What to do when the steering rack leaks, why it happens and how to fix it. Most modern vehicles use power steering to make it easier to control the car while driving. Designers have developed several types of such devices. They can be:

- Hydraulic.

- Electromechanical.

- Mixed.

After some period of operation of the power steering, the owner may notice that the steering rack has leaked. If such a malfunction appears on your car, you need to fix the problem immediately. If you have the ability to handle metalwork tools and know the structure of this unit, you can fix the malfunction yourself. Before you begin to fix the problem, you should understand the reasons for the leak in this device.

What to do if the steering rack is leaking? We fix it urgently

Few car enthusiasts know what to do if the steering rack is leaking. Let's try to figure out why this happens and how to deal with it. After all, the safety of car operation directly depends on the condition of the steering. You should not hope for chance; as soon as you notice the slightest hint of a malfunction, immediately strive to eliminate it by any possible means. The simplest diagnostics can be carried out independently. Having determined the cause of the malfunction, it can be quickly eliminated without any problems in any garage. For this, no special tool is required. You can make do with what you have on hand.

The steering rack is leaking heavily - what to do?

- For print

The steering rack is leaking heavily - what to do?

- Quote

#1 Post by aulas » Jun 25, 2011 8:54 pm

Re: The steering rack is leaking heavily - what should I do?

- Quote

#2 Post by PyxisNavigator » Jun 25, 2011 09:33 pm

Re: The steering rack is leaking heavily - what should I do?

- Quote

#3 Post by yurkaviktorovich » Jun 25, 2011 09:51 pm

Re: The steering rack is leaking heavily - what should I do?

- Quote

#4 Post by Larry » Jun 25, 2011 10:00 p.m.

Re: The steering rack is leaking heavily - what should I do?

- Quote

#5 Post by PyxisNavigator » Jun 25, 2011 10:43 pm

Re: The steering rack is leaking heavily - what should I do?

- Quote

#6 Post by aulas » Jun 25, 2011 10:53 pm

The steering works as before, it just leaks. The machine, as I understand it, is a spool valve. And they already gutted my spool - it was dripping from the top. But it does not communicate with the anthers. Is there a picture where this machine is connected to the rack? In general, based on these pictures, I can’t put together in my head what I saw on the car, the pictures and how it all functions together.

Added after 8 minutes 34 seconds: PyxisNavigator, I looked at the picture - as I understand it, this is the lower spool seal. The top one has definitely been changed, and a new plastic mask has been installed there. But the bottom one - I'm not sure. I gave it to one weird guy for repairs - in our area he is famous as an excellent craftsman. I can’t understand how the leak can come out there from both sides. Inside the power steering cylinder there is a piston, sticking out in the middle of the chamber, on each side of the chamber there is an oil seal. or I misunderstood something.

Technical features

What to do if the steering rack is leaking?

To answer this question, you need to determine the technical features of this mechanism. Then it will become more clear why this happens. First, you should understand that only hydraulic racks leak. Therefore, we will look at them more carefully. Inside their cases there is a special liquid that facilitates the work of the rack, pushing it in the desired direction. The design includes a torsion bar, spool, tubes, and anthers. It is because of the latter that problems with fluid leaks from the system often occur.

The steering rack is leaking, can I drive?

The steering rack is one of the main components in the design of a car. This is a mechanical unit, the main task of which is to transfer forces from the steering wheel to the steering rods of the wheels.

The steering rack is one of the main components in the design of a car. This is a mechanical unit, the main task of which is to transfer forces from the steering wheel to the steering rods of the wheels.

From time to time it, like other automotive systems, needs to be serviced. But often drivers either do not monitor its serviceability or do not have the opportunity to repair the mechanism, for example, due to lack of money. Many motorists put off the problem until later.

Is it possible to drive with a leaking steering rack? The answer worries many motorists. Moreover, opinions are divided. Some boast about their experience of using a car with the current mechanism for several years, while others confidently insist that this will lead to a number of problems. Removing them will be more expensive.

Of course, the car itself and its most vulnerable places play a big role. But in today’s article we will try to consider as objectively as possible whether the car can be used if the steering rack is leaking.

Reiki diagnostics

You can determine a fluid leak by simply looking under the car after a long period of parking. If you see a puddle of dark oily liquid under the rail, then there is definitely a leak. Look under the hood, inspect all the pipes leading to the rack. If you see a leak, take steps to fix it. In most cases, the liquid supply tubes, as well as their connections, turn out to be clean.

In this case, you cannot do without an overpass. Inspecting the rack from below will help determine damage. Don't delay repairs. Dirt will likely get in through the damage. This will lead to rapid failure of the rack. Replacing it entirely can be expensive.

How to fix the problem

Problems with oil leakage in the power steering should be solved according to the reason that caused them. If the steering rack is faulty, then a technical inspection is carried out. You should not immediately replace it with a new unit using repair kits; many service stations restore its functionality.

