Generations of systems

- Carburetor. They had many shortcomings, so they are classified as the first generation. There were frequent cases of fires and pops.

- Single injection - the system could be used not only on a carburetor engine, but also on an injector. A cold “start” has appeared, making the startup process easier.

- Distributed injector. Combines the positive qualities of previous systems and is improved.

Video on the topic

Fuel injection system

- a fuel supply system that has been widely installed on gasoline car engines since the 1980s. The main difference from the carburetor system is that fuel is supplied by forced fuel injection using injectors into the intake manifold or into the cylinder. Cars with such a power system are often called injection cars. In aviation on piston engines, such a system began to be used much earlier - since the 1930s, but due to the low level of electronic technology and precision mechanics of those years it remained imperfect. The advent of the jet age led to the cessation of work on fuel injection systems. The “second coming” of injection into aviation (light-engine) occurred already in the late 1990s.

How does a single injection work?

Single injection is one of the options for injection fuel supply to an internal combustion engine. Its characteristic feature is the supply of fuel to a chamber common to all cylinders. The air-fuel mixture is mixed in it and sent to the cylinder that is in the open state.

At the moment, there are no cars with one fuel injector being produced, but you can find a relatively large number of older cars operating on this principle.

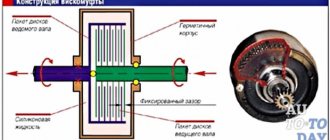

Single injection device. 1 - electric fuel pump; 2 - fuel filter; 3a — throttle potentiometer; 3b - pressure regulator; 3c - nozzle; 3d — air temperature sensor; 3e - idle throttle activator; 4 — engine temperature sensor; 5 — lambda probe; 6 - electronic control unit (ECU)

Mono injection was developed and put into operation as automakers moved away from carburetors. First, they invented the single-injector system, and later the distributed injection for each cylinder, which is used today.

The design of the device directly includes a nozzle operating under pressure, an air temperature sensor, a fuel pressure regulator and a fuel return line. According to modern standards, the fuel pressure for single injection is quite low. An electronic controller is used to control the opening and closing of the nozzle. The solenoid valve is responsible for dosing fuel, and the throttle valve is responsible for dosing air.

The pressure regulator in the single-injection system performs the task of stabilizing the pressure and preventing the passage of air pockets after the engine is turned off (this makes it easier to start the engine in the future).

About the concept

Correct setting of the single injection is important for high-quality fuel supply to the internal combustion engine. A special feature of this useful development is the supply of fuel to a combustion chamber common to the cylinders. This system was invented as an alternative to carburetors. At first, a single-injector design was invented, then they moved on to the manufacture of distribution injections designed for each cylinder.

The design includes a nozzle. She works under pressure. It includes an ambient temperature meter, a fuel pressure regulator, and a return line. The regulator's task is to stabilize the pressure, eliminating the appearance of air pockets after stopping the engine.

Single injection device

The design and operating principle of this system are quite complex and differ from other, more popular ones. Its operation is supported by a large number of sensors that regulate the fuel supply, but this makes it easy to start a cold engine.

A single nozzle is installed above the throttle valve, which regulates the air supply. Fuel is injected between the housing and the valve, and this process is synchronized with the ignition.

Device diagram

Sensors are used to dose fuel at different engine operating modes. The opening of the nozzle is controlled by an electronic controller, and its quantity is dosed by an electromagnetic valve. The mixture from the common chamber one by one enters the cylinders when the corresponding valves open, where it ignites.

Differences between mono injection and distributed injector

- A distributed injector is a special power system with injectors: their number corresponds to the number of cylinders. Which option is better is up to the driver to decide.

- Single injection is a more outdated option, unlike a distributed injector.

- A distributed injector is more economical than a single injection system.

- A distributed injector can have direct and distributed fuel supply.

Considering this mechanism for supplying fuel to the engine, it can be noted that there are certain differences from a distributed injector. And all these differences from a distributed injector are justified by the use and preference of a specific system, which is different for each driver.

How does mono injection work?

- In the functional chain, the single injection is located in front of the DVT cylinders. Through its nozzle, fuel enters the common air chamber.

- The prepared fuel-air mixture is sent to the first opened cylinder.

- The volume of air and fuel transferred inside the cylinders is determined by various sensors included in the mono-injection system.

- Excess fuel is returned from the system via the return line.

In the operating cycle, a nozzle made in the form of an electromagnetic valve provides pulsed injection of fuel. Its design usually includes a spray nozzle, a shut-off valve, a return spring and a solenoid. The throttle valve, which regulates the air flow, is controlled via an electrical or mechanical drive.

How does mono injection differ from injector and carburetor?

The key difference between a single injection and a distributed injector is that it uses one nozzle for all cylinders. A distributed injector has nozzles on each cylinder separately. Thanks to this, when using it, fuel is consumed more economically. In addition, the use of a common injector reduces the life of the engine.

The point is this. If the injector starts to work incorrectly, a poor fuel-air mixture is created, engine performance deteriorates, additional carbon deposits appear, moisture gets inside the combustion chambers, etc. Thus, deterioration of the injector affects the entire cylinder block. In the case of distributed fuel supply, wear of one of the injectors affects the operation of only one cylinder.

