Types of engines

The first full-fledged prototype of an internal combustion engine was designed back in 1806, which belonged to the Niepcier brothers. After this important historical fact there was a short lull.

But, at the end of the 19th century, three legendary Germans launched the automotive industry - Nicholas Otto, Gottlieb Daimler and Wilhelm Maybach. After this, internal combustion engines received many modifications and variants that are still used today.

Let's consider what types of automobile internal combustion engines exist, and also indicate the types of engines:

- Steam engine

- Gas engine

- Carburetor injection system

- Injector

- Diesel engines

- Gas engine

- Electric motors

- Rotary piston internal combustion engines

Engine operating cycle - criterion for classification

The operating principle of the engine is based on the conversion of thermal energy into mechanical energy through certain repeating processes, which constitute a work cycle. Depending on the number of piston strokes spent on such a cycle, engines are four-stroke or two-stroke. All types of internal combustion engines used in automobiles operate on a four-stroke cycle. It includes fuel intake and compression, as well as exhaust gas stroke and exhaust.

A two-stroke engine performs only two piston strokes in one cycle: compression and power stroke. But cleaning and filling of the cylinders occurs during these two strokes, almost at precritical points. These engines have some disadvantages, such as higher levels of exhaust pollution. But with equal volumes, a two-stroke engine is more powerful than a four-stroke engine, and its design is also simpler. The main disadvantage, which is why they have not become widespread in cars, is the high fuel consumption; it does not burn to a significant extent, which is why the exhaust is too polluted.

Steam engine

The first representative of a full-fledged internal combustion engine should be considered the steam engine, which was installed on all vehicles of the 19th century, until the invention of other types of engines.

At that time, locomotives, cars, and even primitive three-wheeled self-propelled vehicles (resembling motorcycles) were equipped with steam engines. An invention of this class conquered the whole world, but by the end of the 19th and beginning of the 20th century it became ineffective, since steam vehicles could not reach a sufficiently high speed.

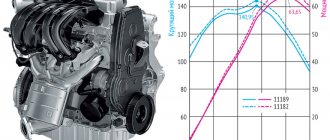

Engine thermal balance

Types of internal combustion engines, what internal combustion engines exist

From an analysis of the engine operating cycle, it follows that only part of the heat released during fuel combustion is used for useful work, while the rest constitutes heat losses. The distribution of heat obtained during the combustion of fuel introduced into the cylinder is called heat balance, which is usually determined experimentally. The heat balance equation has the form Q=Qe+Qg+Qn.s+Qrest, where Q is the heat of the fuel introduced into the engine; Qe is the heat converted into useful work; Qcool - heat lost by the cooling agent (water or air); Qg - heat lost with exhaust gases; Qн.с is the heat lost due to incomplete combustion of fuel, Qres is the residual member of the balance, which is equal to the sum of all unaccounted losses.

Amount of available (introduced) heat (kW) Q=Gt*(Q^p)n. Heat (kW) converted into useful work, Qe=Ne. Heat (kW) lost with cooling water, Qcool = Gw*sv*(t2-t1), where Gw is the amount of water passing through the system, kg/s; sv – heat capacity of water, kJ/(kg*K) [sv=4.19 kJ/(kg*K)]; t2 and t1 are the water temperatures at the entrance to the system and at the exit from it, C.

Heat (kW) lost with exhaust gases,

Qg=Gt*(Vp*srg*tg-Vv*srv*tv), where Gt is fuel consumption, kg/s; Vg and Vb - gas and air consumption, m^3/kg; срг and срв - average volumetric heat capacities of gases and air at constant pressure, kJ/(m^3*K); tр and tв — temperature of exhaust gases and air, C.

The heat lost due to incomplete combustion of fuel is determined experimentally.

Residual term of the heat balance (kW) Qres=Q-(Qe+Qcool+Qg+Qn.s).

The heat balance can be calculated as a percentage of the total amount of heat introduced, then the balance equation will take the form: 100%=qe+qcool+qg+qn.s+qresult, where qe=(Qe/Q*100%); qcool=(Qcool/Q)*100%;

qg=(Qg/Q)*100%, etc.

Gas engine

A gasoline engine is an internal combustion engine, which is fueled by gasoline. Fuel is supplied from the fuel tank using a pump (mechanical or electric) to the injection system. So, let's look at what types of gasoline engines there are:

- With carburetor.

- Injection type.

The modern world is accustomed to the fact that most cars have an electronic fuel injection system (injector).

Carburetor injection system

A carburetor is a type of fuel injection device into the intake manifold with further distribution among the cylinders. The first primitive carburetor was developed in Germany at the end of the 19th century and has a development history of almost 100 years.