The most expensive in terms of costs may be the decommissioning of the power steering pump. Most often, oil seals will need to be replaced, but it can also be a breakdown of the impeller or bearing faults. The main sign of pump failure is the feeling of a tight steering wheel or the appearance of an extraneous hum. If you do not have sufficient experience in diagnosing pump faults, it is better to entrust this procedure to a professional car mechanic.

Oil leakage at joints and lines is accompanied by replacement of the most worn areas. After this, all suspicious areas are tightened again, after which observations are made again for the appearance of leaks on a cold and hot engine.

To avoid having to deal with a hydraulic booster leak, experienced motorists give the following operating recommendations:

- regularly check the level of working fluid in the unit;

- when parked for a long time, the wheels must be aligned, and this is especially true in the winter;

- in order not to damage the pump, it is not recommended to leave the steering wheel in extreme positions for more than 10 seconds;

- periodically inspect the condition of the steering tips, the degree of wear of the boots, as well as the rack itself. Replacing each of these components will cost less than purchasing a complete new rack or amplifier.

As soon as suspicions arise regarding power steering malfunctions, you should not delay repairs. If necessary, it is trusted to specialized service stations.

Debugg

In order to fix the problem, you will have to tinker. Typically, you will have to remove the rack from the vehicle to do this. Let's consider repairing such a rack. Some operations may vary on different models, mainly related to the sizes of fasteners, as well as some fasteners. But, in general, this work is done approximately the same.

But, the anthers may also leak, then the work should be continued:

- Jack up the car and remove the wheels;

- We disconnect the steering tips from the steering knuckle;

- We remove the rack from the car. Usually it is attached to 4-6 nuts, after unscrewing which you need to remove it;

- All that remains is to change the anthers. They are usually secured with retaining rings. Simply remove them using a screwdriver. When installing a new boot, be careful not to damage it.

After this, all that remains is to put the rail in place. Reinstall all parts. Don't forget to bleed the power steering system. This way you can remove any air pockets. If during the work you removed the rack, then it is worth visiting a service station to adjust the wheel alignment angles.

Conclusion

. Reiki leaking is not a rare occurrence. The peculiarities of operation affect this; on some models this is a design flaw. Therefore, drivers have a question about what to do if the steering rack is leaking. The simplest and cheapest option is to buy a rack repair kit and replace damaged parts.

Main functions of sealant

Synthetic conditioner is often added to modern automotive sealants. This substance has an important property. It creates a tiny but durable film on the surface of the metal parts of the power steering system, thereby reducing friction between them. This allows:

- protect elements from premature wear and increase their service life;

- prevent the appearance of microcracks caused by metal fatigue;

- avoid the occurrence of corrosion processes that are detrimental to steering parts.

Manufacturers of these products actively use various substances and components that provide sealants with additional consumer qualities. For this purpose, photopolymers, ceramics, ferrous/non-ferrous metals, etc. are used.

A specially developed and well-chosen sealant composition allows the reconstruction of rubber/plastic seals. This eliminates existing leaks and prevents new damage from occurring. The result is noticeable after 150 km of travel, from the moment the additive is added to the hydraulic fluid.

Diagnosis and elimination of steering rack leaks

As a result of natural wear of the oil seals and the main shaft, steering rack leakage occurs after 120–150 thousand kilometers. Unfortunately, many motorists encounter this problem much earlier. Hence the logical question - is it possible to eliminate the problem that has arisen or is it better to immediately change the unit. Since this malfunction is not uncommon, drivers need to know what to do after it is detected.

Hi-Gear STEER PLUS power steering sealant: features

Hi-Gear STEER PLUS - this additive is very effective in eliminating oil seal leaks, which has been repeatedly proven in practice. It is suitable for protecting elements:

By adding Hi-Gear STEER PLUS sealant to the hydraulic fluid, you can significantly increase the service life of the system and avoid premature failure of the above components. It allows you to reduce power steering noise during operation and helps reduce heating.

Hi-Gear STEER PLUS can be used for preventive purposes. It ensures the elasticity of rubber elements and maintains their shape, preventing the formation of fistulas. This sealant is considered universal because it is suitable for any vehicles equipped with power steering.

The additive is not demanding on hydraulic fluids, their composition and quality. It is quickly pumped throughout the entire system and ensures complete sealing of seals and gaskets from the inside.

Signs and consequences of a malfunction

A problem in the form of leaks is typical for steering racks operating in conjunction with a hydraulic power steering (power steering). Inside the unit body there are 2 oil-filled chambers with pistons that help move the shaft under the influence of pressure created by the pump. To prevent hydraulic fluid from leaking out, the sides of the chamber are sealed with oil seals, inside which the shaft moves. From the outside, the ends of the body are covered with rubber covers (anthers) in the form of accordions; the tie rod ends are passed through them.

When to pay attention to the steering rack and check for leaks:

- oil stains appear on the asphalt where the car is parked;

- the fluid level in the power steering expansion tank gradually decreases;

- the power steering pump makes a hum or other extraneous sounds (depending on the make of the car);

- The steering wheel feels heavy, as if the power steering has stopped helping the driver turn the wheels.

