All about oil cooling radiators

1.3 Junior (105) AR 00530

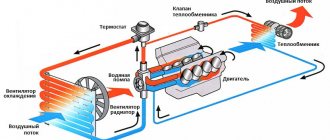

Since the internal combustion engine is a heat engine, during its operation excess heat is generated that must be removed. A liquid radiator, inside of which antifreeze circulates, helps with this. Due to, for example, high efficiency with relatively small dimensions, automobile engines also have additional forced cooling. Simply put, car engines have a combined cooling system in which the liquid system does most of the work of removing heat. Air cooling elements are activated only at high coolant temperatures.

Please note: when talking about the engine cooling system, they often use the concept of antifreeze temperature. However, there are times when the engine oil also needs to be cooled. The oil comes into direct contact with engine components, which become very hot. If the oil temperature becomes critically high, it will lose many of its properties, which will be critical for the rubbing parts of the engine. The task of cooling the lubricant is taken over by an oil cooler, otherwise called an oil cooler. Avto.pro decided to look into its structure and key features.

Why install a radiator on engine oil?

A very simple answer - to cool the lubricant ! But why cool it is a more complicated question.

Let's start with the fact that in 90% of cases, as I wrote above, the car has enough coolant that circulates through the main radiator (the one in front, under the decorative grille) and the heater radiator (which is in the cabin). Heat dissipation, say, on an ordinary foreign car (or a class B - C car) is sufficient.

BUT! There are difficult cases when this is not enough, and then they start connecting oil cooling. This happens mainly on loaded engines.

Some believe that “oil injectors” and an oil cooling radiator work on the same principle, that is, they cool the engine with oil. BUT this is extremely wrong!

Oil injectors work mainly to cool the piston, that is, they take additional heat from the engine so that it does not lose its geometry, I have a useful video about them, I recommend everyone watch it.

But the cooling radiator takes the temperature away from the lubricant so that it does not lose its properties ahead of time.

Purpose of the oil cooler

The engine oil cooler is designed to protect the power unit from wear, which can be caused by oil overheating. This is especially true these days, when molded engines have become widespread and temperature control temperatures have increased significantly. If previously it was enough to create a reliable antifreeze cooling system, now a separate system for regulating the temperature of the engine oil is required. There are several reasons:

- At high temperatures, the oil begins to boil away, which leads to a decrease in its volume and the formation of deposits;

- Along with the decrease in volume at high temperatures, the viscosity of the oil also decreases - it should be neither low nor too high;

- The lubricant quickly ages and loses its properties.

Despite the fact that modern oils have a well-thought-out set of additives, even they cannot protect it from overheating. As a rule, engine oil heats up a little more than antifreeze: 90-100°C versus 80-90°C . Additives demonstrate their effectiveness up to temperatures of 100°C (with rare exceptions), and when overheated they begin to work or decompose.

As a result, after prolonged overheating, the engine oil can only be replaced - ignoring this problem can result in engine failure. The problem can be avoided by using an oil cooler, in which the lubricant is cooled to the optimum temperature.

How can oil lose its properties?

A simple example – we have a truck. As a rule, their speed is low (not high-revving engines), but the loads they carry can be impressive.

As a result, the pump seems to pump (antifreeze or antifreeze), but cannot cool it enough.

This causes excessive heating of the entire engine, and in particular the oil. By the way, the lubricant can also warm up due to the fact that the oil nozzles remove excess temperature from the pistons.

As a result, the oil begins to burn, the level may drop, the viscosity and detergent properties change, and additives do not work. Moreover, coke can form on the walls, so the inside of the engine becomes overgrown with sludge.

The same thing happens if you heat it over a gas burner (if you don’t believe me, try it).

This is precisely why an oil cooler is needed - to remove excess temperature from the lubricant.

Oil radiator design

At its core, this is still the same radiator with some modifications. Firstly, it should be relatively small, because the engine cooling system already takes up a lot of space, and the oil cooler may even be located right in front of the main radiator. Secondly, the layout of the radiator must be well thought out - there should be no pressure drops . Conventionally, oil radiators are divided into two types:

- With natural cooling. The walls of the radiator are blown with oncoming air as the vehicle moves, which leads to cooling of the oil circulating inside the device;

- With forced cooling. The radiator is blown not only by a counter flow of air, but also by a fan.

Both types of radiators have the same design. This is a series of steel or aluminum tubes of oval cross-section, and each of the tubes, as a rule, has a spiral wound on it - this allows you to increase the heat transfer area. In some radiator models, cooling plates . Another element of the oil cooler: a pair of tanks (lower and upper). Fittings are welded to the tanks, to which the oil supply and drainage pipes are connected. Of course, the radiator has special fasteners that allow it to be installed on a car.

As practice shows, passing through radiator tubes without a special fan, engine oil is cooled by 10°C . Forced cooling does not seriously increase the cooling temperature when the car is moving at high speeds, but at low speeds it is extremely effective. The main factors influencing the efficiency of the radiator are the following:

- Material (heat transfer efficiency factor);

- Tube geometry;

- The temperature difference between the oil and the air surrounding the radiator.

