Fuel filter contamination

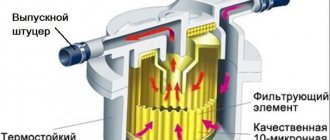

The fuel filter is one of the elements of the vehicle fuel system. It is responsible for filtering and neutralizing rust and dirt contained in metal fuel storage tanks, as well as removing water from fuel.

The types of fuel filters depend on the injection system and the type of power unit. They are divided into:

- Fuel filters for cars with diesel engines.

- Devices for vehicles with injection engines.

- Filters for cars with carburetor engines.

A clogged fuel filter can cause engine damage and stall your vehicle.

Causes of fuel filter contamination:

- Accumulation of dust and dirt as a result of various chemical compounds of gasoline with air and metal.

- Corrosion caused by water condensation.

- Accumulation of tar deposits.

- Clogging of fuel equipment pipes by frozen water crystals at low temperatures.

- Use of low-quality fuel.

Basic requirements for modern filters

As you know, Russian fuel is often counterfeited. It turns out to be of poor quality at most gas stations, and as a result, the car owner has to pay. You should not hope that bad fuel will not cause harm and everything will remain as it is. Additives, rust and small particles of debris will sooner or later do their job - they will worsen the dynamic and operational characteristics of the car. For this reason, the role and importance of the filter cannot be underestimated.

How to identify a malfunction based on symptoms

Basic requirements should be set for filters at the selection stage. If the device does not comply with them, it is better to abandon it, since you cannot count on the efficient operation of the entire fuel system.

Here are some important guidelines to follow.

- Use “original” brands of fuel filters, as most automakers insist on this.

- The filter must be coated with anti-rust compounds, which can be seen on the product packaging (unless, of course, it is a fake).

- A high-quality part should filter out all unnecessary impurities from the fuel as well as possible.

- If the car is diesel, then even more requirements are placed on the filter. First of all, in addition to cleaning small particles of debris, it must be able to separate water.

Article on the topic: Why do you need to break in new winter tires and how to do it?

Signs of a clogged fuel filter

Symptoms of a clogged fuel filter are as follows:

- The fuel consumption of the vehicle increases.

- On inclines, the car begins to jerk sharply.

- Engine power decreases.

- When the car is running, the engine starts to shake.

- The vehicle stalls at idle.

- The car can brake without the driver pressing the pedals.

- When the engine speed increases, failures occur.

There are also signs of a clogged filter that are characteristic of certain types of motors. So, symptoms of a clogged fuel filter on a diesel engine include the inability to start the engine the first time, as well as the appearance of jerks when driving the vehicle.

Signs of a clogged fuel injector filter include a decrease in engine power. This is due to the fact that the engine has a cleaning degree of up to 5-10 microns, therefore, smaller particles leak into the fuel injection system. They do not damage it, but significantly affect the performance of the motor.

Replacement frequency

There are certain service periods prescribed by manufacturers. But in fact, taking into account the quality of the fuel and the condition of the roads, it is advisable to look at the mileage and the condition of the engine. This means only one thing: no one will give you specific dates. Hence the conclusion: if the fuel filter is clogged, then it needs to be changed. This operation is not so expensive as to jeopardize the condition of the entire machine.

We recommend: Which is better, electric corrector or hydrocorrector for headlights on a VAZ 2110: pros and cons

If any of these elements are not supplied to the combustion chamber in the proper amounts and at the proper times, your engine will not run smoothly and may stall at the most inopportune times. The carburetor mixes enough air and fuel together and forces the mixture into the combustion chamber. Your spark plug will then spark at the right time to ignite the mixture, and the explosion will apply a driving force to the piston. The wrong amount of air or fuel will cause the engine to run poorly, as will a weak spark.

A modern car is a complex technical system, which includes a large number of diverse subsystems. Each of them, performing certain functions, contributes to ensuring the performance and safe operation of the vehicle. One of these systems is the fuel system, designed to supply fuel from the tank to the power unit. In general, the fuel system consists of:

Bad fuel - Gas will become obsolete in as little as 30 days, especially fuel mixed with ethanol, as in many areas. Ethanol attracts moisture over time, and the humidity will dilute the gas. Diluted gas may cause your engine to stall.

