0

Now available after "stub" at the factory

0

Real factory power available after chip tuning.

Chip tuning of a diesel engine will help increase the power of your car and save on fuel costs. Changing the firmware of the electronic unit allows you to use all the hidden reserves of the engine and adapt the car to the individual preferences of the owner.

The PowerChip company provides professional chip tuning of car engines. We will carry out all the necessary work taking into account the characteristics of your machine and install high-precision system settings taking into account the customer’s wishes.

Deliberately hiding engine capabilities

No matter how strange it may sound, absolutely every motorist should know how much engine chip tuning costs. This is due to the fact that anyone can reconfigure the operation of the electronic control unit of the car. All foreign automobile industries produce vehicles whose power units may have better characteristics than those “prescribed” by the manufacturer. Basically, this trick helps extend the life of the engine and make the four-cylinder engine less attractive compared to its more expensive six-cylinder counterpart.

The automaker needs to regulate the electronic engine control functionality in such a way that the service interval is as long as possible

It is worth noting that almost all new motorists who prefer to choose exclusively new vehicles from car dealerships pay close attention to the period during which it will be necessary to undergo scheduled maintenance to change the oil and filters

It is difficult for foreign companies to remain among the leaders in the market; they are obliged to create cars that fully comply with environmental standards regarding exhaust gas emissions in all countries of the world. In turn, deliberately reducing the power of the power unit largely helps solve this problem, since a car with low power and low fuel consumption is able to emit fewer harmful substances into the atmosphere.

Features of a modern diesel engine

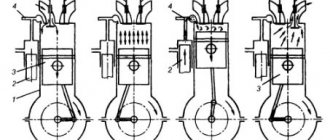

The diesel engine of modern cars is a high-tech unit that is much more advanced than previous generations of engines of this type. The basis of diesel engine operation remains the ignition scheme of fuel in the working combustion chamber according to the compression principle. The greatest changes affected the technology of supplying fuel to the cylinders.

Most current versions of diesel internal combustion engines today have a Common Rail system, which is similar in principle to battery power systems. In a diesel engine, such a system is based on mechanical fuel injection pressure, which is created by the injection pump. Diesel engines with a Common Rail system have a huge range of capabilities for effectively changing the phase and injection time, which is measured by the opening time of the electronic injector nozzle.

This Common Rail system ensures that fuel is supplied to the cylinders of a diesel engine in precisely dosed phases. It is necessary to take into account the provision of the required pressure for any operating mode of a diesel internal combustion engine. Diesel power units also have a whole range of additional systems that are controlled by the electronic control unit ECU (ECU) of the diesel engine.

The main task of high-quality chip tuning is to increase diesel power without noticeable damage to the resource of the internal combustion engine. The diesel engine is controlled by an electronic unit, which has a microprocessor and a basic program preinstalled by the car manufacturer.

The ECU controls the operation of the engine and other automotive systems. The data in the ECU comes from a variety of sensors that constantly record the performance of the diesel engine in different operating modes.

Engine life

Any software modifications will affect the resource of the power plant - the effect can be both positive and negative. The extent of the damage depends on the targets. If you just increase the power a little, roughly speaking, “stifle” the engine, then there will be no significant loss of resource - at most it will decrease by 10-20 thousand kilometers. But if you specifically squeeze all the juices out of the unit, it will have a rather deplorable effect. For example, the resource of a combat turbo engine is about 50,000 km. Speaking about atmospheric engines, you need to understand that an increase in power on atmosphere occurs due to a shift in the cutoff and a change in the ignition angles and fuel maps, because in order to get more power from the unit, you need to drive as much fuel into it as possible. Too high speeds will significantly reduce the engine life - by about 30%.

Introduction

When a vehicle is released, the manufacturer programs the control unit with standard settings, which means that all possible parameters of the power unit can be preserved, and both resource and environmental characteristics can be increased during the entire warranty period. This feature of cars may not suit owners who want to get the full return from their movable property. The diesel engine tuning discussed in the article below helps to achieve a power increase of a maximum of 40%.