It is also impossible not to talk about such an important element of a good radiator as an additional turbine. It improves the circulation of lubricant inside the radiator and prevents blockages. As a result, oil of almost any viscosity circulates properly in the radiator. Cases where the oil turns out to be too viscous and its movement through the radiator tubes is difficult should rather be attributed to engine problems - even an oil cooler without a turbine can “drive” the oil through the cooling circuit.

Device and purpose

The main purpose of the oil cooler is to effectively protect the internal combustion engine from premature wear due to overheating of the oil fluid. This is especially important in modern realities, when motors have increased power and thermostatting temperatures have increased significantly. If in the recent past only high-quality antifreeze was required to cool the unit, today a combined cooling system is needed. This is due to several factors:

Based on its operating principle and internal structure, the oil cooler resembles a classic car radiator. However, it features some modifications and improvements:

Depending on the specific functioning of oil coolers, there are 2 types:

The two varieties have an identical design, which involves the presence of aluminum or steel tubes with an oval cross-section. Each design has a spiral that increases the heat transfer area.

Some models are equipped with cooling plates. The auxiliary elements of the oil cooler include a pair of reservoirs (upper and lower). Fittings and tubes for supplying and discharging oil fluid are combined with them. The unit also has fasteners for easy installation under the hood.

According to experts, when passing through radiator pipes without ventilation, the oil cools by only 10 °C. The presence of forced air circulation does not greatly improve the situation at increased loads on the internal combustion engine, but at low speeds this option is extremely effective.

The quality of the oil cooler depends on several features:

The oil cooler design uses an additional turbine, which enhances the circulation of lubricant in the unit and prevents the formation of congestion. As a result, the system efficiently copes with its tasks, promoting uninterrupted circulation of oils of any viscosity. The likelihood of movement difficulties occurs in rare cases and is explained by problems with the internal combustion engine.

Advantages and disadvantages of oil radiators

An engine oil cooler is not a required part of most cars. For example, similar radiators are installed on cars with a powerful engine, such as the BMW 335i E92 . Also, almost all agricultural machinery, trucks and many van models need oil cooling. the advantages of oil radiators , but let's list them all. The oil cooler provides:

- Stability of lubricant temperature;

- Maintaining normal temperature of the power unit;

- Increasing the service life of engine oil.

Spare parts for BMW 2500

2500 M30B25 (32/40INAT)

Spare parts for Mazda 2

Despite the obvious advantages, the oil cooler, as stated, is an optional component for most cars. Consequently, it places an obligation on the driver to promptly diagnose and maintain it. Here are the disadvantages of an oil cooler:

- It needs maintenance, like cleaning the surface;

- More lubricant needs to be poured into the oil system - some of its volume will be “taken” by the radiator;

- Quite a high price (exception: radiators from lower-level packagers and Asian manufacturers).

As you can see, the advantages of oil coolers look more convincing than their disadvantages. For this reason, they are sometimes installed on cars standard equipment did not include such devices. We'll talk about this, but for now let's figure out how to identify a faulty oil radiator.

How many sections should an oil cooler have?

The oil cooler can have from 3 to 14 sections. The more sections, the larger the heating surface. And the more powerful the heating element of the heater. Which model should you choose? Depends, again, on the area of the room. To heat large rooms you will need a massive, more powerful radiator. In a very small room you can install a mini-radiator with 4-5 sections. The most popular are medium-sized heaters with 7-9 sections. These are the models that are purchased for heating standard rooms in residential buildings and apartments.

What you should know about malfunctions

The oil radiator is operated under rather harsh conditions, but the pressure inside the device is not very high, which a positive effect on the service life. As a rule, car enthusiasts are faced with the need to replace radiators every 3-5 years, although in some cases replacement may be required earlier. It is worth paying attention to the following things:

- Increase in oil temperature;

- The appearance of dark deposits on the walls of the expansion tank of the cooling system;

- Presence of oil leaks.

Let us immediately note one important point: the circulation of coolant and the circulation of oil in their respective systems are interconnected . If the circuits become leaky, one fluid can mix with another, which will have a detrimental effect on the engine. For example, oil may get into the expansion tank. It is strictly forbidden to operate a car with such a malfunction - a seemingly insignificant breakdown in the long term will certainly lead to engine malfunction.

It is recommended to carry out a visual inspection of the oil cooling radiator once a year, or even more often. Oil leaks, dark deposits and greasy spots will indicate that the radiator is depressurized. More often you can observe a violation of the integrity of the oil supply and drainage pipes. Oil may leak around the fitting . These elements of the oil system should be checked first. A less common problem is a violation of the integrity of the radiator itself. Although the radiator is made of metal, its tubes have low mechanical strength - gravel from the road can pierce one of the tubes.

It will be useful: Opel astra h changing the oil in the box

The agony of choice

Since when choosing, everyone has to solve the same issues, it is possible to list the main nuances that deserve attention.

The selection instructions will look like this:

- First, you need to pay attention to the thermal power of the device; after all, it is selected for heating a home. On average, 5-7 radiator sections of standard sizes should be enough for a room of 20-25 m2. In general, it is possible to proceed from the proportion 100W/1m2,

Note! If the room is larger, it is better to buy a larger heater. Otherwise, an uncomfortable temperature difference will occur.

