Problems with clutch 2114. Help urgently PLEASE

Car VAZ 2114. 2006. Mileage 2,800 km. On a warm car, when you press the clutch pedal with your foot, you can feel a crunching sound in the pedal itself. At the same time, at the very end of its stroke, the pedal does not move so smoothly. The service center initially said that the cable was defective, but they replaced it and the problem remained. They began to look further - they said the basket was skewed and the repair was no longer under warranty, but at their own expense. Please tell me what this could really be and if this is really a distortion, then why should I repair it at my own expense, because this is a factory defect. Thank you in advance

Try changing the cable again, let them check whether the sealing rubber is in straight, whether it goes on its own without bending. If it doesn’t change, you need to remove the clutch. Use an imported one as a consolation.

According to the VAZ warranty, the clutch is not subject to warranty repair. So you will have to change the clutch at your own expense and everything will be fine

I agree there is no warranty on the clutch. My 2115 has the same crunch! I went to the service center and complained about a crunching noise: they changed the clutch assembly (they installed Kraft), the crunching didn’t go away (I paid the money), first they completely removed the cable and missed it - to no avail, then replaced it with a new one - to no avail. crunchy! I'll go again! They say the release valve needs to be changed, but I don’t understand something - the release valve is part of the clutch assembly that was replaced for me. or I'm wrong!

Front-wheel drive cars of the new family from Togliatti have lost the classic design of the hydraulic release fork drive. The designers explain this modernization by the greater reliability of the cable mechanisms. However, they also require periodic adjustment, which is confirmed, in particular, by the experience of operating Lada Samara cars.

What should the clutch pressure plate be like:

On the pressure plate basket, you need to check the riveted connections, which, as on the driven disk, must be identical to each other. If they are done carefully, it means that the product was assembled in a factory, and not underground, not done in a garage.

The pressure plate housing must be made by stamping. The front surface of the pressure disk must exclude the presence of even the slightest microcracks or irregularities.

If the appearance of the discs matches those that we described above, then this means that you are looking at products made in accordance with all standards, using high-tech equipment.

Since there are numerous VAZ clutch manufacturers on the market, domestic and foreign, buyers are faced with the question of choice. What to choose - LUK, VALEO, KRAFT, SACHS, HOLA or other manufacturers? Locally produced VIS brand clutches are installed directly at the plant in Tolyatti.

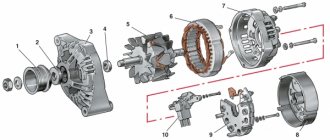

Briefly about the design of a friction clutch and its purpose

Any self-respecting motorist will study the design of the unit before adjusting the clutch on a VAZ 2114. This will help you approach the issue wisely and avoid mistakes.

The mechanical drive design is simple and reliable. Compared to hydraulics, the cable requires minimal maintenance, and changing it is not labor-intensive. The mechanical drive consists of the following elements:

- Adjustable sheathed cable.

- Control pedal.

- Clutch release fork lever.

- Bracket for fastening the end of the cable sheath.

- Brake and clutch pedal bracket.

The mechanism serves to transmit force from the pedal to the release fork, which, in turn, removes the friction disc from the flywheel. Using a cable drive avoids major problems such as fluid leaks and periodic bleeding of air from the clutch control system. The weakest link in this chain is the cable, the quality of which at times leaves much to be desired. Therefore, replacing a cable on a Samara is a fairly common occurrence.

Useful video

You can get more information from the video below:

We're sorry, but the requests coming from your IP address appear to be automated. For this reason, we are forced to temporarily block access to the site.

To continue, please enter the characters from the image in the input field and click "Submit".

Cookies are disabled in your browser

. We will not be able to remember you and correctly identify you in the future. To enable cookies, follow the tips on this page.

When is it necessary to adjust the Lada Samara clutch drive?

As practice shows, the culprits of clutch failures are most often the car owners themselves. A sharp start with “slipping”, as well as prolonged holding of the pedal in a depressed state, negatively affects the performance of the mechanism. The presence of noise or vibration when shifting gears indicates a problem in the transmission line. Below are a few signs that may require adjustment:

- Loss of power due to “slipping”, i.e. unreliable connection between the disk and the flywheel.

- Difficulty changing gears.

- Changing the travel distance of the clutch pedal (the norm is from 125 to 135 mm ).

- Jerking or sticking when pressing the pedal.

Motorists who know which clutch to choose for the Lada 2114 will most likely install it together with a cable. Replacing any element of the clutch should end with adjusting the drive, as well as changing the pedal stroke.

The pedal stroke is measured with a ruler, which is pressed against the floor. The distance between the lower and upper points of the pedal position should be within 125-135 mm. The maximum permissible value is 160 mm. If the pedal stroke goes beyond these parameters, then we can talk about wear of the friction linings of the driven disk.

