is completely absorbed. After this, the filter element should be washed and rinsed under running water.

It is not recommended to dry the part using various heating devices and devices, as the element may be deformed. After drying, install a zero-resistance filter on the carburetor.

When operating a car in normal climatic conditions, it is recommended to wash it every ten thousand mileage of the car. When using transport in less favorable conditions, cleaning is carried out every five thousand. After washing about twenty times, the element should be replaced with a new one, since the working resource is completely exhausted.

The main advantages that tuning fans highlight

Many people wonder, but not everyone knows what a zero will do with a conventional motor.

- The power of the power plant increases to 10%. This is despite the fact that there is still a filter, and particles will not get into the cylinders along with the combustible mixture.

- Nulevik does not require frequent replacement, unlike a conventional filter.

Such an air purifier, as it becomes dirty, is simply washed with a special aerosol. After treatment, the unit can be reused. A modern filter can be installed in a standard place, depending on the shape, but you can simply put it on and clamp it with a clamp on the air supply line.

How to properly care for the filter?

In order to service the zero car, it must be removed from the car. After which it is cleaned with a special brush. The cleaning has been completed, now a special filter cleaning agent is applied to the entire filter. Now you should wait 10 minutes until the product saturates the filter. Then, after this time, the filter is washed in some container with water. And after that you need to rinse the element under running water.

Once the filter has been cleaned, there is no need to dry it at all. The best thing to do is simply remove the remaining water with regular shaking. There are cases when the product has poorly saturated the filter and light spots appear on it. In this case, you will have to use the product again. After completing the entire procedure for cleaning the zero-resistance filter, it can be mounted back. According to factory data, the zeros are designed for 20 washes. Further washing is useless, and replacement is impossible.

Important information should be noted: zero-resistance filters perform well on power plants with large volumes. Weak and small engines will not notice the increase in horsepower from such a device.

People's opinions that if the air filter is completely removed, then the engine will become much more powerful are completely mythical. In reality, nothing like that happens. When the designers invented the engine, they calculated all valve timing, taking into account the resistance of the air filter. So, besides the fact that the motor will become unusable very quickly, due to the entry of a large number of “extra” particles into it, removing the filter will not increase power.

Whether to use a standard accessory or try to tune your car is up to the owner to decide.

What is nulevik

An air filter is needed to clean the air and protect the engine from dust and other foreign objects entering the intake tract.

It’s just important to remember that the more intense the filtration occurs, the less powerful the engine becomes. Since most of the motor power is spent on air intake through the filter, elements made of paper offer strong resistance to air flow

After all, this part is made of dense material. It turns out that the stronger the air resistance in the filter, the more protected the engine is, while precious power is lost. This problem especially increases at the moment when the element becomes dirty.

For this purpose, a purifier with reduced open channel resistance is used. In this case, you can achieve excellent engine power by adding a “couple of horses” to it. Such a zero purifier helps reduce resistance to air intake without reducing its main tasks and even, on the contrary, increasing the capabilities of the engine. If the motor is intended for racing, this element has a place, but if the motor is standard, then is a zero gear needed?

Based on statistics, a nulevik increases engine power by an average of five percent. Outwardly, this is completely invisible, since less than five percent of horsepower is not felt at all, especially for a beginner.

What's the result?

Having considered the pros and cons of a zero-resistance filter, the car owner will decide whether to install this element. If you nevertheless decide to equip the engine of your “iron” friend with a filter of this design, then you should select and install the zero filter with the correct approach to this procedure, so as not to damage the condition of the power unit. Professional racing cars are equipped with such a product as standard, because its effect is very noticeable on their powerful engines. When a car moves at high speed, the air flow creates a turbulence in the intake tract, practically turning into a small hurricane. Due to this factor, a vacuum moment is created in the system, which the zero filter copes with perfectly, straightening the air flow.

In this case, the probability of dust getting into the engine cylinders is very high. For racing cars this is not significant, since after almost every competition their engines are repaired and the piston group is replaced.