Cars admin26.02.2020

Today, the installation of gas equipment is very relevant. There are many companies on the market that produce gas equipment for vehicles. The leading position in this area is occupied by the Italian company Lovato. She has been developing equipment for many years; she began her development of alternative fuels in the late 50s of the last century. The Lovato company produces gas equipment that is used all over the world; every year 5 million motorists buy components from this particular company.

Operation of the gearbox in different generations of gas equipment

When examining in detail the principles of the operation of gas equipment, many people have a question about how liquefied gas (methane or propane), under high pressure, turns into a vaporous gas-air mixture that can be injected into the engine. In different generations of HBO, the process can be organized in completely different ways. Thus, in the most innovative injection systems of the 5th and 6th generations, this issue is not relevant, since direct-flow injection occurs from the liquid phase. However, the bulk of gas equipment on the market belong to the 1st-4th generation, and a reducer is used to convert gas into fuel in such systems. The normal functioning of the vehicle directly depends on its adjustment and quality of work.

Gas equipment Lovato

Most domestic motorists choose Lovato brand LPG, as it belongs to the fourth generation. Also, this equipment is recommended to be installed by car service technicians, since installation does not require special knowledge, because the Lovato LPG setup is carried out using a simplified system.

It is important that the manufacturer provides a warranty on its components for a period of 3 years. This time is quite enough for a mileage of up to 300 thousand kilometers. This figure is one of the highest among 4th generation HBO. According to average data, this is enough for 5 years. When compared with similar companies in this field, their figure is much lower.

However, despite the high results, the driver should remember that it is necessary to promptly diagnose the 4th generation Lovato HBO. Because this will help not only to identify malfunctions, but to a greater extent the safety of operating the vehicle depends on it. Many masters claim that it is periodically necessary to adjust the control unit on the Lovato HBO.

Important! The Lovato company is a monobrand, since it produces all its equipment independently. When purchasing gas equipment from this company, consumers can be sure that all the parts included in the kit are made in Italy.

Lovato HBO must be installed only in specialized car repair shops, since poor installation can lead to malfunction and the system will not be able to function normally. If the installation is completed correctly, the system notifies you with a “Chicken Engin” signal.

Many drivers note that after switching to gas, engine power is greatly reduced. However, this problem is obvious, because during combustion gas has a temperature higher than liquid fuel. But this problem was solved with 4th generation equipment - at the moment, gas enters the engine system in the same way as gasoline. Therefore, the power reduction is only about 2%. Thus, the power of a vehicle is influenced by the quality of the fuel it fills.

You might be interested >> Installation instructions for 4th generation digital gas equipment

The design and key operating principle of the gas reducer

A gas reducer is a mechanism that consists of a number of chambers connected in series, separated by valves. The main thing is the unloading valve at the outlet, which also plays the role of a kind of injection dispenser. This valve can be either electromagnetic or mechanical, and also have additional protection against possible popping.

To properly adjust the LPG gearbox in the event of a malfunction, it is also necessary to have a repair kit, which includes seals, gaskets and rubber wear rings. The gearbox, regardless of generation, always has an evaporative element and an idle channel.

Principle of operation

Liquefied propane or methane passing through the line enters the first stage of the reducer and evaporates with expansion, simultaneously reducing the pressure in the system. Depending on what type the gearbox belongs to, the generation and the manufacturer, there may be one or several stages. Examples include the Lavato LPG gas reducer or Tomasetto LPG reducers, which are aimed at carburetor cars with a two-stage evaporation system, and at the same time are distinguished by a reasonable price, ease of further maintenance and the availability of repair kits at affordable prices.

The exhaust valve passes gas ready for use through a special line into the manifold, then the gas is mixed with air to a certain proportion and enters the engine. During evaporation, the gas expands; if propane is compressed to 16 atmospheres, and methane to 200, then the pressure drops to 1.8 atmospheres. This kind of process, according to thermodynamics, occurs with the rapid absorption of heat and energy from the external environment.

Functionally, the reducer is little different from a standard refrigerator, and therefore the gas reducer freezes during operation. The mechanism may freeze to such a stage that it begins to become covered with ice or frost and becomes unsuitable for further operation, since due to the swollen valve, the installation allows liquefied gas to pass further (in this case, a repair kit and new adjustment of the LPG reducer will be needed). To prevent this phenomenon, the device is connected to the cooling system and installed closer to the heating elements of the car. The temperature of the LPG reducer is the most important indicator; it is precisely because of the peculiarities of the gearbox operation that in cold weather it is impossible to start the engine on gas; first it needs to be warmed up on gasoline, and only then switch to methane or propane.

