The work of many products is based on the use, sometimes in unexpected ways, of a variety of properties of substances familiar to us. An example of this is a viscous coupling - a special device designed for selective transmission of torque, depending on external conditions. For such products, the operating principle is based on changing the viscosity of the liquid poured into it. This is not to say that they are used extremely widely, for example as a manual transmission, but it would be wrong to ignore their use.

Viscous coupling is a viscous coupling, part of a car transmission, a mechanism for transmitting and equalizing torque. Unlike a fluid coupling and a torque converter, a viscous coupling uses a different operating principle. In this device, torque is transmitted not through the dynamic properties of the fluid flow, but using the viscous properties of the fluid filling the internal space of the viscous coupling. Used as an automatic differential lock mechanism.

Viscous fan coupling: design, malfunctions and repairs (video)

The viscous coupling of a car fan is exactly the part that many car enthusiasts know firsthand, but know practically nothing about the features of its design.

But this is a very interesting device in its simplicity, which does not break down very often - it is so reliable. However, a competent car enthusiast should know about the features of the design and operation of both large and small car components so that if they break down, he can quickly figure out whether a trip to the service station is necessary literally on the same day, or whether repairs can be postponed. Avto.pro experts will try to figure out how the viscous coupling of the cooling fan works, what is the principle of its operation, and even how to repair it.

Viscous cooling fan operation

A viscous coupling, also known as a viscous coupling (from the Latin viscosus - viscous) is a mechanical device that transmits torque using a viscous fluid.

In this video, see what the clutch is in this device

The principle of operation of the viscous coupling is carried out thanks to a belt drive that connects the coupling rotor and the crankshaft pulley of the internal combustion engine. There are also car designs in which the clutch is installed directly on the crankshaft or camshaft.

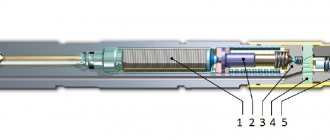

In order to understand how a viscous coupling works, you need to understand what it consists of.

The device consists of:

- Spring.

- Bimetal plate.

- Inlet port B.

- Inlet channel A.

- Camera.

- Return valve.

- Return valve.

- Rear springs.

- Front reservoir.

- Rotor.

- Device body.

- Rotor shaft.

- Bearing shell.

- Rear reservoir.

- Rear plate.

- Rotor.

- Front plate.

- Lid.

Due to the complex design of the device, the price of a viscous fan coupling is relatively high.

In cars where rare clutch models are installed, if it is impossible to repair it and find a new such mechanical unit, the owners have to slightly re-equip and install an electric cooling fan.

This video simply and clearly shows how to determine whether a viscous coupling is working properly or not. Don't miss the opportunity to glean useful information, look:

Functionality check

Viscous couplings of radiators are not so difficult to check. The operating manuals indicate that fan rotation should be checked first on a cold and then on a hot engine. At the same time, on a hot engine, when the engine is revved up, the rotation speed seriously increases, while on a cold engine it does not. The “folk” method of checking is very good, since it also involves caring for the engine cooling system. Here's what to do:

- Without starting the engine, try to rotate the fan blades with your hand or an improvised object. They should spin with little resistance, but without inertia;

- Start the engine and listen. In the first seconds, the motorist should hear a slight noise, which will gradually subside;

- After warming up the engine slightly, try to stop the blades with a folded sheet of paper. They must stop, but with a clearly noticeable effort;

- Remove the viscous coupling and warm it up strongly. Optionally, in boiling water. After this, the clutch should resist rotation. If it turns, there is practically no silicone liquid left inside. It is also recommended to remove the engine cooling radiator and wash it;

- Check the longitudinal play of the device. If there is one, the coupling must be repaired.

Please note that if one of the verification stages has not been passed, there is no point in going further along the list. However, remove the clutch and clean the radiator

It always makes sense, especially if you do this after the summer period, when the honeycombs become clogged with fluff, dirt and dust.

Replacing a viscous coupling using the example of an Audi A6 C5

On these vehicles, the fan with clutch and pulley is mounted on a separate axle and is driven by an auxiliary belt. The clutch rotor is screwed directly onto the threads of the pulley bushing.