Dirty air filter. Because the air filter cleans the air entering the carburetor, it will eventually become dirty or clogged and can prevent the correct amount of air from mixing with the fuel, causing your engine to stall.

Gas Cap - Many gas caps also function as a fuel tank vent, allowing air to enter the tank as fuel. The vent can become clogged and prevent air from entering the reservoir, resulting in poor fuel flow to the engine.

- tank;

- pump;

- filter.

All these elements are connected to each other by a fuel line through which the fuel enters the device for supplying (injecting) it (fuel-air mixture) into the engine cylinders. At the same time, the efficiency of a car engine largely depends on the quality of the fuel, for which the fuel filter is responsible for cleaning.

We recommend: Why a car accelerates poorly: possible causes and their elimination

Air leak. Air can enter the engine through a leak in the intake manifold or head gasket. Worn or dirty spark plugs. Carbon, oil residue and pitting on the spark plug electrodes will cause a weak or inconsistent spark, resulting in poor ignition and possible stalling.

Contaminated fuel filter. Just like with your air filter, when the fuel filter does its job, it becomes less efficient and can become clogged, restricting the flow of fuel to the engine. If the fuel in your tank is old, it should be removed and disposed of properly and fresh fuel added. You can also remove the gas cap and clean the fuel tank vent. Other problems that can cause stalling, such as a faulty ignition coil, worn spark plugs, and a clogged fuel filter, are best left to an experienced professional mechanic.

Hello, dear ones. The question is: How does a car with a clogged fuel filter behave? Let me explain why I'm asking. I drove on gas for several years and had no problems. Then I switched to gasoline, changed the fuel filter, and now a year has passed - we get the following situation. The car does not drive when cold. It manifests itself like this: you press the gas - it stalls for 2 seconds, trying to gain momentum (as if someone is strangling it), but does not gain momentum. and then a sharp acceleration. I almost got into an accident a couple of times because of this at intersections. Once the car is warmed up everything is fine. moves with any pressure. doesn't dull.

A friend said it was most likely fuel. But why then is everything ok when it’s hot?

It must have been the other way around for me too. It runs when cold, then the pump overheats, cannot pump and begins to jerk and stall.

And the fact that I almost got into an accident means there’s less need to “slip”, you could wait it out

Traveling around Baikal. Transfer. Conductor. Guide.

69-77-99 +7

It's not a matter of skipping. and when the traffic light comes on for the opposite side, your car freezes in the middle of the intersection because it cannot move

Hello, dear ones. The question is: How does a car with a clogged fuel filter behave? Let me explain why I'm asking. I drove on gas for several years and had no problems. Then I switched to gasoline, changed the fuel filter, and now a year has passed - we get the following situation. The car does not drive when cold. It manifests itself like this: you press the gas - it stalls for 2 seconds, trying to gain momentum (as if someone is strangling it), but does not gain momentum. and then a sharp acceleration. I almost got into an accident a couple of times because of this at intersections. Once the car is warmed up everything is fine. moves with any pressure. doesn't dull.

What to do if the fuel filter is clogged?

If the fuel filter on a diesel engine is clogged, it is advisable to contact a service center to replace it, but you can try to do it yourself. However, for car enthusiasts who are encountering this problem for the first time and do not have sufficient experience, attempts at self-repair can lead to improper operation of the engine or its final breakdown.

To replace the fuel filter, you will need a set of wrenches and screwdrivers, rubber gloves and a container to collect liquid from the old filter element. To correctly dismantle the device, it is better to use the instructions that come with the car.

If the fuel filter is clogged on a vehicle with a carburetor or injector, it is advisable to immediately contact a service center, since the replacement process requires professional skills and abilities.

After replacing the fuel filter it won't start the first time.

There are 51 replies to this topic

Pressure must be maintained in the fuel rail after the engine is turned off (until the next restart). And when you turn on the ignition, it is this pressure that feeds the injector, and until your pressure reaches the fuel pump, it won’t start. When replacing the filter, there was a leak somewhere, either in the check valve or in the connections to the fuel line.