Compared to carburetor systems, mono-injection allows you to quickly start the engine due to a special valve that starts all the necessary processes.

Fuel injection systems (including single injection) do not suffer from such typical carburetor diseases as frequent clogging, clogging of jets, needle sticking, and the need for adjustment according to mileage.

For ordinary drivers who do not understand the specifics of setting carburetors and the influence of fuel quality on engine performance, the injection system is more convenient because it maintains the driving conditions specified during installation for a long time. The carburetor system, in turn, loses settings over time, so it begins to “burn” more gasoline.

What is a mono injection?

This system is one of the injection options . Its main distinguishing feature is that gasoline is supplied by one nozzle to the manifold , which connects the intake valves of all engine cylinders. Thus, an electromagnetic jet under pressure supplies fuel to the central air chamber, where a fuel-air mixture is formed and supplied to the first opened cylinder. The injector operates pulsed . Its operating cycle and the volume of supplied fuel depend on sensor signals characterizing the mass of air in the chamber, the position of the crankshaft, the throttle angle, engine temperature and vehicle speed. The electronic controller of the system, collecting a lot of information from the machine, controls the operating mode of the injector in real time.

This design is no longer used in currently produced cars, but it can occur quite often on used cars.

Pros and cons of the system

An engine with single injection at one time solved many problems, as it had clear advantages over a carburetor engine:

- The car owner did not even need to know the engine structure, since its operation is automatically regulated using sensors. This has increased the number of owners of cars that are easy to maintain - fill up and drive.

- Fuel consumption is lower and engine efficiency is greater, both when driving in different modes and at idle.

- Compared to carburetor engines, the amount of harmful emissions into the atmosphere is reduced.

- Simple design.

- Quick engine start in any conditions.

However, this design was supplanted by a more advanced injection engine. And the reasons for this were:

- Difficulties with repair and setup - special equipment is required. This is not done at home in the garage.

- Spare parts are not only rare, but also expensive.

- Requires high quality gasoline. If the mixture is not good enough, the engine begins to act up. For domestic conditions, this is especially important, since the quality of gasoline is not guaranteed at any gas station, and it usually does not meet the requirements.

- The cylinders are located at different distances from the nozzle, and the mixture enters them at different times. Therefore, gasoline does not burn completely, and its consumption increases.

- Electricity is required to operate, whereas a carburetor only needs a spark at start-up, and then fuel is supplied mechanically. If the battery is of poor quality or has a weak charge, you will not be able to start the engine.

Design of an injection engine

This is why modern injectors have replaced mono-injection, since they have its advantages, but are devoid of its disadvantages.

What kind of breakdowns can occur in the operation of a single injection?

Since the system uses only one nozzle and many electronic sensors and control units, the owner may face various troubles:

- Problems with starting the engine - it does not start or starts with difficulty, stalls immediately.

- Unstable operation at idle.

- Violations in dynamics, during movement. Fuel consumption may increase, traction during acceleration may deteriorate, and interruptions in engine operation may occur.

All this requires diagnostics, and this can now be done using a laptop and special software. It is better for a specialist to do this, especially since you don’t need to configure anything yourself without having special knowledge. Incorrect settings can further worsen the performance of the motor or it may stop starting altogether.

Using one nozzle is also not a good option. If it fails or becomes clogged, the machine will immediately stop. In this regard, distributed supply is much more reliable and safer, since in extreme cases it is possible to get to the place without one working cylinder.

It is worth keeping in mind that this system is outdated and has a lot of electronics, which also tend to break down. Considering that single injection is used on older cars, problems with the electronic part are also quite likely.

Signs and causes of malfunction

There is most often one symptom of uneven mono-injection: the engine speed suddenly begins to “float”, and it reacts poorly to pressing the gas pedal . This can happen either immediately after starting the engine or during the trip. The repair of the mono-injection system itself does not take much time. Much more time is spent identifying the cause of the breakdown. This task in the Volkswagen Passat B3 is seriously complicated by the fact that this car does not have a computer connection module, and therefore it is impossible to quickly carry out a full diagnosis.

We list the most common causes of uneven injection:

- The gasket installed directly under the mono-injection has lost its tightness.

- The contacts of the wires located under the mono-injection sensor have come loose.

- The problem occurred after the spark plugs were replaced with new ones.

- The seal of the distributor cover is broken (and the crack may not be visible to the naked eye, but it will be enough to cause malfunctions in fuel distribution).

- The compression created by the fuel pump is too high (or vice versa - too low).

- The throttle valve is clogged or covered with a thick layer of carbon deposits.

- The integrity of the wires going to the sensor that monitors the throttle position is broken.

What is mono injection, how does it work, how does it differ from an injector?

1 Until recently, I knew about the injector that, unlike a carburetor, it does not create an air mixture, but instead injects fuel somewhere using certain nozzles, and this injection is controlled by a computer. At first I assumed that the injection occurs directly into the combustion chamber, then, remembering the phrases “direct injection” and “mono-injection,” I assumed (with the help of a more experienced friend) that the injection occurs into the intake manifold. Let's figure out how things really are.

