Many drivers, most often beginners , often have a question: is it possible to effectively flush the injector without the help of knowledgeable specialists. The reason is simple - the considerable cost of this service. Washing the injectors with your own hands will not create any special problems; the main thing is to know the basic rules and methods for cleaning the fuel supply parts.

General information about injectors: types, purpose

You can check the functionality of the injection system and diagnose the serviceability of the injectors with your own hands. It is not necessary to go to the service station every time.

Injectors are mandatory components of the ITS (injector). They are intended for dosed supply of fuel. It is the injectors that make it possible to create a fuel-air mixture (fuel-air mixture) by mixing gasoline or diesel fuel with air. The flammable mixture formed in this way is more easily ignited.

It is customary to distinguish several types of nozzles:

How are diesel engines maintained?

Proper maintenance of a diesel engine will involve not only changing the oil, servicing the timing belt, but also timely cleaning of the injectors. This work can be done in the following ways:

- Using special auto chemicals.

- Using ultrasonic equipment.

The choice of one or another injection system cleaning technology will depend on the general condition of the engine and whether or not the vehicle has signs of injection problems. If the car was purchased on the secondary market, its service history is unknown, or the car has obvious signs of problems with the fuel system, then you should contact specialized service stations, where ultrasonic cleaning of the engine will be performed using appropriate equipment.

As a preventative measure, the removal of deposits on fuel line elements can be done using appropriate auto chemicals.

Most car owners clean diesel injectors with their own hands; fortunately, today in automobile accessory stores you can find various products that are designed to clean injectors. Such additives are added to fuel, they clean and remove deposits and contaminants present in the system, improving the overall condition of the engine.

Why do you need injector diagnostics?

As a rule, if a used car was purchased, or the life of the original car has exceeded the 150,000 mark, the performance of the injection system elements should be checked.

Of course, the life of the injectors is directly affected by the quality of the fuel the owner fills the car with. The situation is depressing in the countries of the former CIS and in Russia, where it is unclear what is being sold at gas stations. After pouring such a composition into the fuel tank of a car, and after driving several thousand kilometers, you have to begin repairing certain parts, including injectors.

Injectors should be checked as soon as the following symptoms are present:

If one of the above-described signs is present on an injection car, then it would be a good idea to check the operation of the injectors. We can say that time and money were well spent. However, you can completely eliminate the topic of money if you learn how to check the injectors yourself.

The injector is checked with a multimeter or Ohm measuring device. The injector is disconnected from the high voltage and then tested. It is necessary to test the compliance of the injector impedance indicators with standard values. If the injectors are low-resistance, then their resistance should be within 2-5 Ohms, if high-resistance - within 12-18 Ohms.

How to disassemble

First you need to remove the nozzle from the rack.

Next, the nozzle is checked visually.

Now it's time to start disassembling.

Due to clogging of the throttle inside the nozzle or due to a weak connection, diesel fuel flows back into the tank, and this, accordingly, leads to abnormal injection and loss of pressure in the rail.

The nozzle sprayer with the needle also deteriorates, although to a lesser extent. The gap between these components of the injector is also small, which can lead to rapid wear. As for the wear of the needle, scratches and damage form on it over time.

When sorting injectors at home, a good, high-quality magnifying glass will be of great benefit. Most of the internal parts of the nozzle are small; a magnifying glass will allow you to see them all without losing anything. Small elements also include round metal balls that perform very important functions inside the nozzle.

Video: Bosch piezo injector device

After repair, the injector will change those characteristics that are encrypted in the code. The control unit must adapt to the new rules, this takes time. As a rule, if you don’t force yourself into the car’s brains, it can take about 1 month for full adaptation. And remember that in some cases it is easier to replace a nozzle than to restore it. Especially if there are noticeably many defects on them.

Source

How to clean injector nozzles at home

When using the chemical flushing method, the driver must purchase a special product, a set of new O-rings, and a fine filter.

Note! The chemical cleaning method is not suitable if the car has old, ceramic, or heavily soiled injectors. Aggressive chemical compounds can damage sprayers.

Many people say that to clean injectors at home yourself, without removing them from the engine, a carb cleaner is suitable - a special product that breaks down the carbon layer. This is true, but you won’t be able to carry out the procedure yourself without removing the injectors from the engine. More on this below.

