The Ford Focus 2 car brand is very popular in Russia; such cars are found on the roads quite often.

- 1 Ford Focus 2 front suspension

- 2 Silent blocks of front arms Ford Focus 2

- 3 Replacing the front arm Ford Focus 2

- 4 Replacing the ball joint Ford Focus 2

- 5 Replacing the front silent block of the suspension arm of a Ford Focus 2

- 6 Pressing in the rear silent block of Ford Focus 2

- 7 How to diagnose the Ford Focus 2 suspension

- 8 How to check the condition of the silent blocks of the front arms of a Ford Focus 2

The car is deservedly popular - it is very reliable, the front suspension is also durable, and the chassis parts almost always reach their intended service life. But sooner or later parts fail and the machine needs repair. Replacing the silent blocks of the front levers of a Ford Focus 2 is usually required after a mileage of 100 thousand km, but during dynamic driving on bad roads, chassis repairs may be required earlier. In this article we will look at how the front levers and separate silent blocks are changed on a Ford Focus, and how the chassis is diagnosed.

Ford Focus 2 front suspension

The front suspension of the FF-2 is MacPherson type, independent, it is designed very simply. A rigid subframe (front beam) is installed in the middle, to which two levers are attached on the sides. A ball joint is riveted at the end of each arm, each of them is connected to a steering knuckle. At the top, the steering knuckles are connected to shock absorber struts, the rods of which are attached to the body through a support bearing. Also included in the pendant are:

- springs;

- stabilizer with struts and bushings;

- hubs with bearings.

The front arms are connected to the subframe using two supports; to ensure a smooth ride of the car, silent blocks are pressed onto the arms at the point of attachment to the front beam; the subframe itself is rigidly connected to the body side members through bolts.

How to replace silent blocks on a Ford Focus?

- How to replace silent blocks on a Ford Focus?

- Where are the Ford Focus 2 silent blocks located?

- Front silent blocks

- Rear silent blocks

- When do you need to change silent blocks on a Ford Focus 2?

- Signs of a failed silent block

- How to replace silent blocks and what you need for this

- Necessary tool

- Replacing front silent blocks

- Replacement of silent blocks of the upper arm of the rear suspension

- Replacing the silent blocks of the front lower arm of the rear suspension

- Replacing silent blocks of the rear lower arm of the rear suspension

A silent block (translated from English literally as “quiet part”) is a rubber-metal hinge, an element of machines and mechanisms. In cars, it connects suspension parts, and, thanks to the elastic insert between the bushings, dampens vibrations between structural units.

- Where are the silent blocks of the Ford Focus 2? Front silent blocks

- Rear silent blocks

- Necessary tool

Where are the Ford Focus 2 silent blocks located?

Front silent blocks

Rear silent blocks

Ford Focus 2 is equipped with an independent rear suspension with four levers on each side. Each lever has its own rubber-metal hinges of completely different sizes and degrees of resistance to loads, through which three transverse levers are attached. These, in turn, connect the trailing arms, which are load-bearing elements.

When do you need to change silent blocks on a Ford Focus 2?

Ford Focus 2 silent blocks are designed for a vehicle mileage of 100,000 kilometers. Poor-quality road surfaces, drying out of the lubricant of parts, and dust or moisture getting into the joints reduce the service life of the hinges by half. Therefore, car manufacturers recommend changing these elements every 30 - 40 thousand km.

You can realize that it is time to make a replacement based on several visible and audible signs.

If the car does not obey the steering wheel or responds late to turning, the silent blocks are worn out. A loud knock made by the rear suspension is also a sign of repairs.

To confirm your suspicions, you can look under the bottom of the car, cleaning the parts that interest you. For comparison, it is advisable to know what the new hinges look like or have them in front of your eyes.

Signs of a failed silent block

You can notice signs of wear on the rubber-metal hinges and examine them in detail in the inspection hole. First of all, attention is drawn to the swollen or displaced rubber of an element, then the degree of its smoothness and integrity.

If the hinge seal is cracked or torn, the arms will bend in their position.

It would be useful to pay attention to the uniform wear of the car tires and check the play in the hinges.