- it is necessary that it be equipped with a low-speed fan, this will speed up the heating of the room,

- it is undesirable to buy a model without a thermostat (despite the fact that such a rarity is unlikely to be on sale),

- You can immediately purchase a special attachment for drying clothes in a heater. Under such conditions, the question of whether it is possible to dry clothes on an oil radiator will not become a problem,

- if the weight of the heater is large, then it must be equipped with wheels, since it will need to be moved from room to room,

- In addition, a necessary addition to the basic package will be a container of water (it will allow you to maintain humidity in the room), and the ionizer will completely make the air space necessary for health.

When choosing an oil radiator, the rating of the best manufacturers can help. Such heaters are used quite often, so statistics allow us to single out several favorites.

Such manufacturers as DeLonghi, Saturn, AEG, Ergo, Electrolux are quite popular. Any of the listed companies produces heater models in a wide price range, so the purchase can be selected to suit any budget.

Selecting an oil cooler

If your car has a standard “supplemented” oil system, then you can search for its components using the VIN code, the parameters of your vehicle, or the radiator code. It’s easier to search for car parameters in online stores - this gives a fairly accurate result. This way you can find codes for both the original radiator and the closest analogues. If the standard equipment of your car did not include an oil cooler, then you will have to select it yourself. Here's what to remember:

- It is better to install the oil cooler together with a temperature sensor and an oil pressure sensor;

- Some models of oil coolers have a built-in fan, but their installation is very difficult, and in some cases it is almost impossible;

- To install the sensors properly, you will need a spacer for the oil filter;

- When choosing between a spacer with or without a thermostat, it is better to give preference to the first option;

- The location for installing radiators must be selected taking into account the fact that the oil supply and drain pipes should not sag.

You can often see branded oil cooler installation kits on sale. This kit may not be cheap, but we do not recommend saving. Also, you should not save on tubes, adapters, fittings and other “little things” that may not be included in the kit - how long the entire oil cooling system will work before depressurization due to mechanical stress or natural aging of materials will depend on the quality of its execution. As for choosing the radiator itself for a non-standard installation, everything will depend on the engine parameters of your car. Many experts advise first installing temperature and oil pressure sensors, and then selecting a radiator based on their readings.

It is better to entrust the installation of the radiator to a specialist. If the device does not have special fasteners, the technician will make them himself. As a rule, the radiator is placed in front of the main engine cooling radiator. The technician will also install a special spacer. It often happens that the spacer does not fit into the regular place of the oil filter - then you will need to install something like a gasket with it. In this case, a fairly long fitting may be required for further installation of the spacer.

Malfunctions

The most common problems with oil radiators are:

A cracking noise is heard when turned on and during the first 10-15 minutes of operation. If after this time the cracking disappears, it’s okay. It occurs when the oil inside the radiator heats up.

Perhaps drops of water got into it, which causes such a reaction. This is possible if the device was assembled in conditions of high humidity.

The radiator does not turn on. First, carefully inspect the cord and plug for cracks or creases. If they are not found, try plugging the heater into a different outlet.

If this does not work, then the problem is in the contact, which has come loose. Try to repair the device yourself or send it to a service center, where experienced technicians will solve the problem.

The device turns on, but does not heat up. At the same time, indicator lights, a fan and other additional devices on the case work.

The cause of such a breakdown is problems with the thermal relay; it cannot be eliminated without special tools. Contact the service center.

Oil is leaking. Such a breakdown occurs due to a manufacturing defect (poorly sealed seam) or a long period of use of the device.

Over time, the metal at the joints burns out and becomes thinner, which leads to this type of failure. Unfortunately, it is impossible to repair an oil leak either independently or at a service center.

If the breakdown is serious, you should carefully consider the prospect of buying a new radiator, because sometimes repairs cost more than a new device.

Excursion to the manufacturers

When choosing a suitable oil cooling radiator, you should pay attention to the manufacturer. If you understand engine radiators, then everything is simple: look for oil cooler radiators in their assortment - almost all major radiator manufacturers produce them too. Unfortunately, their products cost a lot of money, but the price corresponds to the quality. Radiators from the following companies are worthy of attention:

Not as high quality, but much cheaper analogues are offered by DP Group (Turkey), Polcar (Poland), 3RG (Spain), Vika (Taiwan), Dello (Germany), Thermotec (Poland). In fact, these are packers selling products from Turkish, Chinese and Taiwanese factories. There is nothing wrong with Asian auto parts; the cheapest auto parts from these countries are another matter. As a rule, they have a high percentage of defects and non-compliance with the original geometry. In their production, low-quality raw materials are often used. In the case of radiators, this is critical, so Avto.pro advises buying much higher quality products from companies from the list above.

Which is better: oil or convector

When considering the advantages of convectors or oil radiators, it is worth paying attention to such features as power consumption, dimensions and additional functions. If the heater is needed for regular use, then it is better to choose oil models. For periodic use in insufficiently warm rooms, you can buy convectors with a top supply of warm air.

Heating an apartment or house is a task that arises quite often even with centralized heating. This is due to insufficiently warm stationary radiators or poor location of the apartment, damp weather before the heating season or a desire to better warm up the child’s room. In any case, oil batteries will help ensure the desired temperature in residential areas.

