07/17/2021 2,458 Fuel system

Author: Victor

Owners of diesel cars in the cold season often face the problem of difficult engine starting. This is due to the structural features of the internal combustion engine and low temperatures. A fuel filter heater will be a good help in solving this problem. What kind of device this is, what types there are and how to make such a device with your own hands, we will tell you below.

[Hide]

Preparing a sleigh in the summer: ways to eliminate thermal deficiencies

The solution to the problem of reliable supply of combustible mixture to the power unit was found a long time ago - to heat the elements of the fuel line:

- fuel intake;

- pre-filter (separator);

- the pipeline itself;

- fine filter.

Modernized elements are already on sale, which, along with their functional capabilities, can additionally receive heat. However, their cost is quite high. Experienced motorists say that it is much cheaper to make a diesel fuel heater with your own hands , while providing a much longer service life.

Methods to make your car easier to start at low temperatures

It is necessary to use special methods to facilitate the start of a diesel engine at low temperatures, and the most effective method is heating the diesel fuel. In order to facilitate the operation of the fuel pump, you can heat the fuel tank, but this risks freezing the diesel fuel while moving through the fuel line. Accordingly, it is necessary to insulate the fuel line. The most important role is played by proper heating of the fuel filter, in which most of the paraffin formed under the influence of low temperatures accumulates.

Fuel filter heater

Improved fuel intake

To ensure a reliable supply of consistency from the tank in severe frosts, the mechanism must, of course, be heated, since diesel fuel begins to freeze already in the storage container. Before starting the internal combustion engine, it is necessary to warm up the train in advance and bring its capacity into working condition.

There are quite a few methods for creating a positive temperature field in a tank. Previously, a widespread method was to immerse a light bulb , with a power of about 55 W, directly into a container next to the fuel intake mechanism. The light source dissolved crystallized paraffin, which ensured stable fuel throughput.

Another option is do-it-yourself electric heating of diesel fuel , the operating principle of which is identical to the heater built into the seat. The embodiment is as follows:

- drill thin holes in the body of the intake mesh, located opposite each other with a certain offset in pitch (quantity - up to 5 pieces on one side);

- take a wire made of a material with high resistivity (for example, tin);

- form the structure of the heating element by passing plastic material through the holes;

- Connect the ends of the wire to the power supply network.

Worth remembering! When connecting any type of diesel fuel heater to the electrical network with your own hands, you should :

- integrate a fuse into the circuit;

- install a control button;

- install a relay to automate operation.

Causes of problems starting a diesel engine

The starting problem is due to the fact that at negative temperatures, paraffin crystals form inside the diesel fuel, causing it to turn into jelly. The fuel filter becomes clogged, reducing its throughput and reducing the amount of fuel entering the engine. The engine power decreases and it stalls.

In order to prevent thickening, you can add gasoline, kerosene or special additives to diesel fuel, but this method does not always help and has a number of limitations and contraindications. Moreover, low-quality and counterfeit additives can cause irreparable harm to the engine. Do not forget about the low quality of diesel fuel or its inadequacy for the season - these factors also have a negative impact on the fuel filter.

Flow heat exchange: made easy

Even a mixture heated in a tank can easily freeze when traveling along a highway in severe frost, and even at high speeds. Flow-through heating of diesel fuel can be done with your own hands by first selecting the layout :

- simple insulation of the main line using construction materials;

- installation of an electrical tape device;

- installation in front of the fine fuel filter of the heat exchanger.

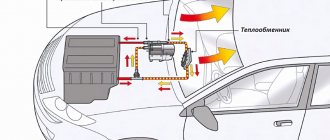

The last method is to create a part that has two independent contours. To do this, you need two tubes of different diameters. Welding centers the thinner part relative to the larger one. In the outer circuit there are inlet and outlet pipes for fuel. The indoor unit is connected to a small circle of the engine cooling system.

To achieve high reliability of winter start-up, comprehensive modernization should be carried out. It consists in the simultaneous application of all the above methods.

