Universal catalyst

What kind of “wonderful” beast is this? YES guys, it's simple. Universal means it fits almost any car, that is, it doesn’t matter what brand or make you have, it doesn’t matter where it is located near the exhaust manifold , or in the highway itself, it doesn’t depend on the cost of the car. You can install it on your car equally and relatively cheaply.

There are two types:

- Ready-made, with pipes or manifold, selected specifically for your model

- Just the cartridge itself, in which there is a metal cylindrical body, and in it there are honeycombs of the new catalytic converter

As you can see, everything has already been invented before us, about the first option, I think it’s not worth telling everything here, it’s so clear - we unscrewed our part of the pipe and installed another, rarely when you need to overcook your muffler a little. However, the cost is not always low, but the second option – a replaceable cartridge – is worth considering in more detail.

This is interesting: Installing a start/stop button instead of the ignition switch: do it yourself

Replaceable universal cartridge

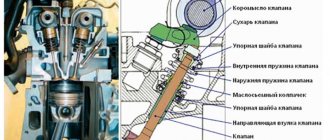

To begin with, I suggest you think about what a catalyst is, what is its main working part? Do you think pipes? Of course not! The working part is the honeycomb that is inside, they are made either of ceramics or metal - but with the addition of noble alloys , such as platinum. It is this composition that burns out (or decomposes) most of the harmful substances that come from the engine.

It is this part, that is, the “honeycomb,” that wears out over time, and may melt, collapse, become clogged, etc. That is, it is no longer capable of purifying gases from the engine; the oxygen sensor (which is installed) behind the catalyst sees this and treacherously displays Check Engine .

If you turn on the logic, you don’t need to change all the metal and other pipes of the entire muffler of the car , you just need to replace these honeycombs, that’s all.

Of course, the official dealer will not do this - they really need to rip off more money from you, but other companies, often from Europe, and even China, thought, why not?

Automotive catalyst: purpose, principle of operation, types

The catalyst is located in the exhaust system and performs the function of removing and pre-purifying gases.

Inside the device, toxins are converted through chemical reactions into less harmful substances. This treatment results in minimizing environmental pollution.

The catalyst is activated as a result of heating, so it does not function when the engine is cold started. It operates in close symbiosis with oxygen detectors.

Thanks to them, the optimal ratio of the composition of the mixture consisting of gasoline and air is formed, which, depending on this, becomes leaner and enriched.

The detectors, guided by the available readings, control the catalyst located between the muffler and the engine.

It is provided to be covered with a special screen, since as a result of strong heating it becomes very hot. The unit can be in several states:

1. Working. Characterized by the normal condition of the car. The error light does not light up when the engine starts.

2. Half working. Traction periodically disappears, the engine becomes less responsive at high speeds.

The car starts worse when started hot and it becomes necessary to repeatedly drive the starter.

When you press the gas pedal, the tachometer needle cannot overcome the 4 mark, and fuel consumption increases.

3. Non-working. It is in such a situation that the catalyst must be replaced, since the vehicle begins to stall immediately after starting the engine or does not start at all.

Attention! You can identify a non-working condition by placing your hand in the pipe when the vehicle is started, checking the release of gases; if this does not happen, then the system does not function.

There are several types of neutralizers:

- tripartite;

- for lean fuel mixtures;

- bilateral;

- for diesel engines.

Double-sided models can neutralize unburned gasoline and carbon monoxide. Three-way modifications additionally break down nitric oxide, releasing oxygen from it. Diesel analogues prevent soot emissions.

We remove the catalyst and install a flame arrester. Video:

DISADVANTAGES OF USING CATALYSTS

Initially, it is worth understanding why a catalyst is needed in a car. It has only two main functions:

- reducing the temperature and energy of gases that are released in the combustion chamber;

- bringing the composition of exhaust gases to environmental standards.

Due to the fact that gases are released at a very high speed and at high temperatures, ceramic honeycombs become clogged very quickly, and the backfiller sinteres or even burns out.

This is the reason that the ability of the resonator to pass gases is sharply reduced. Simply put, the car engine is “choked” by exhaust gases, since the faulty part is not able to remove them.

As a result of this problem, the dynamics of the car drops many times - this can be noticed during acceleration of the car.

In addition, gasoline consumption increases significantly. A car equipped with a catalyst is very demanding in terms of the quality of the fuel used. A minimal deviation from the recommended standards leads to very rapid wear of the catalyst.

Such a list of shortcomings and problems forced motorists to seriously think about finding an alternative to using the above-mentioned exhaust system catalyst.

It is impossible to completely remove the catalyst from the exhaust system. After some time, this will cause a hole scorched by gases to form in the rear muffler canister.