First there was the carburetor. In the carburetor, a gasoline-air mixture is formed from gasoline and air, which is supplied to the intake manifold through an opening opened by a flap. The damper is mechanically connected to the gas pedal. If you pressed the pedal harder, the damper opened, more mixture was in the manifold, more mixture entered the combustion chambers, more was burned, more energy was released: acceleration increased. The main disadvantage of the carburetor is the heterogeneous composition of the mixture entering...

To avoid problems with the operation of the injectors, they need to be cleaned approximately every 30,000 km-40,000 mileage.

Causes of injector clogging. The main and, perhaps, even the only reason for clogging of injectors is the use of low-quality fuel, which may contain heavy fractions. Wax, tars and olefins settle as deposits in the fuel supply system; as a result of their systematic entry into the needle valve and injector filter, clogging occurs and the engine begins to operate incorrectly.

There are two ways to solve the problem: the first is to purchase and install a new spare part, but this will cost a pretty penny; the second is cleaning existing injectors.

Methods for cleaning fuel injectors: There are several ways to clean fuel injectors. Let's look at the advantages and disadvantages of each of them.

Chemical method. To clean injectors chemically, special liquids are used, commonly known as solvents.

Design and principle of operation of the injector

The injector is the most popular electronic-mechanical unit in the automotive industry. The design and operating principle of the injector are both simple and complex. Of course, the average car owner does not need to delve into the jungle of design and software, but it doesn’t hurt to know the main points.

Such things cannot be repaired on your own, but it is worth understanding the injector structure, if only to avoid getting into trouble when paying a bill at a car service center.

What is an injector

An injector is a special nozzle installed on an internal combustion engine, or is part of an entire injection system. It performs the function of a fuel atomizer (liquid or gaseous). At the end of the article there is a video that clearly shows how the injector works.

This development was first introduced into production by Bosch specialists when they equipped the Goliath 700 Sport coupe with…

Single injection is one of the types of injection system for powering an internal combustion engine. In a distributed system, injectors are installed directly in the cylinders or in the intake manifold above the cylinders; each cylinder has its own injector that injects a portion of fuel at the right time. In a mono-injection system, there is only one injector, it fires every time the intake valve opens on one of the cylinders, fuel enters the intake manifold, mixes with air and enters the cylinder whose intake valve is currently open.

The main fundamental difference: in a monoinjector there is one injector, in a distributed one the number of injectors is equal to the number...

In addition, injection can be carried out simultaneously to all injectors or alternately, distributed to each cylinder. One of the advantages of single injection is that you can make it run on gas inexpensively. It's more difficult with an injector.

Ford Scorpio, 1986, hatchback, GL, 2.4i V6 AR(D), manual transmission, HBO III Bingo-M - sold. Ford Scorpio, 1995, station wagon, Ghia, 2.0 16V N3A, automatic transmission, leather, 2 -zone climate control, HBO IV ARGO - sold. Ford Mondeo, 1997, station wagon, Ghia, 1.8 16V Zetec-E, manual transmission, velor, air conditioning, HBO IV ARGO - sold. Ford Mondeo, 1997, station wagon, Ghia, 1.8 TDI, manual transmission, velor, climate control.

Ford Escape, 2000, SUV, 3.0 24V, automatic transmission, 4x4.

Tel….

Mono-injection is a fuel injection system. This fuel supply system is installed on modern gasoline engines. The main difference between this system and a carburetor is that fuel can be supplied to the intake manifold or directly into the cylinder through fuel injection using injectors.

A car that has such a power system is called an injection car. Single injection, the so-called central injection, is based on one nozzle for all cylinders, located instead of a carburetor on the intake manifold.

So, mono injection is an electronically controlled single-point low-pressure injection system for four-cylinder engines. An important feature of single injection is the presence of a centrally located fuel injector. Its operation is controlled by a solenoid valve. The system uses a throttle valve to meter air at the time of intake. And fuel injection occurs by spraying just above the throttle...

It’s precisely the local mechanics who convince me, they say, “…. Well, if you stop somewhere on the highway, then that’s it, you only got hit by a tow, but you cleaned the carburetor and drove off! AND it’s SIMPLE (??) than a mono-injector, and MORE RELIABLE (???).” So I was wondering why the Germans suddenly became inspired to install a mono-injector if the carburetor is much more reliable??? Maybe then modern injectors are actually going back to the Stone Age?

Those mechanics do not know how to hold a tool more complicated than a hammer correctly in their hands, and for them the VAZ chisel is a pearl of the automotive industry. An ideal car in all respects. You start communicating with such people and find out that: - Conder - jerk off. Snot, constantly breaks down, and the main thing EATS PETROL - power windows - jerk off. If the glass breaks, then you can't open or close it and generally show off for the brothers from the mountains. - Power steering - sucks. Just unnecessary parts and constant leaks. And without it, you can also pump up your muscles. - ABS - oh my God... it interferes with braking. Turn it off immediately.

-…

Related videos

Group “ICE Theory” VKontakte:

https://vkontakte.ru/club17394809

Useful video? Thank you in the comments!

Reviews

Vladimir Kolomiets

The hedgehog finally serves for additional swirls, which helps create a better mixture. Air and gasoline mix better in the wilds of these spikes. So cutting them down is stupid. My friend used to make them himself on his buggy so that the mixture mixed up to the cylinders would be better mixed. and became homogeneous.