How do you know if your clutch needs repair or replacement?

Signs that the clutch mechanism is worn out or faulty may include the following malfunctions:

- great effort when changing gears;

- extraneous noises that occur when the clutch is depressed;

- slippage;

- the clutch is not engaged at full strength.

If at least one of these signs is observed, you should conduct a diagnostic inspection of the mechanism or send the car for service. If repair turns out to be impossible, you will have to think about completely replacing the clutch with a new one.

When inspecting a new clutch kit, the closest attention should be paid to the basket. Even if one of its petals is uneven or crooked, you should immediately refuse the purchase.

Let's take action: how to adjust the clutch on a VAZ 2114 car yourself?

The essence of the operation is to force a change in the length of the cable “jacket”, due to which the clutch pedal stroke changes. To complete the process there is no need for high qualifications - a little free time and desire are enough.

Experts have developed a good algorithm for how to adjust the clutch cable on a VAZ 2114; it consists of the following points:

- Open the engine compartment and disconnect the negative battery.

- For ease of operation, disconnect the hose from the air filter and remove it.

- Using two 17" wrenches, rotate the tip nuts and set the desired pedal stroke.

- Press the clutch pedal several times and measure again the distance from the lower to the upper point of the pedal position.

- Tighten the nuts and install the air filter in its original place.

During setup, you should pay attention to the condition of the cable. If there are abrasions on the “shirt” and the steel fibers are partially torn, then you will have to replace the Lada Samara clutch drive cable. Often there is corrosion on the tip, making it difficult for the nuts to rotate. WD-40 will work to solve the problem. It would be a good idea to inspect the pedal bracket bushings and replace them if they are severely worn.

The clutch design itself on the VAZ-2114 (Samara-2) car has been changed and differs from what was installed on the “classic” models of the VAZ family. The main changes affected the system of adjustment, control, and movement of the clutch fork. And, if previously they were hydraulic, now its movement is driven by the clutch cable.

Step-by-step procedure for tensioning the clutch cable on a VAZ-2114

In order to change the length of the clutch cable, we only need a wrench.

1. First of all, open the hood and look for the nuts on the gearbox housing located at the very end of the adjustment unit. Two 17mm bolts.

The clutch cable is marked with a red marker.

2. Next, loosen the locking nut, and then change the position of the adjusting nut, tightening or unscrewing it to the required length.

The nuts will unscrew easily with any pressure.

3. When the nut is screwed on, the clutch pedal will rise, increasing the length of its distance, and if it is unscrewed, the distance to the floor will decrease, pressing the pedal closer to the floor.

The arrow marks the nut for fixing.

There is no doubt that such work is much easier to carry out in the company of an assistant.

4. Upon completion of all adjustment work, the locking nut is tightened as close to the adjusting nut as possible.

When carrying out such procedures, make sure that the clutch cable itself is intact, that there is no damage or scuffing on its body and shell, and that it moves freely inside the elements supporting it. If something like this is discovered, then it is best to replace the cable with a new one, since the wear of the supported one will only increase, and it is impossible to talk about the reliability of the work performed.

Checking work

After you have completed this work, you need to check the correctness of the work performed.

- First, measure the travel of the clutch pedal.

- With the engine turned off, depress the clutch pedal several times and return it to its place.

- Next, we take a new measurement and clarify the received readings.

- If they have not changed compared to the first measurements, then the work has been completed, correctly, and the first stage of verification can be considered completed.

- And if they differ from the first indicators, it means that the locking nut was not tightened tightly, and the adjustment process must be carried out again.

There is one rule among car enthusiasts! A properly adjusted clutch should begin to engage approximately halfway through the pedal stroke.

The following test can definitively indicate the serviceability and correctly adjusted clutch:

- The car must be placed on a flat surface, the handbrake must be turned on, and the engine must be running.

- Next, we turn on the gear and try to start moving.

- If at this moment, when the clutch pedal is not pressed, the car stalls, this means that the adjustment was made correctly.

- And if this does not happen, the car is running in gear with the clutch pedal not pressed, then this will indicate clutch slipping, which will need adjustment.

The principle of clutch adjustment

If, after a preliminary check, you have determined that the clutch cable needs adjustment (that is, tightening - approx.), then do not be alarmed, since the process of such work is not complicated and will not require any additional effort.

Clutch cable tension is adjusted by tightening it under the hood

Such a process consists of simply changing the length of the cable and its sheath from the adjustment unit, due to which its indicators can change both to the smallest and greatest extent.

As you might have guessed, if the length of the cable is reduced, then the pedal stroke will be less, the same applies to increasing the stroke, all that remains is to achieve those cherished pedal stroke indicators of 12.5 centimeters.