History of appearance

The world's first production passenger car without a clutch pedal

The principle of transmitting torque by recirculating fluid between two impeller wheels without a rigid connection was first patented by the German engineer Hermann Fettinger in 1905. Devices operating on the basis of this principle are called fluid couplings. At that time, the development of shipbuilding required designers to find a way to gradually transfer torque from a steam engine to huge ship propellers in the water. With a tight connection, the water slowed down the sharp movement of the blades during startup, creating excessive backload on the engine, shafts and their connections.

Subsequently, modernized fluid couplings began to be used on London buses and the first diesel locomotives to ensure their smooth starting. And even later, fluid couplings made life easier for car drivers. The first production car with a torque converter, the Oldsmobile Custom 8 Cruiser, rolled off the General Motors plant in 1939.

Design and principle of operation

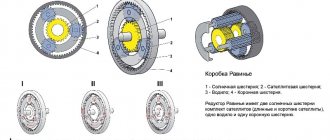

The design of a torque converter

The torque converter is a closed toroidal chamber, inside which the pump, reactor and turbine impellers are coaxially placed close to each other. The internal volume of the torque converter is filled with automatic transmission fluid circulating in a circle, from one wheel to another. The pump wheel is made in the torque converter housing and is rigidly connected to the crankshaft, i.e. rotates with engine speed. The turbine wheel is rigidly connected to the input shaft of the automatic transmission.

Between them is the reactor wheel, or stator. The reactor is mounted on a freewheel, which allows it to rotate in only one direction. The reactor blades have a special geometry, due to which the fluid flow returning from the turbine wheel to the pump wheel changes its direction, thereby increasing the torque on the pump wheel. This is the difference between a torque converter and a fluid coupling. In the latter there is no reactor, and accordingly the torque does not increase.

Torque converter - operating principle

The operating principle of the torque converter is based on the transmission of torque from the engine to the transmission through a recirculating fluid flow, without a rigid connection.

The drive pump wheel, connected to the rotating crankshaft of the engine, creates a flow of fluid that hits the blades of the turbine wheel located opposite. Under the influence of fluid, it begins to move and transmits torque to the transmission input shaft.

As the engine speed increases, the rotation speed of the pump wheel increases, which leads to an increase in the force of the fluid flow, dragging the turbine wheel along with it. In addition, the liquid returning through the reactor blades receives additional acceleration.

The fluid flow is transformed depending on the speed of rotation of the pump wheel. At the moment the speeds of the turbine and pump wheels are equalized, the reactor prevents the free circulation of liquid and begins to rotate thanks to the installed freewheel. All three wheels rotate together, and the system begins to operate in fluid coupling mode without increasing torque. As the load on the output shaft increases, the speed of the turbine wheel slows down relative to the pump wheel, the reactor is blocked and again begins to transform the fluid flow.

Symptoms of a problem

There may be several signs of serious malfunctions of the automatic transmission torque converter. All of them indicate an imminent breakdown of the gas turbine engine and failure.

Sign. A noise resembling the beating of a metal object is heard. It disappears under load.

Problem and solution. Wear of the bearings located between the turbine and the pump. To remove these symptoms and fix the breakdown, you need to disassemble the torque converter and replace the bearings.

Sign. Vibration of the automatic transmission when accelerating above 60 km/h or driving the car on a flat surface at high speed.

Problem and solution. Filter device is dirty. Loss of functional properties of the lubricant. It is necessary to completely replace the ATF in the automatic transmission and install a new filter. It is quite possible that oil starvation has occurred. It is necessary to check the automatic transmission pan for leaks.

Sign. There is no movement back or forward.

Problem and solution. The connection between the turbine and the automatic transmission shaft has broken. To solve this problem, you will need to replace the torque converter. In rare cases, you can get by simply replacing the spline connection.

Sign. The car cannot accelerate and gain the required speed in a short time.

Problem and solution. The overrunning clutch has failed. It is necessary to disassemble the torque converter and replace it.

Sign. Oil overheating. The automatic transmission jerks and kicks.

Problem and solution. For example, if there are problems with wear on the friction lining of the torque converter brake locking piston, it is very difficult to notice the incorrect operation of the device. Because of this, the oil often overheats to 140 degrees Celsius. Overheated lubricant destroys the rubber of gas turbine engine oil seals. Oil begins to flow.

This malfunction continues with complete wear of the clutch lining. Its glued part comes off and travels through the automatic transmission. Then it settles and sticks in the wrong places, causing a blockage. The blockage prevents the free circulation of oil. The pressure drops.

Therefore, both experts and experienced mechanics at service stations ask car owners to carry out regular maintenance. When the clutch wears out, the malfunction is invisible. But subsequently it leads to a complete replacement of the automatic transmission. Although at the initial stages it was possible to get by only by changing the clutch lining.

Infrequent failures of gas turbine engines include the following problems:

- destruction of turbine blades and pump wheel. Leads to breakdown of the gas turbine engine. It needs to be completely replaced. The problem is determined only after opening;

- overrunning clutch wedge;

- unlocking the overrunning clutch;

- overheating with destruction of the hub.

