A cardan transmission is a component of a car that transmits torque between shafts located at a certain angle relative to each other. It is difficult to imagine a modern car without a cardan transmission of one type or another. Cardan drives are typically used in transmissions and steering. The name comes from D. Cardano, who described the device in the 16th century. However, the scientist only described the structure of the cardan, but he cannot be counted among the inventors of the cardan transmission. They brought to life what was described much later, several centuries later. And the name Cardano is now immortalized for centuries.

The following elements are connected using a cardan drive:

- power unit and gearbox;

- Gearbox and transfer case;

- Gearbox and final drive;

- transfer case and final drive;

- differential and a driving pair of wheels.

The main element of the cardan transmission should be called the universal joint. It comes in various modifications:

- equal angular velocities;

- unequal angular velocities;

- semi-cardan elastic joint;

- semi-cardan inelastic joint.

Cardan transmission with unequal velocity joint

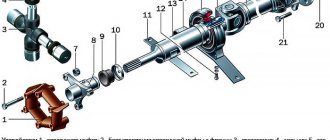

This type of transmission can be found on rear-wheel drive or all-wheel drive vehicles. The structure of such a transmission is as follows: joints of unequal angular velocities are located on the cardan shafts. There are connecting elements at the ends of the transmission. If necessary, a connecting support is used.

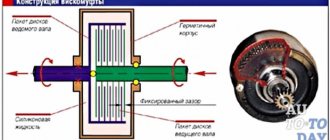

The hinge combines a pair of forks, a cross and locking devices. The fork eyes have needle bearings in which the crosspiece rotates.

Bearings cannot be repaired or serviced. Oil is poured into them during installation.

The peculiarity of the hinge is that it transmits unequal torque. The additional shaft periodically overtakes and lags behind the main shaft. To compensate for this deficiency in the transmission, several joints are used. The forks of opposite hinges are located in the same plane.

Depending on the distance over which torque must be transmitted, one or two shafts are used in the cardan transmission. When the number of shafts is equal to two, one of them is called intermediate, the second is called rear. To fix the shafts, an intermediate support is installed, attached to the car body.

The cardan drive is connected to other elements of the car using flanges, couplings and other connecting elements.

It is safe to say that unequal velocity joints have low reliability and a relatively short service life. In modern conditions, cardan drives with constant velocity joints are used.

Appendix b (for reference). calculation of cardan shaft imbalance

Appendix B (for reference)

Also interesting: Top mini SUVs: rating, the best