Parameters that determine the quality of diesel fuel

The quality of diesel fuel is indicated by the following characteristics:

- Limit temperature of filterability. This indicator determines the lower temperature level at which diesel fuel stops leaking through the filter holes.

- Cloud point.

- Density. The higher this indicator, the more energy is released during fuel combustion.

- Kinematic viscosity. Liquid diesel fuel accelerates wear on the fuel pump. Thick product negatively affects the condition of individual engine parts.

- Cetane number. The rate of ignition of the fuel depends on it. An indicator result in the range of 50-55 indicates high quality, and 40-49 indicates good quality. A cetane number below 40 slows down ignition, which means it increases diesel consumption and leads to engine wear.

- Cetane index. This indicator is the cetane number before adding a cetane booster. The difference between the number and the index should not be large. Otherwise, the composition may be subject to significant changes.

- Factional composition. Characterizes the rate of transition of diesel fuel from a liquid to a gaseous state. Determined by the evaporation temperature.

- Flash point. The higher this indicator, the less likely it is that the fuel will accidentally ignite.

Method for determining fuel density according to GOST

Traditionally, to determine the density of fuel, a special device is used - a hydrometer. This is often a glass tube with a density scale. There are different hydrometers for different types of fuel. In the case of diesel fuel, devices such as AN, ANT-1 and -2 (for petroleum products) are used.

This is interesting: How to quickly pay a traffic fine? 6 easy ways

The device is immersed in the liquid and the indicators are measured: the density of the fuel is the ratio of the mass of the device to the volume it occupies in the liquid.

Based on the results of measurements, the fuel is assigned to one of the types corresponding to GOST:

- summer diesel fuel - density 860 kg/cubic meter;

- winter diesel fuel - 840 kg/cubic meter;

- Arctic diesel fuel - 830 kg/cubic meter.

Since the density of the fuel depends on temperature, all measurements are made at +20 ˚С.

If we take into account the variability of the environment, then with a change in temperature by 1 °C, the density of diesel fuel will also change - by approximately 0.00075. This coefficient makes it possible to calculate the density of a liquid under different temperature conditions. However, this only applies to the pure product.

Fuel does not always have the declared characteristics. Often, a low-quality product contains impurities of unknown origin. Therefore, it is recommended to refuel at proven gas stations, where the quality of the fuel is guaranteed and the risks of getting summer fuel instead of winter or Arctic fuel are minimal.

If there are doubts about the density of diesel fuel, measurements can be carried out independently.

How can you analyze the quality of diesel fuel?

The most accurate method for determining the quality of diesel fuel is professional examination. But this method is not available at gas stations. A portable laboratory can be used to perform rapid analysis, but such equipment is expensive. Another option is to try to determine the quality of diesel fuel yourself.

For this, there are several proven methods that do not allow one to draw an exact conclusion, but make it possible to distinguish good diesel fuel from a fake. Determining indicators such as cetane number and flash level cannot be assessed. However, some obvious violations can be identified.

Visual method

Fraudsters often resort to the following actions:

- they add kerosene to summer diesel fuel in order to pass it off as a winter composition;

- replace high-quality fuel with another product.

To conduct a visual analysis of diesel fuel, you need to take a sample of diesel fuel from a trusted manufacturer, the quality of which is beyond doubt. Then you should buy some fuel at a gas station and compare the compositions.

You need to pay attention to the color of the product. It should be light yellow and transparent. The presence of impurities or sediment, as well as foreign odors, is unacceptable.

Testing on a paper filter

A small amount of diesel fuel should be poured onto a paper filter and monitor its color change. A small spot of light color will confirm the quality of the product. A dark color with sediment indicates a fake.

Testing with potassium permanganate

Using potassium permanganate, you can determine the presence of water impurities in diesel fuel. Crystals of this substance do not dissolve in diesel fuel. The appearance of a pink plume on the surface of the composition indicates the presence of water in it.