How to clean injectors with carb cleaner

The sequence of actions is as follows.

- Removing the nozzle from the manifold and cleaning the outside with a rag.

- Cleaning the insulation.

- Connecting the wiring to a small battery.

- Extending the insulation on the opposite ends of the wires to connect them to the injector later.

- Creating a hole in the cap of a carb cleaner bottle.

- Installing the cap into the rubber hose, clamping the ends of the cap with a plastic tie.

- Connecting the injector to the battery. The correctness of the action is indicated by a characteristic click indicating the opening of the nozzle.

- Putting the adapter with a nozzle on a can of cleaner.

- Accurate pressure supply.

- Clean until the pattern is even.

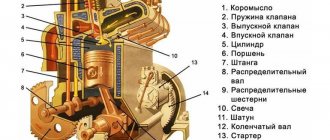

What are fuel injectors

When talking about the design of an injection engine, one cannot fail to mention such an important element as the fuel injector. This part is a valve mechanism with a sprayer. It is responsible for supplying fuel to the engine cylinders. Its main feature is that it provides the required amount of gasoline, that is, it also performs a dosing function.

In the modern automotive industry, these parts are used on both gasoline and diesel engines, as they provide accurate fuel dosage and the most efficient injection of the air-fuel mixture.

Three types

The development of injection systems in fuel-injected cars began in the 1960s. Today, three types are used, which differ in the method of injection:

Electrohydraulic: its main area of application is in engines that run on diesel fuel. Structurally, the electrohydraulic fuel injector consists of a control chamber, a valve, an inlet throttle and a drain channel. It works by applying the existing fuel pressure in the system. The valve opens and fuel enters the injector through the intake throttle. The injector needle regulates the amount of incoming diesel fuel and directs it to the drain area. In this way, the necessary pressure is built up in the housing, so the needle mechanism sprays a dose of fuel through the drain throttle. The electrohydraulic injector is considered one of the most accurate, since during the injection period the solenoid valve opens for only 1 or 2 milliseconds.

Electromagnetic: used primarily on gasoline power units. The nozzle and needle valve play an important role in the device. The signals received from the control unit ensure a continuous supply of voltage to the injector winding. That is, an electromagnetic field is formed that can overcome the force of the needle valve spring and open the injection nozzle. After injection, the voltage drops sharply, the spring returns the needle to its place, and the nozzle closes.

The piezoelectric injector can currently be considered one of the most advanced devices for injecting fuel into engine cylinders. Mainly used on diesel vehicles, as it allows to increase engine thrust. The part consists of a pusher, a special piezoelectric element, a needle and a switching valve mechanism. At the beginning of the cycle, the needle is held in the valve seat by the force of fuel pressure. After applying an electrical signal to the piezoelement, it increases in length and transmits force to the pusher. At this moment, the valve opens and fuel enters the drain pipe. Then the pressure inside drops, so the needle rises and injects fuel.

Injector cleaning methods

Currently, there are two main methods widely used for cleaning injectors of internal combustion engines - liquid (chemical) and ultrasonic cleaning. Both technologies have certain indications for use, have some disadvantages and undoubted advantages, but each of the methods is a complete and sufficient means used as part of servicing the fuel injection system. In some cases, both cleaning methods can be used in combination.

Basic faults

Modern manufacturers produce injectors with a tolerance of 1 micron, that is, the product is capable of performing about a billion operating cycles of fuel dosing and supply. However, they usually fail before their deadline, since their productivity can be sharply reduced due to contamination. The quality of the fuel directly affects the service life of the part.

The main cause of pollution is the inevitable presence of heavy particles in gasoline or diesel fuel.

In this case, the accumulation of dirt mainly occurs immediately after the trip, that is, as soon as the driver turns off the engine. At this moment, the nozzle is very hot from the engine, and the coolant no longer flows because the engine is not running. Light particles of fuel that remain in the body evaporate, and heavy ones settle.

Signs of trouble

The car owner can independently diagnose injector malfunctions. To do this, you need to carefully monitor any changes in engine operation. So, the following signs indicate a problem on any fuel-injected car:

Source

Signs indicating dirty injectors

Characteristic signs indicating that the contamination of the injectors has reached a critical level and urgent cleaning is necessary are:

- obvious failures in engine operation at idle or when accelerating;

- deterioration of throttle response and acceleration dynamics;

- loss of power;

- excessive fuel consumption, high level of CO in exhaust gases.