Conclusion

An engine oil cooling radiator is not included in the standard equipment of all cars, but it copes so effectively with the task of controlling the oil temperature and protecting the engine that many car enthusiasts decide to install this device on their vehicles. The radiator cannot be called a durable car part - it has little mechanical strength, and the connecting elements of the oil system tend to gradually age and depressurize. An engine oil leak should never be ignored, and in systems with a special cooler it can also be observed in the radiator. If the car requires replacement of the oil cooler, we recommend purchasing spare parts from well-known European manufacturers. Although they will not be cheap, they will guarantee the efficiency and durability of the engine oil cooling system.

Sc0rceni › Blog › OIL RADIATOR

An oil cooler is a safety measure for the engines of “charged” cars. Overheated engine oil loses its lubricating properties - this is fraught with premature wear of engine parts. If it is necessary to operate the engine in extreme conditions, a remote heat exchanger is a great help as an insurance against overheating. As the power of automobile engines increased, engineers were faced with the critical problem of removing the ever-increasing excess heat from the engine. The first step towards solving this problem was the appearance of additional cooling fins on the engine sump. However, fins could not radically solve the problem. On trucks, as well as on highly accelerated passenger car engines, the fins on the oil pan did not cope with the task. Overheated oil lost viscosity, the pressure in the system dropped, and the driver had to slow down to reduce the release of heat. Overheated oil prematurely lost its properties: additives disintegrated, and deposits formed on engine parts. It was possible to provide a long service life to a forced engine only through effective heat removal. Air type oil cooler is easy to install as optional equipment

In modern cities, daily standing in traffic jams leads to a similar effect, which is why the design of many cars of the latest generations includes a radiator for cooling the engine oil.

Design and principle of operation of an oil radiator

Depending on the engineering practices of a particular manufacturer, a conventional radiator or heat exchanger located in a coolant environment can be used to cool the oil. The first method is more often used on highly accelerated cars intended for driving at high speed, since under this condition one can count on the formation of a flow of incoming air of great force. As a rule, this is a copper tubular coil, sometimes with additional fins, like a radiator for a cooling system. This radiator is used in the lubrication system of the Toyota Carina E.

To ensure a constant oil temperature, a thermostat is built into the lubrication system along with the radiator. Immediately after starting the engine, while the oil has not yet warmed up, the thermostat valve is closed and the oil does not flow into the radiator. This is necessary to shorten the engine warm-up cycle, especially in cold weather. In older designs, a tap was installed instead of a thermostat, which the driver could open and close at his discretion. Air cooling of oil is more efficient than liquid cooling. But in this case, the system turns out to be cumbersome: an additional radiator and pipelines are required, which, moreover, are susceptible to stone impacts and other mechanical influences. Another drawback lies in the fact that at low speeds with a weak oncoming air flow, the efficiency of the system noticeably deteriorates.

In this regard, liquid cooling looks preferable, because antifreeze constantly circulates in the engine. In addition, such a system is much more compact. But it is not suitable for powerful, forced engines, because it cannot effectively cool the oil under high loads. In addition, there is a danger of depressurization between the circuits, and then oil will begin to flow into the cooling system. And after stopping the engine, it’s the other way around: antifreeze goes into the oil.

It will be useful: The engine starts poorly when cold

Engine oil cooler: improved engine protection

As you know, an internal combustion engine is a heat engine. For this reason, the temperature of the internal combustion engine must be kept within strictly defined limits in order to achieve maximum efficient operation and at the same time avoid overheating of the power plant.

The cooling system on modern engines is a combined solution that consists of a liquid and air cooling system. The main one is a liquid system, which involves the circulation of coolant through special channels inside the engine, which allows excess heat to be effectively removed.

However, this is not enough. In this case, it becomes necessary to cool the engine oil, which is the working fluid in the engine lubrication system and is in direct contact with heated parts. A car oil cooler is used for this.

Engine oil cooler: TOP best quality models

Description and most important technical characteristics of oil radiators for cars: top quality products. Video about installing an oil cooler.

During operation of a car engine, a large amount of thermal energy is released, which must be removed somewhere. For these purposes, a liquid cooling device is used with antifreeze circulating through special tubes.

In addition, modern internal combustion engines, due to their small dimensions and high power, are equipped with forced cooling systems. In some cases, motor oil is used to remove excess heat. It interacts with internal parts of the power plant that are subject to heat and prevents wear.

Oil cooler

Taking into account the fact that modern engines are highly accelerated and the temperature control is also quite high, manufacturers often use oil radiators. This radiator allows you to reduce engine heating using oil.

Also, the presence of this element allows you to more reliably protect the internal combustion engine itself from wear. The fact is that oil is also afraid of overheating, like the metal parts of the power unit. It must be remembered that under the influence of high temperatures the properties of the lubricating fluid change.

It becomes clear that a very important point is that the engine oil does not overheat. In other words, the oil temperature should not be higher than permissible while the engine is running. This is one of the main conditions for the lubricant to fulfill its stated service life, while the engine is reliably protected throughout this period.

It turns out that additional oil cooling is becoming not just an option, but a necessity, especially for highly accelerated internal combustion engines. Now let's look at the oil radiator itself (oil cooler).

Construction of an internal combustion engine oil cooler and selection

So, the oil cooler consists of heat-removing tubes and plates through which heated oil circulates. Due to this, the lubricating fluid is cooled. At the same time, a correctly selected and installed oil cooler does not in any way affect the overall efficiency of the engine lubrication system (there is no loss in oil pressure in the engine).