Diesel vehicles require special preparation for harsh winter conditions. At a minimum, you should find a gas station with diesel fuel for the winter. The trouble is that already at -5°C summer diesel fuel begins to crystallize. Turbidity in arctic fuel occurs at temperatures below -25°C. However, even in the European part of Russia, frosts sometimes exceed this mark. Marketers suggest a way out of the situation by using anti-gels. Experienced car enthusiasts and truckers prefer to take a different path.

We set up heating of a diesel fuel filter at home with our own hands: diagrams

Modern technologies

There are not so many current methods for creating an autonomous thermal field. You can build a diesel engine fuel filter heater with your own hands or make a flow-through design that will heat the fuel at the inlet of the filter element.

As an alternative or additional solution to the problem, heating the fuel lines will do just fine. There are also fuel intakes with thermal radiation elements on sale.

Heating methods

What makes you turn to independent methods, since there are a lot of branded separator structures with a built-in heater on sale? The answer on the surface is a high price. For example, Separ-2000 for KAMAZ will cost almost 40,000 rubles. The amount does not include installation operations. The fuel system of a diesel car has two filters: a coarse filter (separator) and a fine filter. Each of them has its own methodology. There are several designs of heaters:

- Belt flexible (for fine cleaning structures).

- Rod (installed in the separator).

- Bandage (mounted on a fine filter).

- Heated nozzles (for separators).

Experts advise dissipating heat in the housing of both the separator and the fine filter. In a critical financial situation, you should first of all pay attention to the filter element of the second design - the slightest waxing of the liquid is unacceptable for it.

Pre-heating installation

In cold weather, the fuel filter is the first to suffer, as diesel paraffins crystallize and clog it. It needs to be heated.

The most common option is a preheater. It is attached with clamps to the filter. The contacting aluminum side of the device is heated to 110°C. The filter warms up in a few minutes.

The price of preheaters directly depends on the dimensions and technical parameters. Manually operated devices cost $40-$50. Automatic systems are more expensive.

It is worth finding out in advance what the filter is made of. If the design contains plastic (French vehicle models are famous for this), then such a system will not work. The plastic becomes deformed when heated, and the filter may become inoperative.

Remember that the task of such a system is to warm up a portion of the flammable substance in the filter, which will serve to successfully start the engine.

Reasons for installing a winter diesel fuel heater yourself: why and why?

- Paraffin 10-40%.

- Naphthenic 20-60%.

- Aromatic 15-30%.

Anyone who has decided to make a diesel fuel instantaneous heater with their own hands knows that summer grades of heavy fuel begin to lose their quality already at a temperature of about -5°C, and winter grades - at 25°C. Experienced motorists are well aware of the insurmountable difficulties in determining the differences between them without laboratory tests.

Winter metamorphoses

What processes occur with diesel fuel in winter conditions? As temperature values decrease, the viscosity of diesel fuel increases. Experts identify three thresholds for the transformation of emulsion fluidity:

- Turbidity is the beginning of crystallization of paraffins present in diesel fuel. For summer varieties the cloud point is -5°C, and for winter varieties - about -25°C.

- Extreme filterability - in this state, small paraffin crystals can clog the pores of filter meshes and elements, as well as settle in the fuel line channels and paralyze the operation of the internal combustion engine. If you do not install a diesel fuel heater yourself , then summer fuel enters this stage at -7°C, and winter fuel at -35°C.

- Solidification is the absolute loss of fluidity. At this stage, summer diesel fuel turns into jelly at -10°C, and winter diesel fuel turns into jelly at -40°C.

The main difference between diesel fuel brands is the percentage of paraffins that affect the fluidity of the emulsion, which means its use depending on weather conditions and temperature conditions. The most unpleasant period for owners of cars with a diesel engine is the autumn-winter off-season. At this time, the atmospheric temperature fluctuates between +3°C and -5°C and diesel fuel can thicken at any moment. And when there is also water in the diesel fuel, then energy collapse for the car is guaranteed.