It won't take much time to replace:

- since it will not be possible to hold the pulley by the belt, you will have to fix it with a special device through the existing holes; it is quite easily made from a strip of iron and two bolts with nuts in place, or you can try to get by with an L-shaped hexagon from the kit;

- Having fixed the pulley, use a 32 mm open-end wrench to unscrew the rotor nut; remember that it has a left-hand thread and must be turned clockwise to unscrew;

- By unscrewing the rotor, you can remove the impeller assembly with the coupling and disconnect them by unscrewing the four bolts.

The new clutch is installed in the reverse order, after which it can be checked as indicated above, although completely new products have significant rotation resistance even when cold.

How repairs are made

The first thing a car enthusiast should pay attention to is engine overheating. Perhaps it is the viscous coupling that is connected to it, although it is worth checking, for example, the thermostat. If the problem lies specifically in the viscous coupling, it is worth trying to repair it. Although many descriptions say that replacing silicone liquid is impossible and it is poured into the case once until the entire device is disposed of, in practice, adding fresh liquid is very simple. The only problem is to find it. In both offline and online stores it can be found under the names “ viscous coupling repair fluid”

", "

viscous coupling oil

" or simply "

silicone fluid

". If we are talking about repairing a viscous coupling in an all-wheel drive system, then you should buy the original one - inexpensive analogues are not viscous enough. And if you are repairing a viscous fan coupling, you can buy a universal fluid.

So, to repair a broken part, you should start by checking the silicone fluid level

. It leaks very often. It is necessary to fill in new fluid, for which the following is done:

- The viscous coupling is dismantled and disassembled;

- The coupling is laid horizontally, after which the pin located under the plate with the spring is removed from it. If there is no hole for the drain, you will have to do it yourself, which experienced repairmen do not recommend doing;

- After removing the pin, about 15 ml of silicone liquid is poured in with a regular syringe. The liquid is poured in gradually, pausing for half a minute or a minute so that the silicone can disperse between the discs;

- The viscous coupling is wiped, assembled and installed in place.

bearing failure

with which it is equipped. To replace the bearing, you need to actually do the same as described above, and also perform a few more operations. For this reason, we immediately note that when replacing a viscous coupling bearing, the old silicone fluid must be drained, and immediately after replacing the part, a new portion of silicone must be poured. And here's what to do with a broken bearing:

- Remove the viscous coupling;

- After draining the liquid, remove the upper disk and dismantle the bearing using a specialized tool (puller). You will also need to grind down the flare. We strongly do not recommend removing it with improvised means. Afterwards, install a new bearing. A sealed bearing with no visible balls will do. As described above, fresh liquid is poured in;

- The device is returned to its place.

Selecting a new device

Now let's answer the question of how to choose a viscous coupling for a cooling fan. The easiest way to search is in online stores, because here you can, if not buy a new device, then at least find out the code of the original and the codes of all possible analogues. We'll talk about the latter shortly. You can search by:

- VIN code;

- Vehicle data. We are talking about the make, model, year of manufacture and engine parameters. Typically, this search method is the main one in online auto parts stores.

Of course, an important search parameter is the manufacturer of the final product. Many car enthusiasts justifiably do not trust the products of packaging companies. In the case of viscous couplings, you can even take products from such companies, since, in fact, they are produced by a limited number of companies, which are also suppliers to the conveyors of large automobile concerns and whose products are even sold by packers

. It is worth paying attention to the products of these companies:

Very good solutions can be found in the catalogs of Meyle and Febi (Germany). The Polish and Turkish analogs that appeared relatively recently did not perform so well. As a rule, reputable manufacturers of viscous couplings simultaneously produce radiators, fasteners and some pipeline elements. If you are confident in a certain radiator manufacturer, it is worth looking in its catalogs for the viscous coupling you need.

Conclusion

The viscous coupling of an engine cooling fan is a simple and very reliable device that rarely fails. You can diagnose its breakdown without contacting specialists at a service station. One has only to monitor the engine temperature and check the operation of the fan, and everything will become clear. Although viscous coupling repair is not recommended by many experts, even a beginner can handle it. The choice of new devices is quite large: there are products from manufacturing companies from Europe, America and individual Asian countries (the best options), and there are auto parts from packaging companies, the best of which are German, American and French.