Density check

An aerometer is used to determine the density of a substance. It is necessary to place some diesel fuel in a special container and create an environment with a temperature of 200º. Then the indicator should be measured. According to GOST, diesel fuel should have a density of 840 m³ in winter and 860 m³ in summer.

Improve diesel fuel

Antigels or depressants

It is highly recommended to fill them preventively, starting from “zero” temperature and up to November (at the end of this month, as a rule, all fuel is already “winter” and there is no need for a depressant), before each filling of diesel fuel into the car tank, observing the recommended proportions. Use products from reputable, proven companies, for example: Castrol, Shell, Total, Wynns, etc. But be extremely careful in your choice.

Example : I once had to buy “antigel” from a well-known overseas company in the store of a well-known chain of “underhood chemistry” in Russia. Before the autumn trip from the Capital with its 0°C, to the already winter Valdai, where it had been -15°C for a week, having opened the tank and taking an American bottle out of the trunk, the author was horrified to discover that the “antigel”... had frozen and turned into a brown porridge . Luckily, it happened at a reputable branded gas station, where a depressant additive for diesel fuel was immediately purchased and “put into use,” and the bullshit went into the trash bin.

DIY antigel

Most “antigels” contain naphtha and white spirit. These substances are “closest relatives”. But, if naphtha is extremely difficult to find on sale, then there is as much white spirit as you like in any building materials store: as a solvent for paints and as a degreaser. It is appropriate to note that the name of this hydrocarbon does not come from alcohol, which it is not, but from the ancient “white spirit” technology, by which white spirit and kerosene were obtained at the end of the 19th century in England and the USA. Advantages: low freezing point about -63°C, high cetane number relative to kerosene - 40-45, low sulfur content, excellent cleaning properties, etc.

For “budget” protection of diesel from freezing of low-quality diesel fuel, white spirit should be diluted in a ratio of 1:1000-1:500. The main thing is to inject the “life-giving elixir” before refueling and before the potential freezing of the diesel fuel “out of season.” Pouring any depressant into already frozen diesel fuel is useless. Considering that modern PSA Peugeot Citroen diesel engines of the DV and DW families, as well as their variants for third-party manufacturers (BMW/Mini, FIAT, Ford, Mazda, Land Rover/Jaguar, Volvo, etc.) have a less complex system that is picky about fuel quality Common Rail injection, rather than distribution-type plunger fuel injection pumps from the recent past, the practical use of white spirit as an “antigel” is very effective. There are many examples.

Dangerous myth: adding “pure” aviation oil type MS-20 to diesel fuel

Another option is to add “clean” machine oil.

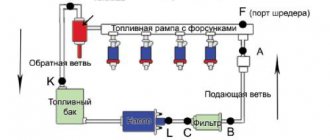

An ephemeral goal: to increase the resource of the injection pump, to protect its plunger pairs from wear. There is a violation of the cause-and-effect relationship. If the car is operated under normal diesel fuel, it does not need any additives. Moreover, the fuel injection pump, or more precisely, the high-pressure fuel pump (high-pressure fuel priming pump) of modern diesel engines with Common Rail are completely devoid of the problems of “classic” diesel engines and pump injectors associated with increased wear. The pump in the Common Rail system has only one task - to maintain the fuel pressure in the rail (receiver) at a given level, and nothing more. That's why it has the simplest piston design.

The tricky part of the situation is that when using a diesel engine on what is known to be a “scorched diesel fuel”, no fuel additives will save you from problems. Even if you add the purest aviation oil like MS-20 to diesel fuel, it will most likely only cause harm. After all, it is known that it easily “binds” components that, during combustion, remain in the combustion chamber in the form of soot. "Aromatics" is a catalyst for the decomposition of oil.

“Clean” oils such as MS-20, and the like, work effectively and are created for conditions in the absence of hydrocarbon “competitors”. In other words: in conditions when one girl and one boy end up on a desert island, a beautiful and harmonious “love story” is obtained, but if the number of boys or girls increases, the further development of the situation will most likely resemble a “dirty group sex.” The same is true for hydrocarbons. The “cleanest” oil mixed in with the purest intentions can ultimately become a source of problems for the engine.