How to replace silent blocks and what you need for this

A common problem is the breakdown of parts of the front suspension arm: the silent block of the rear mount or the ball. When replacing the rear hinge of the Ford Focus 2 front suspension, a repair diagram will not be needed, since the silent block is not removable. In the event of a breakdown, the entire lever will have to be replaced.

Ford Focus 2 front arm silent blocks

On the FF-2 car, two levers are installed on the front suspension - right and left. Each of them is attached to the subframe at two points, through silent blocks. Levers are sold assembled and vary in price, the price depending on the manufacturer. In addition to the original, parts are also produced by various companies, the most famous of them:

- Ruville;

- Konstein;

- Vaico;

- Mapco;

- ABS;

- Delphi;

- Febi;

- Optimal;

- TRW;

The cost of levers ranges from 1,500 to 10,000 rubles; parts can be purchased to order; some auto stores have them in stock.

Levers are most often replaced entirely when they are subject to mechanical damage (in an accident, running into an obstacle). If there is play in the connection of the lever with the front beam, it is more advisable to change the silent blocks - this way the repair will be cheaper. The rear silent block of the front lever is pressed onto the axle; it is more massive. The price of these parts varies, on average 1 piece. costs 1500-2500 rubles, for example, the Lemforder silent block sells for about 1650 rubles.

Currently reading

How to maintain and charge a maintenance-free type of battery for...

ZIL 130 engine: a legend of the Soviet automobile industry

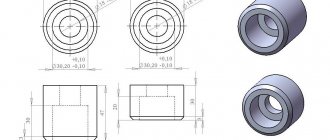

The front silent block of the front suspension arm is pressed into the body of the arm; it is less massive and simpler in design. The front ones are cheaper, their average price is 300-600 rubles. for 1 piece. (the cost of s/w Delphi is about 500 rubles).

Replacing silent blocks

It is easy to replace the front silent block if you have a tool for pressing out.

They first press out the old element, and then press a new one in its place.

Inside the silent block of the front suspension arm there are two metal bushings and an internal clip that fits onto the arm.

The entire space inside the outer casing is filled with rubber.

Before removing it, it is better to make notes on the lever, how the silent block was located on it, as well as how the eyes were located relative to the lever, and the depth of its seating. This will help you perform the installation correctly in the future.

This is very important, because once a new rubber element is installed, it will no longer be possible to remove it without destroying the structure.

If this silent block is heavily worn, you can try to pull off the outer housing using a puller.

Replacing the front lever Ford Focus 2

It is advisable to replace the entire front control arms on a Ford Focus if they have been damaged or are already quite worn out (they have exhausted their service life). Car owners should take into account that after replacing the levers, it is necessary to check and adjust the wheel angles at the wheel alignment stand.

We replace the lever as follows:

- Place the car on a level surface, jack it up and remove the wheel;

- Using an 18mm wrench, unscrew the ball joint nut and use a puller to disconnect the support from the steering knuckle;

- first unscrew the front bolt that secures the lever to the subframe;

- then unscrew the two bolts from the bottom at the back;

- we remove the lever, if it is necessary to change both, we similarly dismantle the second one;

- install new parts in place.

As you can see, changing the levers is very simple and quick; almost any driver with minimal metalworking skills can perform such work.

Chassis. Levers, rods, tips, silent blocks, ball Ford. How to choose.

In this article you will learn what you need to know when purchasing about such suspension parts for Ford as levers, rods, silent blocks, ball joints, steering ends and boots. You will learn what types of faults there are, how they manifest themselves and what spare parts are best to buy. There are separate articles about springs and shock absorbers.

For buyers of spare parts, I suggest looking at the table with brands and quality.

All information was obtained based on reviews from hundreds of people and our own experience. Brands Manufacturer's description

| Original spare parts | Original spare parts can be produced both at the Ford plant itself and with the help of original suppliers. |

| Excellent spare parts (original suppliers to the conveyor) | TRW, Delphi, Lemforder, GKN, ZF, FAG, SNR. |

| Good parts (good quality at a good price) | Febi, Swag, Ruville, Ocap, Flennor, Ocap, Meyle, NK, Sasic. |

| A budget option (Mainly Türkiye, China, Belarus) | BSG, Dominant, JP, Group, DP Group, Mapco, Hans Pries, Fenox, Pilenga Patron. |

Figure - front suspension

1. Suspension arm 2. Ball joint 3. Knuckle 4. Hub 5. Shock absorber and spring 6. Stabilizer link 7. Stabilizer bushing 8. Stabilizer 9. Subframe

Ford front control arms. They consist of a ball joint and two silent blocks. It is permissible to change them separately. The service life depends on the operating conditions of the vehicle, 50-150 thousand kilometers.

