Basic information about the Stinger exhaust system

The main task of the stinger exhaust system is to remove exhaust gases from the cylinders of automobile engines, as well as to cool them, reduce noise levels and toxicity.

The functioning of the presented system is very closely related to the gas distribution mechanism, and more specifically, to the valves and exhaust manifold. The exhaust system is equipped with many structural elements, which include:

- Resonator. The so-called muffler can, in which the flow of processed combustion products is separated. In addition, the rate of release of combustion products is reduced here, and the resonator is made of fire-resistant metal;

- Muffler. It is a metal container, the so-called can, in the middle of which several barriers are placed. Partitions are placed in the middle of the can to change the direction of the exhaust flow of exhaust gases, and therefore reduce the noise level.

- Sensor (lambda probe). The sensor is an oxygen sensitive element that is installed on a thread connection, and it must touch the exhaust gases with the sensitive element;

- Catalyst. The catalyst is a device for purifying the exhaust stream. This container is made from fire-resistant metal. In the middle of this container there is a catalyst base, which is conventionally divided into several categories, ceramic and metal. The metal part of the catalyst is made of corrugated foil, which is coated with an active coating. The ceramic part of the catalyst is made of three exhaust aftertreatment components, which include wire mesh, ceramic pad and thermal insulation;

- Reception tube. It looks like a curved tube, which is made of fire-resistant metal (very rarely stainless steel).

All structural elements of this system are located under the bottom of the vehicle. The process of modifying the exhaust system is the first operation, since this is where vehicle tuning begins. The presented operation is the first due to the fact that it does not require special expenditures of money for the purchase of spare parts, and the effectiveness is quite noticeable. The stinger exhaust system is equipped with an exhaust manifold, which is also called a spider and has 2 main patterns (4-2-1 and 4-1), a direct-flow resonator and a main muffler, rectangular in shape.

How does the exhaust system work?

The operation of the stinger exhaust system is to open the exhaust valve, with the processed products passing into the exhaust manifold. On gasoline car engines, processed products pass through the receiving tube, and on diesel engines, through the compressor tubes and after that into the receiving tube. After this, the gases pass to the catalyst, and there they settle on the surface of the active element of harmful additives

It is worth drawing your attention to the fact that the catalyst can function exclusively at high temperatures, which are about 250⁰. Using sensors, a guidance signal is transmitted to the guidance system and, depending on the amount of harmful additives, the air-fuel mixture is supplied to the cylinders

It is also worth paying your attention to the fact that the level of efficiency of exhaust gas transition directly depends on the degree of purification of the muffler, catalyst and the diameter of the pipes. Otherwise, processed combustion products will accumulate in the cylinders, and this can lead to a decrease in the power level of the car engine, and sometimes even complete breakdown of the fuel system

How to clean the DPF

There are two main ways to clean the DPF from carbon deposits. The first implies the need to remove the filter element from the car, and the second involves performing actions directly on the car. Both methods have their advantages and disadvantages, so we will consider them separately.

Cleaning the particulate filter with removal

The complexity of this method lies in the need to dismantle the diesel particulate filter, as well as the duration of the procedure. On average, it will take about 8 hours to clean the filter.

For cleaning, special particulate filter flushing fluids are used, which can be purchased at automotive stores. It is better to choose formulations from proven brands such as Luffe, Pro-tec, Liqui Moly and the like. These liquids are compositions of petroleum components and various additives that can dissolve soot deposits. Liquids are supplied in 5-liter canisters; on average, the entire canister will be required for one flush. Canisters may have a place on top to attach a hose, some of them have a hose included. The hose makes it easier to fill the particulate filter with flushing liquid.

The housing of the removed particulate filter must be completely filled with washing liquid and left for the time specified in the instructions for use of the composition (about 8 hours). After this, it is enough to rinse the filter with a stream of water to remove any remaining dirt, as well as any remaining cleaning agent.

Please note: Flushing with water must be taken seriously as the cleaning agent is flammable and can ignite if exhaust gases enter. After washing the particulate filter with water, all that remains is to dry it and install it in place.

After washing the particulate filter with water, all that remains is to dry it and install it in place.

Cleaning the particulate filter without removing it

The method of washing the particulate filter without removing it is faster, since the work is carried out directly on the car. The design features of the filter make it possible to supply cleaning liquid through the hole for installing a pressure or temperature sensor, having previously removed them.