Carburetors come in one-, two-, four- and six-chamber types. In addition, there are quite a lot of prototypes.

The principle of operation of the carburetor is quite simple: the fuel pump supplies fuel to the float chamber, where gasoline passes through the nozzles mechanically (the amount of injected fuel is regulated by the driver using the accelerator pedal), and is supplied to the intake manifold. The disadvantage of the carburetor is that it is sensitive to adjustments and also does not comply with international environmental standards.

Injector

An injection engine is a type of fuel injection device into the engine cylinders. Injection injection can be mono or split. Today, this system is increasingly being improved to reduce CO2 emissions into the atmosphere. For injection, nozzles are used, which began to be used on diesel engines even earlier.

With the transition to this system, vehicles began to be equipped with electronic engine control units to adjust the composition of the air-fuel mixture, as well as signal malfunctions within the system.

Carburetor types of car engines - what will replace them?

Let's look at what types of engines are in modern cars. All of them differ from each other in the type of fuel used, in the location and number of cylinders, in the method of forming the working mixture and other parameters characterizing their operation. Many types of gasoline engines are still installed in modern car models.

Gasoline passing through the fuel system ends up in the carburetor or intake manifold. Air also enters there, and under the influence of its flow, active mixing occurs, resulting in a mixture. Then the finished air-fuel mixture is supplied to the cylinders, where it is compressed under the action of the forces of the pistons, after which it is ignited by an electric spark generated by the spark plugs.

All types of car engines that use carburetors are considered obsolete. Currently, fuel supply using an injector is widely used. In this case, fuel is atomized by injectors either directly into the cylinder or through a special intake manifold.

Diesel engines

A diesel engine is a type of engine that consumes diesel fuel like combustible fuel. The main systems and elements of the engine are identical to its gasoline brother, the difference lies in the injection system and ignition of the mixture. There are no spark plugs in a diesel engine, since the mixture does not need to be ignited by a spark.

On engines of this type, glow plugs are installed, which heat the air in the combustion chamber, which exceeds the ignition temperature. After this, atomized fuel is supplied through the injectors, which burns, thereby creating sufficient pressure to drive the piston, which spins the crankshaft.

Turbocharged diesel

Turbodiesel is considered one of the subtypes of diesel internal combustion engines. This engine has a turbine that has the shape of a snail. With the help of a turbine, a larger amount of compressed air is supplied to the engine, which gives a greater detonation effect, due to which the engine can be accelerated faster.

Car piston engine design

The simplest internal combustion engine has an in-line arrangement of cylinders. In modern engines there are from 3 to 6. A more compact car engine has a V-shape, that is, the pistons are located at an angle opposite each other.

A V-shaped engine can have 4, 6, 8, 10 and 12 cylinders. There are also in-line VR and W engines; their design is complex, so it is better to study the engine design on an in-line “four”.

The basis of the engine is the cylinder block. Pistons move in these cylinders. At the bottom of the block, the crankshaft is mounted on friction bearings (liners), a connecting rod is attached to it, and a piston is attached to the connecting rod.

This type of assembly is called a crank assembly. Since the crankshaft has, as its name suggests, the shape of a knee, without a connecting rod it would be impossible to ensure the reciprocating movements of the piston.

The design of the connecting rod is made in such a way that its lower part makes oscillatory movements, and the upper part, connected to the piston, does not move in the lateral direction.

The engine piston has three rings: two compression rings and one oil scraper ring. The purpose of the rings is indicated by the name itself: compression rings provide pressure in the cylinder, preventing gases from escaping into the crankcase, and oil scraper rings remove oil from the cylinder walls and dump it into the oil sump.

A pulley is connected to the crankshaft on the front side to ensure the operation of attachments through a belt, as well as the operation of the timing belt if the drive type is belt driven. If the timing belt is of a chain type, then a star is installed on the crankshaft. An additional sprocket on the crankshaft can be installed if the oil pump drive is chain driven.

A flywheel is installed on the rear side of the crankshaft. The flywheel accumulates mechanical energy and transmits it through the transmission to the drive wheels. The flywheel has teeth for connection to the starter.

The top of the cylinders is hermetically covered with a cylinder head, between which a metal gasket is installed. The combustion chamber is located precisely in the cylinder head, and can be spherical or hemispherical in shape, and in diesel engines the combustion chamber is located in the piston recess.

The design of a classic cylinder head includes:

- camshaft (one or two),

- intake and exhaust valves driven by the camshaft cam.

A spring is responsible for returning the valve to its original location, which is covered with a plate and fixed with “crackers”.