Methods for ensuring the start and operation of a diesel engine at low temperatures

There are not so many ways to start the engine in cold weather and not all of them can be used effectively. Let's say starting a diesel engine using a tug is a rather risky undertaking. The timing drive of passenger cars is belt-type and, due to jerks during towing, it can easily jump over several teeth or even break completely. There is another modern method - the use of special additives in fuel, so-called depressants. However, you should take into account such points as the increasing cost of refilling and the dubious quality of some products in this series. But, according to the reasoning of practitioners, a do-it-yourself flow-through heater of standard diesel fuel has the right to use due to low material costs and efficiency. Electrical and combined systems in the fight against crystallization of paraffin compounds have proven their productivity in all weather conditions. Such heaters are installed on critical components of the fuel system and quickly ensure the working condition of diesel fuel.

What to choose: depressant additives or electric heaters?

To heat a diesel car, you can use fuel additives or electrical devices.

Additives

Fuel additives are actively used by our compatriots. High-quality additives allow you to maintain proper operation of the power unit when operating at low temperatures. Their use must be constant; this is the only way they can provide the proper level of heating. In some cities, it is not so easy to find additives; their constant use requires financial investments. Additives can be used before the paraffin begins to crystallize.

Heaters

Flow and pre-heaters are considered the most productive devices operating from the machine’s electrical network. The use of such a device prevents the appearance of paraffin in the housing of the filter element. Heaters also allow you to remove contaminants that have formed in the fuel lines. The devices are mounted directly on the unit body, and an additional device is installed on the pump grid, designed to accumulate and supply a certain volume of the fuel-air combustible mixture necessary to start the internal combustion engine.

User Erlan Bigozhin showed how the heating system works and how it can be used to melt diesel fuel.

If the machine is used in difficult weather conditions in the Far North, then a heater will be an ideal option. The fuel heating system is connected to the car's electrical network through the cigarette lighter. The voltage consumption parameter and the power of the device depend on the fuel consumption in your car. The use of a heater makes it possible to maintain a certain temperature regime of the filter, as well as destroy crystallized paraffin molecules.

When using the device, the car owner solves the problem of difficult starting of the power unit and helps to increase the service life of the main vehicle system. If the heating device is of high quality, this will ensure proper operation of the motor. Installing the system requires financial costs.

But these costs are offset by the following advantages:

- heating the fuel increases battery life;

- the car owner will not have to buy special additives and regularly pay for their use;

- when the engine is cold started, the working elements of the internal combustion engine system do not wear out so quickly;

- The load on the power unit is reduced, so the car owner does not have to spend money on repairs.

Installing a fuel filter heater will not only allow you to start the engine in cold weather, but will also become a good alternative for car enthusiasts who look after and care for their cars. On the market you can find complex systems that combine several methods to solve the problem of difficult starting. When buying a heater, we recommend paying attention to trusted manufacturers.

User Vitaly Yesin explained in his video how to install a heating system yourself.

Do-it-yourself solutions for a flow-through heater for standard diesel fuel

Methods for implementing reliable fuel supply to an engine using heating have been known for a long time. The main fuel supply units that need to maintain temperature conditions are:

- Coarse filter or separator.

- Fine filter.

- Pipeline main.

- Fuel intake.

In auto stores you can find a wide range of already upgraded components or additional elements to standard units. The only obstacle to their acquisition may be the cost, which is quite high. Experienced car enthusiasts claim that they carry out some work on organizing fuel heating themselves. At the same time, the service life of such devices is in no way inferior to factory samples, and in some cases they can even surpass them in terms of efficiency. According to their functional purpose, the following types of heating elements are distinguished:

- bandage – for fine filters;

- flow-through – installed in front of the filter in the fuel line section;

- flexible tape - heats filters and lines;

- rod - it is possible to make a similar diesel fuel heater with your own hands for subsequent installation in a separator or fuel intake;

- heated nozzles - used to heat separators and fuel traps.

