Did you know that the first cars were electric and used lead-acid batteries? What we are accustomed to consider as the cars of the future - electric cars - appeared before the invention of the internal combustion engine (ICE). More than 100 years have passed since then, but the modern car battery has changed only qualitatively, remaining fundamentally the same as a century ago.

Today, a car battery is considered a consumable item that requires periodic replacement. Exactly how long the battery will last is a question of the quality of manufacture, operating mode, even the condition of the roads, but sooner or later it is replaced with a “fresh” one. What functions does it perform, what characteristics can it have, how to choose and how to extend the life of the battery - read in this article.

What is a battery (battery) and what is it for?

Modern cars are becoming more and more like complex electronic gadgets: smart controls, all kinds of “assistants”, automatic parking and even autopilot are only a small part of the digital “stuffing” that a car is rich in. And all this happiness constantly needs electricity, which must be constantly obtained from somewhere. It is the battery that acts as a storehouse of energy, from where it can be taken at any time. Yes, it performs its clear function: it accumulates a charge, then releases it and then accumulates it again. Great option!

The very concept of a battery is already so familiar to us that it is stupid to ask why it is needed. However, surprisingly few people can say exactly what a car battery does.

Its purpose can be described in three points.

- The battery provides the energy to start the engine at the start.

- The battery serves as a backup source of energy when it is needed beyond what the generator can provide (for example, when turning on the car's air conditioning).

- The battery powers electrical appliances when the engine is off and the generator is not running. For example, DVR, alarm, light, etc.

Purpose of batteries

A car battery acts as both a source of electric current necessary to start the engine and a backup power source if the energy generated by the generator is not enough to power the car. The battery acts as a voltage stabilizer, since it acts as an electrical energy storage device that delivers a large current for a short time when starting the engine, and is gradually replenished by the car's generator during the charging process.

Important! Before checking the power supply and electric starting system, you must make sure that the battery is charged and ready for use.

In what areas is it used?

Rechargeable batteries are used as an additional or main power source. Reliability and ease of use allow batteries to be used in various areas:

- Automotive industry;

- lighting in emergency condition;

- portable electrical equipment;

- medical equipment;

- toys;

- signaling in various fields of application;

- telecommunications equipment.

The use of batteries in toys

The role of batteries in the operation of devices is undeniable. The use of energy sources in almost all industries proves the importance and necessity of knowledge about the internal contents of batteries. With the use of a wide variety of electrical appliances, air conditioners, and multimedia centers in cars, generators do not always cope with providing them with energy. In this case, the energy supply comes from the battery, which also performs the main function of providing electricity to the engine starter. The driver needs to know how the battery works in order to identify malfunctions in the operation of the energy source, the purpose of the battery in order to use the resource correctly, and select the battery for the operating conditions and the vehicle. Read about methods and recommendations for checking your battery here.

Design and principle of operation of the battery

The structure of a car battery

Anyone who has ever held a car battery in their hands knows how much this device weighs. The reason is that its body is densely filled with elements containing lead.

Battery device.

For passenger cars requiring 12-volt batteries, a standard layout is used.

- Six 2-volt elements (usually called banks) are combined into a common housing.

- Each of the elements consists of positive and negative electrodes: lead grids into which the active substance is “imprinted”. The electrodes are separated from each other by separators, so that they do not come into contact with each other.

- And all this is filled with electrolyte - a mixture of water and sulfuric acid.

The active substance on the grids differs in composition: lead dioxide is used for the anode (positive electrode), lead sponge is used for the cathode (negative electrode). In both cases, auxiliary substances (ligatures) are added to the lead components to improve battery performance.

Principle of operation.

The principle of operation of the battery

In the form described above, the battery is considered “charged”. When any device that requires energy is connected to the battery terminals, the lead components react with sulfur oxide and water. Sulfur and lead react and transform into lead sulfate and water. There is less acid in the electrolyte, more water, the density of the electrolyte decreases and after some time the sulfur concentration is not enough to react with the lead components. The battery is running low.

Electrode device

A lead-acid battery can be used as an example. Each cell of such a battery contains a pair of electrodes and separating plates, which are made of porous material that does not react chemically with acid. Such plates are designed to prevent short circuits of electrodes immersed in the electrolyte, and are called separators.

We recommend: Parallel battery connection diagram

The electrodes in such batteries are made in the form of flat lead grids. Powdered lead dioxide (in anode plates) and metal lead in powder form (in cathode plates) are pressed into the cells of such gratings. The use of powders is driven by the desire to increase the interface area at the electrolyte-electrode interface, which significantly increases the capacity of such a current source.