Each gearbox has its own performance, and if the wrong choice is made, the gas supply may be insufficient, the gearbox will work more intensely and cool down more. Ultimately, this can lead to the shutdown of the gas installation and the need for subsequent repairs.

Features of installation and operation

Many car owners choose gas because it is much cheaper than gasoline or diesel fuel. In addition, gas fuel creates a better mixture when interacting with air, this is due to the fact that it has good chemical properties. As a result, it turns out that it burns better, and at the same time does not emit a large chemical residue, and also does not leave traces of soot.

The standard set includes the following components:

- a gearbox on which a valve is already installed;

- ramps;

- gas filter;

- temperature sensor;

- switch;

- wiring;

- detailed instructions;

- warranty card.

Due to the fact that Lovato’s products belong to the 4th generation of LPG, the principle of its operation is slightly different from its predecessors. Thus, gas fuel is supplied to the injectors while taking into account the readings of various sensors displayed on the electronic unit from which the system is controlled. Read more about Lovato gas injectors.

The system operates as follows:

- the gas is in a cylinder, which is installed either in the trunk or in the place of the spare tire;

- after the car warms up, the LPG system issues a notification to the panel that you can switch to gas;

- when switching to the use of gas fuel, gasoline stops flowing into the main transport systems;

- gas begins to flow through the open dampers into the gearbox, then into the injectors, and only then into the combustion system.

It is important that the entire process occurs in stages, and everything is distributed as much as possible, which ensures the normal functionality of the car.

Attention! The gas in the cylinder is under high pressure, and it must be reduced to supply it to the engine system. A reducer is used to reduce pressure.

The Lovato 4th generation HBO connection diagram consists of several parts. The first stage consists of installing the cylinder and gas lines; this process does not take much time and is also not very complicated. Most often, the gas cylinder is installed in the luggage compartment, but the filling hole can be installed in the bumper or near the gas tank. The lines themselves are laid under the bottom of the car.

The second stage is the most difficult - you need to install the fittings. Most often they are installed in close proximity to the injectors that supply gasoline fuel. If the work is not performed efficiently, this can lead to Lovato gas equipment malfunctioning, and new equipment installation work will be the way to eliminate this problem. At the next stage, it is necessary to install a gas reducer, which will monitor the decrease in pressure level in the system.

Important! The Lovato gearbox differs from all analogues in that it is practical and easy to use. In addition, most companies that specialize in the production of these products strive to achieve the same indicators and the same level of quality as the Lovato company.

After the gearbox is installed, all remaining components are connected to the system. At the final stage, the electronic unit is configured. This is a rather complicated process, and if done incorrectly, Lovato's LPG will not switch to gas.

You might be interested >> Features of gas equipment Polytron

Some drivers are wondering how to adjust Lovato's HBO. It is worth noting that adjusting the Lovato LPG is a rather complex process that can only be performed by a highly qualified technician. For this reason, it is not recommended to perform this procedure yourself, since not only the correct operation of the gas system, but also the safety of operation depends on this.

Classification of different types of gas reducers

Device components may vary depending on generation. The methods of locking the unloading chamber and the adjustment methods also vary. In earlier generations there was a vacuum mechanical reducer; the membrane responded to the vacuum level in the intake manifold, to which there was an additional tube. When the engine started, the carburetor began to suck in fuel, and the falling pressure opened a vacuum valve to the gas flow. If the engine stops, the pressure returns to normal and blocks the flow of propane. To adjust the LPG reducer, simply rotate the gas supply metering screw (greed screw). In addition, gas users were attracted by the level of quality of the device, the availability and low cost of the repair kit.

Second generation

Starting from the second generation, the gas installation began to include an electronic gas reducer. The 2nd generation GBO reducer has another important feature - an exhaust installation solenoid valve, controlled from a simple power unit. The electronic gearbox ensures precise engagement and reacts automatically when the motor starts. In worn out and outdated carburetor engines, there is often not even enough vacuum for the membrane to operate. The electronic valve supplies gas based on the results obtained autonomously by the oxygen sensor (lambda probe).

Third and fourth generation

This material talks about the evolution of automobile gas reducers produced by the Lovato company, but most of the following is also true for other brands represented on the Russian market.