That's right - look at the cuffs on the fuel pump and pressure regulator.

So change the fuel filter.

There was the same garbage when I decided to replace the fuel filter, forgetting the popular wisdom that the miser pays twice - I bought a non-original one. Then I asked the same question on one of the auto forums, the following options came up (I saved the style): 1. The module was assembled carelessly. There is a rubber sealing ring that pops out. Gasoline from the system flows into the tank. It takes more time for it to be pumped again. Disassemble the module again and do everything carefully and you will be happy.

2. It seems like Toyota’s fuel pump doesn’t hold pressure and only turns on when the starter starts turning, most likely it was assembled crookedly.

3. There are three options: 1 the filter is cracked (defective) 2 the o-ring was not installed on the back pressure valve 3 the o-ring was not installed on the pump.

In general, after that I just bought the original with all the original rubber bands - I replaced it - and only after that Spasya began to start as before - the first time. The car received a new original fuel filter, and I (in principle, for little money) received life experience

The fuel filter, my friends, is only original. Almost everywhere they say that if you install a non-original one, you sign up for hassle with it in various forms. And if it works without visible jambs, then 2 questions - how well it filters and how long it will last, remain open - only the manufacturer knows . I changed it myself to the original. In principle, there is nothing complicated, the only thing I got stuck on was that I could barely pull the fuel line from the tank, and it was inconvenient. The main thing is to carefully inspect what you are doing and do not forget to remove the rubber seals from the old one and put them on the new one. After the replacement I didn’t feel the difference, there were no problems with the launch either. And how interesting (when I myself) was to look at the mesh and what kind of cocoa was floating in the tank, plus, if desired, to catch it out of the tank.

My car just started having trouble starting. just as stated above. The problem turned out to be the back pressure valve. stopped holding pressure. Replaced it and everything was back to normal. At the same time, I changed the mesh and fine filter. and also pumped out 1 liter of all sorts of crap like water and who knows what from the tank.

If possible, I try to do everything myself; entrusting a car to a Russian car service center is not bad. Replacing the filter is not a difficult procedure at all. I changed it last year, not the original, reading the above, I probably would have listened, but it’s not a fact that the original is the ORIGINAL, but the price is the original. After the replacement, I didn’t feel any changes, etc. Everything was fine. I emptied the tank - it was perfectly clean, as if it had come from an assembly line. Like this.

How does a clogged fuel filter affect fuel consumption?

If the fuel filter in a vehicle is clogged, this will lead to changes in fuel consumption. In order to travel the same distance with a normal and clogged fuel filter, different amounts of fuel are required - with a clogged device, consumption increases noticeably. This happens due to the fact that fuel enters the engine in insufficient quantities and the composition of the mixture changes due to the accumulation of dirt in the filter. As a result, the car's power and speed are reduced, and the driver has to press harder on the gas pedal.

Why doesn't the car start after installing a new TF?

Experts name several reasons why replacing the fuel filter prevents the car from starting:

Unoriginal/poor quality TF

If the filter is chosen incorrectly, but may not fit the standard dimensions of the mounts (worst of all, if it is slightly smaller in circumference). In this case, its throughput is lower than the required standard, which will create difficulties in supplying fuel to the combustion chamber in the required quantity and complicate starting the engine.

The easiest way to check the compliance of the filter model is to temporarily replace the old module. If the car starts to start normally, you will have to buy the TF again.

Airing the engine

If the filter is selected correctly, but the starting problem persists, the manual pump may be to blame, which has created an air lock in the system and is preventing air from flowing into the combustion chamber. To make sure that this is the case, you need to press the pump button 3-4 times - if it does not respond, then there is a problem.

There are several ways to eliminate air congestion:

- to remove the air plug, you must continue to press the button until the button begins to respond normally (helps if the plug is not deep);

- to remove a deep-seated plug, pump out the fuel with a rubber bulb until it begins to flow back (the filter drains should be closed);

- To purge a system with serious air pollution, you need to disconnect the tank with the filter from the system, slowly pump air into the tank with a car pump until excess pressure is obtained, then connect the pipe to the tank and try to start the car.