There are experimental samples of batteries in which lead grids are replaced with electrodes consisting of woven carbon fiber threads, which are coated with the finest lead coating. This technology allows you to use significantly less lead due to its distribution over a large area, which makes the battery not only smaller and lighter, but also increases its efficiency. The efficiency is higher than traditional ones, and the charging time is greatly reduced.

Types of batteries

In an attempt to improve the performance of car batteries, engineers have tried many methods. As a result, today we have different types of batteries, which differ in the chemical composition of the active components and design.

Classification according to the composition of the active substance

The first batteries used lead plates, but this design quickly ceased to suit engineers and consumers: it was heavy, ineffective, and short-lived.

- The first improvement was the addition of antimony to lead, which greatly extended the life of the battery.

- The next stage is to reduce the percentage of antimony to the optimal concentration. This approach made it possible to create low-maintenance batteries: they required topping up water much less often.

- Then metallic calcium began to be used to coat the plates - this is how calcium batteries (aka Ca-Ca) appeared. Calcium has seriously changed the operating parameters of batteries: in previous models, water loss due to electrolysis at 12 V required constant topping up, and calcium alloys made it possible to increase this threshold to 16 V. Thanks to this, it became possible to make maintenance-free batteries in a completely sealed, non-separable case.

But calcium batteries also have a huge disadvantage: sensitivity to full discharge. Calcium sulfate, which settles on the electrodes, does not completely decompose during charging, which means that one deep discharge of the battery can “kill” it.

The most modern solution is hybrid batteries (aka Ca+): calcium additives are only on the positive electrode (since this is where water decomposes during electrolysis), and the negative one is coated with low-antimony lead.

Classification by electrolyte type

Conventional liquid technology, in which a solution of acid and water was poured into the battery, caused many complaints. For example, sensitivity to tilt and vibration. The need to maintain the battery also did not add to the pleasure of using it. In general, this technology had room to grow.

AGM technology has replaced it. In an AGM battery, the electrolyte is “bound” by fibrous separator layers. Thus, the battery receives additional advantages: the separators compress the active layer and do not allow it to lag behind the plates, have greater conductivity than the liquid and contribute to the delivery of a more powerful current.

Maintenance-free car battery design

The rechargeable battery (ACB) of a car is a particularly significant element of the machine. It is a source of current that has the ability to store the energy needed to operate the electrical elements of the vehicle.

Its functions are responsible for:

- Starting - supplying energy to the starter, which is responsible for rotating the engine when starting.

- Generation of current for the operation of electronic systems in case of insufficient generator power.

- Powering devices when the car is not started.

Characteristics of a maintenance-free battery

Battery marking

Today's level of technical development has made it possible for automakers to use the most advanced and high-quality batteries - maintenance-free batteries.

The design of a maintenance-free car battery has characteristic features that give consumers a pleasant opportunity to pay a minimum of attention to this battery.

Car Battery Maintenance

It is worth noting that a maintenance-free battery is a modern source of energy, which in its design does not require or have special holes for adding water or electrolyte; the case of these batteries is completely sealed.

More than 150 years have passed since the development of the car battery and its basic structure remains unchanged for any type of battery to this day. The main elements of the battery are: acid and lead plates.

Battery design

Modern batteries consist of the following main elements:

- Plates (voltaic cells)

- Separators - interlayers

- Pole terminals

- Sealed housing (monoblock)

- case cover

Battery cells

Battery plates

The technical design of rechargeable batteries includes galvanic cells (plates) - chemical sources of electricity. There are 6 of them, they are connected to each other in series using jumpers. One negatively charged terminal of the block is attached to the positive terminal of the other.

Galvanic cells are located in a separate housing, and they are separated by partitions. Together, the batteries form a battery.

The galvanic cell of a car battery is a reversible source of chemical current - this means that the charge-discharge cycle can be repeated several times.

It consists of two electrodes (semi-blocks) of different polarities - lead lattice plates. The electrodes are placed in a solution of sulfuric acid (38%!) and distilled water.

Their mixture is an electrolyte - a substance capable of conducting current.

Separators - interlayers

Between the electrodes, to avoid short circuits, there is a separator - a dielectric layer. The separator acts as an insulator and does not allow electrodes of different polarities to come into contact, but does not disrupt the electrolytic conductivity of the battery.

The separator is made of plastic with a microporous structure, in the form of an envelope, placed on galvanic elements of a positive charge. This technique helps the active mass from the positively charged plates not to settle at the bottom of the monoblock and not come into contact with the negatively charged plates.

The development of an envelope-shaped separator device allowed battery manufacturing companies to come up with low-maintenance and maintenance-free batteries.