Source

Viscous coupling and everything you need to know about it.

The work of many products is based on the use, sometimes in unexpected ways, of a variety of properties of substances familiar to us. An example of this is a viscous coupling - a special device designed for selective transmission of torque, depending on external conditions. For such products, the operating principle is based on changing the viscosity of the liquid poured into it. This is not to say that they are used extremely widely, for example as a manual transmission, but it would be wrong to ignore their use.

Viscous coupling is a viscous coupling, part of a car transmission, a mechanism for transmitting and equalizing torque. Unlike a fluid coupling and a torque converter, a viscous coupling uses a different operating principle. In this device, torque is transmitted not through the dynamic properties of the fluid flow, but using the viscous properties of the fluid filling the internal space of the viscous coupling. Used as an automatic differential lock mechanism.

Design and operation of the fuel injection gasoline engine power system

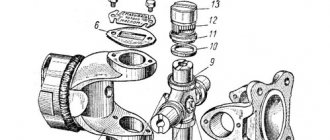

Advantages of the gasoline injection system: high liter engine power and improved efficiency due to precise distribution of fuel doses across the cylinders and lower intake tract resistance (no carburetor), the ability to precisely control the composition of the combustible mixture, minimal toxicity of exhaust gases.

Gasoline injection power systems are classified according to the following criteria:

at the fuel supply location - central (mono) injection, distributed (injectors at each intake valve), direct (injectors in the cylinder head).

Consider a power system with gasoline injection. Gasoline from the tank is supplied under pressure through a hydraulic accumulator and fuel filter to the dispenser-distributor, and from it to the ramp - a special pipeline in which constant pressure is maintained. The ramp contains injectors that inject gasoline into the intake manifold. Since constant pressure is maintained in the ramp, the amount of fuel injected by the nozzle will depend only on the time it opens. Knowing the air flow and the coefficient α required in this mode, you can supply an exact dose of fuel. The amount of air is measured by a flow sensor. It also influences the fuel pressure regulator, which, in turn, affects the metering distributor, providing the specified pressure and cyclic supply. The pump is designed to supply fuel 5...10 times more than is needed to operate the engine at full load, so most of the fuel from the pressure regulator goes to drain, which ensures that fuel is pumped through the filter several times an hour.

When starting the engine, the starting nozzle is turned on, and air enters the cylinders through a special additional channel in the intake manifold.

In a fuel injection system, the functions of controlling and processing signals for the power supply and ignition system are performed by an electronic control unit. It contains complex programs that take into account all possible engine operating modes. By accessing the program stored in its memory, the microprocessor provides precise control signals for injectors and other units.

The work of many products is based on the use, sometimes in unexpected ways, of a variety of properties of substances familiar to us. An example of this is a viscous coupling - a special device designed for selective transmission of torque, depending on external conditions. For such products, the operating principle is based on changing the viscosity of the liquid poured into it. This is not to say that they are used extremely widely, for example as a manual transmission, but it would be wrong to ignore their use.

Operating principle of viscous coupling

What is a viscous cooling fan coupling? This is a special mechanism that performs the function of selective transmission, which depends on external conditions and torque. The viscous coupling looks like a housing that is completely sealed, with two rows of discs located inside. One of them is connected to the driven shaft, the second to the driving shaft. These disks are interleaved with each other. Each of them has both holes and protrusions, and the distance between the planes of the disks is minimal. The viscous coupling body is filled inside with a viscous liquid, which is often made on a silicone basis. Viscous coupling fluid has specific features that allow it to be used effectively.

These are: An increase in viscosity with increasing stirring intensity. High coefficient of expansion during heating. When the car moves at a constant speed, the viscous coupling discs rotate evenly and the oil does not mix between them. When the speed of the driven and drive shafts differs, the speed of rotation of the disks also differs. As a result, the viscosity of the fluid increases, and it affects the transmission of torque to the driven shaft. When the disc rotation speed difference is very large, the viscous coupling oil becomes so viscous that it becomes blocked. The liquid turns into a state close to solid.