Since the rack body is a solid structure, drips are detected only under its ends, covered with anthers . To see them, just look under the car or into the engine compartment.

The consequences of a hydraulic fluid leak at the first stage are not fatal. After detecting leaks, you can continue driving, but only to a garage or car service center. Further operation of the vehicle without repair is permitted under two conditions:

- The steering wheel does not get “heavier”, and the power steering pump functions properly, without unnecessary noise.

- It is necessary to constantly add fluid to the power steering reservoir.

Important point! A ride like this can end badly. Once parked, a larger amount of oil will leak out of the rack, causing the hydraulic pump to fail after starting the engine. Repairing both units will cost twice as much.

Signs of malfunction and causes of their occurrence

Most often, oil begins to leak from the steering rack as a result of wear of the rubber seals (oil seals, cuffs, gaskets). But the cause of the malfunction may also be damage to the shaft or its corrosion, so for an accurate diagnosis you need to conduct a thorough inspection of the car at a special stand in a car service center.

The mechanism can leak under the influence of such factors:

- constant driving on curbs, potholes and potholes;

- rupture of the rubber covers (boots) covering the ends of the power steering housing - moisture enters the shaft through the holes formed, causing rust on its surface;

- Fixing the steering wheel in the extreme position for too long (more than 5 seconds) while driving;

- use of low-quality hydraulic fluid;

- the presence of foreign impurities in the oil inside the power steering (metal shavings, dirt and debris);

- parking the car for a long time with the wheels turned to the side (especially in the cold season);

- driving with worn steering joints and shaft connections;

- significant overheating of the power steering pump;

- low-quality car components.

How does the steering rack leak?

If the seals or the body of the unit are damaged, the tightness of the entire system is lost, the internal pressure is disrupted, and fluid leaks out from the steering rack.

The following external signs indicate that the rack has begun to leak:

- oil puddles that appear on the road under a car while parked or when the car is stopped under a stop sign;

- lowering the fluid level in the power steering reservoir;

- in the area of the power steering system, the bottom of the car becomes wet, characteristic stains and smudges appear.

How does the car behave?

An experienced motorist notices steering rack leakage not only by external signs, but also by how the car behaves while driving.

If there is a leak, you can observe the following phenomena:

- The power steering pump starts to hum;

- turning the steering wheel requires more force than usual;

- while driving you hear a knocking or vibration of the steering wheel;

- decreased vehicle controllability;

- When the wheels are stationary, the steering wheel moves freely.

Causes of leaks

There are several common reasons why the steering rack leaks:

- The main thing is driving with torn rubber covers. Moisture penetrates through the holes and gets onto the shaft, causing corrosion. The rusty surface becomes rough and begins to rub the seal lip. The slightest gap is enough for oil to escape under pressure.

- Failure to comply with the rules for handling the hydraulic booster. Holding the steering wheel in the extreme position for a long time leads to an increase in pressure inside the chambers and squeezing of the seals. If the driver constantly repeats the mistake, oil leaks from the rack will inevitably appear.

- Adding unsuitable hydraulic fluid or other composition that destroys the rubber of the seals.

- Long-term operation without replacing fluid that accumulates debris and small chips. In this case, the oil seal leaks due to abrasion.

- Critical wear of the hinge joints of the steering tips with the shaft. Due to the dangling rod, air and moisture penetrate under the boot, causing corrosion. The process then proceeds according to the scenario described in the first paragraph.

Options for solving the problem

Before drawing any conclusions, it is necessary to get to the insides of the unit and study the degree of wear of the parts. What to do when oil leaks from the rack are detected:

- Place the car on the inspection ditch, secure it with the handbrake and remove the front wheels, placing reliable blocks.

- Using a puller, press the steering rod ball pins out of the steering knuckle eyes. First unscrew the hinge nuts.

- Remove all elements that interfere with dismantling the rail. On most passenger cars, you have to remove the battery, air filter and absorber tank.

- Turn the steering wheel all the way to lock it with a mechanical anti-theft lock. Disassemble the steering shaft to rack mount.

- Empty the power steering system and disconnect the fluid supply pipes from the unit.

- Unscrew the steering rack and remove it from the car. On some models it is attached to the body, on others - to the subframe.

Note. An experienced technician is able to perform repairs without removing the unit from the machine. But if you tackle the issue yourself, it is better to remove the rail. This makes it easier to disassemble and replace worn parts.

To get to the seals, you should pull off the rubber covers secured with retaining rings or metal clamps. After this, the reasons why the steering rack leaked become visible. What action to take depends on the technical condition of the internals:

- You are lucky if there are no traces of rust on the shaft, only streaks are visible. It is enough to replace the seals, both parts.

- The rusty shaft will have to be dismantled. Small pockets of corrosion are removed by grooving and grinding on a machine, after which repair seals are installed, the inner diameter of which is selected according to the new shaft size.

- It is better to replace a shaft that is too rusty with a new one, it will be more reliable and cheaper in the long run.