- incorrect assembly of the filter, which leads to distortions or rupture of the seals;

- Incorrect connection of injectors (the wires should be reconnected);

- incorrect placement of camshafts due to chain wear;

- the presence of factory plugs at the outlet to the pump and drainage of excess in some models of auto fuel filters.

Spark plugs are installed incorrectly, or spark plug deposits have occurred

To check the accuracy of the installation of the spark plugs, you should check for serviceability and reinstall the coils. And if carbon deposits have formed on the spark plugs due to interruptions in the air supply or poor flushing of the fuel system, then it is better to replace them.

Poor fuel quality

Low-quality fuel quickly clogs any filter, rendering it inoperable. In this case, problems will begin with the flow of residual fuel into the combustion chamber, the mixture will be oversaturated with air and will begin to explode instead. To burn evenly and give energy.

In this situation, the only correct solution is to drain the bad fuel and flush the fuel system.

Other reasons

Less common reasons why the engine does not want to start after replacing the TF include:

Fuel filter contamination indicator

A contamination indicator is a device that allows you to monitor the process of contamination of the fuel filter and signals the need to replace it. It allows you to determine exactly when the filter needs to be replaced. This sensor allows you to reduce wear on fuel equipment, as well as reduce the cost of replacement elements. Unfortunately, not all vehicle manufacturers install indicators on their models.

How to determine a clogged fuel filter if there is no indicator?

To determine if the filter is clogged, you need to locate it (in most cars it is located near the fuel tank under the car), and then loosen the clamp that secures the fuel line hose. The end of the fuel hose is lowered into a glass container, and the car is put on the brakes and switched to neutral. The ignition key is set to the first position so that the engine does not stall. If fuel enters the vessel at a lower speed than it leaves the tank, the filter is clogged.

Source

The fuel pump does not pump: causes and diagnostics

Let's start with the fact that if the gas tank is full, charged, dry and there is a spark, the starter turns the engine normally, but the engine does not seize, then you should pay attention to the gas pump. A common problem is that there is no power to the fuel pump after the ignition is turned on. In a similar way, the malfunction manifests itself in motion, when the power to the fuel pump is lost and the engine suddenly stalls.

An equally important point is how much the fuel pump pumps. In other words, the pump may hum and buzz (power is being supplied), but not create the required pressure in the fuel line. The pressure in the fuel system with a working fuel pump must be more than 3 bar (which depends on the specific car model). The indicated pressure is accumulated in the fuel rail and has an indicator of 300 kPa and above.

To check, you need to measure the pressure in the fuel rail with a pressure gauge, taking into account the indicators that are the norm for a specific car model. Using the example of injection VAZs, the pressure when the ignition is turned on is 3 atmospheres, at idle the figure is 2.5 atmospheres, when you press the gas 2.5-3 atmospheres. This method will help you accurately determine:

- malfunction of the fuel pressure regulator in the rail;

- breakdown of the fuel pump or a noticeable decrease in its performance due to wear;

- severe contamination of filters (fuel filter and/or fuel pump mesh);

In the second case, when you press the gas, the pressure does not increase; in the latter case, the pressure gauge needle rises, but very slowly or jerkily.

A decrease in pressure below the norm will lead to the fact that the engine may not start or start with difficulty, stall, jerk, operate unstably and with failures. If this happens due to the fault of the pump and not the fuel filter, then there is a high probability that the coarse filter screen of the fuel pump is clogged. In this case, there is no need, since it will be enough to replace or even clean the mesh.

If you suspect that there is no voltage to the fuel pump, there is a quick way to check. It is enough to turn the ignition key and listen, as when you turn the key you should hear a slight hum from the fuel pump. If such a buzzing noise is not heard, it means there is no power to the fuel pump, there are problems with the wiring, etc.

We add that this method of determining the operation of the pump by sound is not suitable for all cars. On some models (especially premium ones), sound insulation is at a high level and the fuel pump turns on immediately after opening the driver's door, and not when turning the key in the lock. In this case, it may seem that the fuel pump does not work when the ignition is turned on, and the sound of the pump may simply not be heard.