As for the oil coolers themselves, there are several different solutions that differ in the quality of materials (thermal conductivity, design, size, shape, etc.). Also, the oil radiator can be with natural or forced cooling.

- In the first case, such a radiator is simply blown by counter currents of air as the car moves.

- Devices with a forced cooling circuit have a fan that blows on the radiator and cools the oil better, regardless of how fast the vehicle is moving, that is, how intense the flow of oncoming air is.

In order to increase the cooling surface, a spiral is separately wound on each tube, which is a thin steel tape. Also, in some oil cooler designs, the tubes may pass through the cooling plates.

The above tanks are separated by partitions; fittings are welded onto them, to which the oil supply and oil drain pipes are connected. Also, special radiator mounts are welded to the structure.

Also, when changing the engine oil, the waste can be easily and quickly drained from the oil cooler, which will mean removing the old lubricant to the maximum possible extent.

Note that such a radiator can be installed separately, that is, even in cases where the car was not originally equipped with this solution. It is important to take into account some features in order to decide which oil radiator is best to choose.

First of all, you need to pay maximum attention to the main characteristics:

- The device must be made of quality materials. If the engine is forced, it is desirable that the radiator has effective solutions for better oil circulation through it.

- Another indicator is the temperature difference at the inlet and outlet of the oil cooler, as well as the declared decrease in the temperature of the engine oil when using a particular radiator.

As a rule, passing through the radiator tubes with natural cooling (using outside air), the oil temperature drops by an average of 10 degrees Celsius.

You also need to take into account that in winter, the operation of the radiator can lead to the fact that the oil temperature may not increase for a long time, that is, the lubricant will slowly warm up and liquefy due to heating. In simple words, you need to be prepared for the fact that with the onset of cold weather the radiator will need to be shut off or removed. When choosing a device, you should remember this feature.

Rating of the best oil radiators for internal combustion engines

When choosing a suitable radiator model, you should take into account the reputation of the manufacturer. If you are not familiar with the main suppliers of such products, we suggest that you familiarize yourself with the rating of the best brands supplying oil systems for internal combustion engines.

AVA is one of the most popular and trusted manufacturers of car cooling systems. The company's production facilities are located in 7 European countries, and its headquarters are in the Netherlands.

Oil radiators from AVA are actively installed on cars of the European, American, Japanese and domestic automobile industry. All products comply with ISO 9001 standard and European Union regulation TP TC 018/2011.

Car owners note that in addition to high build quality, AVA products have an adequate price tag. In total, the brand’s assortment includes more than 13 thousand items, covering 98% of car models from different manufacturers.

When searching for oil radiators, you can find both budget and premium models that are not inferior in quality and functionality to standard options.

Sakura

Since its founding, the Sakura brand has been producing high-quality oil radiators that are in demand all over the world. The brand supplies products to both the secondary and primary markets, so some components are installed on cars of leading automakers. The production process is certified by SAE, SAE and JIS, and the facilities are located in Indonesia under the leadership of ADR Group.

When creating the Sakura company, ADR Group developers aimed at Korean and Japanese car assembly. Every year the company sells colossal volumes of radiators, which receive positive reviews from both car owners and independent experts.

Due to their great popularity, Sakura components are often counterfeited. Therefore, when looking for a suitable model, you need to pay attention to the brand name, 2-color printing, product code and brand prefix. The packaging tongue should also contain words of gratitude for your choice. On cheap analogues you can find traces of welding of low quality.

Nissens

Nissens is considered a leader in the production of air conditioning and refrigeration systems.

It was founded in Denmark in 1921 and has 2 divisions - Auto and OEM, targeting different markets. The company's offices are located in Germany, Spain, Ukraine, China, Italy and other countries.

The brand's product range includes automobile oil radiators of all types, components of climate systems, electric fans, compressors, dryers and related parts. Car owners speak positively about the quality of the products, their reliability and durability. In addition, the products are offered in a wide price range.

However, Nissens parts are often counterfeited. In order not to encounter a cheap analogue, you need to take a responsible approach to the choice, paying attention to the geometry of the radiators and the presence of stickers.

NRF's head office is located in the Netherlands. It has gained a good reputation in the production of heat exchangers for various industries. The bulk of the facilities operate in France and the Netherlands. The catalog contains over 7 thousand items that have international ISO certification.

Oil radiators from NRF have proven themselves to be reliable and durable components that provide effective cooling of the power plant. In addition, they are characterized by resistance to corrosion and vibration, as well as aerodynamics.

SWAG is a large auto parts manufacturing company that designs, manufactures, packages and sells various types of products. At the moment, the brand is part of the famous Bilstein Group with an annual turnover of 6 million euros. SWAG components comply with the ISO 9001:2008 quality certificate.

Oil coolers for engines are in demand due to their reliability, wear resistance and corrosion resistance. In addition, they are sold at affordable prices and often do not differ in quality from standard models.

Dello

Dello is a well-known German brand that previously provided car maintenance and sales services. Soon the concern reformatted its activities and began supplying auto parts to the market, including oil radiators for various car models.

The company's product range includes both inexpensive products in the budget price segment and high-quality replicas of original models for leading automakers.

Thermotec

Polish auto parts supplier Thermotec has been on the market since 1900. He works closely with the Inter Cars concern, developing a large number of parts for engine cooling systems. Oil radiators from Thermotec are characterized by high-quality assembly, affordable price and durability.