It is also possible to independently replace the standard fuel intake units in the fuel tank with heated products. This, of course, will cost more than homemade devices, but it means saving at least 1500-2000 rubles for the work.

How to make heating of diesel fuel in a car tank with your own hands?

The mechanism that ensures the reliable supply of flammable liquid from the vehicle’s standard tank must be heated. You need to understand that in severe frosts, diesel fuel begins to lose fluidity already at the inlet of the fuel intake. Therefore, before starting the engine, it is necessary to preheat the fuel composition and ensure its working condition in cruising mode.

Vintage light bulb dipping method

In past times, when one could only dream of the current abundance of automotive accessories, diesel owners created a positive temperature field in the fuel tank using an ordinary 12 V light bulb with a power of 50-55 W. For this, in addition to the light source, we used:

- Electrical wires with a cross section of 2.5mm².

- Switch.

- Fuse.

The lamp is immersed through the neck of the tank directly into the fuel. Be sure to place it next to the fuel intake device. Only in this way will it be possible to effectively dissolve crystallized paraffin and ensure the stability of the flow of fuel into the pipeline. To prevent homemade heating of diesel fuel into the tank with your own hands from causing harm, a fuse must be included in the control circuit. Today this method looks archaic, but who knows what situation we might unexpectedly find ourselves in on a long journey? Perhaps this is how you can get out of an emergency situation when there is nothing suitable at hand.

Wire heating

The option is more reliable and effective than the one described above. Based on its operating principle, it can be compared to the functioning of a heater that is built in to heat seats . The implementation scheme is simple and accessible to any car enthusiast:

- Make holes in the body of the intake mesh, up to 8-10 pieces on one side; they must be located opposite each other with a certain pitch offset.

- Prepare a special wire made from a material with high resistivity, for example, nichrome.

- Create a heating structure by threading the wire through the holes.

- Drill two holes in the intake cover to install the terminals and connect the wire to them.

- Connect the heating element to the vehicle's on-board network.

Types of heaters

There are several ways to insulate the filter device and ensure its heating. Let's take a closer look at each type of heater.

Bandage patch

The bandage type of devices is made in the form of an overhead clip. It is intended for installation on the external part of the filter element and heating it before starting the power unit. For optimal operation, the device is connected to the vehicle’s on-board network, the voltage source being the battery.

Flow-through

Flow-type devices are used as auxiliary components. In accordance with the instructions, installation of such heaters is carried out on the line in front of the filtering mechanism, in a section. This allows you to efficiently warm up the fuel at startup and during operation of the internal combustion engine. The fuel is first heated and then passes through the filter.

Tape flexible

Such devices are intended for external thermal insulation and heating of fuel system elements. Flexible tape heaters effectively heat not only the body of the filter mechanism, but also the lines. Depending on the need, the devices can be heated either before starting the internal combustion engine or during engine operation.

Heated nozzles

The attachments are mounted on standard fuel intakes. Their installation allows you to take part of the fuel from the gas tank at low negative temperatures down to -40 degrees. In such cold weather, standard systems cannot independently remove fuel from the tank. The nozzles come into operation when the ignition is turned on. They effectively heat the fuel, which leads to a decrease in its viscosity parameter and the volume of paraffins. The attachment systems are connected to the battery.

Special fuel nozzles

Flow type for diesel

Belt type systems

Bandage type device

How to make your own heating of a standard coarse diesel fuel filter?

A proven method for adjusting the temperature regime is to modernize the fuel pre-treatment unit. Among all the options, two need to be highlighted:

- Installation of the glow plug in the regular place of the drain valve.

- Installing a heating device into the fuel supply fitting housing.

Important! The first tuning method requires thoughtful actions. The unit to be dismantled is designed to remove water sediment from diesel fuel. Conclusion - such a modernization is suitable for owners who fill their cars with high-quality ingredients.