Timing drive, most often chain or belt. The chain drive requires plastic dampers and a mechanical or hydraulic tensioner. The timing belt drive has a simple design and includes a belt, an idler pulley and a tensioner.

Gas engine

Gas engines today are almost never used in the automotive industry in their pure form, since frequent engine breakdowns have led to their complete abandonment. Instead, gas installations can often be found on gasoline cars, which significantly saves money on fuel.

Gas from the cylinder is supplied to the gearbox, which distributes the fuel among the cylinders, and then the fuel enters directly into the combustion chambers. The gas is then ignited with the help of spark plugs. The only disadvantage of using a gas installation is that the engine loses 20% of its potential resource.

What types and types of engines are there?

Absolutely any motor unit operates on the same principle. Fuel is supplied to it. It is burned. During the combustion process, energy is released, and then this energy is converted into mechanical energy. This whole procedure is repeated several times. This repeating process is called a tact. Depending on how many strokes the piston makes, all propulsion systems can be divided into two-stroke and four-stroke. All power units that cars are equipped with are based on a four-stroke cycle. During the cycle, the fuel mixture is supplied, the piston stroke occurs (up and down) and gases are removed.

Two-stroke engines work a little differently. During the stroke, the power stroke is completed and the fuel mixture is compressed. The piston is filled and cleaned within the allotted time. These engines have a significant disadvantage - they emit a lot of exhaust gases. They also consume too much fuel. That is why they are not used in vehicles.

Injection engine

The operation of this unit is arranged somewhat differently: fuel is injected in small portions into the air. The pressure sprays fuel through the nozzle, thereby significantly reducing its quantity, since it is dosed by a special device. This makes such engines more economical, and a dosed portion of the fuel mixture reduces the amount of harmful substances in the exhaust gases and increases the efficiency of the engine.

This type of engine includes mechanical and electronic types. The mechanical one dispenses fuel using levers, while the electronic one uses a special system that controls the amount of fuel mixture. Such systems allow fuel to burn more completely, thereby reducing the amount of harmful substances entering the atmosphere.

Electric motors

Nicholas Tesla first proposed the use of electricity for cars. Electric motors are not common today, since the battery charge only lasts up to 200 km, and there are practically no gas stations that can provide a car charging service.

The well-known global company, the manufacturer of electric cars Tesla, continues to improve electric motors, and every year gives consumers new products that have a greater range without recharging.

Classification of cars by engine type

Depending on the type of engine used, all cars are divided into two categories: gasoline and diesel. Cars equipped with gasoline engines use gasoline as fuel. Cars that use a diesel engine as a power unit run on diesel fuel. Diesel fuel is cheaper than gasoline, but a diesel engine is more expensive and more difficult to maintain. In addition, a car equipped with such an engine has certain problems starting it in winter.

In this regard, the following advice can be given to owners of diesel units: never purchase diesel fuel “from hand”. The fact is that in Russia, many motorists often prefer to refuel with friends who have diesel fuel at their disposal. These could be military personnel, agricultural workers, or employees of mining enterprises who use diesel fuel-powered equipment in their work.

Typically, such fuel is not designed for use in modern passenger cars, so motorists who purchase it may have serious problems starting the engine in winter. Also, low-quality or low-quality fuel can easily damage it. Thus, if you do not want to get additional problems with your diesel engine, buy fuel for it exclusively at official gas stations that can provide you with a guarantee of the quality of the diesel fuel they sell.

A diesel car has a large number of both pros and cons, so when purchasing it, be sure to contact a specialist who will advise you and give advice on the need for such a purchase, because if you are limited in financial resources, it may be It is better to buy a car equipped with a gasoline engine. Typically, such cars cost significantly less than their diesel counterparts, although in the future the increased cost of gasoline compared to diesel fuel can eat up the entire amount of savings. There are a number of other nuances that only a specialist can explain to you during a personal consultation, so don’t skimp and contact him. As a last resort, take a knowledgeable friend with extensive driving experience with you to the car dealership.

Hybrids

Probably the most desirable engines today. It is a mixture of a gasoline internal combustion engine and an electric motor. There are several options for how this engine works.

- The motor can operate on alternating power supply. The vehicle is initially driven on gasoline while the generator charges the battery, and then the driver can switch to electric power.

- The engine and electric motor operate simultaneously, which helps save fuel consumption by one and the same distance with other types of internal combustion engines.

Rotary piston internal combustion engines

The rotary piston power unit is not widely used in the automotive industry, although you can find car models that use this type of internal combustion engine. The creation of such a motor was proposed by the designer Wankel.