Due to contamination of the thin channels of the injector with tar and carbon deposits, its throughput decreases - the engine experiences fuel starvation.

It is useful to remember that if cleaning the injectors is not an emergency, then it makes sense to combine this operation with a scheduled replacement of engine oil and spark plugs.

General information about injectors: types, purpose

You can check the functionality of the injection system and diagnose the serviceability of the injectors with your own hands. It is not necessary to go to the service station every time.

Injectors are mandatory components of the ITS (injector). They are intended for dosed supply of fuel. It is the injectors that make it possible to create a fuel-air mixture (fuel-air mixture) by mixing gasoline or diesel fuel with air. The flammable mixture formed in this way is more easily ignited.

It is customary to distinguish several types of nozzles:

Why do you need injector diagnostics?

Checking injectors

As a rule, if a used car was purchased, or the life of the original car has exceeded the 150,000 mark, the performance of the injection system elements should be checked.

Of course, the life of the injectors is directly affected by the quality of the fuel the owner fills the car with. The situation is depressing in the countries of the former CIS and in Russia, where it is unclear what is being sold at gas stations. After pouring such a composition into the fuel tank of a car, and after driving several thousand kilometers, you have to begin repairing certain parts, including injectors.

Injectors should be checked as soon as the following symptoms are present:

If one of the above-described signs is present on an injection car, then it would be a good idea to check the operation of the injectors. We can say that time and money were well spent. However, you can completely eliminate the topic of money if you learn how to check the injectors yourself.

The injector is checked with a multimeter or Ohm measuring device. The injector is disconnected from the high voltage and then tested. It is necessary to test the compliance of the injector impedance indicators with standard values. If the injectors are low-resistance, then their resistance should be within 2-5 Ohms, if high-resistance - within 12-18 Ohms.

There are several ways to flush diesel injectors.

Flushing diesel injectors may be required after a certain mileage of any car with a diesel engine, because the quality of diesel fuel at our gas stations, to put it mildly, leaves much to be desired.

In this article, we will look in detail at the main reasons why you may need to flush the injectors, in what ways this can be done in your garage and with what. I have already written about the ways in which you can effectively wash the injectors of a car with a fuel injection system (I advise you to read about it here, as well as here), and the washing principle described there is very similar to washing diesel injectors. So I advise you to read it, follow the links, there you will find something useful for diesel engines. But this article will describe several methods for washing diesel injectors, since deposits from low-quality diesel fuel may differ slightly from gasoline deposits on the injectors of a car with an injection system.

Deposits on the injector valve.

In general, during operation of a diesel engine, injectors are subject to high temperature loads and operate under high pressure. Let's add to this the not very good quality of our fuel, which has an increased percentage of heavy fractions, leading to contamination not only of the injectors, but also of the entire fuel system.

As a result of engine operation and fuel combustion, as well as when the engine is turned off but still hot, fuel residues on the surface of the injectors gradually turn into solid resinous deposits and carbon deposits, which gradually become thicker (see Fig. 1), and the spray holes of the injectors become polluted.

As a result, the injectors begin to work poorly and there is no longer a clear fuel atomization pattern; in addition, the tightness of the injector shut-off valve and its seat is gradually lost. Simply put, the injectors begin to pour fuel instead of spraying it. Naturally, this disrupts the normal operation of the diesel engine and causes the malfunctions described below to appear.

Let's look at diesel engine malfunctions that will tell you that it's time to flush the diesel injectors:

- The diesel engine became difficult to start (what else to do if a diesel engine began to start difficult, I advise you to read here) and not suddenly, but gradually, and if suddenly, then after refueling with low-quality fuel.

- Interruptions in diesel operation (the engine troits) at idle (or stalls) or interruptions during transient conditions (fuel misfires).

- Engine knocking at partial load.

- Popping or sneezing noises in the intake tract (manifold) or air filter.

- Deterioration of throttle response (acceleration dynamics) of a diesel car.

- When the gas is applied sharply, dips in the speed increase appear.

- Periodic failures when supplying gas (the engine may at times slow down on its own, regardless of the position of the gas pedal).

- Fuel consumption gradually increased (read how to reduce fuel consumption here).