Separator drain valve upgrade

It is immediately worth noting the need to have a lathe or the services of a qualified turner. Preparation and installation of the glow plug in place of the drain valve occurs according to the following scheme:

- a sleeve is machined from metal, which matches the configuration of the plastic drain cap;

- a thread is cut on the new bushing with the appropriate pitch;

- a hole is drilled on the cylindrical generatrix and an internal thread is cut to fix the stud using a tap;

- an internal thread is cut into the cavity of the part;

- the glow plug is screwed in;

- install the assembly unit into the separator body and connect the wires: “+” to the heating element, and “-” to the stud.

Modernization of the separator fuel supply fitting

Another option is heating a diesel fuel filter with your own hands , it is more common and, moreover, the reconstruction does not involve the removal of important structural elements. The tuning scheme is similar to that described above and includes the following steps:

- drill a hole in the fitting body;

- cut a thread in the cavity corresponding to the thread pitch of the glow plug;

- screw the candle into the new hole;

- Connect the device's power supply from the on-board network.

In this version, the heating element is located in the upper part of the separator filter , as in most factory-made copies. The operating efficiency of this design exceeds the efficiency of the first method. The electrical part, as usual, consists of a switch and a fuse.

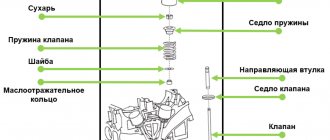

Improvement of fine filter elements

Quite often, at the final stage of fuel purification, the filter element becomes clogged with crystallized paraffin. As a result, the supply of diesel fuel to the working cavity of the high-pressure pump stops and the likelihood of its breakdown increases. To prevent this from happening, we will consider two options for organizing the heating of a fine filter, which can be implemented independently.

Option 1

To work you will need the following parts and equipment:

- about 6-10 meters of nichrome or copper wire with a cross-section of 0.5-1 mm;

- control button;

- fiberglass and heat-resistant sealant;

- fuse 10-15 A and relay;

- two plumbing clamps;

- tin, rosin and soldering iron.

The procedure for organizing this type of instantaneous diesel fuel heater with your own hands includes the following points:

- apply sealant to the fiberglass fabric and glue it to the element body (dry for about 24 hours);

- wind the wire in small increments onto the body of the part and secure the ends with clamps;

- apply fiberglass with sealant over the turns of wire and let dry;

- Solder the contacts for connecting the wiring onto the clamps and assemble the electrical circuit.

Useful recommendation! It is better to use a toggle switch and a relay through the positive line, and connect the negative line to the battery. In order not to forget the device is turned on, the “plus” should be taken from the ignition switch.

Option 2

The method relates to bandage-type heating. Suitable for its implementation:

- electric heated mirrors;

- heating film (similar to underfloor heating);

- flexible heater.

The workflow is simple and consists of the following points:

- wrap the heating element around the filter and secure it with insulation;

- connect the wires;

- lay foil thermal insulation 0.5 cm thick on top of the heater;

- Lay thick paper or fiberglass on top of the finished structure and secure with clamps.

Experts recommend additionally including a temperature sensor in the electrical circuit so that it adjusts the operation of the system.

Process Basics

Typically, the diesel fuel filter is heated by some kind of electrical device. The most effective is the overhead bandage heater.

- It is installed on a fine filter - the most vulnerable point of the machines in question.

- It resembles a clip.

- It is connected by wires to the battery.

- It is turned on by the driver before starting the engine.

Also find out why the idle speed is high and the idle speed adjustment of the VAZ 2107.

Although there is another option for providing heat. For example, the fuel filter for a diesel engine is heated by a flow-through heater.

- It is installed directly into the fuel line immediately before the fine cleaning element.

- Looks like a pipe.

- Also connects to the battery.

There are also tape heaters with which the cleaning element is wrapped. They are also connected to the on-board electrical network. From the information provided it should be clear how filter heating works in diesel engines. It simply heats the fuel using miniature heating elements powered by battery electricity.

More precisely, here are instructions on how to use, for example, an overhead device.

- Turn on the device a few minutes before starting the engine, at least ten minutes.

- Start the engine after the fuel has warmed up.