Yura P

There are many mistakes in the story about the operation of the monoinjector; you need to first read the literature if you are not sure, and then shoot a video. He also called it a carburetor...

jeka744 jeka744

I looked at this review today. I have a Vectra A 90 year old C16nz engine, according to the first estimate, one-to-one single injection. Individual channels were also idled. just today is the current of his numbers. I would have seen...

VW. Das Auto.

Re: single injection or injector

Chameleon, here you, my friend, are completely wrong. Caprik's explanation in this case is a little closer to the truth. VAG (Volkswagen-Audi Group) MonoJetronik/MonoMotronik (RP/PM-AAM-ABS engines) have - TPDZ (throttle position sensor), DTOZH (coolant temperature sensor), DTVV (intake air temperature sensor), RPХХ (forced idle speed regulator, no longer a sensor, but “the brain takes it out”), LZ (lambda probe, not on all engines). None of these injection engines (engines) have an air flow sensor (flow is considered “bypassing” according to the values of TPS - throttle opening and TPS - air temperature). There is also no CPPS (crankshaft position sensor) on any of these engines. Something like this. OF the “electronic” VAG carburetors I know (from hearsay) Pierburg 2EE (the last “E” in the name means “electronic”), unlike the “regular” ones...

Design and malfunctions of an injection engine Mono injection / distributed injection. Emergency mode. Diagnostics

(To the first page of the article)

Single injection / distributed injection

At first, microcomputers were not fast enough to count each cylinder. All parameters were calculated on average for the entire engine, that is, they were selected based on the performance of the worst cylinder. This system is called mono-injection, since it is characterized by the presence of only one nozzle that injects fuel into the intake manifold channels for all cylinders. This is not entirely optimal. As microprocessor performance increased, it became possible to count each cylinder separately. In addition, they began to install a separate injector for each cylinder. This made it possible to install the injectors in close proximity to the cylinder, which improved the quality of the mixture. But in general, the operating principles of mono- and distributed injection are not particularly different.

…

Single injection is a complex technical device that is part of the fuel injection system. This part is installed on almost all modern cars of foreign and domestic production, including the VAZ Priora. The Audi 80 also has mono injection. The main thing that distinguishes it from the “medieval” carburetor is the ability to inject fuel directly into the cylinder using special nozzles. And all cars that are equipped with this part have exclusively an injection type of power supply.

Thus, mono injection is an electronically controlled single-point system that supplies fuel to the cylinders at particularly low pressure. As noted above, a distinctive feature of this part is the presence of a nozzle. This element is controlled by a special solenoid valve and is an integral part of such spare parts as mono-injection.

Malfunctions

As you know, domestic gasoline is full of all sorts of foreign impurities in the form of...

Buying a car is an expensive purchase and a very responsible process. It consists not only in choosing the make and model of the car, but also in taking into account a number of other parameters and characteristics. These features include the choice of fuel supply system.

Many car enthusiasts have heard about single injection and injector, but have little idea of the difference between them, although this is very valuable knowledge, often influencing the choice of car and its subsequent operation.

What does mono injection and injector mean?

Single injection is one of the types of injection fuel supplied to the intake manifold using a single nozzle for all cylinders.

The injector is a distributed type system in which fuel is injected individually to each cylinder.

Comparison of mono injection and injector

What is the difference between mono injection and injector? It is important to understand that a single injection is essentially the same injector. Operating principle…

Single injection is an injection system for supplying fuel to the engine, which is used in not very modern cars. This is a transitional fuel supply system that has been introduced into widespread use in place of the carburetor. A feature of fuel injection in this system is that it uses one nozzle, which is located in place of the carburetor. This injector sprays fuel into all cylinders. Unfortunately, due to new environmental standards, today this method of supplying fuel to a gasoline engine is not in demand; it has been replaced by distributed injection.

Of course, the mono-injection system outperforms the carburetor fuel supply system, and has both advantages and disadvantages; we’ll look at which ones below.

Advantages of the single injection system:

Simplified engine starting. With the help of an electromagnetic valve, which controls all processes of the single injection, easier engine starting is possible, compared to... These are different engine fuel supply systems. Carburetor is a mechanical passive system; in it, the formation of a combustible mixture and its supply to the cylinders is carried out due to the suction flow of the intake manifold. Advantages of a carburetor: it has no electronic components.

Disadvantages: like any multi-component mechanical system, it is difficult to set up and operates unstable.

Injection (injector) is a type of power supply in which gasoline is forcedly supplied under pressure using a special gasoline pump. The first models were controlled mechanically and performed worse than the carburetor. A modern ECU (electronic control unit) of the injection system is a specialized computer that fully monitors and controls all engine operating parameters. Types of injections: 1. Single injection - actually an injector instead of a carburetor, one for all cylinders. Not currently applicable.

2. Distributed simultaneous injection: fuel is supplied by a fuel pump to a special fuel...

You do NOT have a single injection. Each cylinder has its own injector, so the injection is distributed. Mono injection is a single injector that sprays fuel into the intake (like a carburetor). Both can be either mechanical (in your case) or electronic. We do not touch direct injection. In general, you have distributed mechanical injection. You can also call it a mechanical injector, which would also be correct. I noticed that a little more than a shitload of people call everything that doesn’t look like a regular injector a mono-injector. P/s about the problem, depending on your luck. I drove for three years, I didn’t know any grief, at the beginning I just had to tinker for a couple of days: I adjusted the ignition and idle, drove around, adjusted it again. My brother has already driven his barrel for more than 100,000 miles with only one small problem - it doesn’t start right away, just crank it for a few seconds...