- A complete replacement of the rack is carried out after identifying critical wear of the gears, manifested by knocking while driving. An accurate diagnosis is made after disassembling the unit.

To remove the shaft, you need to unscrew the protective covers (if equipped) and the gear adjustment washer, having previously marked its position. Then both shafts are removed - the steering drive and the rack and pinion. Lastly, the polymer bushings and oil seals are carefully knocked out (held in place by retaining rings). Upon completion, the body is thoroughly washed.

Advice. Before choosing a repair method, show the removed unit to a master auto mechanic. He will determine the degree of wear of the shaft and tell you how best to proceed in your situation.

If you decide to do all the repair work yourself, then it is better to choose option No. 3 - simply change the shaft and seals. Original spare parts will last at least 100 thousand km, provided that damaged rubber covers are changed in a timely manner.

The option with grooving and grinding is less reliable - the work is performed by people and not always with high quality . After careless processing, the surface of the shaft will remain rough and will immediately begin to wear out the newly installed oil seals. The rail can leak again literally after 20-40 thousand km.

Installing the unit and assembling the car is done in the reverse order. Pay special attention to filling the system with hydraulic fluid, which should also be changed. There should be no air pockets left in it. After checking the functionality, be sure to visit a service station to adjust the camber angles of the front wheels.

Instructions for replacing the mechanism

As mentioned, if the unit is critically damaged, its urgent replacement is necessary. To do this, you will need several tools and consumables, including WD-40, bricks or boards, wrenches of various diameters (depending on the car model), and a hammer.

Follow the steps below to perform the procedure yourself:

- With the car on a flat surface, apply the handbrake and place wheel chocks (bricks, boards) under the rear wheels.

- With the steering wheel straight, loosen the wheel nuts and remove the wheels, gradually gaining access to the steering system.

- Remove the absorber, then unscrew the tips. They can be knocked out with a hammer if you intend to replace the tips along with the rail.

- Unscrew the fastening nuts on the clamp that hold the mechanism. Now remove the clamp and pull the unit out from the passenger side (this is more convenient).

- Install the new unit, then perform the previous four steps in mirror order. Congratulations! You have completed the task!

The procedure is simple even for a “green” motorist. You can do it yourself without resorting to the services of car services.

Finally

If you are faced with regular leaks, think about whether it is worth aggravating the situation and not taking action. Pay attention to every component and assembly of your car. This is the only way it will last for many years.

What problems do you have with your car? And how often do you have to service the steering rack? Write your answers in the comments and share useful information with your friends! See you again!

Causes of steering rack oil leaks and elimination of consequences

What to do when the steering rack leaks, why it happens and how to fix it. Most modern vehicles use power steering to make it easier to control the car while driving. Designers have developed several types of such devices. They can be:

- Hydraulic.

- Electromechanical.

- Mixed.

After some period of operation of the power steering, the owner may notice that the steering rack has leaked. If such a malfunction appears on your car, you need to fix the problem immediately. If you have the ability to handle metalwork tools and know the structure of this unit, you can fix the malfunction yourself. Before you begin to fix the problem, you should understand the reasons for the leak in this device.

Violation of the tightness of hoses and tubes

This reason is one of the most common, but it is also the easiest to eliminate. And repair work in this case is not too expensive. First you need to inspect all connections, seals, tubes and lines for strength and tightness. Places that are in doubt should be dismantled and re-strung. It is quite possible to perform such operations yourself, in a garage, and save on repair costs.

Power steering high pressure hose

Why does the steering rack leak?

The operating principle of the power steering rack is based on the use of working fluid pressure, which drives the mechanism for turning the front wheels.

The hydraulic power steering pump is driven by the operating power unit of the vehicle. At the same time, it supplies oil under high pressure to the distributor, which is installed in the steering rack housing. The distributor spool device distributes the fluid flow in the desired direction to help turn the front wheels. There can be several reasons for a leak, the most common are:

- oil seal leak in the steering rack;

- significant wear of the rack;

- air entering the system;

- filling with the “wrong” working fluid;

- pump overheating.

This is not the entire list of signs of malfunction for the appearance of leaks in the system. Some drivers use various additives, which, according to their manufacturers, should improve the properties of the oil, but this is not always true. Do not allow dirt to get into the oil tank and miss the deadline for replacing the working fluid.

Driving style, and especially the condition of the road surface, also greatly influence the service life of the parts of this mechanism. If a vehicle often hits curbs with its front wheels or moves along bumpy roads, then as a result of such operation, oil leaks from the joints of the unit.

The wear of the oil seal or rack can be accelerated by the presence of tears in the protective boot. Dust gets into the cracks, which, in combination with oil, becomes an abrasive, and it accelerates the wear of the rubbing surfaces of the rack mechanism, after which oil flows in the mechanism of this unit.

Steering racks: faults and restoration

Is there an alternative to costly replacement of a unit due to leaks or knocking noises? We understand the main faults and original techniques for repairing steering mechanisms.