Chip tuning of a diesel engine or gasoline engine: impact on the resource of the internal combustion engine

It is quite obvious that even if all the firmware and configuration operations are performed correctly, an increase in power and torque will one way or another mean wear and tear on the internal combustion engine.

First of all, accelerated mechanical wear of loaded elements and friction pairs occurs (piston ring and cylinder walls, connecting rod and main bearings at the junction with the connecting rods, crankshaft, in the crankshaft bed in the BC, etc.)

For example, the operation of a piston ring in a cylinder has the following features. While the fuel in the cylinder is not burning, the rings experience minimal stress. The piston ring wall is parallel to the cylinder wall. However, at the moment the fuel ignites, a pressure surge occurs, as a result of which the ring in its groove begins to twist under the load.

The rotation angle of the ring in new engines is small, but gradually the elements wear out naturally. As a result, the piston ring, under load, begins to hit the cylinder walls with its edge. Without going into details, the annular grooves are broken and the cylinder walls are severely worn out.

As for the liners, as well as supporting elements, in addition to friction, the parts are also affected by the so-called radial deformation. In simple words, the shape of the holes changes. It is quite obvious that gaps form in friction pairs and shock loads appear. The inserts simply break, and they can also be turned.

So, chip tuning allows you to change the parameters that were configured at the factory. As a result, torque and power increase, but at the same time the loads in the most important components of the internal combustion engine also increase. Naturally, the wear balance predicted by the engine designers will also be disrupted.

It turns out that although an increase in power does not particularly affect the friction force, there is an increase in pressure on the walls of the sliding bearings and other elements. As a result, shock loads increase, wear processes progress rapidly, gaps increase, etc.

It is worth adding that such processes affect not only the internal combustion engine, but also the gearbox. At the same time, the catalyst and oxygen sensor can fail faster. The service life of engine and transmission oils is also reduced, meaning lubricants need to be changed more often.

On many engines, in addition, oil consumption increases due to waste. The cooling system of the internal combustion engine, which works more intensively as a result of the increase in power, also experiences additional loads. For this reason, you need to monitor the performance, quality of antifreeze and cleanliness of the cooling system channels.

Installation of special modules

Installing the modules is not difficult, but you must follow the specific instructions that come with each unit. There are 4 categories of blocks in total:

- Block for changing injector control signals.

It is designed to control the activity of the injectors - it slows down or stops the needle from rising. As a result, fuel consumption is optimized and combustion efficiency increases. The block is connected to the injectors using wires. Compatible with all diesel engines with a modern fuel supply system.

Block for changing the fuel pump operating system.

Interacting with the fuel mixture compression sensor, this unit underestimates the readings coming from it. This leads to a decrease in pressure in the fuel injection pump and increases engine dynamics. In this case, the engine resource does not suffer in any way. The unit is connected to the fuel pump and the ECU using wires. It may well be combined with older diesel engines that were manufactured before 2008.

A block that changes the readings of the fuel rail pressure sensor.

Using this device, the ECU is “deceived” - it is informed that the pressure in the fuel rail is reduced. The control unit “thinks” that the engine speed has dropped and begins to change the dynamics of the injectors. This leads to a reduction in fuel consumption and an increase in engine power. The unit is connected to the ramp pressure sensor using wires. It can only be combined with modern engines.

With its help, fuel pressure is determined. When it increases, an impulse is sent to the ECU to increase the injector timing. The module has a built-in special program that corrects engine operation without an ECU. The sensor readings do not change. The block can be combined with all types of modern engines.

Positive aspects of using modules:

- Motor power increases.

- Fuel consumption is reduced.

- Installation is simple and will not cause any difficulties for anyone.

- The service life of the cylinder block is slightly reduced.

- The service life of the fuel pump is also reduced.

- Harmful substances begin to be released more actively.