- The toxicity of exhaust gases has increased (dark smoke comes out of the exhaust pipe).

- Well, and loss of engine power.

The first method for flushing diesel injectors. To begin with, I will describe the simplest method, which is simple in that a special preparation is used (there are now a lot of them in any car shop), based on a solvent, which is simply poured into the fuel tank of the car, and a liquid designed for a certain amount of fuel in the tank, at the engine starts cleaning. But here I want to warn many car owners that such chemicals should be treated with caution and carefully read the instructions.

The thing is that chemicals that are aggressive to deposits begin to “lift” and clean dirt not only on the injectors, but throughout the entire power system, including the fuel tank. And the dirt dissolved by chemicals lifted from the walls or bottom of the tank will clog all the filters of the power supply system (fuel supply), and the biggest blockage will be in the fuel receiver grid in the tank.

Therefore, if you are not sure of the cleanliness of your tank (which, by the way, I advise you to periodically check for the presence of water and dirt - this can be done by opening the hatch at the top of the tank and shining a flashlight), then I advise you to abandon this method of washing.

However, modern cleaning chemicals have now been developed that begin to dissolve dirt only when they reach the operating temperature of the engine. That is, it turns out that after pouring such a drug into the tank, it does not dissolve the dirt in the tank, since the temperature of the fuel in the tank is not high.

But when the engine starts and the fuel with the cleaning agent dissolved in it begins to flow into the hot engine (and hot injectors), only then does the drug activate its action (that’s why the fuel additive is called active) and begins to dissolve the dirt. That is, it starts working only at high temperatures.

An example of such a cleansing drug, called “Elial”, is shown in the photo on the left, and I will not describe its effectiveness, it is best to read about it on the forums of the relevant topic, since I have always said that the opinion of the majority of people is always truer than the opinion of one person. You can also type this liquid into any search engine and read in more detail about its technical properties.

The second method of cleaning diesel injectors works effectively and its advantage is that it is easy for any car owner to do in their yard or garage, even a novice.

The principle of operation is that a highly effective additive from the reputable company Liqui Moly is used, shown in the photo on the left and in the video below.

The standard fuel supply hose is disconnected and lowered into a can of additive (on some machines it is sometimes necessary to extend the standard hose with a piece of additional hose connected through an adapter steel tube.

How to do the washing is shown in detail in the video below.

The advantage of this method is that if there is dirt on the walls of the fuel tank, it does not dissolve, since the fuel line is disconnected from the machine system, and the return hose must be lowered into a separate container so that dirt does not get into the fuel tank and clog the standard filters.

In addition, there are other drugs, for example, the well-known “Winn's”, shown in the photo on the left. By the way, it has a larger container, and it can be poured into a transparent container into which the fuel supply hose from your car is lowered (to the very bottom). The return hose goes down the same way. At the same time, I advise you to use an inexpensive fuel filter (transparent) on each hose (both supply and return).

The advantage of this method is that during engine operation, after half an hour of engine operation and washing of diesel injectors and high-pressure fuel pumps, you can visually see how the flushing fluid and filter darken, becoming saturated with dissolved resins. By the end of flushing, the liquid turns from transparent yellow into a dark brown or even black liquid (the color depends on the degree of contamination of the injectors and the fuel system).

After cleaning the injectors, you should remove the container with Vince and do not connect the hoses to the fuel system of the car for now, but pour a couple of liters of clean diesel fuel into another container, lower the fuel hose into it and let the engine run for about twenty minutes to finally wash out the remaining flushing fluid from the fuel injection pump and sediment residues. After this, you can connect the hoses to the fittings of the vehicle’s fuel system.

How to disassemble

What does an injector consist of?

First, you need to remove the injector from the rack.

Next, the nozzle is checked visually.

Now it's time to start disassembling.

Due to clogging of the throttle inside the nozzle or due to a weak connection, diesel fuel flows back into the tank, and this, accordingly, leads to abnormal injection and loss of pressure in the rail.

The nozzle sprayer with the needle also deteriorates, although to a lesser extent. The gap between these components of the injector is also small, which can lead to rapid wear. As for the wear of the needle, scratches and damage form on it over time.

When sorting injectors at home, a good, high-quality magnifying glass will be of great benefit. Most of the internal parts of the nozzle are small; a magnifying glass will allow you to see them all without losing anything. Small elements also include round metal balls that perform very important functions inside the nozzle.