To avoid such problems, it is recommended to assemble the flame arrester and replace the catalyst with it. The design of the flame arrester allows exhaust gases to be removed from the vehicle directly and without delay, and its operating principle has absolutely no effect on engine performance. The flame arrester effectively reduces the temperature of gases.

The only significant drawback is that the level of gas waste emitted into the atmosphere increases significantly, so their use is prohibited in European countries.

How to install a universal filter?

Everything is very simple here, let's look at each of the options:

- Main - that is, located at the bottom of the car, somewhere close to the muffler resonators . It is easy to install - we cut out the old catalyst, usually physically cut it off from the “pipe” and weld in another - universal (selected in size and throughput). Everything is simple here, the only thing you need to do is find a service with a good welder. After all, the durability of the structure will directly depend on the quality of the seam.

- Collector type . This is where things get more complicated; just cutting off the manifold and welding a new one won’t work (although this also happens). Therefore, it is often necessary to remove the entire structure, cut the catalyst and physically change the honeycomb. As I already wrote above, they come in their own metal case. The work is difficult but possible. I repeat once again - it also happens when a part is cut off from the manifold and a new one is welded, actually a new universal catalyst.

Is it possible to drive with a pipe instead of a catalyst?

The answer is definitely yes, you can. Many drivers practice a budget-friendly way to solve the problem - they remove the old neutralizer and install a straight section of pipe. But you need to understand the consequences of such a ride:

- The sound of the exhaust system will become louder. Due to its design features, the catalyst muffles some of the noise and if a flame arrester is not installed, the sound of the engine will increase.

- The service life of the muffler and resonator will be reduced by 20-30% due to the higher temperature of the incoming gases.

- You may get into trouble during your inspection. After all, a flame arrester enclosed in a neutralizer barrel does not differ in appearance from the latter, and a straight pipe may raise questions.

Insert - a pipe used instead of a catalyst

Replacing an unusable catalyst with a straight pipeline will not relieve you of the problem with the correct operation of the lambda probe. It will still have to be solved using the methods listed above.

Straight pipe section in place of the catalyst

As long as the legislation of the Russian Federation allows the operation of cars that meet the requirements of the Euro 2 standard, the flame arrester will remain an alternative to an expensive catalyst. For many motorists, this measure is necessary, because purchasing a new product costs 50–100 thousand rubles. not everyone can do it. And if you are good at welding, you can make a flame extinguisher yourself, thereby saving 7-10 thousand rubles.

This is interesting: Tinting and the law - just about complex things - norms, inspection rules

DESIGN FEATURES

The flame arrester body consists of two parts - external and internal.

To ensure that unnecessary noise does not appear during operation of the exhaust system, special noise reduction systems are used.

The noise reduction system of the flame arrester is conventionally divided into 2 types:

Unfortunately, high temperatures cause fillers to burn out very quickly. Their service life can be extended using a special stainless steel mesh. Using passive noise reduction is much more practical. To avoid unnecessary noise, the flame arrester body is made of two layers. In this case, all vibrations that the inner layer creates will be damped by the outer one.

The material from which the outer layer is made must be resistant to corrosion - sudden temperature changes, in combination with salts, kill even steel with aluminum impurities in a couple of years, so the body is needed from stainless, heat-resistant steel. You should take into account the volume of the flame arrester itself, which determines how the following resonator and muffler will work. If there is insufficient volume in the resonator or muffler, when you sharply press the gas pedal, an unpleasant rattling sound occurs, and at the exit from the muffler the overall sound level becomes higher. In the case where the muffler and resonator are of the direct-flow type, the rattling is usually not so noticeable.

How to make a flame arrester instead of a catalyst with your own hands: main steps

The technology given below allows you to quickly make your own pre-resonator for engines up to two liters in volume. To do this, you will need two pieces of metal pipes of different diameters up to 2 mm thick. Each of them will perform a specific role:

- Internal - must match in size with the standard neutralizer that will be dismantled.

- The outer one is 60-70 mm shorter than the inner one, the diameter should be 30-40 mm larger than that of the inner pipe.

At the preparatory stage, along the entire plane of the inner pipe in the part that will be covered by the outer part, you need to drill holes with a diameter of 3 mm.

As a filler, you should prepare 25-30 pieces of kitchen mesh brushes. You also need a grinder and a welding machine. To make a flame arrester with your own hands instead of a standard catalyst efficiently and quickly, you must adhere to the following production line:

- Using a grinder, cut off the flanges of the faulty neutralizer, which will then be welded to a homemade resonator.

- Make vertical cuts 30 mm long on the pipe and bend the metal inward to a pipe of smaller diameter.

- Weld the outer pipe to the inner one on one side.

- Place a dish brush onto the inner tube and push it with the metal bar towards the welded end. Repeat the operation with the next pipe cleaners until the entire space between the pipes is filled to the top edge.