Also in the general list of possible reasons why the fuel pump does not pump, the following are noted:

- failure of the fuel pump fuse;

- fuel pump relay failure;

- problems with the ground of the fuel pump;

- malfunction of the electric motor of the fuel pump;

- oxidation or damage to fuel pump contacts and terminals;

- the fuel pump itself is faulty;

Wiring to the fuel pump

On most cars, the wiring to the fuel pump consists of three wires: “plus”, “minus”, and also a wire for indicating the amount of fuel in the gas tank. If the fuel pump does not pump, then the cause may be a lack of power.

To check the power to the fuel pump, just take a 12-volt light bulb and supply it with power from the external connector of the fuel pump. After turning the ignition, the control lamp should light up. If this does not happen, then the problem is in the external circuits. If the lamp comes on, it will indicate the need to check the internal contacts of the fuel pump.

To check the external wiring, you should alternately connect the positive and negative contacts, which are removed from the fuel pump power connector, to the ground of the pump. The contacts must also be connected to the fuel pump relay. If you place the negative contact on ground, after which the ignition is turned on and the light comes on, then this means that this contact is faulty. If the light bulb does not light up, then problems with the “plus” are obvious. If you place a contact on the relay and the light comes on, there is probably damage to the wire on the section that connects the relay and the fuel pump itself.

Fuel pump electric motor

If checking the pressure in the fuel rail and the external wiring to the fuel pump gives positive results, then you should check the fuel pump motor. This electric motor is responsible for circulating gasoline inside the fuel pump.

When checking, you need to take into account that the terminals on the fuel pump themselves tend to oxidize, as a result of which power is not supplied and the pump does not pump. In this case, the motor is working, but the terminals need to be cleaned or re-soldered.

To check the fuel pump motor, you will need to attach the test lamp wires to a cleaned and serviceable terminal of the electric motor, after which you should turn on the ignition. If the light comes on, this will indicate that the fuel pump motor is not working.

Fuel pump ground contact

Problems with the fuel pump mass may be indicated by a fuel level sensor that is not working correctly. The mass may be poorly secured; in this case, the fuel pump does not pump fuel. The ground wire is usually located under the dashboard and runs through the cabin. It is necessary to find the specified wire, check and clean all contacts, then securely fasten the ground to the fuel pump.

The fuel pump relay is often mounted next to the fuel pump ground, that is, under the dashboard. A normally operating relay after turning on the ignition for a couple of seconds allows the pump to create pressure in the system and immediately turns off.

When the ignition key is turned, the driver hears a characteristic click (the relay is turned on), then a similar click will indicate that the fuel pump relay is turned off. If such clicks are not heard, this indicates a malfunction of the relay or its contacts. The optimal solution would be to replace the fuel pump relay with a new or known-good device. Let us add that the cost of spare parts is quite affordable.

Fuel pump fuse

During diagnostics, be sure to check the fuel pump fuse. The specified 15 A fuse is usually located in the fuse box in the engine compartment and is marked FUEL PUMP, which means fuel pump.

The fuel pump fuse needs to be pulled out and its contact inspected. The integrity of the contact will indicate that the device is normal. A damaged contact will indicate that the fuel pump fuse has blown. In this case, you need to install a new fuse, which has a very low cost (as in the situation with the fuel pump relay).

Fuel filter: purpose and types

A fuel filter or FF is one of the components of the fuel supply system in a car. Without it, there would be no filtration; debris would constantly get inside the engine, significantly reducing its service life. The purpose of the fuel filter on diesel engines is even broader - to prevent water from entering the system.

TFs are classified by type, depending on the injection system and engine modification. There are 3 main types of filters.

- Standard TFs designed for cars with carburetor injection.

- Devices with a high threshold for the retention of microparticles of dirt, intended for nozzle systems (injector).

- TF for diesel engines.

Checking for counterfeit

The element operates under pressure, especially on diesel systems, where the pressure is the highest. The slightest deviation from the norm leads to difficulties in starting the internal combustion engine, and then to problems with the engine installation.

If difficulties are observed after replacing the filter, it is worth carrying out the first check. It is also possible with an old cleaner that has been replaced, provided that it is still working, although it is “fading out.” You need to remove the new filter again, replace it with the old one, and test how the engine starts. If everything returns to normal, you need to go to the store for the original part, since in 99% of cases a discrepancy is observed when an analog part or a fake is installed.