Video: Bosch piezo injector device

After repair, the injector will change those characteristics that are encrypted in the code. The control unit must adapt to the new rules, this takes time. As a rule, if you don’t force yourself into the car’s brains, it can take about 1 month for full adaptation. And remember that in some cases it is easier to replace a nozzle than to restore it. Especially if there are noticeably many defects on them.

Source

How to disassemble a gasoline injector nozzle

Flushing the injector and nozzles is not an easy task even for an experienced motorist, not to mention beginners. During operation, small particles and various kinds of deposits constantly accumulate in the fuel system of a car, so the injectors, being the most vulnerable to all kinds of chemical compounds, often become clogged. Low-quality fuel plays an important role, the use of which greatly worsens the situation. In such cases, you need to wash the injector and injectors without removing it yourself.

Do-it-yourself injector cleaning

To clean the sprayer from dirt, you will need:

- rinsing agent;

- small tube (several pieces);

- a couple of clamps;

- wiring with clamping ends (“crocodiles”).

In the procedures described below we will be talking about injectors previously removed from the engine.

The sprayer is washed as follows:

- The container with the cleaning agent must be hermetically connected with a tube and clamps to the removed element.

- The injector leads are connected to the battery using wires. The “minus” is attached to the battery terminal, while the “plus” remains loose.

- Next, you should pump the cleaning agent inside the sprayer by periodically connecting the part to the battery voltage - this is necessary to get to the needle of the device.

- After two or three opening/closing, the tube is disconnected from the nozzle, and then they wait some time for the substance to act on the dirt inside the part. While the dirt is softening, you should start blowing out the remaining nozzles.

- As soon as the initial flushing is completed, the procedure should be repeated. You may need to blow through the parts more than twice to get a decent result.

Chemical cleaning of the injector

The essence of dry cleaning technology is based on the use of a cleaning liquid containing active components, for example, a solvent. In short, a washing device (you can assemble it yourself) is connected to the device that supplies gasoline, the substance is poured in and the atomizer is cleaned. The work takes place with the engine running, during which the dirt, along with the cleaning fluid, burns inside the internal combustion engine.

The advantage of the process is that the parts of the cylinder-piston system are simultaneously cleaned of carbon deposits.

Chemical reagents for cleaning injectors

In order not to make a mistake when purchasing a cleaning fluid, it is best to opt for the most famous brands:

- LIQUI MOLY is versatile and will suit any car. It is distinguished by gentle cleansing, but does not fight carbon deposits well.

- Wynn's is a caustic dirt cleanser that can remove traces of carbon deposits and tar deposits. Does not fit some car models.

- Carbon Clean - acts gently, but efficiently. Something in between the two previous options. Do-it-yourself injector cleaning will be most effective with this product.

- Laurel is an expensive analogue of Wynn's.

Equipment and materials for cleaning the injector

The device and device for washing can be made with your own hands from the simplest materials at home. We will need:

- empty plastic bottle (2 l);

- two-meter rubber tube;

- clamp securing the tubes (4 pieces);

- pump with built-in pressure gauge;

- several terminals and wires.

The resulting equipment is perfect for washing the required element without first removing it from the engine.

The procedure for chemically cleaning injectors without removing them from the engine

Let's consider the main stages of flushing an injector mounted on an engine:

- First, you will need to turn off the fuel pump.

- After this, we connect the tube of our homemade device and tighten the ends with clamps. This must be done reliably, otherwise an accident may occur due to pressure.

- We close the return so that the chemical does not get inside the tank.

- Fill in the flushing liquid.

- Turn on the liquid pump.

- Let's move on to the main stage. We ask the assistant to start the engine. At this time we turn on the pump with a pressure equal to three atmospheres. The rinsing will take approximately 15 minutes.

- If the process goes well, then by the end of the work the smoke should stop coming out of the exhaust.

- You can change the spark plugs (if necessary).

- At the end, we turn off the homemade device and put the car system in order to check the operation after the procedure. If everything was done as it should, the car should function properly.

When is cleaning required?

Despite all the advantages, the injector quickly becomes clogged when using low-quality fuel for a long time, which reduces engine efficiency. This is the main drawback of this element of the fuel system. Then the question of flushing the injector arises.