It is important to note that a different composition is used to clean the particulate filter without removing it. This is due to the fact that the work is carried out directly on the car, and there is no way to ensure that petroleum products will be completely removed from the particulate filter

Therefore, a water-alkaline based composition is used for cleaning. with washing liquid. The liquid will allow the remaining alkali to be neutralized after cleaning.

To wash the particulate filter without removing it, you will need to get a spray gun.

Please note: You can also initially find cleaning fluids in aerosol cans. To effectively use the liquid in the can, be sure to read the instructions for it

Before washing the particulate filter, the car engine must be warmed up, after which it is necessary to wait until the temperature in the filter element reaches about 40 degrees Celsius. This must be done to increase the efficiency of the alkaline composition.

The composition is sprayed onto the particulate filter under a pressure of about 8 bar. In this case, the spraying process should be interval: the liquid is injected for 10 seconds, then you need to wait 10 seconds before injecting a new dose. This will require about 1 liter of cleaning fluid.

It is also important to rotate and move the spray probe to clean the entire particulate filter. After washing with an alkaline composition is carried out, clean water is sprayed in the same way

After completing work on cleaning the particulate filter with liquid agents, it is recommended to carry out the procedure for burning off the remaining soot by operating the vehicle at high speeds for 20-30 minutes.

How does the exhaust manifold work?

VAZ 2107 exhaust pipe mounting

The design of the exhaust manifold, which is actively used in exhaust today, appeared almost at the same time as the first internal combustion engines. By design, this is equipment that is mounted on the engine. The manifold consists of several pipes, the main task of which is to connect all the engine cylinders with the exhaust system catalyst (catalytic converter). The most common material for making collectors is cast iron or stainless steel. Recently, it is not so common to see ceramic devices of this type.

We can talk for a long time about which collector is better, cast iron or stainless steel. But today many agree that it is preferable to purchase cars with a similar stainless steel unit. Considering the fact that the exhaust manifold is almost constantly under strong influence of high temperatures, condensation remains after operation. Cast iron structures sooner or later begin to corrode, while stainless steel is resistant to corrosion. Ceramic collectors are good only because they are cheap, but they do not last long and cannot withstand the truly extreme temperatures that sometimes occur inside the unit.

The principle of operation of the device is not at all complicated. All gases that have already been exhausted in the cylinder are sent to the manifold thanks to the exhaust valve. From there they have a direct path further – to the exhaust system catalyst. In addition to removing gases, the manifold also works as a device that helps the engine bleed. This is possible due to the pressure difference in the engine chambers and the manifold. Since the pressure in it is lower, a kind of wave is formed inside, traveling after reflection from the resonator back towards the combustion chamber. The higher the engine speed, the faster such a wave moves. Accordingly, at high speeds, getting rid of exhaust gases occurs much faster. It is also worth noting that the exhaust manifold today is the most popular element of a car exhaust device in terms of tuning.

Ways to muffle the exhaust sound

Before tuning the exhaust system, you need to understand the reasons why the sound of the engine becomes louder over time. The operation of the engine itself is a fairly loud process, but the muffler and other components of the exhaust system perfectly suppress this loud noise. Without a muffler, the engine noise is very loud.

The noise occurs because the fuel mixture explodes in the combustion chamber, releasing gases that then exit into the exhaust pipe. We will not talk in detail about the operation of the engine, you can read about this in another article, but here we will talk specifically about how to muffle the exhaust sound.

The explosion releases energy that pushes the piston, and when the piston has moved the required distance, the exhaust valve opens, through which the exhaust gases exit and go further through the exhaust system. To effectively absorb noise, thick metal parts are used. So, the thicker the metal used in the exhaust system, the quieter the car will drive due to the fact that there will be less vibration.

The exhaust manifold is the first one to absorb the noise, which is why it is made so large and thick, so it best dampens the noise that comes from the cylinder block. Even if you compare the exhaust pipe of any more or less normal foreign car with the exhaust pipe of a domestic car, you can see that in foreign cars the pipe is heavier and thicker, which is why such a car runs quieter.

This is why when you drive an old VAZ 2114, the noise is such that you can’t hear what the passengers in the rear seats are saying, which is why you start thinking about how to muffle the exhaust sound.

The exhaust system also has a resonator, which is needed to reduce the speed of gases through the exhaust pipe. And after the resonator comes a muffler. When exhaust gases pass through the resonator, they lose some energy and continue to flow more slowly.