The silent block lasts an average of 50-150 thousand kilometers, depending on the type of driving and the condition of the roads, it bears the entire load, it serves as a transmission link between suspension units. The first signs of its malfunction are the behavior of the car. The car “throws” along a flat road; when inspecting the suspension, the silent blocks may look torn, with peeling, or with cracks.

Replacing a silent block is a complex operation that requires a special press and mandrels of a certain size, as well as a qualified craftsman who will carry out the entire operation of pressing and pressing silent blocks. Unfortunately, craftsmen are not always able to perform these operations correctly; sometimes the lever is damaged during pressing, sometimes it is pressed in crookedly; in any case, this affects the durability of the replaced unit. When replacing silent blocks, use the services of only well-equipped service stations with reliable technicians.

Figure - Front lever Ford Focus 2

If an additional malfunction of the lever is identified at the service station, for example, a ball joint requires replacement, then it will be cheaper to replace the entire lever assembly. This will be cheaper than replacing the ball joint and silent block separately, and more reliable, since the silent block on the new lever will be installed at the factory.

A ball joint is a ball joint that connects the vehicle's knuckle and the control arm. She is under a lot of stress. Failure is accompanied by a knocking sound; if the part is not replaced in time, the wheel may “fold”, that is, fall on its side.

If you choose a front lever or ball joint yourself, pay attention to the diameter of the ball joint - according to the VIN number, it may not be cut off, if this happens, then you need to scroll through the catalog to the knuckle and look at the note - it says what ball joint the knuckle fits.

Steering rods and ends.

Tie rods and ends transfer the driver's force when turning the steering wheel to the steering knuckles, due to which the car can turn. The steering rods have a thread and a nut with which the so-called toe angle is adjusted. The rod is connected to the rack by a hinge; a corrugated steering rack boot is placed over the joint, which can become damaged over time or wear, and dirt will get inside the joint, which can lead to failure of the steering rod. For prevention, it is necessary to inspect the rack boots at every maintenance.

Drawing - steering rack, manual for auto mechanics

Drawing - steering tip

Steering ends serve to transmit force from the steering rod to the steering knuckle of the car. The boot may tear, crack, or the clamp may fall off. If this happens, then water will get inside the joint, play will form, and the driver will feel play in the steering wheel, and will also hear extraneous sounds. If you need to replace the steering tip, buy only high-quality spare parts, because every time you replace the steering tips, you need to go to the procedure for adjusting the wheel alignment, and this costs approximately 1,500-2,000 rubles. Therefore, it is profitable to buy a good part and replace it for a long time.

Wheel hub. It is an important element of the car design; the car wheel is attached to it on one side, and the suspension on the other side (via a fist or axle). The car hub has a bearing, which can be either removable during repairs or not. Often on Ford cars, when replacing a wheel bearing, the hub assembly with the bearing is replaced, for example, the front hub of a Ford Focus 2 or the rear hub of a Ford Mondeo.

Wheel hub drawing (designated 0482-cuf)

The stabilizer link connects the stabilizer bar and the suspension arm (or shock absorber). The location of the suspension and roll in corners are affected.

Figure - stabilizer strut (diagram)

Picture - stabilizer link

As a conclusion, we can say the following - choose the chassis parts carefully; your safety and the durability of your car directly depend on their quality. Parts that should be replaced in pairs - stabilizer struts and bushings, springs and shock absorbers - change only in pairs.

Replacing a ball joint for Ford Focus 2

The front suspension arm (FSL) is sold in car dealerships assembled with silent blocks and a ball joint, but if the FAL itself is still in good condition and the ball joint is loose, there is no point in changing the entire arm. Changing the support on the RP is not difficult; we perform this work in the following order:

- remove the lever from the car;

- take an electric drill with a 9 mm drill, drill out the rivets approximately halfway, there is no need to drill out the rivets to the end;

- using a chisel and a hammer we knock down the rivets;

- remove the ball joint from the lever;

- We install the new part on bolts and nuts.