Purpose of the gas reducer

Heating and evaporation

The first task of any automotive propane reducer, regardless of generations of gas equipment, is to transfer gas from a liquid state to a gaseous state and maintain the gas temperature in a stable state during engine operation.

The second task is to ensure gas pressure at the outlet of the reducer, in accordance with the current fuel demand of the car engine. The tasks, in general, are simple, but very important for the proper operation of the entire gas system of any generation of gas equipment.

The result of this task depends not only on the quality of the Lovato gearbox, but also on the competent and honest fulfillment by the LPG installer of several conditions:

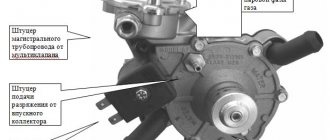

- It is important to connect to the engine cooling system so that the circulation of coolant through the gearbox is effective in all operating modes of the internal combustion engine, and at the same time, this connection should not affect the operation of the heater or other vehicle devices. Simply put, the gas reducer should not cool down during operation, and all devices that worked in the car before and after the installation of gas equipment should work without changes.

- The maximum power of the Lovato gearbox must match or exceed the engine power (in the case of 1st and 2nd generation systems, installing a gearbox larger than the required power is not recommended). This is important not only for efficient gas evaporation, but also for the ability of the reducer to maintain a stable differential pressure, which is extremely important for Lovato 4th generation LPG systems.

If the vehicle is equipped with a gearbox of less power than the required power, this will not allow the Lovato gas system to operate normally and safely under high engine load conditions (there may be interruptions in operation, expressed in jerks, or a noticeable loss of power compared to gasoline, and In some cases, during sudden acceleration, a gas smell may appear).

Gas purification

For long and trouble-free operation of any Lovato gas reducer, the absence of dirt and deposits on the working mechanical parts of the system is of great importance. To achieve this, most gearboxes are equipped with Lovato gas purification filters at the inlet. It is very important to change the filter elements in a timely manner (in accordance with the service book), since their contamination directly affects the performance (power) of the gearbox.

Vacuum reducer Lovato (1st generation of gas equipment)

This is a completely mechanical device, created and intended only for carburetor cars. The Lovato vacuum reducer has a built-in mechanical “Car Safety” function (when the engine is turned off, the gas supply is shut off regardless of the position of the ignition key).

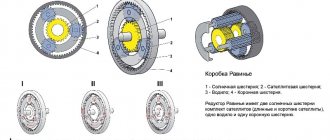

The reducer consists of 2 stages: the first serves to evaporate the gas and reduce the pressure to 0.45 - 0.65 bar, the second chamber is connected to the mixer, depending on the pressure in the intake manifold of the car, it increases or decreases the amount of gas supplied by the Lovato vacuum reducer into the engine. In the product line, Lovato's first generation gearbox is called RGV and is available in two versions for engines up to 122 hp. (RGV90) and up to 160 hp. (RGV140).

Advantages and disadvantages

The advantages of 2nd generation HBO include:

- Can be used in both fuel injection and carburetor engines.

- The simplicity of the design has been preserved.

- Easy to install and assemble.

- Easy to adjust.

- Possibility of regular engine start on a gas mixture at positive temperatures.

But there are also disadvantages that were inherent in 1st generation HBO:

- The main one is the lack of feedback from the engine. This leads to inefficient operation of the vehicle in some of its operating modes. And also to premature failure of engine elements, with incorrect adjustments of the mixture quality or ignition timing.

- Increased fuel consumption.

- Preserving the possibility of gas backfires in the intake manifold.

- It is not possible to ensure emissions in accordance with Euro-3 and higher standards.

- Delayed reaction to pressing the accelerator pedal.

All these factors gave impetus to the emergence of a new generation - HBO 3.

Electronic gearbox Lovato (2nd generation LPG)

The 2nd generation Lovato electronic gearbox was created with the advent of injection cars on the market, since the vacuum one could not provide comfortable switching from gasoline to gas and back on this type of car.

Its design is almost identical to the vacuum reducer, but the vacuum membrane, which provides the “Car Safety” function, is removed from it. Instead, an electric valve is installed, controlled by a switch. The latter is obliged to de-energize (close) the valve if the engine is not running. Lovato's 2nd generation electronic gearbox in the Lovato product line is called RGE and is available in three versions for engines up to 122 hp. (RGE90), 160 hp (RGE140) and up to 300 hp. (RGE220).