- Turn off the device when the engine warms up.

- The service life of such a device should be about five years.

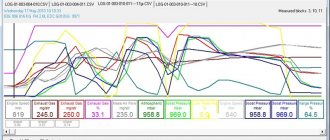

However, if you suddenly have doubts whether such a device works, is there a filter heating on the machine at all? In this case, we will list how to check the presence and operation of the fuel filter heating, point by point.

- Inspect the line near the purifier. Finding where the device is located is natural.

- Touch it with your hand to see if it’s warm, if it’s at least warm.

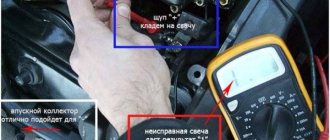

- Take an electrical tester, disconnect the power from the installation, check the power supply.

- Check the installation resistance, compare the value with the passport data.

This is the sequence.

My own master

Now let's look at how to heat a diesel filter on your car with your own hands. Let's first consider installing an overhead bandage heater. It must be purchased first. We think that there should be no questions about where to buy heating at all - you just need to visit a large auto store or online sales site.

But let's say it has already been purchased. What are we doing.

- We wrap the cleaning unit with a heating element, strengthen it with thermal insulation, and also with plastic brackets.

- We connect one wire to the ground (body) of the car.

- The second, in accordance with the diagram attached to the product, is carried out through the salon.

- We install the standard switch for the driver plus the relay from the kit according to the diagram.

- We connect the wire from the relay to the fuse, then to the positive terminal of the battery.

Please note that detailed instructions describing installation must be included inside the product packaging, among the accompanying documentation.

Now let’s look at how to make heating exclusively with your own hands, without store-bought equipment. For this method we will take the following materials:

- nichrome in the form of wire, 10 m;

- standard button;

- fiberglass, sealant;

- standard fuse;

- two universal clamps;

- soldering iron with soldering accessories.

We heat the fuel from the engine cooling system

A composition heated in a tank or separator can easily lose fluidity when passing along the entire highway, and even at high vehicle speeds. In this case, the car enthusiast can choose and make with his own hands any layout of the diesel fuel heater using simple technologies:

- basic insulation of the fuel line with building materials;

- installation of an electric flexible heater by winding or applying it to the surface of the unit;

- installation of a heat exchanger in front of the fine filter element.

The last method is to make a part that has two independent contours. The simplest example of such a device consists of two tubes of different diameters. The thinner tube is welded and centered inside the larger one. The outer circuit consists of pipes for passing diesel fuel. The small circle of the cooling system is connected to the indoor unit. Variations of this design are possible, where the circuits intended for diesel fuel and hot antifreeze can be swapped. More complex specimens contain an internal block made of a spiral type. High reliability of diesel starting in winter conditions can be ensured only with comprehensive modernization. Its essence lies in the use of several of the methods described above, which heat the components of the fuel system.

Heaters powered by electricity

Electric heaters are connected to a 220 V network using a cable. There are three types of devices:

- external;

- invoices;

- built-in

The latter type is installed in the cylinder block, having previously removed the anti-ice plug. After being plugged into the network, the coil heats up and the heat is transferred to the block and antifreeze.

The coolant circulates naturally without additional pumping. Because of this, heating occurs slowly. But the advantages of such a device come at a price. The devices can be used in places where there are sockets (garages, equipped parking lots).

If we compare built-in heaters with overhead heaters, the former are considered more efficient because they come into direct contact with antifreeze. But invoices also have their advantage. They do not affect the standard cooling system, so after their installation there is a warranty for car repairs.

The most popular manufacturers of electric models are the northern companies DEFA (Norway) and Calix (Sweden).

Sputnik is considered a popular domestic electric heater due to its affordable price and good heating. The Tyumen company produces Severs surface-mounted electric heaters, which are connected to the motor through pipes. The heater is equipped with a thermal switch and temperature regulator, and also has a built-in valve through which the coolant pulses. This significantly increases the efficiency of the device.