Not so long ago, automakers allowed mechanisms to be repaired, sold original spare parts and developed restoration technologies. However, the shop was later closed, citing a security threat. Although no fundamental changes were made to the design and manufacturing technology of steering racks. Fortunately, there is still an alternative to costly replacement of a unit due to leaks or knocking. With a qualified approach, slats can be successfully repaired without any safety hazard.

A SPOK IN THE WHEELS

There are two types of oil seals in the steering gear. Power cuffs seal the rail - they are designed to work under high pressure: up to 150–200 bar. The steering shaft seal is a regular oil seal that can withstand pressure ten times less.

There are two types of oil seals in the steering gear. Power cuffs seal the rail - they are designed to work under high pressure: up to 150–200 bar. The steering shaft seal is a regular oil seal that can withstand pressure ten times less.

Around 2005, almost all automakers dramatically changed their policy - steering racks were declared beyond repair. The sale of original spare parts and access to information about the technology for restoring components was closed. However, this did not put an end to the renovation industry. For most cars, steering gears are made by large third-party manufacturers, such as ZF. Therefore, original spare parts and technical information remain available. In addition, no one canceled the unification. Often, new models from one automaker are equipped with spare parts from other cars from the early 2000s. In addition, there are manufacturers specializing in the same oil seals and bushings. Using their catalogs, it is not difficult to select a spare part of the required type and size - nominal or repair. So for now you can fix almost any rail.

Detection of rack leaks

To identify such a malfunction you will not need expensive special equipment, computer diagnostics or other tricks. The occurrence of such a problem can be heard or seen with your own eyes. A previously inaudible sound that appears when the power steering pump is operating, oil stains under the car indicate problems with this device.

An excessively loud sound from a running pump may indicate a breakdown in this unit or insufficient oil level. Fluid stains under the car indicate leaks in the power steering system. Experts also note the fact that the use of counterfeit spare parts during repairs also accelerates the wear of parts with the appearance of leaks.

Power steering sealant Servolenkungsoil Verlust Stop: properties

This product is very popular among domestic and foreign motorists. It has passed the necessary technical tests and received high marks from experts in the automotive industry.

By using Servolenkungsoil Verlust Stop, you reduce the hardness of the elastomer seals, making them less susceptible to deformation and wear. The system better keeps hydraulic fluid in a closed circuit, preventing it from leaking. Additional additives included in Servolenkungsoil Verlust Stop give the sealant the following properties:

- the oil service life increases (the presence of antioxidants affects);

- ensures cleanliness of the power steering system;

- inconsistency is reduced;

- steering qualities are improved.

Servolenkungsoil Verlust Stop sealant prevents oil loss, which reduces vehicle maintenance costs. In addition, it allows you to avoid additional costs for power steering repairs.

How to fix a leaking steering rack

If a leak is found in the steering rack, it needs to be repaired. You should not put off solving the problem until a later date; this will only make the problem worse. If you have a tool kit, you can fix the leak yourself. The process of repairing the steering rack will be slightly different for different car models, but the procedure is approximately the same. The algorithm for performing the work will be something like this:

- the front wheels are placed in a straight-line position, while the steering wheel is securely fixed;

- in the engine compartment, you should remove all parts that will interfere with the dismantling of the product being repaired;

- using available means, the removed mechanism is cleaned from dust and all kinds of contaminants;

- Next, all fasteners are treated with a lubricant such as WD-40 or a similar liquid. After a short period of time, the fasteners can be removed;

- It is necessary to drain the oil from the tank, then remove the supply pipes. To avoid damaging the edges of the nuts, use a special wrench that completely covers the nut;

- Before removing the cardan from the mechanism, its position is marked with marks. This will allow you to correctly install it in its place in the future;

- After this, remove the oil seal along with the ball bearing.

Operating principle of hydraulic rack control system

Comfortable driving and, most importantly, safety on the road depend on the normal operation of this unit. It must be said that the type of hydraulic steering, or more precisely with hydraulic booster, is by far the most common. The main structural elements of a hydraulic steering rack are a circuit through which the working fluid circulates, a gear shaft, a support sleeve, a special spool mechanism, a block with valves located on the steering shaft and a double-acting piston.

In general, the principle of operation is as follows. The system design includes a pump that is driven by the car engine. A rail is connected to it. When you turn the steering wheel using a torsion bar, access to the left or right cylinder opens, where oil flows under high pressure, which ensures that the car turns without any effort on the part of the driver.

Of course, the design is somewhat bulky, but even despite this fact, it is used in the vast majority of budget cars and almost all SUVs and trucks, providing reliability and ease of operation.

Additive Suprotek GUR

To restore performance and extend the life of the power steering

Types, composition and principle of action

Today, products from many foreign manufacturers are on sale. There are 2 main types of sealants used everywhere:

- the first - to eliminate leaks in the sealing elements;

- the second is to improve the performance of the power steering system.

Standard sealants (type 1) contain components that promote controlled swelling of rubber parts. It is necessary to understand that these compounds, passing along with hydraulic fluid through the system, lead to swelling of the rubber over the entire surface, and not just in places of deformation. However, this also has a positive effect: rubber parts regain their elasticity, which increases their service life.