Atmospheric engines

Let's figure out what the pros and cons of chip tuning of naturally aspirated engines are.

Nowadays there are quite a lot of cars with naturally aspirated engines. Let's say right away that there will be more disadvantages. Chipping for such engines adds very little horsepower, almost unnoticeable in practice. It's all about the features of tuning naturally aspirated engines.

And the advantages include the refusal to comply with strict environmental standards, which will increase responsiveness at medium speeds. You won't be able to save fuel significantly either; chip tuning doesn't have much effect on this. That's all there are to the pluses.

The best option for a naturally aspirated engine would be to tailor the firmware specifically to a specific engine and test it on running drums or while driving on the road. But it should be noted that such an operation will cost a decent amount and, as a rule, is used only for thorough tuning, when all the hardware is completely changed.

Installation of pre-heater

In winter, warming up a diesel engine is problematic. In severe frost it does not start. To make life easier for the unit, motorists use a preheater. The device is a small boiler that heats the burner. It turns on automatically or by remote control. Warm-up time depends on the outside air temperature and the power of the device. As a rule, this takes about 20 minutes. Webasto and Eberspächer are the most famous companies that produce preheaters. The first is more reliable, and the second is more compact. Some foreign-made diesel models (Volvo, Ford and Land Rover) are equipped with heaters at the car plant. By the way, there is a not very bad Russian analogue - “Binar 5”, which is produced by. But there is an opinion that it is not entirely reliable. However, this is not so, because in recent years a Bosch pump has been installed on Binar 5. For normal functionality, the preheater must be connected to the vehicle cooling system. Plus, the battery is in good condition. If the battery is dead, it may be discharged and the car will not start. Since the PP is a necessary thing, its installation should be carried out by professionals. But every car owner must remember that if the car is new, the dealer can remove the car from warranty for unauthorized design changes.

How to add power to the engine

So, let's go. The list of popular solutions for increasing engine power includes:

- boring the cylinder block and installing a sports crankshaft;

- replacing pistons/connecting rods with lightweight ones;

- replacing the camshaft to shift the valve timing;

- modification of the air system and intake;

- replacing the exhaust system with an improved one;

- engine chip tuning;

- installation of turbocharging;

Let us add that we will not talk about such exotic solutions as nitrous oxide systems NOS or “nitro” (from English Nitrous Oxide System). Such solutions are installed on specially prepared racing cars and are not a way to permanently increase the power of the internal combustion engine, as they produce a temporary effect.

Complex or partial modification of components

Now let’s take a closer look at the above methods of modifying the motor. Let's start with the difficult one. Replacing the crankshaft and boring engine cylinders, preparing the cylinder head, as well as replacing pistons, connecting rods and camshafts is the so-called “iron” tuning.

The method makes it possible to reduce losses during operation of the internal combustion engine, increase efficiency, increase the physical volume of the engine, increase the compression ratio, improve the filling of the cylinders and influence the efficiency of gas distribution at different engine operating modes. This approach can be implemented either partially (only individual nodes are changed) or comprehensively. Let us add that on many cars it will not be possible to bore the block too much, since the walls of the cylinder block are quite thin and are designed to be bored to 3 repair sizes.

The increase in torque characteristics, maximum power and a number of other parameters directly depend on the amount of modifications. Separately, it should be taken into account that installing, for example, only lightweight connecting rods or pistons will not lead to a significant increase in power, and will already require significant financial costs against the backdrop of a slight increase. For this reason, it is better to “pump” the engine comprehensively.

Note that this procedure is quite expensive and requires additional modifications to the power system in the case of injection engines and a number of other changes to the standard design. During operation, such an engine requires increased attention, refueling with high-octane quality fuel and expensive motor oil. At the same time, fuel consumption increases. Engines after such tuning are very afraid of detonation and often have a short resource.

https://youtube.com/watch?v=_4ozjkC5faY

Turbocharging on an atmospheric internal combustion engine

An equally complex way to increase engine power is to install a turbocharger on a naturally aspirated engine. Note that this approach is more effective compared to the modifications to the atmospheric internal combustion engine described above. Moreover, in combination with replacing engine components with reinforced parts (as in the first method), it becomes possible to obtain very impressive results.