Counterfeit goods are easily identified at the purchase stage. You just need to be careful, especially if they offer to purchase the part at a reduced cost. The fuel filter is a consumable that requires periodic replacement. Therefore, it is very often counterfeited.

It is more expensive to use such an element. For example, if even after installation there are no starting problems, there is a high risk of the filter curtain rupturing or the smallest particles of debris passing into the engine. Only high-quality products assembled according to all design rules can filter fuels such as diesel fuel well and completely. Any discrepancy will sooner or later lead to a problem.

You need to understand that original filters for diesel systems are much more expensive. They not only perform mechanical cleaning, but are also able to prevent water from entering the system, and in winter they also provide the required temperature to avoid crystallization of paraffins.

The effect of a clogged fuel filter on car performance

It goes without saying that a clogged fuel pump easily leads not only to deterioration of engine performance, but also to engine breakdowns. The filter becomes dirty for various reasons, the main ones being:

- accumulation of substances containing resins inside the filter;

- a large amount of dust and dirt entering the FF due to low-quality fuel with air and metal impurities;

- clogging of the fuel system hoses with solid particles of water that got in with the fuel.

General recommendations after replacing the TF

After you have installed a new filter in the fuel system, you should immediately bleed the system, since a one-time start of the pump is not able to “blow out” the pipelines completely. For different types of filters, this procedure may differ slightly:

- In modern diesel engines and fuel-injected cars, you should turn the ignition on and off 3-5 times with the key in the lock without cranking the starter to allow the pump to run for bleeding.

- In older diesel cars, the system is pumped using a rubber bulb.

- In old carburetor cars, pumping is performed by repeatedly pumping the fuel pump (press the lever 10-20 times) or by starting the engine half a turn.

After this, you should start the engine - the car should start. If not, go to a professional service station.

For external TF

In such a system there are usually two filters - fine and coarse fuel filters, which should be changed in pairs. The main problem of a bad plant here is the fuel hoses, which gradually swell and block the fuel flow. When installing a new filter, they may simply burst due to the increased influx of fuel.

The malfunction is checked simply: the supply hose is removed from the fuel rail, the ignition switch is turned to the “on” position to start the fuel pump. If the fuel stream is weak, check the serviceability of the hoses (pressure level with a pressure gauge); if it is strong, look elsewhere.

For a composite TF

The composite filter has an additional built-in pressure regulator and is designed for powerful cars. Sometimes this regulator is faulty from the factory (up to 3% defective), and sometimes the problem is with the same swollen fuel lines.

The check is carried out in the same way: disconnect the supply hose, turn the ignition key, do not start the starter - check the fuel pressure visually or measure the pressure in the fuel lines with a pressure gauge.

TF in the fuel module of the tank

Now this is how filters are installed in most modern car brands: they are mounted in a single assembly with a boost pump, fuel pressure regulator and level sensor. If the car does not start after installing it, you will have to disassemble the module.

It is necessary to turn off the fuel supply, turn the key in the ignition switch and check the speed and amount of fuel flowing out (you can measure the pressure in the fuel lines with a pressure gauge). If the jet is weak or absent altogether, the module will have to be dismantled, since:

- the seal ring is missing or damaged;

- the hose is not put on or is loosely put on the filter or pump;

- The pressure regulator is not fixed;

- The electrical terminal is not connected to the pump.

After eliminating the listed “jambs”, the fuel module will work as expected, and the car will start without problems.

In conclusion, it should be noted that if, after replacing the fuel filter, your car begins to start with difficulty and malfunctions, this is a non-critical and solvable problem. With the correct and consistent method of finding the cause of poor fuel delivery, you can fix the problem yourself.

Most often, the car does not start well due to low-quality fuel, faulty electrical connections and air-filled fuel lines, which is easy to check using available methods and quickly corrected. However, if after performing the above manipulations, the engine continues to act up, you should contact professionals at a service station as soon as possible for an in-depth diagnosis of the fuel system.