Sealants of the second type incorporate the above-mentioned metal conditioners. They have a protective effect on power steering components, and also reduce heating and improve the performance of the vehicle control system.

The use of sealant leads to other positive effects:

- eliminates unpleasant noise during power steering operation;

- drying out and cracking of rubber/neoprene sealing components is not allowed;

- the seals/gaskets return to their original size.

Causes of oil leakage from the rack

Despite the reliable design of this unit, it remains operational for about 120, maximum 150 thousand km, and often much less. And then the driver observes a low oil level, characteristic oil stains on the asphalt, or even hears extraneous noise when the pump is running. All this indicates a malfunction of the hydraulic system.

Experts call the following the most common steering rack malfunctions:

- air entering the system;

- significant wear of structural parts;

- oil seal leak, which is the most common;

- pump overheating;

- use of low-quality working fluid.

It should be noted that this is not the entire list of reasons why the rack leaks. In addition to oil seals, vulnerable parts of the design of this unit are sealing rings, sliding bushings - the so-called “back plates”, bearings and support bushings, and hydraulic barrier rings. It is these structural parts that are the most vulnerable because they are constantly exposed to high loads, which are actually the first cause of wear.

There are cases of dirt entering the system through a tank or a torn protective boot. After all, dust and dirt that get into the oil turn into a kind of abrasive for structural parts, which significantly accelerates the wear of rubbing surfaces. Many drivers miss the deadline for changing the working fluid, others use low-quality fluids from unknown manufacturers.

That’s why the question arises: the rack is leaking, what should I do?! The first desire of many drivers, especially those with little driving experience, knowing about the complexity of the design and the possible consequences of a malfunction, is to replace the entire unit. Yes, indeed, this measure will give a 100% result and confidence that such a malfunction will not happen again in the near foreseeable future. However, there is a big problem - the price of the issue. A new unit is expensive. It should be understood that the main parts of its design are highly reliable and have an increased service life, so they can serve for a long time.

The conclusion suggests itself. If a leak appears, it means restoration or repair is necessary, and certainly without the need to replace the entire unit.

What to do if oil leaks from the power steering

Most modern cars are equipped by manufacturers with a system to facilitate steering - the so-called power steering (power steering). This unit significantly reduces the effort required by the driver to perform a steering maneuver.

The road surface is characterized by the presence of various holes and irregularities. The power steering is designed to effectively dampen the shocks and vibrations that arise due to this. It also directly affects the directional stability of the vehicle, and it feels more confident on the road. The appearance of a hum or other extraneous noise in the steering area indicates that the power steering or one of its components has begun to lose lubrication. Failure to correct this problem promptly will lead to costly repairs later.

Restoration and repair procedure

There are several ways that a car owner can take in order to eliminate a power steering rack leak. The first, a complete replacement, has already been discussed. Experts question the appropriateness of this action. Although, everyone is free to spend their funds at their own discretion. You can, probably, thinking like this, and change the car itself for a new one. The next option is to drive with a leaking device and constantly replenish the working fluid to the required level. It’s a fairly common phenomenon among car enthusiasts when, for some reason, they don’t get around to making repairs. But in vain, because wasted time only further aggravates the problem.

The third option is a method that can be recommended immediately after detection of digging from under this node. We are talking about the use of special sealants.

Elimination of power steering steering rack leaks without repair work. Sealants

It is clear that over time, the most vulnerable elements of the power steering - oil seals, under the influence of high pressures, lose their properties, in particular elasticity. This leads to deformations and violations of the tightness of the system. It is impossible to replace the oil seal without removing and disassembling the unit itself. In a sense, an alternative to these complex measures that require time and money can be additives in the form of liquid agents added to working fluids.

Currently, two types of such funds are common.

The first is sealants, directly for eliminating leaks through oil seals and other seals. They contain components that penetrate rubber seals. They restore elasticity to the seals and cause a certain degree of swelling of these elements. The second type is special sealants that contain additional additives, the purpose of which is to improve the operation of the hydraulic system. Their peculiarity is the fact that, along with restoring the properties of sealing parts, they reduce friction, temperature and generally reduce the risk of malfunctions. Such products owe their additional qualities to special conditioners and other substances whose action is aimed at restoring seals and protecting rubbing parts.

Among other things, the use of sealants ensures cleaning of the channels through which the hydraulic fluid moves, the efficiency of the cleaning abilities of ATF increases, the mismatch between the servo mechanism and the steering drive is eliminated and, as a result, the service life of parts is significantly increased, the serviceability of the working fluid is extended, and the costs of repair work are reduced. After filling and the start of the sealant, leaks, as a rule, stop after 150 kilometers. A single fill is enough for 20-30 thousand kilometers. The figures indicated are not accurate and may vary depending on the specific sealant produced by a particular manufacturer.

Causes of oil loss in power steering

Before you think about how to solve the problem with lubricant leakage, you need to understand why this happens. Repair work will depend on this to eliminate oil leakage from the power steering. Experts count 3 main reasons:

- Steering rack leaking.