Some car owners speak negatively about the geometry of the radiators, claiming that they are 0.5-1 cm thicker than the original models. However, this does not have much impact on quality.

Behr-Hella

The brand is part of the Behr Hella Service GmbH concern, which is known for producing high-quality spare parts for cars. Production facilities are located in 32 countries, and annual turnover exceeds 5.8 billion euros.

Hella oil radiators, made using innovative developments and technological solutions, are in particular demand among drivers. The products are characterized by high build quality, fault tolerance and a relatively low price.

Elring

The Elring concern is in penultimate place in the ranking of oil radiator manufacturers. The company's product range includes over 20 thousand items of engine components, including oil filters. Products from Elring are designed for 98% of car brands and models of the European market, and about 60% of the Asian market. A large number of goods are supplied to the factories of Opel, Ford, Mazda, VW, Volvo, etc.

To distinguish an original radiator from a fake one, you should pay attention to the nanogram with the code, the brand logo and the inscription “Original” or “Das Original”.

The nanogram should be viewed from different angles, since the color appearance changes depending on the viewing side.

Ossca

The ranking of the best oil radiators is completed by Ossca, founded in 1995 in China. The brand's products are aimed at owners of BMW, Audi, Skoda, VW and Opel cars. All items from the catalog comply with DIN ISO 9001 certificate.

Units from Ossca are in demand due to their affordable price and good build quality. Products are offered in boxes with a proprietary design, which allows you to distinguish a counterfeit from a branded product.

What's the result?

As you can see, the use of oil coolers significantly increases the efficiency of engine cooling, improves the protection of the internal combustion engine and maintains the performance of the oil at high temperatures.

This also helps to maintain a stable operating temperature of the engine at different operating modes. At the same time, the power unit is reliably protected, since the lubricant does not lose its properties when exposed to strong heat.

Engine oil pressure: what it depends on, how to measure it correctly. What is the oil pressure on different engines in idle mode and under load.

What is a dry sump engine system, operation and design of a dry sump engine lubrication system. Features, advantages and disadvantages.

Why the oil pressure light comes on after the engine warms up: the main reasons. What should a driver do if the oil pressure comes on when the engine is warm.

Why does oil get into the intercooler? Do-it-yourself localization and elimination of possible faults. How to rinse and clean the intercooler from oil yourself.

The main reasons why problems arise with oil pressure in a diesel engine. What features should be taken into account when diagnosing, recommendations.

Why there may be low oil pressure in the engine, the oil pressure light blinks at idle or under load. Fault diagnosis and repair.

What to do if antifreeze gets into the oil

Depending on how the antifreeze got into the oil, there are certain ways to troubleshoot problems specific to each case.

| Why does antifreeze get into the oil? | Method for eliminating the cause of antifreeze penetration into the oil |

| Worn cylinder head gasket | Remove and install the block head. Replace seal gasket. |

| The cylinder head gasket is broken. The antifreeze oil partition is cracked. | Crack repair. |

| The gasket is deformed. | Replacement of the internal part of the deformed head adjacent to the motor. |

| The gasket is poorly installed. | Reinstallation, high-quality tightening of bolts. |

| Low quality antifreeze. | Replacing the fluid with a high-quality one. Repair, replacement of gaskets and cylinders. |

| The fluid pump is not installed correctly. | Reinstalling the pump. |

Oil cooler – additional engine protection

All engines have a cooling system containing coolant and a radiator in which this liquid is cooled after passing through the engine cooling system.

However, it is possible to more effectively cool your car's engine using oil coolers. They are used to dissipate heat from the engine using oil that is located directly in the engine and is an integral part of its operation. The use of an oil cooler is becoming very popular among car enthusiasts and this is quite logical.

Typically, a car engine has two cooling systems, at the top and bottom respectively. It is very important that the engine oil does not overheat; ideally, its temperature should not go beyond the limits stated by the manufacturers as recommended. Only then will the oil serve you for the entire stated service life and reliably protect your engine.

Modern cars produce much more heat than their older brothers, and maintaining engine temperatures at normal levels is a top priority not only for car manufacturers, but also for car owners.

As operating temperatures increase, irreversible changes in the working parts occur in the engine, and the oil naturally begins to evaporate, like any liquid. It decreases in volume, thickens, and loses viscosity.

This means that additional cooling will not harm the oil at all.

It will be useful: The fuel level sensor of the VAZ 2115 does not work

What is an oil radiator?

An oil cooler consists of heat-sinking tubes and plates through which hot oil circulates and is cooled at the same time. The oil cooler is mounted in the engine crankcase system and does not interfere with its operation at all. The efficiency of an oil cooler depends on the type of materials used in its manufacture, their thermal conductivity, design and shape. There are oil radiator systems with artificial and natural cooling systems.

Artificially cooled systems are equipped with an additional fan, which provides greater air flow to the radiator and better oil cooling.

The oil cooler is designed in such a way that blockages and oil congestion in it are absolutely excluded. Pipeline systems allow oil to circulate freely throughout the system and waste oil to be completely removed when it is replaced.

Please remember that if you use an additional oil cooler, your vehicle will require more oil than usual. Since when the radiator is connected to the engine cooling system, it is necessary to fill its piping system with oil.