Another myth: adding alcohol to diesel fuel will remove water from it

Apologists for this idea argue that the property of alcohol to dissolve well in water will help remove it from the fuel tank, after which the mixture will burn in the cylinders along with the fuel. At the same time, for some reason, it is forgotten that diesel fuel: a mixture of very active hydrocarbons, and the alcohol that gets into it, immediately forms a solution with them, and not with water. It’s just as it was at the bottom of the tank – it will remain there. Alcohol dissolves with water only when there is nothing else nearby that is more active. So, don’t be under any illusions: in order to remove H2O from the fuel tank, you will have to flush it. Don’t be fooled by freebies and promises of miracles.

The diesel engine is demanding only in that all actions must be carried out preventively, in advance. Skeptics and poorly educated car enthusiasts consider this to be one of its shortcomings. But, if everything is done “as it should”, the diesel engine will not let you down even in the most extreme conditions. Moreover, in operation, any of them is more profitable financially and emotionally than gasoline ones. You just need to understand that the trouble-free and reliable operation of any car for many years and hundreds of thousands of kilometers is the merit of the driver, his care for the “iron horse” and not some kind of illusory reliability.

Methods for checking diesel fuel quality

Along with simple and visual methods for determining fuel quality, there are also complex ones that are carried out only in laboratory conditions using special equipment.

Independent

Since diesel fuel is a typical liquid, its quality can be judged, for example, by standing in a transparent vessel and the appearance or absence of sediment or a change in color. If there is no sediment, the fuel is good; if there is sediment, it is bad. Darkening of diesel fuel indicates the presence of kerosene and gas oil fractions in excess of the norm or the presence of tars.

To identify solid inclusions, you can use a paper filter. High-quality fuel will appear as a small light spot, and low-quality fuel will appear as a large and dark spot.

By settling, the presence or absence of moisture in the fuel is revealed, which, being heavier, will settle to the bottom, forming a clear boundary with diesel fuel. Water in diesel fuel is a scourge for the engine. It causes corrosion in the fuel system. But most of all, water causes damage to injector nozzles, initiating cavitation and metal erosion.

The comparative method is clear: the fuel being tested is placed next to a sample of a quality product. As a result of comparison, you can see that low-quality fuel will appear darker, and sediment or water may form.

Laboratory

In laboratory conditions, the main characteristics of the fuel are determined and its quality is judged by them.

1. The cetane number is usually measured by the motor method on a 1-cylinder diesel engine with a mechanically variable compression ratio. To do this, we need several reference samples of fuel with a precisely established central frequency. By changing the volume of the combustion chamber of the test bench, identical flashes of the tested and reference fuel are achieved. Then comparing their combustion process, the cetane number is determined.

2. The study of the fractional composition of diesel fuel is also standardized. The hardware side of the process may be different, but the essence is the same. One hundred milliliters of diesel fuel is poured into the flask and heated evenly. In this case, the following is recorded: the temperature of the beginning and end (96%) of distillation, as well as the corresponding distillation values of 10, 50 and 90%.

In high-quality fuel, most of the fractions are distilled in the range from 250 to 350°C. The lightweight fractional composition, improving engine starting, increases the rigidity of its operation. Weighting this indicator, increasing viscosity, worsens the quality of atomization and combustion of fuel.

3. Fuel viscosity is characterized by kinematic and dynamic indicators. The first of them is measured by a viscometer with a calibrated channel based on the time of flow of a given volume of liquid. By multiplying the kinematic viscosity and the density of the substance, the dynamic viscosity is determined.

4. The lubricity of diesel fuel is determined using a steel ball with a given diameter and hardness, which is rolled over a plate soaked in the test liquid with a calibrated force, speed and time. Then it is measured and, based on weight loss, a parameter characterizing the lubricating properties of the product is calculated.