Gas reducer Lovato for injection system (4th generation LPG)

The advent of gas injection systems required the creation of a fundamentally different gearbox (see the section on the principle of operation of gas equipment). The main purpose remained heating and evaporation of the gas coming from the cylinder, as well as maintaining a stable differential pressure at the outlet of the reducer.

By differential pressure we mean the difference between the pressure at the output of the gearbox and the pressure in the intake manifold of the car engine. And when the driver presses the accelerator pedal, the gas pressure at the outlet of the gearbox will increase in proportion to the increase in pressure in the intake manifold, due to constant feedback from the manifold to the working diaphragm of the gearbox.

Injection gearboxes are usually single-stage. But, despite the apparent simplification of the design, choosing a good and suitable gas reducer for a given vehicle and gas electronics can be quite a difficult task.

The reducer must reliably heat the gas before supplying it to the gas injectors and provide stable pressure, as discussed above. The 4th generation Lovato gas reducer must efficiently handle some transitional moments during engine operation. For example, for many gearboxes, a very difficult mode is exiting the cut-off mode (engine braking); in this mode, many gearboxes strongly increase the differential pressure, which often leads to the engine trying to stall. The second critical point is a sharp increase in the load on the engine - many gearboxes, due to insufficient performance, first drop pressure, and only then begin to equalize it.

Thanks to a well-thought-out design, all Lovato gearboxes are practically free of the above-mentioned disadvantages. And minor pressure deviations are compensated electronically, because In the software of the electronic unit of the Lovato gas system, the company's engineers take into account all the behavioral features of their gearboxes.

At the time of writing, Lovato produces 3 models of 4th generation propane injection gearboxes:

- RGJ 3.2.L - for cars of low and medium power, allowing the Lovato gas system to operate confidently on engines up to 150 horsepower;

- RGJ UHP - for medium and high power vehicles, allows you to install Lovato LPG on engines up to 350 horsepower;

- RGJ 3.2.L-DD - for kits intended for cars with direct gasoline injection. With this reducer, the outlet pressure changes in a different ratio (increasingly) in relation to the pressure in the intake manifold, which allows it to provide more comfortable conditions for the Lovato gas control unit (ECU) when working with direct injection.

All Lovato propane reducers are designed and manufactured in strict accordance with European standards ECE 67R-01 and certified in Russia in accordance with the Technical Regulations of the Customs Union (TR CU 018/2011).

Methane reducers differ from their propane counterparts by the presence of an additional stage to reduce the pressure from 200 Bar to 10 Bar. For methane gearboxes, heating is less important, since methane enters the gearbox in a gaseous state. Lovato methane reducers have high performance and reliability, which is confirmed by the frequent choice of these components by automakers when installing a gas system on a conveyor (OEM projects).

Lovato methane injection gearboxes

At the time of writing, Lovato produces 2 models of methane injection gearboxes:

- RMJ 3.2.S - for cars of low and medium power up to 190 horsepower;

- RMJ 3.2.HP – for medium and high power vehicles, allows the system to confidently operate on engines up to 272 horsepower.

All Lovato methane injection gearboxes are manufactured in accordance with the rules of ECE R110, ARAI, INMETRO and comply with ISO 15500 - 9 standards, certified in Russia in accordance with the Technical Regulations of the Customs Union (TR CU 018/2011). Both gearbox models are equipped with an electric shut-off valve with an extended inlet filter. They are equipped with a pressure gauge with the ability to connect a level sensor with an indication of the gas reserve with output to the fuel type switch.

Lovato traditional methane reducers

Lovato produces 3 automotive gas reducers for traditional systems:

- RME 090 – for cars of low and medium power, designed for engines up to 122 horsepower;

- RME 140 – for cars up to 190 horsepower;

- RME 180 – high power gearbox for engines up to 245 horsepower.

All RME model gearboxes are a three-stage gearbox for carburetor (gas supply through a mixer) systems using compressed natural gas. Production is carried out in accordance with ECE R110, ARAI and INMETRO regulations, complies with ISO 15500 standards. Gearboxes are certified in Russia in accordance with the Technical Regulations of the Customs Union (TR CU 018/2011). The gearboxes are equipped with a solenoid valve located between the second and third stages, and a mixture quality adjusting screw.