Separately, a ball joint can be purchased in auto stores at a price from 650 to 1350 rubles; spare parts are produced by the following companies:

- TRW;

- NK;

- Sidem;

- Fenox;

In the package, along with the part itself, there are three nuts with three bolts securing the support to the lever, as well as a nut securing the support to the steering knuckle. This is very convenient - you don’t need to look for fasteners when replacing a part.

You may also be interested

If play is felt at the same time, the shock absorber may be faulty, but there may be other reasons for the defect in the suspension. To confirm your guess about a faulty shock absorber, you need to inspect the arch above the wheel; if the shock absorber rod is stained with oil, it means the strut is leaking and should be replaced.

To check the play in the steering rods, you need to swing the wheel left and right by hand; to check, the wheel should be hung on a jack or car lift.

Then you need to pull the steering tip and rod with your hand - parts with play need to be replaced. I measured it with a ruler on the second lever, and then tried it on a couple of times on the car - it’s not difficult to just insert it and you can immediately see the mismatch of the holes in the silent block.

Don't kick me, like: I heard it all! And in the end: I do what I want, even if I cut it with a chainsaw. And the ass that rides in it is also mine - if anyone remembers about safety!

Replacing the front silent block of the suspension arm of a Ford Focus 2

To repress the small silent block of the front RP, it is more convenient to use a puller, but if you don’t have one at hand, you can try to repress the s/w using improvised means. To do this, you will need a piece of pipe of the appropriate diameter and a bolt (stud) with a nut and washers.

To make the block move easier from its place, treat it with WD-40 and let it sit for some time (15-20 minutes).

We place a thick wide washer under the piece of pipe, turn the nut with a wrench, and begin to press out the steel.

We take a new sales block and press it into the lever.

The new s/b may be difficult to fit, so you need to be patient and take your time. The sales block is pressed in in the same way as it is pressed out. It is necessary to install the rubber seal so that the rubber flanges protrude from the iron.

To make the salenblock fit into place more easily, it would not be superfluous to treat the outside with silicone grease. The lubricant will not corrode the rubber, but it will be easier to press in the s/b.

Materials and equipment for replacement

Next we will describe the sequence of dismantling the front suspension elements, removing and installing new materials, but this will require certain tools and accessories:

- Set of keys and sockets (including keys with sizes 15, 18, 21);

- Angle grinder with cutting wheel (“Bulgarian”);

- Hammer, chisel;

- Puller (three-jawed);

- Puller for ball joint;

- Bench vice;

- How;

- WD-40 and thread lockers;

- Sandpaper;

- Jack;

- Device for pressing out and pressing in bushings;

- New silent blocks (front, rear).

It is better not to start work without these materials and tools.

Pressing in the rear silent block of a Ford Focus 2

It is difficult to press out the rear silent block on the Focus, and since it has already served its purpose and is not needed, it can be removed in any way. We do this:

- we knock down the outer ring; if you apply force, it should move out of its place;

- We cut off the inner ring with a grinder; here it is important not to cut down the lever itself;

- we clean the seat under the s/b from dirt, sand it, and lubricate it with lithol;

- we heat the inner race of the sales block and cool the lever pin in ice water;

- Until the s/b has cooled down, quickly put it in place, while aligning the marks. The marks on the silent block are two slots in its body; they need to be aligned with the “edge” of the lever (see the figure below);

- Having installed the s/b, we finish it in place with a hammer.

- We put the lever on the car and go to adjust the wheel alignment.

How to diagnose Ford Focus 2 suspension

If a knock appears in the Focus 2 suspension, it is not at all necessary; it occurs due to faulty levers. There may be knocking noises in the chassis of the car:

- shock absorbers;

- steering rods and ends;

- front strut support bearings;

- bushings and stabilizer links.

Diagnostics of a car's chassis usually begins with shock absorbers. All car enthusiasts are well aware that the main function of shock absorbers is to dampen vertical vibrations. If the shock absorber struts are faulty, the car will sway violently up and down when driving on uneven roads and when cornering. We check the serviceability of the shock absorbers very simply - when the car is standing still, we press on one front corner of the body with our hands and immediately release our hands. If the car immediately returns to its original position, the shock absorber struts are working properly. If the body continues to move for some time, it means that the shock absorbers have lost their elasticity (they do not hold), and therefore they need to be replaced.