Pole terminals

The battery terminals are made of lead. Their size varies depending on the polarity of the terminal, so the positive one is larger in relation to the negative one. This feature is not accidental and serves as protection against incorrect connection of battery elements, which in turn eliminates the loss of active masses and helps to avoid a reduction in battery performance.

Sealed battery case

The battery case (monoblock) has undergone its evolution from wood, coated on the inside with sheet lead, then - ebonite.

In the 40s The first cases made of synthetic materials appeared in the 20th century. Modern batteries are made of synthetic polypropylene. Great demands are placed on the materials of monoblocks regarding its durability and safety. The housing is designed to withstand constant contact of chemical components, vibration and temperature changes.

case cover

The purpose of the housing cover is to tightly close the inter-element connections of the battery. In previous batteries, the cells had threaded plugs designed to add electrolyte and remove gas during battery operation. In the design of a maintenance-free battery, the plugs are not installed at all, or are tightly closed. Gases are removed using a central ventilation system.

It consists of two parts and is equipped with a labyrinth. With the help of a labyrinth, water vapor generated during battery charging is condensed and flows back into the battery. The lid integrates a central gas outlet and a gas ignition protection system.

The ignition protection is made at the outlet of the gas outlet from the battery in the form of a small round disk; it is called a frit.

The principle of operation of the frit is the free passage of gas into the atmosphere, but when the gas ignites, preventing the fire from breaking through to prevent the battery from exploding.

Battery types

All car batteries, as mentioned earlier, are identical in design and filled with electrolyte, only slightly differing from each other. Each modification is designed to achieve a specific goal to the detriment of other characteristics.

Battery with liquid electrolyte

They are open systems, i.e. gas released during charging may be released into the atmosphere. It has excellent performance characteristics, a long shelf life of up to 15 months, but there is no protection against electrolyte leakage.

Battery Economy

This type of battery is optimal in terms of cost and service life; it uses less lead.

It has a reduced engine cold start power and a slightly reduced service life (4 years or 80,000 km).

At the same time, a more favorable price, less weight and a low self-discharge current, which does not increase as the battery ages. Can be used in cars with a start-stop system.

We recommend: Checking the electrolyte level, density and charge of the car battery

Improved battery

They have the abbreviation EFB (Enhanced Flooded Battery) - an enhanced battery with liquid electrolyte. Structurally, they are distinguished by a thicker negative electrode grid, which provides high resistance to corrosion when loaded with high current, as well as the addition of carbon to the active mass of the negative electrode, which leads to improved charging ability.

It has protection against deep discharge and excellent performance characteristics, but there is no protection against electrolyte leakage.

Its design uses a passive mixing element; it reduces electrolyte stratification, i.e. the formation of layers with different concentrations of sulfuric acid, which is concentrated in the lower part of the galvanic cells, which leads to insufficient electrolyte density in the upper part. This occurs when charging and discharging processes are repeated frequently.

Battery AGM

Absorbent Glass Mat is fiberglass with very high absorbency.

They are also called recombination and are used on cars with a start-stop system and energy recovery function. In such batteries, the electrolyte is adsorbed by a fiberglass mat.

They are a closed system, i.e. all galvanic elements are isolated from the atmosphere by valves.

It is protected against leakage, even if the battery case is damaged, the probability is insignificant and amounts to no more than a few milliliters. They have a long service life, excellent performance and high reliability. But, on the other hand, it has a high cost and higher sensitivity to elevated temperatures.

Gel batteries

There are also batteries with a gel-like electrolyte; it is formed by adding silicic acid to it. They are ordinary lead batteries.

They have a very low probability of electrolyte loss, high cyclic resistance and reduced gas formation.

Their mass distribution is limited by a number of serious disadvantages, such as: deteriorated starting properties at low temperatures, high cost, intolerance to elevated temperatures and the associated unsuitability for installation in the engine compartment.

Battery disconnect devices

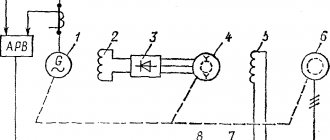

The battery connection circuit may use squibs or shutdown relays for safety, especially if it is located in the passenger compartment or trunk.

The task of these elements is to disconnect the starter and generator wires from the battery at the time of an accident, because Shorting these wires may cause a fire.

But the power supply to the on-board network is retained to ensure safety functions (hazard alarms, lighting, etc.)

Charge and discharge processes

The process of charging a battery means that the battery accumulates electrical energy. As a result of this process, electrical energy is converted into chemical energy.