- Leaking power steering pump.

- Poor tightness of tubes and hoses connections.

Constantly squeezing oil out of the power steering reservoir leads to a decrease in its level, down to a critical level. Before performing an inspection, find the tank and see at what level the working fluid is in it. It is used in a special type and resembles the same lubricant that is poured into automatic transmissions. The oil itself also loses its properties during operation - it burns out and becomes contaminated, not to mention possible leaks. Experienced car mechanics advise making a complete replacement every 70-100 thousand kilometers traveled by the car.

Repair

The obvious option for eliminating leaks if sealants do not help is restorative repair. Currently, the car market offers special repair kits that can be used to eliminate leaks from the device.

These include seals and other small parts included in the design that are most often the cause of the problem. Such repair kits can be selected for any make of car. They are relatively inexpensive. With sets of sealing parts, they usually purchase sets of boots with clamps and special lubricant, in order to replace everything at once, without leaving behind old seals and dust protection, which can tear at any time.

Repair procedure

When the causes of oil leakage are identified, it is better to entrust their elimination to a specialist and carry out restoration work in a service station.

Repairs are carried out in the following order.

- The rack is dismantled from the car, for which it is hung on a lift, then the engine protection is removed, the heat-insulating plate is dismantled, the fasteners are unscrewed, it is removed from the mounts and pulled out. It should be noted that experts advise removing the device directly together with the steering rods. This allows for complete tightness when installing new boots.

- unscrewing from steering rods;

- unscrewing the bottom plug of the gear wheel;

- removing the retaining ring and knocking out the shaft;

- dismantling the lower oil seal;

- removing the pin that locks the upper oil seal;

- removing the retaining ring;

- pulling out the rail itself;

- removing the oil seal and bushing;

- removing the oil seal, plug, and then removing the spring and the clamping mechanism.

- Replacement of seals and, if necessary, damaged parts. If there is rust on the shaft, it is replaced with a new one. Experts do not recommend messing with grooving and grinding the shaft.

- Assembling the unit and installing it on the car is carried out in the reverse order.

Depending on the specific car model, the repair procedure may differ slightly, but the principle remains the same and in most cases, for high-quality repairs, disassembling the hydraulic unit is indispensable.

Steering rack leakage - causes and consequences

As a rule, the steering rack begins to leak at 150,000 km. This is due to wear on the main shaft and oil seals. As for new cars, the racks can leak much earlier. The question arises: is it worth repairing the rack or purchasing a new one?

About the signs of malfunction and their consequences

Steering rack leakage is typical for a unit with power steering. Inside the rack there are two chambers with pistons, where oil under pressure enters, thereby the piston, under the influence of oil pressure, helps move the shaft in the required direction. The presence of oil seals on the sides of the rack allows you to maintain pressure. The outer end of the steering rack housing is covered by a boot on both sides, covering the tips.

How can you tell if your steering rack has started to leak?

- Fresh oil drops appeared under the car.

- The fluid level in the power steering reservoir decreases.

- When you turn the steering wheel, the power steering pump makes a hum or rustle.

- It becomes harder to turn the steering wheel.

Since the rack body is a solid structure, leaks can be detected in the area of the ends. It may be necessary to remove the steering tip boot.

Consequences of driving with a current rack

- The power steering pump will gradually wear out and heat up due to insufficient oil level.

- Frequent addition of oil to the tank will be required.

- If all the oil leaks out during a long period of parking, the power steering pump will immediately fail.

About the causes of leaks

Today there are 5 known reasons:

- Operating a vehicle with torn steering rack boots. Because of this, dirt and water gradually gets onto the rack shaft, causing corrosion. The rough surface of the rust begins to wear away the lip of the oil seal, opening up access for oil leakage.

- Incorrect operation in the form of holding the steering wheel for a long time in the extreme position, which causes an increase in pressure in the rack, where the oil tends to squeeze out the oil seal.

- Adding oil of a different classification or mismatch of oil, leading to destruction of rubber products.

- Untimely oil change in the power steering system. During operation, dirt and chips accumulate, which also destroys the seals.

- Activation of steering rods, the looseness of which leads to water and dirt entering through the boot onto the shaft. The further process is similar to the first point.

The rack can be repaired, but the cost of restoration will directly depend on how timely the fault was detected.

How to prevent such troubles?

The steering rack, like all components and assemblies, must be monitored. Once a year you need to put the car on a lift and check the hinge joints for functionality, the boots for integrity, and the oil in the power steering system for freshness.

What breaks in the steering rack, why does it start to leak?

No car can do without a steering rack.

It is the rack that connects the steering wheel to the steering wheels. Moreover, we are talking not only about the front wheels, but sometimes about the rear ones. On modern cars with fully controlled chassis, some semblance of a steering rack is also present on the rear subframe. On our YouTube channel you can watch a video review about steering racks.

You can select and buy a steering rack for your car in our used spare parts catalog.