Note! Experts recommend cleaning every 20,000 km. But the frequency may vary depending on the quality of the fuel used and the design features of the injection system.

There are a number of signs that indicate the need to flush the fuel system elements. The most common ones include:

Signs of faulty injectors

These are not all the reasons, as there are many of them. Therefore, if you have the slightest doubt, you need to seek help from specialists to conduct a full diagnosis of your vehicle. The cost of this service may vary depending on the city in which the procedure will be performed.

Why clean injectors?

For high-quality atomization of fuel in the combustion chamber, diesel engines use special nozzles, which may differ in their

operating principle, design and manufacturer.

Modern injection systems allow the air-fuel mixture to be sprayed in the form of a spray, which ensures high-quality combustion of diesel fuel with the highest possible operating efficiency of the power unit. During engine operation, various deposits form on the injectors, which leads to problems with fuel atomization.

Even when using high-quality diesel fuel that meets all European standards, over time the injectors begin to fail, and numerous deposits and contaminants lead to increased diesel consumption, vibration and a decrease in engine power. This problem can be solved either by completely replacing the injectors or by cleaning them using special auto chemicals and appropriate equipment.

Diesel engines operate at elevated temperatures and under high pressure, and when combined with the use of low-quality fuel, injection elements quickly fail.

As contamination increases, the throughput of the channel decreases, which deteriorates the quality of mixture atomization, noticeable vibrations appear, the engine runs unevenly and fuel efficiency deteriorates.

The more often a car owner flushes the engine, the easier it is to keep the injectors and the entire fuel system clean. By performing such work regularly, you can get by with the use of additives added to the fuel, and the engine will always run smoothly, without detonation, while maintaining optimal fuel consumption. If the car owner neglects to timely clean the injectors, then serious problems arise in the operation of the engine. Ultimately, the injection will have to be changed, which leads to a significant increase in costs for the car owner.

Additional recommendations

Having understood the washing technology, you can make sure that it is not so complicated if we are talking only about the technical component. Selecting the necessary materials, preparing tools and creating a special device for the job is quite simple. To do this, you only need to have desire, free time and the skills to use conventional tools that are present in the driver's kit.

Cleaning injectors without removal

But with the choice of a high-quality cleaning agent, things are much more difficult, because this is a responsible task. An incorrectly selected product can damage the injectors and make them unsuitable for further use. Such an error will entail not only temporary, but also additional financial costs. Therefore, it is important not to make mistakes when choosing.

Video - Cleaning injectors through the fuel tank

Bad gasoline and a significant age of the car are the two most common reasons why fuel injectors have to be flushed.

Fuel injectors are essentially solenoid valves that, when voltage is applied to them, open the path of fuel into the intake manifold. When there is no power, the shut-off needle lowers under the action of the return spring and closes the channel in the sprayer. Over time, deposits accumulate on the nozzle seat, causing the needle to lose mobility. As a result, the seal of the injectors is broken. A sign of such a malfunction is poor starting of the engine, even when warmed up: the fuel mixture turns out to be over-rich. In addition, contamination of the nozzle holes leads to disruption of the atomization and a decrease in the total amount of fuel supplied. Because of this, when you sharply press the gas, dips appear, the engine loses power, and begins to work unstably.

A radical solution to the problem is to replace the injectors. But there is a cheaper alternative - rinsing. For those who are not afraid to get under the hood, I will tell you how to do it yourself. No fancy tools or special skills are required. It is better to do the work outside or in a well-ventilated area.

We carry out the operation on an editorial Lada Granta car with an eight-valve engine and a mileage of 100,000 km. At this mileage, the injectors of most cars already need “wet cleaning”. You will need an aerosol can with a carburetor cleaner (its price is about 500 rubles). We also have to assemble a simple electrical circuit from a battery, a button from a household bell, and wires with female lugs 2.8 mm wide.

HOW ELSE CLEAN INJECTORS

The cost of the drug is from 250 rubles

The instructions for the preparations promise that after washing, not only the injectors and the fuel system will become clean - soot will be removed from the valves and surfaces of the combustion chamber. There is only one question: where will he go? Obviously, into the exhaust system. And there the designers placed a catalytic converter and oxygen sensors. Soot particles and liquid combustion products will fall on the delicate ceramic honeycomb. And then - depending on your luck. Pieces of carbon deposits stuck to the surface of ceramic honeycombs are hotspots - the honeycombs can melt. The combustion products of a mixture of gasoline and liquid greatly increase the temperature of the exhaust gases, which is also dangerous for the catalytic converter.