How viscous couplings for transmissions are designed and work

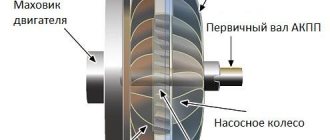

First, let's study the design of the all-wheel drive viscous coupling. This mechanism has the shape of a cylinder, the design of which is sealed. The main components of the design are flat-shaped perforated disks and a special liquid. Disks are divided into two groups, which differ in connection with the shafts.

Viscous coupling in section

About 80% of the internal structure is dedicated to a special silicone fluid. It acts as a connecting element between the disks. This liquid is characterized by high kinematic viscosity. At the same time, it does not have lubricating properties.

Scientists have created a unique organosilicon liquid that becomes less viscous when heated. In this case, the siloxane becomes so thick that it even shows signs of a solid substance. This allows the viscous coupling to transmit torque under conditions of different rotation speeds of the parts.

The viscous coupling has found wide application in automatic systems operating on the all-wheel drive principle. If driving conditions are within normal limits, the force from the motor is transmitted to one axle. A second axle operating in freewheel mode is connected through the coupling. When the main axle slips, the viscous coupling is blocked, which causes the force from the motor to be distributed to the driven axle.

When the car drives out onto a flat road, the fluid returns to its previous state, the blocking is removed from the viscous coupling and the second axle again operates in freewheel mode. This is roughly how a viscous all-wheel drive coupling works.

Work of a part in a transmission.

When driving in normal mode on normal surfaces, the angular speeds of the wheels of both axles are the same. The viscous clutch disks rotate at equal speeds, the transmission of torque from the engine to the driven axle is minimal. In fact, the car becomes completely front- or rear-wheel drive.

When driving on ice, snow, dirt, or uneven surfaces, the synchronization of wheel rotation is disrupted, and the viscosity of the fluid in the device increases, increasing the transmission of torque to the second axle. Theoretically, such power transfer in some emergency modes can be up to 100%, although, as a rule, even partial connection of the second axis is enough to safely overcome the problem area.

Important! It should be understood that the viscous coupling is by no means a full-fledged center differential that provides redistribution of engine torque to both drive axles.

The use of the part is justified on uneven surfaces, when there is ice in the city or on a wet road. When driving in complete off-road conditions, the delayed response of such a self-locking differential is unacceptable. In addition, constant loads can lead to overheating of the fluid in the device, loss of its working properties and complete self-locking, which can lead to breakdowns of other vehicle systems.

Currently, on vehicles with automatically connected all-wheel drive, viscous couplings are operated in “pre-launch mode”. It is characterized by a constant transfer of 5% to 15% of engine power to the driven axle, which significantly reduces the reaction time of the mechanism.

Figured out the operation of the radiator viscous coupling

Since I haven’t found a clear description of the operating principle of a viscous coupling, I’ll try to do it myself. Maybe it will help someone

I would like to immediately express my deep gratitude to AVSh for the consultations. Very helpful, thank you.

So, the radiator viscous coupling consists of two main parts:

1. Housing on which the fan is screwed.

2. A disk with fins, which rotates inside the housing on a bearing and is rigidly connected to the motor pump shaft.

On the viscous coupling body, at the front, there is a bimetallic spring with a spiral curl. The center of the spring is connected to an axis, which rotates approximately 25 degrees when the spring heats up (easily checked with a hair dryer). Shutters/valves are rigidly attached to the axle, which, when rotated, open holes for the overflow of working fluid from the central part of the coupling to the outer part.

This farm works as follows:

When starting the engine, the working fluid, under the influence of centrifugal forces, is displaced from the outer radius of the housing into the internal cavity. As long as the bimetallic spring is not heated, the valves are closed. As soon as the spring begins to heat up, the valves open and part of the working fluid enters between the rotating disk and the clutch body. Torque begins to be transmitted from the engine to the fan. Moreover, the magnitude of this moment depends on the amount of liquid, or more precisely on the degree of heating of the spring and the angle of rotation of the curtains/valves.

As soon as the spring has cooled, the valves close and fluid collects in the central part of the coupling.