- Bend the cut ends of the outer pipe and weld to the inner pipe.

- Weld flanges on both ends of the product.

There is an option, shown in the photo, which does not use filler in the form of kitchen mesh brushes. This increases the life of the unit, because they burn out sooner or later. Due to design features that ensure a certain direction of exhaust gases inside the housing, the acoustic characteristics of the device are improved.

For engines with a volume of more than two liters, it is recommended to make a damper based on a standard catalytic converter. The manufacturing technology depends on its type and has its own characteristics for each car model.

Manufacturing recommendations

To make a flame arrester from a catalyst with your own hands, you need to find two metal pipes. In this case, the dimensions of one of them must fully correspond to the parameters of the exhaust pipe. Since not every car owner will be able to find pipes made of a heat-resistant alloy, a failed muffler can be used to make a flame arrester.

At the same time, the proposed alteration is not complicated and to bring the idea to life, a minimum set of tools will be required:

- welding machine;

- a set of brushes for washing dishes;

- drill;

- Bulgarian;

- cutting wheel;

- metal brush.

First you will have to dismantle the muffler, since it is necessary to remove the faulty catalyst. It is the dimensions of this element that must match the parameters of the smaller pipe. The second pipe will be 5 - 6 cm shorter and cuts must be made at each end. On a pipe with a smaller diameter, holes with a diameter of about 3 mm will have to be made. When it is perforated, the surface must be cleaned with a brush and inserted into a larger one strictly in the center. Then you need to bend it along the previously made cuts and weld it. In this case, you need to make sure that the seams are tight. Having turned the pipes with the open side up, you should put pipe cleaners on the smaller one and compact them tightly in this kind of container. All that remains is to bend the petals to a small diameter pipe and weld them.

It is enough to carefully study the drawing and all possible questions will disappear by themselves. When assembling the exhaust system, a newly installed flame arrester is installed instead of the old catalyst.

Why is one thing replaced by another?

The catalyst can become unusable simply by exhausting its resource. This does not happen with new cars, but if the car was bought second-hand and managed to travel 150 thousand km or more, it means that the catalyst in it is seriously worn out. And since it is impossible to clean or restore it, there is only one way out: replacing it with a flame arrester.

High mileage is not the only reason for wear of the standard catalyst. It can also become unusable due to bad fuel. Unscrupulous sellers, trying to increase the octane number of their low-quality gasoline, add additives containing lead to it. Exhaust gases from such fuel cause overheating and subsequent melting of the catalyst sections.

Finally, flame arresters are installed in cars due to the high cost of branded catalysts. This is the most popular reason, especially now, when the price of catalysts has become simply prohibitive and can vary from 50 to 250 thousand rubles.

PRINCIPLE OF OPERATION OF THE FLASH EXTERNER

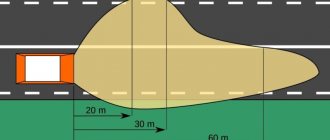

During operation, the flame arrester receives exhaust gases that enter the exhaust system, processes them and removes them. At the exit, the temperature of the gases becomes significantly lower, and their speed drops significantly.

In addition, the flame arrester breaks the primary flow of gases that come from the collector. This approach is used for the purpose of stable operation of the main resonator.

In addition, the flame arrester mixes all the unstable flows ufpjd from the cylinders into one stable flow. Thanks to the design of the body of the part itself, the flame arrester significantly reduces the level of noise that appears inside it due to the beating of gases.

How long does a flame extinguisher last? Pros and cons of the device

Rust removalLearning to remove rust from a car on your own

Flame arrestors installed separately usually operate successfully for five to ten years. Collective flame arresters last less (up to five years), since they have to work in the “hottest” conditions. The lifespan of this car part can be even longer if it is made by a reputable company using high-quality materials. It is also necessary to take into account operating conditions, vehicle characteristics and mechanical effects on the product.

Now a few words about the pros and cons of installing a flame arrester. The most significant advantage is the price of this device. By installing a budget flame arrester instead of an expensive catalyst, you can save a lot of money. The flame arrester is less demanding on fuel quality compared to the catalyst - this is its second absolute advantage. Since the quality of gasoline at our gas stations often leaves much to be desired, this advantage is quite significant. In addition, the flame arrester slightly increases engine power, since it has a direct-flow structure (and not a honeycomb, like a catalyst).

Of course, the flame arrester also has disadvantages (where would we be without them). The main one is environmental pollution. Without a catalyst, all outgoing exhaust gases go outside without any purification. So, if you care about clean air on the planet, then it is better to install a new catalyst.