For example, an atmospheric engine that produces about 200 hp in stock, after modifications to the hardware and installation of a turbine, can easily produce 500 horses or more. It turns out expensive, but very effective.

The disadvantages include the need for careful selection of spare parts, the need to fine-tune the motor and resolve complex technical issues. Not every specialist will undertake such work.

Budget ways to increase power: intake, exhaust, chip tuning

It is quite obvious that such improvements are carried out as part of preparing the car for sports competitions or to create individual projects. Ordinary car enthusiasts don't need this. For this reason, simple and cheap ways to increase the power of a power unit are very popular.

These include installing a zero-resistance air filter (nulevik), which has less intake resistance and allows the engine to receive more air. The increase in power is minimal (especially on an atmospheric engine) or not noticeable at all (from 0.5 -2.5%), but the solution itself is available to every car owner. Note that many drivers are skeptical about this method, since the big disadvantage is the poor filtration of the air that enters the engine and pollutes the power unit.

A more noticeable effect is achieved by tuning the exhaust (removing the catalyst, installing an exhaust with pipes of changed diameter, installing a direct-flow muffler). The main task is to reduce the resistance that is created when exhaust gases are released. These gases move more optimally in the modified exhaust system. In this case, the engine picks up speed better, and the acceleration dynamics become more intense. On some cars, after professional selection of pipe diameters and proper installation, the power increase can be up to 5%. The method will require certain financial costs, but it still remains much cheaper compared to modifying the internal combustion engine or installing a turbine on the engine.

The list of available ways to increase engine power is completed by chip tuning. This solution involves making changes to the ECU firmware on injection engines. We would like to add that both naturally aspirated and turbocharged petrol and diesel engines can be chipped.

The advantages include a programmatic increase in power and torque, improved engine response to pressing the gas pedal, and a reduction in turbo lag on turbocharged units. In other words, there is no need to change any units and components. After high-quality firmware, the engine runs more stable at idle, there is no drop in power after turning on powerful consumers (air conditioning, heated seats, mirrors, etc.). The disadvantages are considered to be increased demands on the quality and octane (gasoline)/cetane (diesel) number of fuel, as well as a decrease in engine life. It should also be taken into account that unprofessional ECU firmware can cause serious malfunctions in the operation of the motor or failure of the control unit itself.

Advantages and disadvantages of diesel internal combustion engine firmware

Installing a tuning unit parallel to the ECU is not particularly difficult; reflashing the ECU on your own is a rather complicated operation without experience, software and technical equipment. The programming of the control unit is carried out by qualified specialists. Software chip tuning allows you to increase diesel power by an average of 15-25% without major alterations, which involve deep boosting the diesel engine by replacing components and parts of the internal combustion engine.

Advantages of chipping a diesel engine

- The process of flashing a diesel ECU is reversible;

- the price of high-quality diesel chip tuning is quite reasonable;

- ECU firmware does not take much time and can be adjusted;

- chip tuning of a diesel engine eliminates modifications to the intake and exhaust manifold;

- the ability to flexibly change ECU parameters to adjust the program during tuning;

- the stitched diesel engine “pulls” confidently without noticeable power losses;

- Driving a car during daily use becomes more comfortable;

- chip modification of a diesel engine can increase the threshold of maximum speed and torque characteristics;

- chip tuning means the absence of noticeable interventions, which is important for a car under warranty;

Share with friends on social networks:

Telegram

Pros and cons of engine chip tuning

Just like every stick has two ends, engine chip tuning has pros and cons. When deciding whether to upgrade their car, the owner needs to evaluate the merits and risks associated with this operation.

