Hello, dear friends! We continue the topic of consumables and important car parts. And what details are not important there, you ask? Yes, indeed, all elements are closely interconnected with each other. Including our hero today, which is the throttle valve. In the photo you can see what this element looks like.

This is what I propose to talk about today. Let's look at the design diagram of this unit, why this regulator is needed, what a damper position sensor is, and so on. There will be a lot of information, so make yourself comfortable. We begin.

Device Features

Gasoline and oil in the engine are the same norm as the presence of a throttle unit in the internal combustion engine (injector and carburetor). But what is it?

The throttle valve, or simply the throttle valve, is a component of the intake system of automobile engines that run on gasoline and are equipped with a fuel injection system into the engine. The purpose of the device is to regulate the amount of supplied air (oxygen) that enters the power unit to create an air-fuel mixture that is optimal in terms of characteristics.

There is a DZ between the car’s intake manifold and the air filter itself to ensure the supply of exceptionally clean air in the required quantity.

In simple terms, this is an air valve. When the throttle is open, the pressure inside the intake system is equal to atmospheric pressure. If the assembly is closed, then the angle changes and a vacuum is created.

Although the device is not as simple as it might seem. Indeed, in addition to the main function, the DZ is part of the engine cooling system. The housing provides for channels through which coolant circulates (coolant, in case anyone has forgotten). Plus there is a pair of pipes, one of which connects to the crankcase ventilation, and the second is combined with a gasoline vapor recovery system.

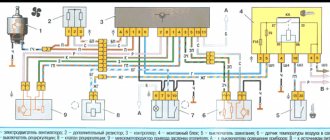

The valve looks like a round plate that can rotate and change position around its axis a full 90 degrees. That is, to open and close completely. Inside the housing there is a drive, an IAC and a remote control position sensor, also known as a device called a potentiometer. All together this forms our favorite throttle unit.

And now I’ll simplify everything as much as possible so that you understand why this adjustment is needed and why the engine is equipped with a remote control. When you press the gas pedal, a sensor (we'll talk about them later) comes into play, opens the throttle and lets a certain amount of air into the engine to create the desired mixture of fuel and oxygen. That is, as you understand, the remote control is needed to gain speed and increase engine speed.

Remote control drives

Cars like VAZ 2114, 2110 usually have a mechanical drive, while many Nissan, Chevrolet, Toyota, Audi, Skoda, Opel and Renault cars are equipped with an electric drive.

Therefore, before you start repairing your Lancer 9 or an old Zhiguli car, and read the signs of damper malfunctions, determine where the element is located and what drive the remote control has.

Mechanical drive

Mechanical types of such devices are used mainly on old and budget cars. The drive is connected to the gas pedal and directly to the damper using a special metal cable. It is the cable that directly affects the operation and the efficiency of the entire throttle assembly depends on its integrity.

All components of the remote control are assembled into a block consisting of a housing, a remote control, a position sensor for this very damper and an XX regulator.

The design is extremely simple, as is the principle of operation, maintenance and adjustment. You can troubleshoot problems yourself and you don’t need any special training for this.

Electric drive type

A modern car is equipped with an electronically controlled electric drive. This allows you to achieve the desired torque parameters, regardless of the engine operating mode.

An important advantage is that the operation of the electric drive ensures optimal opening and closing of the air supply when pressing the gas pedal. Therefore, low fuel consumption is achieved, and engine operation complies with environmental and safety standards.

Compared to a mechanical drive, what is the difference between them? Actually significant:

- there is no mechanical connection between the gas pedal and the remote control;

- The idle speed is adjusted by shifting the remote control.

There is no hard connection; the electronics are responsible for engine operation, air supply and creation of the air-fuel mixture. From the point of view of the operational and technical characteristics of the machine, I consider this an excellent development. The only problem is that such a drive is more complicated and it is problematic to repair it with your own hands.

Although in fact the remote control rarely breaks down. Therefore, it usually requires replacing the sensor, replacing the entire throttle assembly, or simple cleaning. But I’ll tell you about repairs and maintenance separately.

Cleaning the throttle valve in a Mitsubishi Lancer 9

How to clean the throttle valve

After driving a little, I realized that in hot weather the gas starts to bite. Firstly, when you press, you feel a “step” and secondly, when you release the pedal, the speed does not drop to normal. Well, I’m thinking, yeah, right now I’ll change the throttle cable, maybe it’s just hairy, and that’s all. It’s useful to have a look and the cable is generally normal. After that I thought that I probably needed to clean the entire throttle body, lubricate it and everything would be fine. But that was not the case, after re-reading the Internet, I realized that this is a disease in 9 Lancers, in particular the 1.3 and 1.6 engines; there is no such problem on two-room cars.

Actually, what is the problem itself: due to the design features, the axis on which the brass patch is located is subject to play. All due to the lack of a locking ring. The axle moves back and forth, and the result is the deterioration of the patch itself and the damper body. + For myself, I also realized that it is necessary to wash the damper more often, because the dirt on it is an abrasive that helps to erase the damper.