That's it, the cycle is over.

As we can see, the main thermal element is a bimetallic spring. The composition of the working fluid has nothing to do with the operation of the clutch (it seems to me, correct me if I’m wrong). I filled it with transmission oil instead of silicone.

Now about the main thing - how much to pour this oil.

We lay the part of the body with the spring horizontally. Pour oil into the central hole almost to its edges.

At first I poured more, as a result the viscous coupling worked constantly due to the presence of oil between the disc and the housing. I had to remove and drain the excess.

To remove the clutch from the engine you need to:

1. Remove the belt and tension roller of the air conditioner. So as not to interfere.

2. Loosen the generator belts. The pump pulley is screwed with the same nuts as the coupling. Therefore, if you do not loosen the belts, the pulley will warp.

3. Remove the right battery so that it does not interfere with lifting the radiator casing.

4. Loosen the radiator casing to make it easier to remove the fan with clutch.

The coupling is easy to disassemble:

1. Unscrew the 4 nuts securing the fan and remove it.

2. Unscrew the 8 bolts holding the body together. The most important thing here is to take the right screwdriver with the right profile. If you pick with something you don’t need, you’ll tear off the splines.

3. Separate the housing halves with a slotted screwdriver.

Don't lose the rubber seal. She is trying to jump out of the groove.

There was condensed silicone inside my coupling. Apparently due to old age. I washed it with the same transmission. Especially after the first installation of the coupling on the engine, it was well washed

I checked the operation of the clutch with a rolled up newspaper. While the viscous coupling is cold, the fan can be stopped easily with the help of a newspaper. When it gets hot, it doesn't stop.

That's it, that's all.

Good luck with the repair

Yes, I forgot.

What inspired me to do this was Exist, who wanted $253 for a new viscous coupling. KAZLY Modified on May 22, 2010 by SCB

Where are viscous couplings used?

There are actually only two main applications, but now there is only one left:

- Used to cool the engine. A viscous coupling with a fan was attached to the rod. It was driven by the crankshaft of the car via a belt drive. The faster the engine rotated, the thicker the liquid became and the connection with the fan became tighter. If the revolutions dropped, then such strong mixing did not occur, which means there were slippages, that is, the fan rotated and did not cool the radiator as much. Such a system is effective for the cold (winter) period, when the engine does not warm up much, but is also cooled. Nowadays, the use of such systems on new cars is no longer seen; it has been replaced by electronic fans (with sensors in the liquid), which are powered by electricity and are in no way connected to the engine crankshaft.

- Automatic all-wheel drive connection. It is in this direction that viscous couplings remain very much in demand. Almost 70 - 80% of crossovers or SUVs now use such systems. True, they are gradually beginning to be replaced by fully electromechanical options, but for now they are more expensive and not so practical.

On the one hand, a viscous coupling is a very simple, cheap, practical and universal mechanical device, on the other hand, it has quite a lot of disadvantages.

How to check a viscous coupling

The resource of this device in the design of the car is designed to cover 200 thousand km.

To check whether the fan and clutch are working well, you need to know the signs of malfunctions of these parts:

- If the engine heats up quickly, then this is the first sign of a viscous coupling malfunction. This appears due to the release of the gel or the untimely operation of the bimetallic plates. In this situation, when the motor gets very hot, the fan spins at a low speed, or does not turn on at all.

- The cooling fan starts spinning when the engine is still cold. This occurs due to changes in the properties of the gel, hardening of the lubricant and failure of other elements of the viscous coupling.

Reasons for failure or poor performance of a viscous coupling:

- The resource has been exhausted.

- Mechanical damage.

- The bearing has expired or broken prematurely.

- Axial runout of the fan impeller. Part of the propeller blade is broken.

- Lack of lubrication of the coupling shaft.

- Contamination of the coupling connection.

Advantages and disadvantages of a fan driven via a viscous coupling:

- A more reliable fan with a viscous coupling than an electric fan. It often happens that after winter, the electric drives of the fan fail and the electronic control circuit of the propeller is disrupted.

The advantage of a viscous coupling is that there is no electronics or electricity involved.