Safety of Lovato gas reducers

Traditionally, Lovato pays the closest attention to safety issues, and the gearboxes, of course, meet all the necessary safety standards for gas equipment. For example, Lovato injection gearboxes - in addition to the mandatory solenoid valve that shuts off the gas flow if the car does not use gas fuel or the engine is not running - are equipped with a separate additional safety valve. The safety valve is activated (reduces the pressure inside the reducer) if the pressure inside the reducer exceeds the norm (approximately 4.5-5 Bar). The presence of a safety valve guarantees the integrity of the reducer and also prevents rupture of the gas hose at the output of the reducer. This is just one example of why we think Lovato is ahead of the curve when it comes to HBO safety.

Authentication of Lovato gearboxes

Today, Lovato gearboxes have deservedly gained immense popularity among both gas equipment installers and ordinary users. The natural reaction of the market was the appearance of counterfeits. While their level is quite low - they are not difficult to distinguish visually, but Lovato is already taking active measures to protect its products. Each gearbox is marked with a special code, and for each product it is possible to determine not only when the part was produced, but also for which country and which supplier sold it.

The authenticity of Lovato gearboxes of any generation can be verified

Beware of fakes!

In gas-cylinder equipment, the gearbox is given the greatest importance among all components. Its task: to provide the driver with the opportunity to reduce the pressure coming from the cylinder. Repair, namely adjustment, on a car gearbox involves working with one or two regulators: this is the main difference.

In principle, a gas reducer is a primitive pressure regulator designed to independently maintain a standard pressure value based on fuel consumption. As practice shows, the device supports it with minor fluctuations. The pressure decreases slightly with increasing gas flow. This is not a very significant point, but requires attention.

Installation of Lovato products

The LPG installation process from Lovato is divided into the following components. The cylinder and gas lines are installed. This is the simplest stage, because the cylinder is usually placed in the trunk, and the lines are located under the bottom of the car. The filling hole can be installed both in the bumper area and in the immediate vicinity of the gasoline “refueler”.

At the second stage, holes for the fittings are drilled. This is one of the most difficult stages in installing gas equipment. Poor quality work will negatively affect both fuel consumption and the performance of the system as a whole. The fittings are attached in close proximity to the gasoline injector.

Fittings

The nozzle angle should provide the least resistance to the gas as it enters the cylinder. The fittings must be cut at the same distance and at the same angle.

At the third stage, a gas reducer is installed. As mentioned above, it serves to reduce the pressure of the gas mixture when it is supplied to the engine. In addition, it is designed to maintain the stability of this pressure. The process occurs automatically, since the gearbox is controlled through the computer, which in turn is guided by readings from sensors. It is worth noting that during operation of the reducer, fluctuations in gas pressure occur, but they are not significant. Thus, the gas reducer is of greatest importance among all components of the gas equipment system.

The gas reducer from Lovato is universal, simple and reliable. He is a role model for other manufacturers who strive to achieve this level of quality.

The gas reducer is installed in the inside of the engine compartment. After fastening, the gas line is connected to it, then the gas filter, valves and injector ramps are installed.

Lovato gearbox

The ramps are installed taking into account that the length of the hoses from the gas valves to the fittings is minimal.

At the final stage, the electrical component is adjusted. This is a complex process on which the very performance of the system depends. Some of the wires go into the cabin to the ECU, and some go to the engine injectors.

The control unit must be connected to the gasoline fuel system control unit, as well as temperature and pressure sensors. The amount of gas mixture supplied to the combustion chamber of the engine depends on their operation.

The installation process is labor-intensive and requires high qualifications. Doing the work yourself is strictly not recommended. This is a question not only of engine performance, but also of the safety of the car owner.

Manufacturer's offer

The Lovato gearbox design is characterized by versatility, simplicity and reliability. For Turkish artisanal producers, the manufacturer is a role model. Almost all generations of Turkish gearboxes have adopted the design of a flattened “drum”, at the ends of which there are two stamped covers. belongs to a family-type enterprise that was founded in the post-war period in conditions of acute fuel shortages. In modern conditions, Lovato is one of the leaders in the global gas cylinder system market. Repair, namely adjustment, of Lovato analogues depends on the following factors:

- generation of mechanism,

- number of regulators,

- fuel system.

Manufacturer product range:

- Lovato propane vacuum reducer for 90 and 140 kW. The device is intended for 1st generation LPG systems on carburetor-type cars with a power of up to 123 horsepower. The reducer is intended exclusively for conversion to propane.

- Lovato electronic propane reducer 90, 140, 170 kW. The device is intended for 1st, 2nd and 3rd generation HBO systems on cars of injection, mono-injection and carburetor types with engine power up to 123 horsepower. The reducer is designed for propane-butane.