We check the other side in the same way, and you also need to know that the shock absorbers can knock as the car moves - the knock is clearly audible on an uneven road.

You can check the serviceability of the shock absorber strut in another way - with both hands, grab the wheel in its upper part, and rock it with movements towards you and away from you. If play is felt at the same time, the shock absorber may be faulty, but there may be other reasons for the defect in the suspension. To confirm your guess about a faulty shock absorber, you need to inspect the arch above the wheel; if the shock absorber rod is stained with oil, it means the strut is leaking and should be replaced.

To check the play in the steering rods, you need to swing the wheel left and right by hand; to check, the wheel should be hung on a jack or car lift. Then you need to pull the steering tip and rod with your hand - parts with play need to be replaced.

Play when the wheel rocks up and down may also indicate that the wheel bearing is faulty. The bearing is also checked by hanging the wheel, but in this case the wheel still needs to be rotated with one hand, holding the spring with the other hand (so that it does not create unnecessary vibrations). Increased noise when the wheel spins indicates that the bearings are humming and faulty.

Replacing silent blocks in the front and rear suspension arms

Now it is possible to inspect the silent blocks. If there are ruptures, bulging, peeling, scratches and chips, it is necessary to urgently replace the silent blocks.

It is recommended to inspect the entire upper arm for defective parts. If found, replace it. The lever is installed in the reverse order of removal. Silent blocks of the front lower arm of the rear suspension Install a spacer with the parameters height in mm and width 20 mm between the rear lower suspension arm and the upper spring plate.

After clamping the lever in order to apply pressure to the suspension, you need to use a jack. Remove the bolts securing the front lower arm of the rear suspension to the trailing arm bracket. Unscrew the bolts securing the front arm to the rear suspension cross member bracket. Remove the front lower arm of the rear suspension from the vehicle chassis.

If there are ruptures, one-sided bulging, peeling, scratches and chips, it is necessary to urgently replace the silent blocks.

How to check the condition of the silent blocks of the front arms of a Ford Focus 2

Checking the condition of the Ford Focus 2 should be done on a pit or a lift. The malfunction of the rear silent block can be determined by external inspection - if the rubber is torn, it will be noticeable that the rubber has peeled off from the metal, or the rubber clip has dried out and cracked. The front s/w is more reliable and fails less often, but it also wears out over time. The condition of the front sales block can also be judged by its appearance - if the rubber begins to stick out from the body or has lost elasticity, the block should be changed.

Signs of malfunction and when it is necessary to change silent blocks on a Ford Focus 2

The service life of the hinge depends on the operating conditions of the car, i.e. quality of the road surface. The lower it is, the faster the node will become unusable. The average service life of silent blocks does not exceed 100 thousand kilometers. Under domestic road conditions, this element should be inspected every 50,000 km, but if the machine is used on unpaved roads, diagnostics should be performed even more often.

The main sign of joint wear is a significant decrease in the maneuverability of the car, extraneous noise in the suspension, and a slow response to steering wheel turns.

The first signs of a faulty silent block in a Ford Focus 2 can be noticed quite simply; to do this, you need to perform the following steps:

- Place the car on the inspection pit.

- Clean rubber-metal hinges from dust and dirt.

- Carry out a thorough visual inspection of the metal and rubber parts of the part.

If wear of the metal bushings or damage to the rubber part (ruptures, cracks, etc.) is detected, the unit must be replaced completely.

- The car is raised on a lift, the wheel is removed, and the CV joint nut is unscrewed.

- The drive is removed from the hub unit, the latter is moved to the side as far as possible

- The wheel boot clamp is removed, the boot is pulled from the CV joint to the center of the axle shaft

- The CV joint retaining ring is taken out, the CV joint itself is carefully removed or knocked off the drive

- The wheel boot is being replaced

- The machine is assembled in the reverse order

A guarantee is provided for all types of work on diagnosing and replacing the internal and external CV joint boot of a Ford Focus. Our store offers a wide range of original and non-original spare parts. We guarantee impeccable quality of work, competitive prices and prompt repairs.

To make an appointment at our Moscow service station, just call.