- The viscous coupling provides more power, the fan rotates at a higher speed. If the clutch sits rigidly on the crankshaft of the internal combustion engine, then the rotation speed is very high.

The power of the clutch connected to the crankshaft is several kW (kilowatts). And the power of electric fans has a power of several tens of watts. Thanks to this, a fan with a viscous coupling is used in agricultural machinery, military equipment, and special equipment.

Disadvantages of viscous coupling:

- Complex design, more difficult to repair. It is cheaper to buy a new assembly assembly.

- Has good mass. The weight on the internal combustion engine crankshaft is significant.

- Switching on temperature control is not entirely correct. There are errors in turning the cooling fan on and off.

- At high speeds there is an increased noise level.

- According to the schedule, you have to refill with gel or oil with the required viscosity.

- The viscous coupling partially takes away the engine power.

This list of shortcomings of viscous couplings influenced the decisions of the owners of automakers. They refused to use such devices in passenger cars.

INDEPENDENT REPAIR OF VISCOUS COUPLING

If you notice the engine overheating, do not rush to replace the viscous coupling. You may be able to repair the broken part yourself. The most common cause of failure is silicone leakage from the base of the part. To fill in new fluid, you need to: Remove the viscous coupling from the water pump, and then disassemble it. On the device disk itself there is a plate with a spring, under which there is a hole for silicone liquid.

You need to remove the pin with extreme care and then use a syringe to fill in the lubricant. Keep in mind that during such repairs the part is placed horizontally. Using a syringe, it is enough to draw up fifteen milliliters of oily liquid. Slowly pour the silicone inside. Wait a few minutes without removing the syringe from the hole so that the liquid has time to flow deeply into the viscous coupling. Wipe the surface of the device from excess liquid if necessary. Place the pin in place and then install the part.

If you are not well versed in cars and do not know how certain parts work, it is better not to start repairing them yourself. The point here is not the possible breakdown of parts of the vehicle, but the difficulty of putting everything back together.

Bearings are also a common cause of viscous coupling failure. There is only one sign of such a malfunction: various kinds of noise in the area of the cooling radiator. To repair the device, you first need to remove it. To do this, unscrew the three bolts that secure the part. After this, the viscous coupling can be easily removed from the engine compartment. After removing the device, you can begin replacing the bearing. Replace them only when you have disassembled the unit and drained the oil fluid. Use a special tool to remove the bearing - a puller. If you use improvised means, you can completely damage the assembly. Having installed the new bearing, you can begin installing the device.

Do not forget to fill in new silicone fluid, which was drained before repairing the viscous coupling. When you notice “wrong behavior” of the coupling, you do not need to immediately change the entire part, because it can often be repaired. No special skills or abilities are required for this task. The only difficulty that may arise is finding a puller to remove the old bearing. The tool is not sold in every automotive store, which makes it difficult to repair the viscous coupling yourself. If you have visited all the auto stores you know and haven’t found a puller, ask your driver friends. The rest of the details are easy to find.

Removing the UAZ viscous coupling with your own hands

Let's look at how to remove this part along with the fan, using cars from the Ulyanovsk Automobile Plant as an example. So, for convenience, you need to remove the radiator and fan casing (blinds). Next, using a 12mm wrench, unscrew the two mounting bolts of the pump pulley. Please note: the viscous coupling nut has a left-hand thread. Therefore, you need to unscrew it clockwise, and screw it in the opposite direction. After this, use a 32mm wrench to unscrew the coupling securing nut. Keep the crankshaft pulley from turning. If the nut is difficult to move, you can use a hammer. Gently strike the key in the direction it is facing away. Next, the coupling is successfully removed from the pump shaft. Using a 13mm wrench, unscrew the 4 fastening screws of the fan impeller. We take the mechanism out and install a new one.

Installation of the element is carried out in reverse order. The bolt rods are screwed into place using fine-nose pliers. Next, the coupling is installed and the fastening nuts are tightened by hand. There is no need to tighten the bolt on the coupling itself. It self-tightens when the engine starts.

So, we found out what a viscous coupling is.

How does a viscous cooling fan (CO) coupling work?