Pros of car engine chip tuning

Let's start with the positive. As a result, chip tuning can increase engine power and improve acceleration dynamics. The car becomes more responsive to the gas pedal, and dips disappear when the speed increases sharply. On the track when overtaking you will feel much more confident.

However, the advantages of chip tuning are not noticeable on all engines. We'll talk about this in more detail below, but the overall picture is this: turbocharged engines are more susceptible to software modernization than naturally aspirated ones.

The main advantage of engine chip tuning is that it costs an order of magnitude cheaper than physical boosting. In addition, the factory settings can be easily returned if you do not like the result of the upgrade. In the case of forcing, a “rollback” to the previous state is impossible.

Cons of car engine chip tuning

Now let's move on to the disadvantages of engine chip tuning. There is no consensus among craftsmen and motorists here. The direct relationship between problems and reprogramming of the on-board computer is difficult to trace, and all statements with the subjunctive mood can be disputed.

Opponents of chipping argue that any interference with the ECU software has negative consequences. If not now, then in the future. The main disadvantage of engine tuning chip, according to them, is the reduction in engine life. Opponents also point to increased fuel consumption. How valid are such statements?

It is almost impossible to trace the direct dependence of increased engine wear on chip tuning. This is a rather controversial minus. Driving style and quality of maintenance have a much greater impact on engine life.

The statement about increased fuel consumption looks even more controversial. In fact, sometimes it is possible, on the contrary, to reduce this indicator. This is especially common when chip tuning a diesel engine. In general, we can say that, in general, diesel engines respond better to chipping than their gasoline counterparts. Engines running on heavy fuel have more room for maneuver. Let's look at this topic in more detail.

Features of the procedure

Diesel tuning contributes to:

- The performance of the power unit increases, the dynamics properties improve, and vehicle control becomes noticeably easier. Moreover, all of the above advantages do not require large investments of money (if we draw a parallel with the costs of introducing various design upgrades to the mechanics of the motor);

- the amount of fuel consumed is reduced by 3–5%, which makes it possible to use a lower octane number;

- in certain models you can remove speed limits;

- All power unit errors accumulated in the vehicle control unit will be reset.

As practice shows, unsuccessful tuning of a diesel engine can contribute to the failure of the control unit. This can happen even if it is possible to roll back the changes made.

Among the other negative properties of an illiterate procedure, it is worth noting:

- noticeable reduction in the service life of some engine parts;

- increased fuel consumption;

- problems when undergoing scheduled maintenance, due to the fact that the vehicle’s exhaust emissions have increased;

- Fuel injection problem.

Among other things, you should remember that you will have to pay a considerable amount for professional chip tuning of the power unit.

What is engine chip tuning?

Translated from English, the expression chip tuning means “chip tuning.” During this operation, the on-board computer is configured as required by the owner. In essence, engine chip tuning is a change in the mode of electric controllers that control the operation of fuel injection and ignition systems. To do this, you need to reprogram the central on-board computer, calibrating the settings so that the efficiency of the motor increases.

Why don't manufacturers set the optimal settings from the beginning? Why do they artificially reduce engine power? There are several reasons forcing car manufacturers to take such measures.

Environmental requirements

Industrialized countries (especially Europe) have strict laws aimed at protecting the environment. Car manufacturers are forced to adapt to these standards by artificially lowering engine performance. Sometimes, in order to reduce the level of carbon dioxide and other harmful components, the engine power is reduced by 20%.

Subtleties with car taxation

Another point is taxes. By artificially reducing engine power, you can “adjust” the technical characteristics of the car so that it falls into the group of vehicles that are taxed at a lower rate. For some buyers, this factor is of great importance. The manufacturer receives new customers without special costs.

Power in reserve for the future

The third reason is not so obvious, but also has a right to exist. Developers can deliberately “strangle” the engines of some models in order to subsequently release “improved versions”. It is enough to change the ECU firmware settings, update the cosmetic interior and body to make a more prestigious (read: expensive) model. Maximum external effect with minimum investment. Just marketing.