In general, like everyone else, I washed the damper and saw the cracks:

Here it is, new one is quite expensive

The photo quality is not very good, but the cracks are clearly visible

After washing, because of the cracks, the idle speed increases, more air is sucked in, the effect of a slightly open damper (before washing, dirt serves as a sealant)

Molybdenum grease is visible on the sides

In principle, there are several solutions, for example, buying a new one or salvaging one. Or another solution, I found people on the Internet who suggest the following method:

— A brand new nickel (flap) is being manufactured. — We place 2 ball bearings on the axle (closed type bearing with lubricant inside). - A groove is machined in the axle (to install both the support washer and the locking ring). - The throttle valve is disassembled and cleaned - We grind the throttle valve and expand the size. — The throttle valve is coated with a special lubricant. — The throttle valve is assembled in reverse order

They ask for their services from 5000 rubles. And they even seem to offer a guarantee; they gave me 5 years and 150,000 km. The system is simple, I give away the old one and immediately get a modified damper in return. I don’t know, I decided to fall for it, one of these days they will deliver it to me, I’ll install it, and write back. In theory, this should work and the disease will be cured...

Remote control position sensor

Another important component of the assembly, which causes most of the problems. No, in practice, the DZ is quite reliable and durable; it does not have to be serviced every few hundred kilometers.

To maintain low and high speeds, provide cooling and other functions that are assigned to the shoulders of the assembly, efficient operation of the sensor is necessary.

This regulator is called a potentiometer. When you press on the gas or accelerator pedal, the position of our damper changes, as does the voltage supplied to the car controller. When the position is closed, the voltage is 0.7V. The maximum open position supplies 4V. Based on this data, the sensor regulates the supply of the air-fuel mixture.

If the position sensor fails, then the car will not know the exact current position of the damper. This entails the following malfunctions:

- in all engine operating modes the speed fluctuates;

- when idling, the speed increases and reaches levels higher than the required ones;

- if you disengage the gear while driving, when you go into neutral, the engine may stall;

- in some cases, the check lamp on the dashboard lights up, that is, Check.

To check the status of the sensor, you will need a multimeter. Turn on the ignition, place the probes on connectors C and B. When the position of the damper changes, the voltage parameters on the multimeter should change.

A little about the renovation

See also:

Towbar for Tiguan: which one to choose, installation nuances

Some install 4 dampers at once, others come up with original solutions for their carburetor, just to improve the performance of the engine. In any case, installing additional dampers affects not only the cost of the work, but also subsequent possible negative consequences.

Maybe I’m just not a fan of modifications and tuning, so I’m skeptical about this kind of hobby. I like to put the parking brake down and take off. Well, at least the horsepower under the hood allows you to do this.

But I also know this. If you rape your own car, it will soon refuse you. A particularly common mistake is ignoring throttle valve malfunctions. By the way, it is often called a nickel. I can’t say what exactly this is connected with, but our people are such inventors. Why call a spade a spade if you can invent something original?!

A few words about the renovation.

- For easier and more correct repairs, it is best to remove the unit and gain full access to it. How to remove? Usually you just need to dismantle the assembly from under the engine compartment, unscrewing one screw after another, disconnect the cable, and so on. Each tube must be disconnected and checked for integrity. After all, incorrect operation may be due to the fact that some components, for example, a pipe, are broken or cracked. The fault does not always lie with the remote control or its sensor;

- After dismantling it is easier to understand what the problem is. Let me remind you that the remote control rarely breaks down. The main malfunctions are contamination or damage to pipes, wiring, etc. Therefore, check for serviceability and clean the device;

- The main sufferer of the unit is the remote sensing sensor. The most basic problems consist of a break in the supply wiring or wear of the resistive layer of the tracks intended for the slider to move. Such faults can be easily detected by disassembling the sensor;

- The electronic remote sensing system is much more complex. Here you cannot simply replace or adjust the cable. This requires so-called adaptation. This is the return of the remote control to the initial operating parameters after a failure in the electronic component. It usually appears due to short circuits, sudden voltage surges in the on-board network, replacement and dismantling of the electronic control unit, etc.

Resetting and resetting on modern cars is performed using special software. That is, the machine is supposed to be connected to a computer or laptop. There are many problems and features depending on the specific car model.

Therefore, if you have no experience in adaptation, do not have software and the slightest understanding of making changes to a car using a laptop, then it is better not to take on electronics. Go to the nearest car service center and let the experts do their job. Setting up and calibrating remote sensing is a delicate matter.

FakeHeader

Comments 33

How to check the throttle valve of a VAZ 2114

but I didn’t break down the prices

For prices you should write to TITUS, he restores them, I bought them a long time ago, I won’t tell you now)

then we'll wait for his comment

Here comes his comment!)

but I didn’t break down the prices

3600 rubles cost to repair the 4G18 throttle, or exchange it for a restored one.

There have been no cases of failure of our chokes over 5 years of operation with about 5,500 units restored; or rather, there was exactly 1 case of our error during operation - the owner’s unit was replaced free of charge.

Each of our units comes with a guarantee (a sign of the guarantee is the engraving of the Amadeus logo on the body of the unit or on the damper itself) and information support.

Everything else - with a description of the methodology, reviews, etc. - is in my car’s journal.

If you need help, please contact