The movement is carried out due to the rotation of a three-tooth rotor, which allows for any 4-stroke cycle of a Diesel, Stirling or Otto without the use of a special gas distribution mechanism. This motor was actively used in the 80s 20 st.

Car engines

Supercharging of automobile engines: purpose, classification, regulation.

One of the most effective measures to increase the engine's liter power is supercharging, which allows you to increase the mass of the fresh charge. In carburetor engines, supercharging is almost never used due to the risk of detonation.

The influence of the crankshaft speed n on the liter engine power must be assessed using the complex factor n ηv ηm. When the rotation speed increases, to boost the engine, it is necessary that this multiplier be maximum.

Supercharging with a turbocharger has become much more widespread in the world, i.e. a supercharger driven by a turbine operating on exhaust gases.

Classification of types of ICE supercharging.

Aggregate supercharging is carried out using a supercharger. It is divided into:

mechanical supercharging, which uses a compressor driven by the engine crankshaft;

turbocharging, where a compressor (usually centrifugal) is driven by a turbine rotated by engine exhaust gases;

“Comprex” supercharging, which consists of using exhaust gas pressure acting directly on the air flow supplied to the engine;

electric supercharging, which uses a supercharger rotated by an electric motor;

combined supercharging combines several schemes; as a rule, we are talking about combining mechanical and turbocharging.

Unitless supercharging. This includes:

resonant boost (sometimes called inertial or acoustic), implemented due to oscillatory phenomena in pipelines;

dynamic charging (high-speed or passive charging) increases the pressure in the intake manifold due to specially shaped air intakes when driving at high speeds;

Refrigeration charging is achieved by evaporating fuel or any other flammable liquid with a low boiling point and high heat of vaporization in the incoming air; it is not used on automobile engines.

Mechanical boost

Mechanical supercharging makes it easy to increase engine power. The main element in such a system is the supercharger, driven directly from the engine crankshaft. A mechanical supercharger is capable of pumping air into the cylinders at minimum speeds and without delay, increasing boost pressure strictly proportional to engine speed, which is an important advantage of such a scheme. However, mechanical supercharging also has a significant drawback - it takes away part of the engine power for its work.

Recently, improvements in supercharging concepts have taken the path of creating control systems to increase torque at low engine speeds, as well as reduce inertia.

There are several ways to solve this problem:

use of variable geometry turbine;

use of two parallel turbochargers;

use of two sequential turbochargers;

combined boost.

A variable geometry turbine optimizes exhaust gas flow by changing the area of the inlet channel. Variable geometry turbines are widely used in turbocharging diesel engines, for example the turbocharging of the TDI engine from Volkswagen.

A system with two parallel turbochargers (biturbo system) is mainly used on powerful V-engines (one for each cylinder bank). The principle of operation of the system is based on the fact that two small turbines have less inertia than one large one.

When two turbines are installed in series on an engine (twin-turbo system), maximum system performance is achieved by using different turbochargers at different engine speeds.

Combined charging combines mechanical and turbocharging. At low engine speeds, air compression is provided by a mechanical compressor. As the speed increases, the turbocharger picks up and the mechanical compressor turns off. An example of such a system is the twin-supercharging TSI engine from Volkswagen.

After the abandonment of carburetors and the transition to electronic fuel injection, turbocharging on gasoline engines became especially effective. Impressive fuel efficiency has already been achieved here.

In general, it should be recognized that turbocharging, increasing thermal and mechanical loads, forces the introduction of a number of reinforced components into the design, which complicate the engine both in production and during maintenance.

Hydrogen motor

The hydrogen engine is considered the KNOW-HOW of the modern world. A hydrogen type unit is installed in the car. The difference from gasoline engines is the fuel supply. If for gasoline fuel is supplied at the time the piston returns to the HTM, then for a hydrogen power unit at the moment when the piston returns to the HTM.

In the future, it is planned to create a closed-type hydrogen engine, when there will be no need to emit exhaust gases, and at 500 km the car owner will be able to forget about refueling the car.

It is worth understanding that cars with such an engine will not be very cheap until they completely supplant their gasoline brother.

Diesel engine type

Diesel engines deserve special attention . Their operating principle is based on the ignition of the working mixture during compression. When air is drawn in, the process occurs under high pressure, causing the mixture to spontaneously ignite. After ignition, the piston stroke occurs, which then displaces the exhaust gases.

This type of engine has lower fuel consumption and a small amount of harmful substances in emissions. The efficiency of this power unit is also much higher. Diesel engines now continue to improve and even frost is no longer an obstacle to starting the engine.

Different types of diesel engines have different characteristics that depend on the time of year. These power units do not have an ignition system, because the fuel ignites due to high pressure, which causes the piston to move.