The rack and pinion steering mechanism is very simple. As such, the rack is located inside the housing. Both ends of the rack are connected to the steering knuckles of the suspension. The rack teeth mesh with the input shaft, which is an extension of the steering shaft.

To ensure that the driver does not have to exert great physical force when turning the steering wheel, the rack is equipped with an auxiliary reinforcing mechanism.

Rack with hydraulic booster

The classic version of power steering is hydraulic. The pump creates hydraulic fluid pressure and directs it to the spool valve, which is located on the input shaft. The distribution of hydraulic fluid occurs at the moment of rotation of the input shaft, i.e. when turning the steering wheel. The distributed fluid under high pressure is directed through tubes into the steering rack housing.

Inside the rack housing there is a piston installed on the shaft. Essentially, this is a metal ring or washer that divides the rack body into left and right parts. Or, in other words, on two hydraulic cylinders located along the steering rack.

There is a hydraulic spool valve located on the input shaft. When the steering wheel is turned, it opens the supply of hydraulic oil to one or another hydraulic cylinder. That is, a certain force is applied to the steering rack, which adds up to the physical force applied by the driver to the steering wheel. Thanks to this, the steering wheels of the car turn with much less effort.

The power steering pump is connected by a belt to the crankshaft, and therefore its performance depends on the engine speed. In order to get rid of this dependence, the pump is equipped with a flow control valve (pressure flow valve), due to which the hydraulic cylinders receive the same flow of hydraulic fluid.

An additional spool valve in the power steering pump even limits the amount of oil supplied to the distributor. This way, when the car is moving, the influence of the power steering is reduced to prevent the steering wheel from turning too easily.

More precise control of the steering gain, depending on the speed of movement, is carried out using a valve with electromagnetic, that is, computer-controlled.

There are times when the power steering pump stops pumping, i.e. does not create pressure. A stuck pressure flow valve may be to blame for this. The power steering pump can be returned to service by removing and cleaning it.

Rack with electro-hydraulic booster

A rack with an electro-hydraulic booster is essentially designed in a similar way. The only difference is that the power steering pump is driven by an electric motor rather than an attachment belt. With this design, the electronics can vary the degree of steering assistance from maximum when maneuvering in a parking lot to minimum when driving on the highway.

Electrically assisted rack

The electric power steering mechanism has no hydraulics at all. The increase in force when turning the steering wheel is carried out by an electric motor. The electric motor applies force directly to the steering shaft through a separate gearbox.

What breaks in the steering rack?

Most often, breakdowns and malfunctions of the steering rack with hydraulic cylinders come down to oil leaks. Oil leaks occur through oil seals, or as they are also called - power seals - hydraulic cylinders that seal the shaft (the rack itself). The oil pressure in the hydraulic cylinders is high, reaching 150-200 bar.

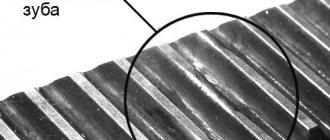

Moreover, leakage occurs not so much due to oil pressure, but due to wear of the inner circumference of the oil seal. The fact is that due to corrosion of the rack shaft, roughness appears on its surface, which lifts the oil seal. He, in turn, gives a leak.

Corrosion on the surface of the rack shaft is primarily caused by moisture entering through a torn or incorrectly installed boot. The anthers must be secured with special clamps designed for this purpose, which allow the steering rod to rotate.

With severe corrosive wear of the shaft, the shaft support bushings wear out. In the resulting gap, the shaft begins to knock.

In the input shaft and distributor housings, the oil pressure is lower, so conventional oil seals are used there. However, they can also leak. Again, due to corrosion, which gets to them along the steering shaft.

But due to metal powder or shavings in the hydraulic oil, wear may occur on the surface of the input shaft housing and distributor. Most often this applies to those steering racks where the distributor is fixed with fluoroplastic bushings.

Another part of the steering rack that is subject to wear is the block in its adjustment mechanism. The block presses the input shaft gear against the rack teeth. The pressing force is adjusted at the factory, calibrated by a spring. Those. If there is play between the gear and the rack, it cannot be eliminated by tightening the adjusting nut. You will have to disassemble this assembly and, most likely, wear of the cracker will be discovered.

In particularly advanced cases, you may encounter wear on the gear and rack teeth. In this case, for economic reasons, repairs are not practical. It is better and cheaper to buy a used steering rack.

Features of wear of electric power steering racks

The electric power steering rack also suffers from corrosion. But in this case it will not flow, because... there's nothing to leak there. It immediately begins to knock due to severe wear of the guide support bushings. Worst of all, corrosion can take much longer to develop and can cause serious damage to the shaft, making it impossible to grind it down to repair size.

By creating racks with an electric pump or electric motor, engineers wanted to simplify their design. But in practice, the same electric motors turned out to be not very durable; both the electric motor itself and the bearings of its shaft fail. The electric pump can turn off while driving, which causes serious problems in driving. The electronics may simply be faulty: for example, the pump may not turn off when the engine is stopped, as a result of which the electric motor quickly drains the battery.