The use of oil radiators increases the engine cooling efficiency several times, as well as the engine protection mode with motor oil. After all, when operating at normal temperatures, the oil is not exposed to negative factors, and, therefore, operates normally and lasts much longer.

How to distinguish an effective oil cooler from a less efficient one. You need to pay attention to the following characteristics:

- A good oil cooler is equipped with an additional turbine that improves the circulation of oil in the radiator.

- Large temperature difference at the inlet and outlet of the radiator.

- Claimed reduction in oil temperature when using a radiator.

The advantages of using an oil cooler are:

- Supplying the coolest possible oil to the engine for efficient operation.

- Maintaining engine temperature in operating mode.

- Maintaining oil temperature within the manufacturer's recommended range

- Improved engine protection efficiency.

Oil radiators made in India are especially widely represented on our market. They are affordable and of very good quality.

Let's understand the details

If you compare the price of a simple fan heater and an oil heater, the result will obviously not be in favor of the latter. People who have little understanding of the intricacies of the operation of various types of heating devices may be tempted to save money, which they will bitterly regret in the future.

Strengths of an oil cooler

Such heating devices are simply ideal for the role of an additional heat generator in the house.

Ease of use provides the following set of advantages:

- reliability , such devices are used not only for heating a house, for example, oil radiators for hydraulic systems are used when it is necessary to maintain a constant temperature of hydraulic oil. This is an important task, they cope with it excellently, so their efficiency at home is high,

- efficiency - thanks to the presence of a thermostat, the heater will not work invariably. After the oil temperature in the device reaches the set value, the heating element will operate in a cyclic mode, periodically turning on when the oil cools down to the threshold indicated below,

- installation like this is not needed , just a radiator in the right place. Manufacturers quite often equip heavy models with wheels and a handle, so that in addition, the child can transport it from room to room with his own hands,

- the surface of the device does not heat up , the high temperature in most cases is about 80? C (but this is the maximum), in most cases it is in the range of 60-70? C. So you can safely leave the radiator in the nursery,

- the fan, if provided by the manufacturer, rotates at low speeds and does not drive dust around the room, as a simple fan heater does,

- Manufacturers produce models of oil radiators in a wide range of prices , so it is possible to choose both a budget option and a more expensive model,

- Often, when choosing an oil cooler, whether it burns oxygen is almost the main criterion . In this regard, there is no need to worry, the heating elements do not come into contact with air, so the air space is not burned out,

- Due to the developed fins, oil heaters have a huge surface area . This increases heat transfer.

Note! When using fan heaters, the already dry air space of the winter period becomes simply unbearable. So the oil heater wins in this regard too.

There are not so many disadvantages, it is possible to note only:

- slow rate of room heating,

- price, after all, the price of such devices reaches several thousand rubles, so the purchase does not always seem justified.

As for how much energy an oil cooler consumes, it is prohibited to exceed the power indicated on the package per number of hours of operation. It is necessary to take into account the cyclical operation of the heating element, and this indicator depends on many factors (number of rooms, ambient temperature, etc.).

Characteristics of oil radiators

In most cases, the documentation indicates the following characteristics of the oil cooler:

- power – characterizes the high heat output of the heating device. They are produced in the range of 0.5-3.0 kW, but high power does not indicate that it can completely replace central heating,

- protection from liquids - in most cases, this parameter is not paid much attention to, but it would be worth it. It is possible to determine whether a heating device has such protection by looking at the markings, so the designation IP20 means that there is no such protection at all, IP24 provides protection against splashing water, IP21 is an intermediate option (protection against drops),

- In addition, modern devices have a compartment at the bottom for storing the cord, this is very comfortable, you won’t have to stumble over it while the radiator is turned off,

- As for voltage, all oil heaters operate from a 220V network, so in this regard they are universal,

- In addition, in the documentation, the manufacturer in most cases shows the dimensions of the heater. Their width and height are comparable to simple heating radiators; there is a huge range of values in depth; both narrow options (thickness about 10 cm) and more substantial options (20-30 cm) are available for sale.

Why a cooling radiator may be needed in the lubrication system

As the power of automobile engines increased, engineers were faced with the critical problem of removing the ever-increasing excess heat from the engine. The first step towards solving this problem was the appearance of additional cooling fins on the engine sump. However, fins could not radically solve the problem. On trucks, as well as on highly accelerated passenger car engines, the fins on the oil pan did not cope with the task. Overheated oil lost viscosity, the pressure in the system dropped, and the driver had to slow down to reduce the release of heat. Overheated oil prematurely lost its properties: additives disintegrated, and deposits formed on engine parts. It was possible to provide a long service life to a forced engine only through effective heat removal.

Air type oil cooler is easy to install as optional equipment

In modern cities, daily standing in traffic jams leads to a similar effect, which is why the design of many cars of the latest generations includes a radiator for cooling the engine oil.

Design and principle of operation of an oil radiator

Depending on the engineering practices of a particular manufacturer, a conventional radiator or heat exchanger located in a coolant environment can be used to cool the oil. The first method is more often used on highly accelerated cars intended for driving at high speed, since under this condition one can count on the formation of a flow of incoming air of great force. As a rule, this is a copper tubular coil, sometimes with additional fins, like a radiator for a cooling system. This radiator is used in the lubrication system of the Toyota Carina E.