Until the engine is warmed up, the thermostat directs the flow of coolant in a small circle. In this mode, the substance in the viscous coupling is squeezed out by a rotating disk into a reserve tank. There is no engagement between the disk and the case, the fan does not rotate.

The entry of coolant into the radiator causes deformation of the bimetallic plate, activation of the valves and accumulation of viscous coupling fluid not in the reserve tank, but in the space between the disk and the housing. Due to viscosity, the unit to which power is transmitted from the shaft is blocked. The fan rotates, directing air flow to the radiator, reducing the coolant temperature.

When it cools down to the operating threshold level of the temperature-dependent unit, paths open for liquid overflow, the force of viscous friction between the disk and the housing decreases, and the fan stops.

Role in the internal combustion engine cooling system

A viscous coupling fan is installed on vehicles with a longitudinal engine (usually all-wheel drive and rear-wheel drive models). With this arrangement, it is most advisable to connect the radiator fan pulley to the water pump pulley. As you know, rotation of the water pump is transmitted by a service belt from the crankshaft pulley.

The disadvantage of this design is that the rotation speed of the fan impeller will always be proportional to the crankshaft speed. Such a device will result in the engine being excessively cooled at high speeds in cold air conditions, which will reduce its efficiency. In addition, the permanent connection of the impeller and the crankshaft pulley will increase mechanical friction losses, which will take away power and increase fuel consumption.

The viscous fan coupling allows you to adjust the rotation speed of the impeller depending on the engine temperature.

Device

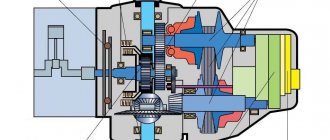

The difference in the design of viscous fan couplings for Toyota, BMW, Mercedes, Audi. is minimal, since they are all designed and work according to the same principle.

A shaft with a connecting flange is attached to the cooling pump drive, so its rotation speed is always proportional to the crankshaft speed. A drive pulley, in turn, is attached to the shaft, which rotates in the working chamber. The working and backup chambers are separated by plates. The transition between chambers is only possible through inlet valves and return passages. Initially, the backup chamber is filled with special silicone oil. The drive pulley, or disk, as it is also called, has oblique teeth around its circumference, which, when rotated, allow the oil to be expelled back into the reserve chamber. The surface of the drive disks, like the dividing plates, has special ribs that turn the working chamber into a kind of network of labyrinths through which silicone oil circulates.

The coupling housing, to which the fan impeller is attached, is connected to the shaft (viscous coupling rotor) via a conventional ball bearing. The inlet valves are connected to a bimetallic plate, which is located in front of the viscous coupling housing. When heated, the plate expands, which leads to an increase in the flow area of the valves.

How to check in the transmission?

The most accurate results are obtained by checking the viscous coupling removed from the transfer case.

For this it is enough:

- Remove the part;

- Turn the differential gear with a wrench and a dynamometer (or measure the force with a spring dynamometer).

The force should not exceed the limits established by the manufacturer (can be found in technical writings for the device and reference books for components).

You can check the part without removing it. To do this you should:

- hang out the driven axle wheel;

- try to turn it by measuring the force with a dynamometer;

- calculate the torque using the known wheel diameter

If the obtained value does not exceed the limits specified by the manufacturer, the part is working. If the wheel cannot be turned at all, the device must be urgently changed.

Video tutorial.

How to check the VO viscous coupling?

Checking the viscous coupling VO is not difficult:

- Start the engine “cold”;

- After 30-60 seconds, the fan noise will decrease - it will go into idle mode (at this moment it can be stopped by any obstacle, for example, a rolled up newspaper, but safety precautions do not recommend doing this);

- After some time, when the engine warms up (controlled by a temperature sensor), the viscous coupling will begin to increase the speed of the unit;

- In this case, there should be an unambiguous reaction to an increase in engine speed - the engine rotates faster - the fan rotates faster.

You can also check the device while on the move (more precisely, while parked in the middle of the day). When the temperature rises at idle, we can definitely talk about problems with the viscous coupling.

How to check the viscous coupling of a cooling fan

After the car has been idle for a long time, the viscous coupling needs an oil change, as well as a check of the condition and operation in general. In addition, failure is possible due to wear or other reasons.