- Lovato methane gearbox. The 2nd generation device is used for converting cars and buses to methane fuel.

Gear settings

Repair, namely adjustment, of the gearbox requires orientation in its settings. Propane analogues usually have two regulators, but there are also one. Methane type gearboxes are almost always characterized by one regulator. In their management, these settings are the most problematic.

Repair for the gas generation of gearboxes with one unique setting involves manipulation exclusively with the pressure of the transmitted gas.Lovato gearbox Vehicle owners with particular enthusiasm prefer to “tighten up” the pressure themselves. Having set the only correct and, what is very important, true pressure value, the fuel reducer alone will make it possible to limit gas consumption at operating power due to an element called the greed screw.

Repair has some difficulties when the screw is in the “closed” position. To maintain idle speed in this case, it is necessary to increase the pressure, the process of which involves:

- Checking the gearbox before tuning, namely, whether the “greed screw” is open.

- After the previous stage has been completed, adjustment work can begin.

Lovato gearbox design

Adjustment process

The Lovato gas regulator itself is presented in the form of a screw compressing a spring. In order to install it, you should consider:

- when tightening, the gas supply will be reduced by the reducer,

- when unscrewing, it will grow.

Sometimes screws are found with left-hand threads, most often they are right-hand threads. This moment depends on the designer’s imagination of the manufacturer. To simplify this task slightly, it is necessary to take into account: with any rotation it is characterized by the above characteristics of changes in gas pressure.

Adjusting the idle speed on vehicles is explained by the degree of engine shaking. His calm work indicates that the gearbox repair was carried out competently and efficiently.

So, start the engine and hold the throttle open. Then we smoothly release it and slow down until the power unit stalls. At the same time, do not forget the condition: the gas reducer of the car engine must continue to work. For “dummies”, an explanation: the engine will not stall completely if you start twisting the throttle valve in an arbitrary direction. If worse motor performance is observed, you will have to change the direction of rotation of the gearbox and restore its stable operation.

gear lovato

Setting up HBO yourself. Setting up the gas reducer

Description

: Instructions on how to quickly and correctly configure LPG on your car. Normal gas consumption for Lanos... Highway 7.5l, city 11-11.5l. Mixed mode 10l. Regular spark plugs A17DVRM clearance 0.9. If you liked the video, don’t forget to subscribe to the channel, this will help us make more interesting videos for you. Thank you for watching!

gas reducer repair kit replacement

One of the most important elements of gas equipment is the reducer, which is designed to monitor the decrease in gas pressure levels.

The Lovato gas reducer has an advantage over its analogues in that it is the most practical to operate and simple in design.

Many companies producing gas equipment components strive to achieve the same level of quality as Lovato.

Let's sum it up...

From all of the above, we can conclude that when it comes to the question of which gas reducer is better: vacuum or electronic, the second one will be more preferable. It allows for fine tuning through two levels of adjustment. Correct tuning of the electronic gearbox allows you to achieve good performance both at idle and under load. It is also worth mentioning one important and at the same time useful feature of the electronic gearbox - independent transition from gasoline to gas. The electronics will do this for you, so you no longer need to press anything in the cabin, everything will happen automatically.

For skeptics who will immediately begin to argue that it is expensive and there are no spare parts for electronic gearboxes - I will answer, the cost of “vacuum units” is practically no different from the price of electronic gearboxes, and today you can find any spare parts, if not here, then abroad .

Review of Lovato gearbox models

Lovato is the oldest company specializing in the production of LPG. This is a family-owned Italian company that has adopted the principle of “lean production”, when every detail is made with a minimum of losses, with the highest quality and eliminates the appearance of defects. That is why the price of a Lovato LPG reducer may be lower than its analogues, but higher in terms of quality characteristics. The diagnostic cable connectors to the Lovato gas equipment are universal; repair kits for the Lovato gas reducer can be purchased in any city.

The range of gearboxes of this company is represented by the following products for engines with injectors and carburetors, for different temperature conditions.

Modern gearboxes for propane gas equipment

Modern gearboxes for propane gas equipment from Lovato have practically no analogues in terms of compactness and reliability. The devices are among the most popular:

On a note! There is no need to drain condensate from the 4th generation Lovato gearbox. The design does not provide for a drain; all condensate, as planned by the developers, goes into the combustion chamber for processing.