Read

Land Rover Discovery 3 automatic transmission repair

Overheating of the transmission fluid can cause rapid loss of functionality.

Sign. The smell of burnt plastic spreading into the cabin. A common problem on Toyota Camry 50.

Problem and solution . A clogged radiator is the problem in this case. It is recommended to remove and clean it. Changing the oil and filter device is a must.

Sign. Kicks, delays when switching gears in winter.

Reason and solution . This can be facilitated by cold starting. To avoid these symptoms, the automatic transmission needs to be warmed up in winter. At temperatures below 0, the car owner must warm up the automatic transmission to an operating temperature of 70 degrees Celsius and only then start driving.

Attention! Unresolved problems and left for later, symptoms of torque converter malfunctions on the DSG can lead to destruction of the pulleys and broken belt or chain. We will have to restore the CVT box completely.

On cars of an older year of manufacture, the rocker itself fails. It locks in one position. Here you will need to replace the selector and gear shift knob. This can be done without removing the automatic transmission.

Lock mode

Torque converter design with locking

In order to cope with the main disadvantages of the torque converter (low efficiency and poor vehicle dynamics), a locking mechanism was developed. The principle of its operation is similar to the classic clutch. The mechanism consists of a locking plate, which is connected to the turbine wheel (and therefore to the gearbox input shaft) through vibration damper springs. The plate has a friction lining on its surface. At the command of the transmission control unit, the plate is pressed by the lining to the inner surface of the torque converter housing using fluid pressure. Torque begins to be transmitted directly from the engine to the gearbox without the participation of fluid. This results in lower losses and higher efficiency. Locking can be enabled in any gear.

How to check the automatic transmission gas turbine engine

Car owners are interested in how to check the operation of the torque converter. Experts say that without disassembling the gas turbine engine, checking the “donut” is impossible. Error codes about malfunctions and emergency mode may appear on the dashboard monitor, but the final verdict can only be made after disassembling the gas turbine engine.

This is because most failures occur at the mechanical level. This requires disassembling each component separately and inspecting it visually.

At home or in the garage, the car owner will be able to disassemble the torque converter only if he well understands the principle of operation and structure of the device. You need to have a special machine on which you can clamp the donut and carefully cut it to get to the inside. You will also need specialized tools to identify the fault and remove it.

Read

Diagnostics and repair of Mazda 6 automatic transmission

If the car owner is not good at this or is not an experienced mechanic, then at the first sign of trouble, it is better to contact experienced mechanics at a service station. What are the external manifestations of a breakdown of the gas turbine engine of the automatic transmission in the next block.

Slip mode

The torque converter lockup may also be incomplete and operate in the so-called “slip mode”. The locking plate is not completely pressed against the working surface, thereby ensuring partial slipping of the friction lining. The torque is transmitted simultaneously through the blocking plate and the circulating fluid. Thanks to the use of this mode, the car's dynamic qualities are significantly improved, while maintaining smooth movement. The electronics ensure that the lock-up clutch is turned on as early as possible during acceleration, and turned off as late as possible when the speed decreases.

However, the controlled slip mode has a significant drawback associated with abrasion of the friction surfaces, which are also subject to severe temperature influences. Wear products enter the oil, worsening its performance properties. The slip mode allows you to make the torque converter as efficient as possible, but at the same time significantly reduces its service life.

Do-it-yourself automatic transmission torque converter repair

Repairing an automatic transmission torque converter will not be more expensive than buying a used gearbox. To carry it out you will need:

- pit or overpass;

- wrenches and repair kits;

- valve for removing automatic transmission;

- test equipment;

- lift;

- oil;

- new filter device.

To repair the torque converter, you need to remove the automatic transmission from the car and completely dismantle it. Pull out the torque converter and install it on a special machine, on which you carefully cut the housing along the seam and separate it into two parts.

Experts do not recommend repairing the torque converter yourself. It is also not recommended to pour various cleaning liquids into it. Since, in addition to caked oil and carbon deposits, they destroy seals, oil seals and other rubber gaskets. Read

Automatic transmission repair dp0 al4 Peugeot 307

Experienced mechanics prohibit the use of old oil seals and O-rings. Although they have not been used, their lifespan has expired. Since rubber dries out over time, it bursts. Unnoticeable microcracks on such an installed oil seal can lead to a complete replacement of the device in the future.

After completing all repair work on the automatic transmission torque converter, it is recommended to install it in the box and carry out balancing. Otherwise, the disturbed balance will kill all mechanical parts of the automatic transmission.

Welding of the body is required. This is done to ensure the tightness of the device.

Attention! The solvent will not be able to wash away the adhesive from the clutches that has spread throughout the automatic transmission.

The cost of repairing a torque converter in large cities of the Russian Federation starts from 4 thousand rubles. Therefore, if the car does not move, and a friend advised you to buy a contract automatic transmission, then you should not buy it right away. Restoration can be much cheaper.