It is quite difficult to recognize a viscous coupling failure, but there are ways to check its performance.

Look at the speed of the device with a cold and warm engine. In the first case, strange sounds are usually not observed, and the number of revolutions is normal. When it’s hot, the picture is different: extraneous noises are heard, and the rotation frequency of the viscous coupling may not correspond to the norm.

Various types of noise often appear due to faulty bearings. Also, the cause of the device malfunction may be sealing of the oil seals, or leaking special silicone liquid.

Using viscous couplings for wheels of one axle.

Another option for using the coupling is possible - for wheels of the same axle. In this application, the device is installed between the axle differential and the axle shaft. In this case, when cornering or one of the wheels slips, the device helps to redistribute the torque between them, ensuring safe maneuvering or passing through a problem area.

There are solutions in which a pair of parts are placed on the wheels of one axle. This design allows you to abandon the axial (cross-wheel) differential. At the same time, the use of a pair of viscous couplings makes it possible to provide all modes - both differential rotation and blocking of the axle wheels.

How does a viscous coupling work in a transmission?

One of the main applications of viscous couplings is in all-wheel drive systems and transmissions in general. What it looks like - the picture explains

The all-wheel drive device using a viscous coupling is based on the fact that the rear axle is connected only when necessary. Under normal conditions, such a car is front-wheel drive, but when there is a difference in the angular speeds of rotation of the wheels of different axles, the viscous coupling is activated, and the torque begins to be distributed between the various axles.

In fact, this turns out to be a self-locking automatic center differential. In such a situation, when the wheels begin to slip, the driver does not need to take any action. However, it is worth keeping in mind that such plug-in all-wheel drive has limited use. It works well on bad roads, in icy conditions, in the city, but is not suitable for real off-road use.

The reason for this is the delay in the response of the viscous coupling during constant changes in the traction of the wheels with the coating, its overheating, and, ultimately, failure. In addition to providing all-wheel drive, such a device can be used to unload the wheel when cornering. A drawing will help you understand how this happens.

In this case, the viscous coupling is placed on one bridge between the differential and one of the axle shafts. When entering a turn at high speed, the grip of the inner wheel deteriorates and it begins to slip. Thanks to the viscous coupling, the torque is redistributed between the wheels, ensuring safe cornering.

Considering the important role that the viscous coupling plays in driving safety, and also that it operates in an all-wheel drive system, it is often necessary to check its current condition and performance. What actions need to be taken for this, as well as additional information about such products, you will receive from the video

Pros and cons of viscous all-wheel drive couplings.

Like any device, VZ in all-wheel drive vehicles has both advantages and disadvantages.

- Automatic connection of all-wheel drive or mutual locking of axle wheels, which significantly increases cross-country ability and traffic safety on difficult surfaces;

- The simplicity of the technical solution and, accordingly, its low cost and reliability - manufacturers most often make the devices maintenance-free, counting on a service life equal to the life of the car.

In practice, mileage of 90-100 thousand km (in difficult conditions and less) becomes the limit due to the loss of the liquid’s properties and malfunctions in other vehicle systems. At this mileage, it is recommended to replace the device.

- Delay and non-linearity of response do not allow absolute control of all-wheel drive;

- In most cases, on vehicles equipped with viscous couplings, manual activation/disengagement of the second drive axle is not provided;

- Limited dimensions impose restrictions on the transmission of torque, as well as on the possibility of long-term operation under load (overheating and failure are possible);

- The joint operation of air intake and electronic systems such as ABS, ESP and similar is difficult, since they solve opposite problems.

Source

Principle of operation

The all-wheel drive system is quite reliable. But you must always remember and understand that a crossover cannot and should not travel off-road. Difficult road conditions are contraindicated for him. And if the driver does find himself in an unpleasant situation, he needs to wisely use the capabilities of all-wheel drive.

In automatic mode, the control unit itself “makes a decision” when to engage all-wheel drive. When turned on manually, the all-wheel drive works all the time, that is, the engagement clutch of the second drive axle is locked (engaged). To protect components and mechanisms from heavy overloads, automatic shutdown of forced locking is provided.