Replacing a mechanical injector with an electronic one

Attention owners of Audi 100 (80) with 5-cylinder engines (AAR, NG, NF).

It's no secret that the 5-cylinder engine (AAR, NF, NG) is the strongest and most reliable engine of all Audi engines. In terms of mechanical reliability, it simply has no equal. Together with a stainless body, an impeccable interior and an outrageously strong chassis, these cars still have no analogues in our market. But, unfortunately, they have one drawback - mechanical fuel injection! In terms of its structure, this injection is not at all bad and in terms of reliability it is quite consistent with its car! But old age and the low quality of our fuel are taking their toll. While it works well, there are no problems, but as soon as the injection starts to break down, then hold on and be prepared to spend more than the cost of the same car on repairs! A lot of people, especially in the regions, were forced to sell this wonderful car due to...

Features of the operating principle of single injection

The principle of preparing the air-fuel mixture is simple. The injector, controlled by the ECU, dispenses the required amount of fuel, and the throttle valve supplies the required air. The combustible mixture is distributed among the cylinders using special sensors.

Engine compartment

Gasoline is supplied to the combustion chamber between the engine body and the throttle valve. To ensure good performance characteristics, ignition and mono-injection work harmoniously. This became possible thanks to the management of all processes from a single controller.

The operating mode of the fuel system is influenced by the following factors:

- crankshaft rotation speed;

- ratio of components of the fuel-air mixture;

- throttle position;

- gasoline pressure in the fuel line.

Mono-injection control has a lot of negative feedback coming from sensors. All information received by the ECU serves to reduce emissions of harmful substances and improve the dynamic performance of the vehicle. On a technically sound car with single injection, the exhaust fully complies with modern environmental requirements.

The concept of single injection

Single injection is a type of injection system. Its distinguishing feature is related to the fuel supply. It first enters a chamber common to all existing cylinders, and once in the chamber, it is mixed with air. The resulting mixture enters the cylinder, ready to receive it.

The mono-injection system was invented as an alternative to carburetors. First, they invented a single-injector design, and then they began to produce distributor injection designed for each of the cylinders. Today there are very few cars left with single injection, but they still remain in operation.

On a note! Cars with single injection are completely out of production.

Setting up mono injection in garage conditions

The correct operation of the mono-injection system depends on the crankshaft rotation speed, on the ratio of the volume of incoming air and its mass, on the angle at which the throttle valve is open, on the absolute pressure in the intake, etc. There is also a connection with the oxygen sensor (lambda probe). The signal from the oxygen sensor is sent to the adaptation system, which adjusts the operation of the single injection, making the necessary changes in different operating modes of the internal combustion engine. It is quite obvious that during the operation of the vehicle, malfunctions occur in this system.

One of the most common problems on cars with single injection is that the revs begin to float. As a result, the engine may operate unstably under load, at idle, in transient modes, etc. In such a situation, repair and adjustment of the mono-injection is necessary. Let us immediately note that determining the cause is not easy, since computer diagnostics are not provided for such machines. The problem is that there is no diagnostic connector.

Taking into account the fact that the scanner cannot detect the error, it is necessary to check individual elements one by one that may affect the operation of the monoinjector. The following breakdowns are noted in the list of faults:

- The tightness of the gasket installed under the monoinjector is broken. Loss of tightness leads to uneven distribution of fuel. In this case, the gasket should be replaced with a new one.

- problems with the contact group or wiring to individual electrical elements of the mono-injection unit. Possible damage, breakage, loss of insulation integrity, etc. To check, each element and its wiring must be “ringed” with a multimeter.

- The operation of single injection is affected by the type of spark plugs installed. If, after replacing the spark plugs, the engine begins to malfunction, then to check, you can screw in the old spark plugs and evaluate the stability of the internal combustion engine.

- The dependence of the monoinjector and ignition suggests the need to inspect the distributor and its cover. Minor defects or a breakdown of the cover is a reason for replacement.

- Additionally, you should check the TPS sensor, which determines the throttle position. Checking is carried out with a multimeter.

- You should also pay attention to the pressure that the fuel pump produces. If the device is faulty or malfunctioning, then repair or replacement of the fuel pump is necessary. Don't forget about fuel filters, which can become clogged.

- carbon deposits and deposits on the throttle valve must be removed (cleaning the throttle valve), since contamination can have a significant impact on the performance of the single injection.

The most common problems associated with the monoinjector were discussed above. If self-checking does not yield anything, it is better to visit a car service center. Also, the mono-injection system after repair, cleaning or as a result of failures needs to be adjusted and further diagnosed. Let's look at how this is done using the example of a Volkswagen B3 with a monoinjector.

- The first step is to check the resistance of the incoming air temperature sensor. The measurement is made using a multimeter, after which the obtained values are compared with the nominal values in a special table. If the air temperature is between 20 and 25 degrees Celsius, then the resistance should be between 1800 and 1900 ohms. Heating of the sensor means that the resistance should decrease, cooling will lead to an increase in resistance. This must be checked by heating and cooling the sensor yourself.