Source

Fuel consumption

Fuel consumption is the first obvious sign of a clogged filter. Every driver can determine it, just drive the estimated distance. Experienced motorists know how much gasoline is consumed on a particular road and distance. Obviously, if the filter is clogged, the consumption will increase noticeably. Fuel enters the internal combustion engine in small quantities; due to the concentration of debris in the filter, the composition of the combustible mixture changes. This explains the fact that the power and speed of the car decrease; the driver sometimes needs to press the accelerator harder.

There is also a special device that allows you to monitor the process of clogging of the TF, signaling the need to replace it. This tool can be used to determine when replacement will be required and will reduce damage to the fuel supply. This is a sensor that allows you to reduce wear on the fuel supply system, as well as reduce the cost of consumables and replacement elements.

However, such indicators are not installed by all vehicle manufacturers. However, it is not difficult to detect a clogged filter without a sensor. In addition to the above characteristics, the clogged TF can be calculated directly. To do this, you must first find it: on most cars it is located near the gas tank under the bottom. Then loosen the fixing clamps, lower the end of the fuel drive into a glass container, and be sure to place the car itself at neutral speed. In this case, the engine must operate in idle mode - if fuel flows at a lower speed than from the tank, it means that the fuel pump is clogged.

In fact, replacing the TF is not particularly difficult, especially if we are talking about a gasoline unit. It is necessary to prepare tools, which include a set of screwdrivers, gloves and a container for collecting liquid from the old TF. To avoid making any mistakes, it is recommended to use the instructions for a specific car. Installation of the TF must be carried out strictly according to the instructions. The new filter must be installed according to the direction of fuel movement.

Forget about fines from cameras! An absolutely legal new product - Traffic Police Camera Jammer, hides your license plates from the cameras that are installed in all cities. More details at the link.

- Absolutely legal (Article 12.2);

- Hides from photo and video recording;

- Suitable for all cars;

- Works through the cigarette lighter connector;

- Does not cause interference to radios and cell phones.

Source

Other causes of difficult starting

In other cases, if the filter is “original”, there are no errors in installation, etc., difficulties with starting primarily hint at airing of the system. The culprit is the diesel filter manual pump, which is also easy to check. You need to press it three or four times - if the button stops responding, there is definitely a problem. You can solve it in 3 ways.

- Plug the drain from the fuel filter and use a special bulb to remove the diesel fuel. See if fuel goes back into the tank. If yes, the plug is eliminated; if not, you will have to find the depressurization point.

- Press the button many times until it starts working. However, this cannot be done if the air lock is firmly seated throughout the entire profile of the tube, and the pump itself is faulty.

- Remove the hose that integrates the fuel tank with the filter. Then carefully pump air into the tank using a wheel pump. This ensures excess pressure. Then return the pipe and try to start the engine.

The next possible problem with difficulty starting a diesel engine after replacing the filter is a crooked assembly. Distortions of the gasket, violations of its integrity, confusion in connecting the injectors, etc. are often observed.

Russian fuel has shown its worth here too. Difficulties in starting the engine should always be looked for in the quality of the fuel, although it is connected only theoretically with changing the filter. In this case, the same situation will occur with the old filter. However, people often forget that after replacing the fuel pump, they refuel in a different place than usual, or the batch of diesel fuel turns out to be defective. This is where the problem arises, and it turns out that the filter has nothing to do with it.

Some filter models initially have a stupid design. For example, options such as Parts Mall PCA-035 are equipped with plugs at the factory. They are installed on both sides of the part - on the drain and on the outlet to the pump. These plugs are made of plastic; they are practically invisible, as they are deeply recessed, very small and invisible. They are installed for the sole purpose of preventing the filter from becoming clogged until the time of sale. Many people don’t know, they install the part as is, as a result, starting the engine is not only complicated, but completely absent.

- engine operation is affected by spark plugs, which may also be installed incorrectly;

- there may be problems with coils that need to be checked for integrity;

- Frequent washing of injectors with chemicals that leave black soot on the spark plugs can lead to problems;

- difficulty starting the engine also occurs due to incorrect placement of the camshafts;

- on older machines, malfunctions with the engine itself are possible, as a result of chain wear or jumping of the belt drive teeth.