To ensure a constant oil temperature, a thermostat is built into the lubrication system along with the radiator. Immediately after starting the engine, while the oil has not yet warmed up, the thermostat valve is closed and the oil does not flow into the radiator. This is necessary to shorten the engine warm-up cycle, especially in cold weather. In older designs, a tap was installed instead of a thermostat, which the driver could open and close at his discretion.

An oil radiator in the form of a coil was used in the lubrication system of the GAZ 24 Volga

Modern designs often use liquid oil cooling. The operating temperature of the oil should be approximately 10-20% higher than in the engine cooling system. The average operating temperature of the coolant, even in summer, is 75-80 degrees, due to which the oil is cooled. In the case of cooling, the heat exchanger is combined with the outer part of the oil pump housing, to which the oil filter is attached. At the outlet and inlet of the filter, the oil comes into contact with the coolant through the walls of the channels. This solution was used, for example, on the Renault Megane I with a 1.6-liter gasoline engine or on the Nissan CD20T diesel engine, which was installed on the Nissan Serena minivan.

What and how to flush the engine cooling system of oil?

Good afternoon. Today we will talk about how to flush the engine cooling system of oil? This is especially true for cars equipped with automatic transmissions and oil-antifreeze heat exchangers, since in them the risk of oil getting into the antifreeze is much higher. The article discusses working flushing methods and popular misconceptions.

The article was written based on my own experience! All the tips in the article have been tested in practice!

The main problem when oil gets into the coolant is the formation of an emulsion.

She looks like this:

The main difficulty with the emulsion is that it clogs all the hoses and pipes, and the engine begins to overheat. Those. It flows very slowly and does not remove heat, and it is quite difficult to wash it.

Non-working methods for flushing the cooling system of oil (popular misconceptions).

Flushing the cooling system with plenty of running water.

We brought the radiator into the garden and washed it with reverse flow, water from a well. This did not help, large drops of oil are expelled by water, but the emulsion on the walls is not washed off (cold water cannot soften it). It takes more than one ton of very hot water to completely flush the cooling system of the emulsion.

Hot water is EXPENSIVE, not everyone has access to unlimited free hot water, so we write in non-working methods.

Flushing the cooling system with whey.

I read this method on the Internet and decided to test it.

The flushing method is as follows: drain all the liquid from the cooling system and replace it with whey, in the warm season we ride for 2-3 days, drain the inversion, rinse 2-3 times with cold water and fill with antifreeze.

Whey is freely sold in dairy departments.

We tested this method after we flushed the cooling system with water more than 10 times, and the radiator was flushed with a reverse flow.

We also write down the method as non-working! No, the serum turned black and washed away some dirt, but it washed off the emulsion no better than water!

Partially working methods for flushing the cooling system.

Flushing the cooling system with FAIRY dishwasher.

The washing method is as follows: pour in detergent (about a 10-liter glass), warm up the engine to operating temperature and drain all the liquid from the system.

Repeat if necessary.

At the end of the flushing, we flush the cooling system with water 2-3 times, drain everything and fill it with antifreeze.

The method is partially working. The detergent actually partially removes the oil emulsion, but it falls off in fairly large pieces that do not pass through the radiator honeycombs, thermostat and thin hoses of the cooling system.

To summarize, you can wash it, but the product is not effective enough; it breaks down the emulsion, but does it in large pieces that do not pass through the radiators.

Flushing the cooling system with automatic powder.

The method is slightly better than washing with dishwasher (less foam), but is fundamentally no different.

The only method of flushing the cooling system that worked was flushing the cooling system with diesel fuel (DF).

Desperate to wash the engine of the emulsion, I risked flushing the cooling system with diesel fuel.

Many are afraid to do this for fear of igniting the diesel fuel - nothing will happen to it, do not forget to remove the thermostat, otherwise you will not be able to flush the radiator.

Some people fear for the safety of the pipes; oily diesel fuel can cause the pipes to swell and deteriorate - this is also nonsense! They will swell much faster with an oil emulsion.

Methods that have not been tested.

Acid washing.

Here I include washing with carbonic acid (carbonated water), acetic acid, citric acid; obviously, these acids will not take on an oil emulsion. But it is quite possible to flush the cooling system from scale and dirt with them.

Washing with soda.

Soda will also not remove the oil emulsion, but aluminum will thank you for it! When flushing the cooling system with soda, it is diluted in a ratio of 100 g/liter.

That's all for me today. If you still have questions about how to flush the engine cooling system of oil or if you want to supplement the article and share your experience, leave a comment.

Best regards, administrator

Share

Advantages and disadvantages of an oil cooler

Air cooling of oil is more efficient than liquid cooling. But in this case, the system turns out to be cumbersome: an additional radiator and pipelines are required, which, moreover, are susceptible to stone impacts and other mechanical influences. Another drawback lies in the fact that at low speeds with a weak oncoming air flow, the efficiency of the system noticeably deteriorates.

In this regard, liquid cooling looks preferable, because antifreeze constantly circulates in the engine. In addition, such a system is much more compact. But it is not suitable for powerful, forced engines, because it cannot effectively cool the oil under high loads. In addition, there is a danger of depressurization between the circuits, and then oil will begin to flow into the cooling system. And after stopping the engine, it’s the other way around: antifreeze goes into the oil.