- Also, using a multimeter, the resistance at the monoinjector injector is measured. A normal operating indicator is a resistance in the range from 1.2 to 1.6. Slight deviations are acceptable as the multimeter may have inaccuracies.

- The next step is to adjust the idle speed on single injection. For this setting, voltage is supplied from the battery to the regulator contacts (12 V). At the same time, the accelerator is set to its extreme position. Next, use a multimeter to check for a short circuit. To do this, you will need to place the multimeter probe in the gap that exists between the accelerator limit switch and the rod. If the gap is too large, then the short circuit will not be visible on the multimeter. This means that the specified gap needs to be adjusted. This is done using a screw made for this purpose, which is located at the bottom of the monoinjector. The screw changes the position of the limit switch.

- After cleaning or carrying out other work on the monoinjector, it is necessary to adjust the position of the monoinjector throttle valve. To set this up, the mono-injector must be installed on the car, after which the injection nozzle connector, the throttle position sensor connector, the incoming air temperature sensor connector, etc. are connected. Next, you should connect the fuel lines. Now the terminals are disconnected from the battery, after which you should turn the key in the ignition switch. These steps allow you to reset the monoinjector settings. Then the battery can be connected, after which the mono-injection will begin to work with the original factory parameters.

We add that after resetting the mono-injection system, you should recheck the voltage at the throttle valve connector. More precisely, the measurement is carried out on pins 1 and 5. To measure, the ignition is turned on, after which the multimeter should display 5 or 6 Volts. Now the measurement is made on pins 1 and 2, the reading should be 0.186 Volts. If the data differs from the specified parameters, adjustments should be made.

To solve the problem, you will need to slightly unscrew screw 4 on the throttle cover, after which the multimeter will be connected to contacts 1 and 2. Then the cover is slowly turned in different directions, recording the voltage changes on the multimeter at each offset. With these actions it is necessary to achieve the recommended voltage readings. As a result, a serviceable single injection with all functional and connected sensors will function normally after tuning and cleaning the throttle.

The difference between mono injection and injector

Buying a car is an expensive purchase and a very responsible process. It consists not only in choosing the make and model of the car, but also in taking into account a number of other parameters and characteristics. These features include the choice of fuel supply system.

Many car enthusiasts have heard about single injection and injector, but have little idea of the difference between them, although this is very valuable knowledge, often influencing the choice of car and its subsequent operation.

The content of the article

Definition

Single injection is one of the types of injection fuel supplied to the intake manifold using a single nozzle for all cylinders.

The injector is a distributed type system in which fuel is injected individually to each cylinder.

Comparison

It is important to understand that a single injection is essentially the same injector. The principle of operation of the two subtypes of one system is the same. Their main difference is that in mono injection there is only one nozzle, from which fuel is supplied to the cylinders.

Injector

In this case, the fuel mixture travels different distances to the cylinders, which does not ensure its uniform distribution in each of them.

The injector, due to the presence of nozzles according to the number of cylinders and the original design, provides distributed fuel injection. This device guarantees the injector better performance than a single injection, primarily in terms of efficiency.

The injection system is more modern than mono-injection, but is also considered more complex. At the same time, the injector is promising in terms of improvements. There is a modified injector in which fuel is supplied under high pressure directly into the combustion chambers, which provides even more accurate dosing. Mono injection cannot boast of such a device.

Conclusions TheDifference.ru

- Single injection is a system for supplying a fuel mixture using one nozzle to all cylinders;

- Injector - an engine power system in which the number of injectors corresponds to the number of cylinders;

- Mono injection is considered obsolete compared to the injector, but the design of the injector is more complex;

- The injector is more economical than a single injection system;

- The injector can be distributed or with direct (direct) fuel supply.

Requirements for setting up mono injection on an Audi

You can get to the unit by removing the air filter. It is necessary to inspect whether the gap of the idle air control limit switch is set correctly. How to act without errors?

- Auto ignition turns off. The block is removed from the IAC connector. 6V is supplied to the two contacts located at the top. The control rod should move in.

- To properly configure the Audi 80 mono injection, you should adjust the position of the shock absorber.

- A test instrument is connected to the two contact outputs of PXX at the bottom. It is more convenient to use a device that can make sounds: a short circuit is easier to detect.

- Now it's up to the 0.45 and 0.5 mm probes. They will act as assistants in measuring the distance between the throttle screw and the PXX rod. A short circuit should occur when a half-millimeter probe is inserted. This should not happen when using the second probe.

- A control measurement in setting up the Audi mono-injection is important for the normal functioning of the unit. In this case, there is no need to use the IAC connector. The ignition is turned on and the potentiometer helps measure the reference voltage. The malfunction can be judged by readings other than 5V. If there is a slight difference, for example, 0.2 V, we can talk about problems in the electrical network. It is better to contact specialists for qualified diagnostics in order to definitely find out the causes of defects or to adjust the operating mode of the structure.

Common problems

In the lexicon of motorists, mono-injection is lovingly called “Monic”, and its problems are by no means encouraging. What do servicemen face?

- There is a “walking” of revolutions. This indicates defects in the temperature sensors.