The cost of the service is from 2500 rubles

The equipment supplies solvents to the input of the fuel rail, which remove tar deposits from the injectors and dirt from the surfaces of the valves and combustion chamber. The concentration of cleaning components is much higher than when pouring the cleaner into the fuel tank. Consequently, the amount of substances entering the exhaust gas catalytic converter is also significantly greater. The consequences of this are described above.

The cost of the service is from 4000 rubles

The nozzles in the bath with the cleaning solution are exposed to ultrasound, which frees the surfaces from contamination. But first the injectors need to be removed. You can do this yourself or entrust all the work to the masters. The disadvantage of this method is the likelihood of complete failure of the nozzle.

Cleaning the injectors of the injection power system is not the easiest operation, so they are far from daring to do it themselves, preferring to trust the services of service centers and service stations. Some people simply don’t want to bother, citing lack of time, while others are simply not sure that they can do everything right. For those who want to maintain their car themselves, without spending money on service stations (which are not always done well), we will consider the technology for cleaning the injector in a garage.

Washing without removal

What you will need:

- Set of wrenches;

- Screwdrivers “+” and “-“;

- Flushing fluid;

- Fuel hose;

- Fitting for tubeless wheel – 2 pcs;

- Bottle;

- Clamps;

- Drill 10 mm;

- Compressor with pressure gauge (can be used for a car);

Making a device for washing injectors without removing them from the car

- In a 1.5 liter bottle, drill a hole in the bottom with a diameter of 10 mm.

- Insert the wheel fitting into the drilled hole.

- Similarly, drill a 10 mm hole in the bottle cap.

- Insert the wheel fitting into the bottle cap and screw it on.

- Unscrew the spool valve from the fitting in the bottle cap.

- We attach a fuel hose to the fitting installed on the cover and secure it with a clamp.

This is what should happen

Nozzle cleaning device

Relieving pressure in the fuel rail

- In order to relieve pressure in the fuel rail, you need to remove fuse F3 (15A) it is located under the central panel where the foot air ducts are.

- After that, you need to start the car at the residual pressure and let it run until the car engine stops.

- After which you can start working

Connecting the device to the fuel line

- Under the hood we find a fuel line pipe (if the engine has a return line, there will be two pipes, one of them goes to the fuel rail, so you need to connect to it).

Connect to the “straight” hose

- We take two Keys on “17” and unscrew the fitting connection, carefully without damaging the tube.

- You need to unscrew it like this: position the keys like scissors and squeeze them; you must follow the correct direction so that the fitting and nut are unscrewed and not tightened.

- After the fitting connection is unscrewed on the tube, you will see a rubber ring; it must be removed; if it is in poor condition, it is better to replace it.

- Next, we connect the hose from our device to the tube and tighten it with a clamp.

- Pour washing liquid into the bottle and tighten the cap.

- We pump a pressure of 3 atm into the bottle with a compressor.

- We hang the bottle with the cork down and start the car.

Washing process

- We start the car on the flushing fluid and let it use up half of the flushing fluid.

- Next, we stop the car engine and let it sit for 20 minutes. This is necessary so that all the dirt in the injectors becomes sour and dissolves.

- We start the engine again and press the accelerator pedal and keep the speed around 3000 rpm. This must be done until the flushing liquid runs out.

- Next, remove the flushing device and screw the fuel line hose into place.

Attention

Don't forget to install the rubber O-ring when connecting the tube and the fuel line fitting.

Cleaning Frequency

Car manufacturers usually indicate in the technical documentation after how many kilometers the injector needs to be cleaned. But here it is worth noting that they do not take into account the peculiarities of car operation, or rather, the fact that the fuel that we sell at gas stations is not always of high quality. And such gasoline primarily affects the rate of clogging of the injectors.

Experienced mechanics have found that in our conditions, injector nozzles need to be cleaned approximately every 10 thousand kilometers. But this figure is conditional, since everything depends on the quality of the fuel being poured. Some may not need such an operation even after 15 thousand km, while others are forced to clean it after 5 thousand km. Therefore, it is better for the car owner to navigate the car itself, whose behavior itself will tell you that there are problems with the power system.