The battery is powered by the generator when the car engine is running. The voltage that a standard charged battery produces during operation is 12.65 V.

The charging process can be described as the transition of lead sulfate and water formed during battery discharge into lead, lead dioxide and sulfuric acid. At the same time, the amount of sulfuric acid becomes greater, the density of the electrolyte substance increases.

As a result, chemical energy is accumulated and restored, which is later necessary for generating electricity.

The battery discharge process is characterized by the release of electrical energy to the battery consumers. A reverse chemical process takes place - chemical energy is converted into electrical energy.

The battery is subjected to a discharge procedure in the presence of an electrical current consumer connected to it. In this case, sulfuric acid disintegrates, and accordingly, its content in the electrolyte substance decreases.

The ongoing chemical reactions contribute to the formation of water (H2O). With an increased water level, the density of the electrolyte decreases.

Discharging the battery leads to the formation of lead sulfate. This effect is the same for positive and negative electrodes.

Main characteristics of the battery

Energy Conversion Ratio

The energy supplied to the battery when the battery is charging is greater than the energy it gives out during discharge. The excess of the “charge” energy to the “discharge” energy is based on the need to cover the costs of electrical and chemical processes.

For a full charge, you need 105–110%! energy of the amount previously consumed. Thus, the conversion factor will be between 1.05 and 1.10.

Capacity

The capacity of the battery is proportional to the amount of electric current supplied to it. The unit of capacity is ampere hours (Ah).

Capacity indicators are affected by discharge current and temperature. It tends to decrease with increasing discharge current and decreasing temperature, in particular at values less than 0 degrees.

Rated voltage

The standard voltage of each battery element corresponds to 2 V, and the voltage of the entire battery chain is equal to the number of galvanic cells. The machine's battery consists of 6 batteries, which corresponds to a nominal capacity of 12 V.

Cold crank current

This indicator characterizes the starting capabilities of the battery when operating in low temperature conditions. This parameter is measured at –18 °C.

The voltage of a fully charged battery does not drop below the specified value for a certain amount of time.

The current level affects the starting of the car engine, since the higher the current value in cold cranking, the easier the engine will be to start in the winter season.

Technical (operating) characteristics of car batteries

A car battery has quite a few operating parameters that are important when choosing a battery. If you make a mistake in even one of them, the battery will not be usable. Main characteristics.

- Capacity, Ah (ampere*hour).

- Starting current, A (ampere).

- Polarity.

- Execution of the case.

- Terminal type

- Mounting type.

Nominal battery capacity

Battery capacity is the amount of electricity that a battery can supply over a certain period of time. Measured in Ah (amps per hour). This is one of the main parameters not only of a car battery, but of any battery in general. The higher this indicator, the longer the battery can support the operation of the car’s electrical appliances while parked.

TOP battery rating

Many brands, many advice, difficult choices - these are the problems buyers face. We offer a small, our, subjective rating of battery brands.

- The first place in terms of quality and durability is rightfully occupied by OEM batteries. OEM is an analogue of a part that was installed from the factory. Of course, you will have to pay a lot more for a battery that proudly displays the Mercedes or Honda logo than for any other brand, but the result is worth it. The most popular battery brands on the market are Varta and Bosch. They have earned a reputation as reliable, trouble-free batteries that faithfully work out every penny invested.

- Among those who like to pay less and get more, the Topla brand is especially valued. This is, of course, not Bosch, but it may well please you with its long service life.

- And our hit parade is completed by budget brands Sada, Styer, Bi-Power and Ista. Although they are not expensive, they are quite capable of providing stable performance. You can remember them when you need a battery urgently, but you don’t have enough money.

Tips for battery operation and maintenance

In order for the battery to last as long as possible, you need to pay very little attention to it. Here are some tips for operating a car battery.

- Deep discharge is the enemy of the battery. Every time the battery is discharged to zero, irreversible sulfation of the electrodes occurs, calcium batteries especially suffer from this. From time to time, it is advisable to fully charge the battery with a special charger and under no circumstances allow it to completely discharge.

- The second enemy is vibration. Due to strong shaking and regular impacts, the active layer falls off the plates. AGM batteries suffer less from this, liquid batteries suffer more.

- Battery terminals are prone to oxidation, which impairs contact. Periodically you need to pay attention to the condition of the terminals and, if necessary, clean them of oxides.

- Pay attention to the battery case. Dirt, oil, and moisture contribute to current leakage and self-discharge.

- Electrical problems can also damage the battery. Especially problems with the starter and generator - adjacent elements.

- A swollen case with traces of electrolyte indicates that it is time to buy a new battery. A damaged battery must not be used!