- The Swallow loses power, which means air has entered the unit.

- Due to the stuck “limit switch” on the idle speed control, the engine is in constant idle mode.

- The engine refuses to start.

- Having released the gas pedal, the car enthusiast sees that the speed has dropped.

What is a mono injection? Advantages and disadvantages of mono-injection in relation to the carburetor and injector

Category: Technical zone

Many car enthusiasts have heard about single injection more than once. However, not every driver can explain what it is.

Single injection is an injection system for supplying fuel to the engine, which is considered transitional. Mono injection has one nozzle through which fuel is supplied to all cylinders simultaneously. Nevertheless, mono-injection has pros and cons when compared with injection and carburetor fuel supply systems.

Advantages and disadvantages of mono injection:

- The fuel injection system is uniform, which cannot be said about single injection. This is justified by the fact that in a single injection there is one nozzle, thanks to which fuel is supplied simultaneously to the existing cylinders. However, in an injector, the number of injectors is equal to the number of cylinders;

- In mono injection, fuel, unlike an injector, travels an unequal distance to the cylinders. Therefore, the injector is more economical. However, mono-injection outperforms a carburetor in fuel economy;

- thanks to the solenoid valve, which monitors the operation of the mono-injection, starting the engine is much easier, unlike a carburetor;

- the injection system is more modern than mono-injection;

- The design of a single injection is simpler than an injector;

- Compared to a carburetor, a reduced amount of fuel ejected from the engine cylinder is observed when using single injection;

- mono-injection does not require manual adjustment of the fuel supply system, unlike a carburetor;

- The efficiency of a single injection is higher than that of a carburetor. This allows you to achieve better dynamic performance of the machine;

- repair of a single injection and its components is more expensive than a carburetor fuel supply system;

- Unlike a carburetor, mono-injection is power dependent and requires a high battery charge.

In any case, dear car enthusiasts, the choice is yours.

You may also be interested in the following articles:

Sincerely, Site Administrator bibimobil.ru

If you notice an error, select a piece of text and press Ctrl+Enter

Setup Tips

Setting up a single injection is most often required when the engine speed fluctuates. This can be observed both at idle and while driving. Engine malfunctions are most noticeable when changing gears. All these symptoms indicate that adjustment of the mono-injection will be required in the near future.

Carrying out the adjustment

Description of the sequence of actions:

- Using a multimeter, check the resistance of the intake air temperature sensor and compare it with the table values;

Intake air temperature sensor - Check whether the sensor circuit is operational;

- Check the pressure of the injectors;

- Set the idle clearance;

- Check the accelerator regulator and limit switches;

- Adjust the throttle position.

Once the adjustment is complete, you need to start the car. A test drive should show no floating rpm. Otherwise, it is necessary to additionally check the associated systems.

Maintaining a single injection in good condition is only possible with high-quality diagnostics. It is necessary to pay attention to any changes in the behavior of the car. The sooner a problem is noticed, the cheaper it will be to fix it. It is necessary to pay regular attention to injection.

Distinctive features

As described above, mono injection has better technical characteristics than a carburetor. Its main advantage is optimally stable engine operation in different temperature conditions under different loads. Automatic adjustment allows you to optimize engine performance without the need for manual adjustments. This allows the operation of the engine to be fully automated and the driver does not need to adjust it. Turn on decompression at startup, warm up.

But not everything is so smooth when equipment parts wear out . The presence of a large number of sensors in systems with single injection and the complexity of their control systems leads to a greater likelihood of violation of operating conditions. Wear or failure of one sensor leads to problems or failures in engine operation and starting. The complexity of setting up a single-injection system forces the involvement of specialists. Or you have to independently search for technical information to study it.

A word from the expert opinion

Why are settings reset? Difficulties and an urgent need to “reboot” the unit arise among those who like to drive short distances. This problem is inherent to vehicle owners who prefer to regularly start the engine while simultaneously pressing the gas pedal. How to proceed?

- The engine starts and warms up. The cooling fan should operate twice. The optimal oil temperature is +80 degrees.

- We turn off the power unit by turning off the ignition.

- The connector from the control unit must be disconnected to clear the RAM.

- The above connector is turned on again.

Sources

- https://portalmashin.ru/service/engine/chto-takoe-monovprysk.html

- https://AvtoNov.com/%D1%87%D1%82%D0%BE-%D1%82%D0%B0%D0%BA%D0%BE%D0%B5-%D0%BC%D0%BE %D0%BD%D0%BE%D0%B2%D0%BF%D1%80%D1%8B%D1%81%D0%BA-%D0%B8-%D0%BA%D0%B0%D0%BA -%D0%BE%D0%BD-%D1%80%D0%B0%D0%B1%D0%BE%D1%82%D0%B0%D0%B5%D1%82/

- https://FB.ru/article/454806/nastroyka-monovpryiska-poshagovaya-instruktsiya-sovetyi-spetsialistov

- https://DriverTip.ru/osnovy/chto-takoe-monovprysk-kak-on-rabotaet.html

- https://scart-avto.ru/remont/chto-takoe-monovprysk-kak-on-ustroen-kak-rabotaet-i-chem/

- https://SwapMotor.ru/ustrojstvo-dvigatelya/monovprysk.html

- https://KrutiMotor.ru/nastrojka-monovpryska/

Complexities and conveniences of both systems

In case of malfunctions in the operation of mono-injection systems, the sensors and injector coil must be checked. It is not difficult to identify a fault with a potentiometer ohmmeter, but it is expensive to replace. An original part may cost more than a used engine. The sensors must match the parameters exactly and, preferably, be tested on a known-good engine. The operation of the system can be disrupted by loaded “memory” in the control unit. But a tuned unit with working sensors will produce good results in engine operation.