For methane gas equipment

Lovato products for methane gas treatment are manufactured strictly in accordance with European standards and Russian Technical Regulations:

On a note! Gas pressure equalization devices from Lovato ensure smooth engine operation due to high precision settings and enhanced quality control at every stage of product assembly.

Lovato 2nd generation electronic gearboxes

Lovato gearboxes of the 2nd generation are in particular demand among Russian car owners. These are reliable devices that can last up to 2-3 years without overhaul. Overhauling the Lovato gas reducer is usually required due to low-quality fuel. Using the Lovato gearbox repair kit and a pair of keys, you can do this yourself:

Principle of operation

Lovato products belong to fourth generation systems. The operating principle of this generation of equipment is that gas is supplied to the injectors depending on the readings of the sensors, which are sent to the electronic control unit.

The system looks like this. Gas is stored in a gas cylinder. It can be located in the trunk of the car or under the bottom where the spare wheel is mounted.

At the moment of switching to gas, the operation of the gasoline fuel system stops. The dampers open and gas flows through the reducer to the injectors, after which it enters the combustion chamber. Gas fuel is supplied distributed, sequentially or in parallel.

The gas in the cylinder is under high pressure. In order to feed it into the engine, the pressure must be reduced. This is done in a device called a gearbox.

How to set up and adjust

To correctly adjust the gearbox according to the instructions with your own hands, you need to understand the settings. Devices for propane systems have two or one regulator. Adjusting a methane device is a more complex process. Methane modifications are almost all equipped with one regulator.

Description of setting with 2 screws:

- the car is started with gasoline and warmed up until the temperature sensor shows the operating value;

- the dispenser should be at maximum,

- The idle speed screw is screwed in until it stops, then unscrew it 3 turns;

- the sensitivity screw is set to the average value at idle on gas fuel;

- reduce the number of revolutions by rotating the screw, while adjusting the position so that the car does not stall;

- reach the value where the speed reaches its maximum, then slowly tighten the sensitivity screw;

- when changing speed, an adjustment is made to the maximum value;

- achieve when the screw is screwed in almost all the way, and the car at idle shows a value of 1200 rpm. in a minute;

- reduce to 1000 rpm. in a minute.

Finalizing settings:

- slowly unscrew the screw until the speed parameters change;

- turn back again;

- perform a re-throttle, the motor should feel the pedal without any problems, otherwise repeat the operation.

Then comes the dispenser setup:

Final stage:

- sharply press the gas pedal, turning the sensitivity screw until you feel a failure;

- turn the regulator half a turn;

- repeat the dispenser settings.

Setting with 1st adjustment screw:

- The car should run on gas fuel, at idle speed, about 1100 rpm. in min.;

- tighten the screw, reduce the speed and set it to 1000 rpm. in a minute;

- adjust the dispenser, tighten it 1/2 turn and drive, as soon as the machine starts to work jerkily, adjust the screw until smooth.

On a note! The adjustment is made with a working idle speed control system (the resistance parameters between the contacts of the system are checked with a multimeter in car repair shops). Gas fuel consumption also depends on the correct operation of the MAP sensor; Lovato usually comes with it complete with the 4th generation gas equipment.

© Andrey Zelin (YMBR)

To begin with, we will divide all gearboxes of the 2nd (2+) generation into 3 groups.

Method for adjusting gearboxes with two adjusting screws

The gearbox regulates two main parameters: the pressure in the second stage (hereinafter referred to as “sensitivity” - this is closer to the truth) and the amount of gas passing through the idle channel - the idle screw.

The engine must be started on gasoline and warmed up to operating temperature.

Initial adjustment position:

- the dispenser is turned to the maximum (maximum cross-section of the gas supply channel);

- screw the idle speed screw all the way and then unscrew it 3–5 turns;

- The sensitivity screw is set to the middle position.

Idle speed setting

Start the car on gas. If this fails, then start it on gasoline and switch to gas, maintaining the speed at about 2000 rpm. Reduce the speed to idle and turn the idle speed screw to find its position when the engine does not stall. If the engine stalls, repeat the operation until the idle speed is stable (idling speed). Then, turning the idle speed screw, you need to find the maximum speed. Next, gradually tighten the sensitivity screw; if the speed changes, then you need to adjust it with the idle speed screw to maximum. If that doesn’t work, turn the sensitivity screw 2 turns and repeat again. As a result, the sensitivity screw is turned almost all the way, the engine idles at maximum - somewhere around 1100–1200 rpm. Using the idle screw, turn it in to lower the speed slightly below the nominal speed and then turn it back, set it to 950–1000 rpm.