The main signs of clogged injector nozzles are:

If all this is present, and the on-board computer does not show any errors, it is most likely that the injectors are clogged and require cleaning.

Why do you need to monitor the condition of your injectors?

To understand why injector contamination affects the operation of the power plant, let’s briefly consider the principle of its operation. The task of the injectors is to timely supply fuel in a finely dispersed state to the intake manifold or directly to the cylinder so that it mixes with the air before combustion.

Why do you need to monitor the condition of your injectors?

In order to ensure this, the nozzle design uses a shut-off valve with a needle. When fuel is not supplied, the needle closes the nozzle (small cross-section holes). Also includes a solenoid and core. The latter is connected to the valve. When voltage is applied to the solenoid, the resulting electromagnetic field acts on the core, which ensures its movement (retraction). At the same time, it pulls a valve with a needle, as a result, fuel under pressure passes through the channels to the atomizer, from where it is injected into the manifold.

To ensure high-quality mixture formation, gasoline must be injected in a finely dispersed state (in the form of fog). Only under such conditions is high-quality combustion of the mixture ensured. Good atomization is provided by the holes in the nozzle, but they have very small sections. Dirt, getting into the nozzle along with gasoline, clogs these holes, which immediately affects the quality of atomization. Because of this, the fuel no longer arrives in the form of a mist, but a stream, so it mixes much less well with the air. As a result, gasoline does not burn completely and some of it simply flies out into the chimney. This results in a drop in power, an increase in gasoline consumption, and interruptions in engine operation.

What are injectors and why do they get dirty?

Injectors are a special design that sprays fuel into the engine. They look like small holes through which fuel is injected. The top of the design is a thin needle valve.

Cleaning injectors

Due to the fact that the injectors are constantly under thermal influence, they conduct fuel through themselves, sometimes of dubious quality, even containing resins, they soon become clogged. Plaque forms on the needle valve. The needle stops performing its functions correctly, depressurization occurs and fuel enters the cylinder.

Cleaning methods

To remove dirt and deposits from the injectors of the injection power system, two methods are used - ultrasonic and liquid.

The first method is based on the phenomenon of cavitation, in which ultrasound acting on a liquid leads to the formation of microbursts. The essence of such cleaning is that the nozzles are placed in baths with cleaning liquid, and then exposure to ultrasound is provided. This cleaning method is very effective, but the equipment for its implementation is expensive, so it is more suitable for service stations.

The liquid method does not require any special equipment, and it can be done in a garage, that is, you can wash the injectors yourself. The essence of the method is very simple - all contaminants are removed by washing with a cleaning liquid supplied under pressure.

Cleaning injectors with ultrasound

This cleaning method requires removing the fuel injectors from the engine. The essence of this extremely effective method of removing stubborn contaminants is to use the energy of ultrasonic waves and the cavitation effect.

The nozzles are immersed in a cleaning stand bath filled with a special chemically neutral liquid. At the bottom of the container there is an ultrasonic emitter, the operation of which initiates the occurrence of acoustic cavitation in the liquid (the formation of tiny air bubbles). When microscopic cavitation bubbles rupture (collapse) in a liquid medium, local but extremely powerful acoustic waves are formed, the impacts of which have an intense cleaning effect on the outer surface and internal cavities of the nozzle. To increase the efficiency of removing contaminants, control electrical pulses are sent to the nozzles, which periodically open and close the solenoid valve. It is important to understand that the intensity of cleaning depends on the power of the emitter and the temperature of the liquid in which the nozzle is placed.

After undergoing ultrasonic cleaning, the performance of the injectors is checked on a special stand, where the supply performance and quality of fuel atomization can be accurately assessed.

The ultrasonic method of cleaning injectors is best used when there is a significant decrease in the performance of the injector and, therefore, there is serious contamination. It must be remembered that ultrasonic cleaning of fuel injectors requires high qualifications, otherwise violation of the established cleaning technology with “aggressive” ultrasonic waves can lead to irreversible destruction of some elements (ceramic coating, electromagnet windings).

It is worth noting that, despite some limitations in use, the ultrasonic method makes it possible to incomparably better clean the injector channels from dirt and resinous deposits.