To install a flame arrester, electric or gas welding is required, so doing it yourself is quite problematic. The installation of a manifold and a free-standing flame arrester is different because in the first case the exhaust manifold must be removed. However, it is hardly worth saving on this procedure: installing a collector flame arrester costs 6-8 thousand rubles, and a free-standing one costs 3-5 thousand rubles.

Can I do it myself?

Of course you can, and they are made in every garage. Often they are installed in place of a freshly knocked out catalyst.

However, it is worth learning that if you want your flame arrester to work for a long time, then it must be made of stainless steel. Because it perfectly resists rust and road reagents.

If you weld from ordinary steel, then its service life will be limited to a maximum of 5 years. In fact, it will simply rot. But if you still choose stainless steel, the service life can extend to 10 years, or even more. The only thing is that stainless steel is easy to weld.

Now we are watching a useful video.

That's all for me, read our AUTOBLOG.

Similar news

- Thermal tape for the muffler. Why do you need to wrap?

- Catalyst for KIA RIO and CEED. Problems, removal

- Remove (cut) the catalyst. And don't make mistakes + video

Trailer Raccoon: technical specifications, price, where to buy

- Mazda 3;

- Hyundai Elantra;

- Chevrolet Lacetti;

- Ford Focus;

- Renault Megane;

- Toyota Prado 120;

- Hyundai Solaris;

- Opel Astra;

- Niva Chevrolet;

- Kia Rio, etc.

The use of deception should not be ignored. You already know about the consequences of such a rash decision.

Advantages and disadvantages

In conclusion, I propose to look at the pros and cons, that is, at the possible negative and positive consequences if you replace the standard catalyst with a not quite standard flame arrester.

Why is it justified to independently manufacture a flame arrester unit?

It is quite difficult to purchase a flame arrester for a certain brand of car. In addition, most copies are made for cars with an engine capacity of up to two liters. Therefore, some car owners prefer to make the device themselves. The operation, of course, is technically more difficult than repairing scratches on a car body.

Considering that the bulk of factory resonators are made on the basis of a standard catalytic converter, it is quite possible to make a flame arrester unit yourself. Before starting work, it is important to take into account one detail: the dimensions of the extinguisher must correspond to the format of the neutralizer, otherwise all the pros and cons of replacing the catalyst with a flame arrester are neutralized. Lack of volume threatens to result in unpleasant rattling in the muffler when you press the accelerator pedal.

For those who still decide to buy a factory device

Practice proves that almost all traditional damper options made in the form of a single-layer casing burn out very quickly. From here there is an unambiguous conclusion - you only need to take two-layer products.

Products from Fox in the form of a PP1 damper made of AISI-409 steel, where the filler is so-called metal wool, received good reviews. Model PP3 without filler and divider will cost less. Car enthusiasts also praise the domestic manufacturer MG-Race , which produces inexpensive devices in a two-layer casing.

How to repair or replace the trunk lock on a Lada Kalina

The positive aspects include the following:

- lower costs for the purchase and installation of a stronger;

- the possibility of switching to cheaper fuel of lower grades;

- increase in engine power;

- protection of the engine from breakdowns.

It is a mistake to think that the flame arrester ruins the engine. Everything happens differently. It becomes easier for the motor to work. Problems arise only if the trick is abandoned and the ECU is configured incorrectly. Therefore, it is important to contact specialists.

Now as for the shortcomings. The disadvantages or consequences will be:

- the level of harmful exhaust gas will increase;

- You will definitely have to flash the ECU if snag is not used;

- The service life of the muffler will be reduced.

As you can clearly see, there will be no serious consequences if you install it correctly and use high-quality components. At many points you can even win.

It's up to you to decide whether to install a flame arrester or not, or buy a new expensive catalyst.

USING A FLASH EXHAUSTER WHEN TUNING

When installing a tuning exhaust system of the direct-flow type, the sound requirements are somewhat different: you need a thoroughbred, loud sound with a predominance of low frequencies. Therefore, the direct-flow flame arrester used for tuning can be simpler in design. It must be reliable, have a two-layer casing and a flow area corresponding to the motor power.

Catalytic converters compress the exhaust too much. When exhaust gases pass through the catalysts, there is a strong decrease in the throughput capabilities of the route. Flame arrestors are free from this drawback and allow you to normalize the average gas pressure.

The appearance of the flame arrester is also important. The ability to use different colors and types of paints allows you to tailor the design of the flame arrester to the style of the car.

Unfortunately, even well-known brands for the most part do not have direct-flow resonators with a two-layer casing, since in the West control over the purity of exhaust gases is much stricter. Therefore, low-resistance metal-based catalysts are popular there. They consider it acceptable to leave a standard catalyst behind the tuned manifold. Lack of interest in parts that can be used instead of a catalyst is considered the main reason why Western manufacturers do not produce any parts of this kind.