Setting the sensitivity of the gearbox

Gradually unscrew the sensitivity screw until it begins to affect the engine speed at idle, then turn it back 0.75–1.25 turns. We try to accelerate sharply - the engine should respond well to the gas pedal. If it responds poorly (“dull”), repeat the operation.

Dispenser setup

On a gas-powered engine, set 3000–3500 rpm, and tighten the metering screw until the threshold for changing the speed is found. It can be heard by the sound of the engine running. You can turn the dispenser screw more/less to make sure. Unscrew the dispenser screw 0.5–0.75 turns from the found threshold.

Final adjustment

It is also carried out in several steps. Sharply press the throttle, then turn the sensitivity screw 0.25 turns until you feel a dip in the speed gain. After this, unscrew the sensitivity screw 0.5 turns. It is better to carry out the last operation not by ear, but by “starting” the car from a stop at low throttle. After this, repeat the procedure for setting up the dispenser.

The gearbox is configured. You can drive safely. The only problem that may arise is high CO levels. A characteristic sign is a strong specific smell of unburnt gas from the exhaust at idle. In this case, you need to tighten the XX screw a little. To pass a technical inspection, it’s a good idea to go to a service station with a gas analyzer and check the CO level in the exhaust.

Method for adjusting gearboxes with one adjusting screw

The only adjustment screw is the combined idle/sensitivity control. How to configure such a gearbox. As in the previous method, start the car on gas (or on gasoline with subsequent transfer) and adjust the idle speed. Set the adjustment screw to the maximum speed - 1000–1100 rpm. Then, turning the screw, reduce the speed a little less than the nominal one and then, turning it back, set it to 950–1000 rpm.

Adjust the dispenser as in the previous method. You can tighten the dispenser screw 0.5 turns and ride. If the machine does not start to “stupid”, you can press it another 0.5 turns. As soon as the machine starts to become dull, unscrew the screw until the dullness disappears. This will be the most efficient mode without damaging the engine due to a lean mixture.

Do-it-yourself installation of HBO 2

The second generation gas cylinder equipment system is quite easy to install if you understand the basic principles of its operation.

The step-by-step installation guide for 2nd generation HBO includes the following steps:

Installation of gas cylinder and multivalve

This process is the same for both the first and fourth generations. The first thing you need to decide is what shape of cylinder you need, as well as the installation location. Step-by-step instructions for installing the cylinder on a classic, as well as in the trunk instead of a spare wheel, can be found here.

Installation of VZU

As in the previous paragraph, you should decide on the location of the remote refueling device. Usually it is mounted under the car bumper, because... this is the least labor-intensive option.

The very first installers did not bother with the placement of the VSU and mounted it directly in the trunk of the car next to the cylinder. It's even easier. But with this installation method, you will have to open the trunk to refill the cylinder.

In more expensive and modern cars, the VZU can be placed in the gas tank flap. In this case, the aesthetic appearance of the car will not be affected, but you will need to carry a special adapter for the gun with you. And when refueling, give it to the gas station employee.

Gas line laying

The next step is to lay a gas line from the LPG cylinder to the engine compartment. The installation is carried out under the bottom of the car, positioning the pipeline so as to minimize the risk of damage. Some installers advise placing the gas line next to the gasoline line. For safety reasons, we would still advise separating these highways.

Note! The outlet and inlet of the line are made slightly larger in diameter in order to be able to insert seals into them.

Read about what materials are used for highways here.

Mixer installation

The next step is to select a mixer that will be installed between the car's intake manifold and the carburetor. It is imperative to ensure a tight connection and prevent possible air leaks at the connection points.

Installation of solenoid valves

The next step is to install the gasoline and gas solenoid valve. Please note that there are several types of electromagnetic gas valves. The best option would be to choose a valve with a coarse filter.

Gearbox installation

Installing the gearbox is not a complicated procedure, but it must be done correctly, otherwise the entire system will work unstably. Read about how to properly install the gearbox on a classic in this article.

Connection and sealing

Next, all components of the system are connected and sealed well. At this stage, it is impossible to detect a leak, because There is no gas pressure in the system yet. After refueling (the first refueling should not exceed 5 liters of gas), you must carefully check all connections using a soap mixture. If a leak is detected, the connection must be sealed. If you can’t do this without disassembling it, you need to “repack” the connection.

Note! A more complete guide to installing 2nd generation HBO on a carburetor can be found here.