In case of malfunctions, the carburetor is repaired mainly by eliminating mechanical damage, corrosion and dirt . As well as optimal adjustment of the adjusting screws.

Therefore, for those who are afraid of electronics like fire and, in case of some failures, rush to sell their car, it is better to recommend a carburetor. But if anyone wants their engine to work optimally and use its resource economically , sacrificing complexity, then it is better to choose the electronic option.

Auto and motorcycleComment

Disadvantages [ edit | edit code]

The main disadvantages of engines with a control unit compared to carburetor engines:

- High cost of components (this was relevant until about 2005),

- Low maintainability of elements (lost relevance due to the development of their mass production and increased reliability),

- High requirements for the fractional composition of fuel,

- The need for specialized personnel and equipment for diagnostics, maintenance and repair, the high cost of repairs (lost relevance due to the massive distribution of mobile devices and diagnostic programs).

- Dependency on power supply and critical requirement for a constant supply voltage (for the more modern electronically controlled version).

- Gasoline is supplied under pressure, which increases the likelihood of a fire in the event of an accident. Therefore, in early systems, the fuel pump circuit had an automatic switch that was triggered upon impact, and in modern systems, the controller switches off the fuel pump in emergency situations.

Device

The single injection device is a complex mechanism that requires some attention, and its study requires time. To ensure air dosing during the creation of the fuel mixture, a throttle valve is used. In a special pipeline, fuel is distributed among the cylinders.

If the unit does not have time to warm up, then the installation acts in such a way that there is as much fuel in the engine as possible in order to maintain shaft speed. Based on the temperature sensor, the required amount of fuel is calculated.

Differences between mono injection and distributed injector

- A distributed injector is a special power system with injectors: their number corresponds to the number of cylinders. Which option is better is up to the driver to decide.

- Single injection is a more outdated option, unlike a distributed injector.

- A distributed injector is more economical than a single injection system.

- A distributed injector can have direct and distributed fuel supply.

Considering this mechanism for supplying fuel to the engine, it can be noted that there are certain differences from a distributed injector. And all these differences from a distributed injector are justified by the use and preference of a specific system, which is different for each driver.

Differences between mono injection and carburetor

- Mono injection is a method of supplying the mixture through one nozzle to all cylinders. It's better than a carburetor.

- Using a special valve that provides control of all processes, you can easily start the engine, which cannot be said about carburetor systems. This structure makes this option preferable.

- Possibility of reducing fuel consumption: carburetor elements are designed to make it higher due to incorrect settings; using the method under consideration, this figure can be significantly reduced. According to this parameter, the scheme under consideration is better than others.

- There is no need to manually configure the system to operate the engine. If the same thing happens in the carburetor circuit or in the area of the distributed injector, you may need the help of specialists.

- More advanced performance indicators associated with the highest accuracy of the operation of the circuit - pressure, voltage, etc. As a result, optimal dynamic characteristics of the engine and other mechanisms are achieved. The main thing is to check the pressure in a timely manner and carry out work to normalize this indicator. It is also important to compare the voltage.

This system ensures high quality engine operation and creates optimal conditions for its functioning - normal pressure and others. Which type of device is better is up to each user to decide for himself.

Disadvantages of the system

The description of this type of filing suggests the existence of certain disadvantages:

- High cost of purchasing components and carrying out repair work. Traditionally, no driver, when purchasing this fuel supply system, expects breakdowns, but you need to be prepared for anything.

- Low suitability of many elements for repairs. Of course, this event is cheaper than a complete replacement, but this does not exclude its high cost.

- The need to purchase quality gasoline. In our country it is not always possible to purchase it, which is due to the sale of low-quality liquids by many gas stations.

- Severe dependence on electrical power. On this issue, the injector and carburetor system win, since the process is simpler.

In order to have fewer operational defects and prevent wear of parts, it is necessary to regularly measure pressure and voltage and normalize other indicators. Despite the shortcomings, there are aspects that make this system better than some others.

How the system works

Mono injection, in addition to the nozzle, consists of a temperature sensor, regulator and fuel return line. Compared with modern parameters, single injection requires very little pressure.

Principle of operation:

- The nozzle through which fuel is directed into the chamber is opened by a special controller.

- The fuel dosage is controlled by a valve, and the air supply is controlled by a throttle valve (DZ), controlled by an electric drive. The finished fuel assembly ends up in the cylinder that opened earlier than the others.

- Pressure stabilization is carried out by a regulator of the same name. It does not allow air pockets to enter the system when the internal combustion engine is turned off. Thanks to this design solution, starting the engine is easier.

An injector is an electromagnetic valve that provides fuel injection in pulses. It consists of a spray nozzle, spring, valve and solenoid.