Gases lose the largest share of their energy in the muffler. If we consider a good muffler, then it contains several separate housings, after passing through which little remains of the noise.

Design of the structure and purpose of its components

White smoke from the exhaust pipe, the main causes

The parts that make up this design have different functional loads and their own designations, reflecting the stages of their work. The exhaust system diagram itself and the names of its parts look like this:

- exhaust manifold;

- exhaust pipe;

- catalyst or in other words catalytic converter;

- resonator or flame arrester;

- muffler.

The exhaust manifold is an attached type of equipment of the power unit, and is designed to receive exhaust particles and gases of the fuel mixture from the combustion chambers of each cylinder into it, and is made mainly of ceramics, cast iron or stainless steel alloys with increased heat resistance.

Exhaust system design

The downpipe, referred to by car enthusiasts as the “pants” due to its similar appearance, is designed to combine several streams of exhaust gases into one and further transport them to the catalytic converter (catalyst). The pipe is often equipped with a so-called corrugation, which dampens the vibration transmitted to the entire structure of the exhaust system by the running engine.

The catalyst is a ceramic honeycomb, the surface of which is coated with a layer of an alloy of platinum and iridium, which allows exhaust gases to enter into a chemical reaction with them, resulting in their separation into oxygen and nitrogen oxide. The released oxygen in the catalyst helps to burn the remainder of the fuel mixture more efficiently, as a result of which only a nitrogen-dioxide-carbon mixture is supplied to the muffler. The operation of the catalytic converter is monitored by a special lambda probe sensor, transmitting a signal to the control unit of the vehicle's power unit. A similar sensor is installed on the exhaust manifold to analyze the toxicity indicators of the exhaust gases entering the catalyst.

All components of the exhaust system are connected to each other through flanges using fastening bolts and heat-resistant seals, which are responsible for the tightness of this structure, without which the full operation of the engine of a modern car is impossible.

Exhaust system diagram

Resonator

It is made in the shape of a cylindrical can. It is in the resonator that the first separation of the exhaust gas flow occurs. Also, by increasing the diameter, the exhaust speed decreases.

Gases gradually dissipate in this chamber. Thanks to this, vibrations and partly sound are dampened. Just like the “pants,” the resonator is made of fire-resistant metal.

Basic information about the exhaust system

Causes of strong white smoke from the exhaust pipe

Before we talk about repairing the exhaust mechanism, we will briefly talk about what an exhaust mechanism is and what its main function is. The exhaust mechanism releases processed combustion products.

The design of a standard exhaust mechanism includes the following basic elements:

- A converter or as it is also called a catalytic converter. The presented device began to be used in modern cars quite recently. Its main function is to burn carbon monoxide and reduce the toxicity of exhaust products to a minimum;

- The exhaust manifold, which is part of the vehicle's attachment. Its main function is to collect combustion products in one tube;

- Muffler. Its main function is to reduce the noise that is generated during the release of processed combustion products into the environment.

Basic faults

If the resonator or muffler is damaged, the driver will hear a fairly loud roar and the exhaust mechanism will start firing. In addition, damage to the exhaust system can lead to the following problems:

- Reduced engine power;

- Engine speed instability;

- Ingress of combustion products into the car interior;

- Soot formation above the muffler.

The exhaust system must be repaired immediately when such a need arises, as this can lead to more serious damage. One of the most common causes of exhaust system breakdowns is burnout of exhaust system elements and seams.

Also, the breakdown may consist of a large accumulation of salts and reagents, or various chemical compounds. Together with sudden temperature changes, this can lead to breakdown of the functional elements of the exhaust system. The resonator is also subject to the same damage.

Exhaust system diagnostics

The diagnostic process is quite simple, since you can immediately hear a malfunction of the exhaust system by the specific noise that comes from under the car. After carrying out noise diagnostics, you need to carry out visual diagnostics, but to do this, you first need to drive the vehicle onto a lift or into an inspection hole. Main causes of malfunctions:

- Mechanical damage;

- Muffler performance under extreme conditions.

There are several ways to solve these problems:

- Exhaust system repair;

- Complete replacement of the exhaust system.

Do-it-yourself exhaust system repair

If you drive a vehicle carelessly or drive on poor road surfaces, elements of the vehicle's exhaust system are usually damaged. In the presented system, temperature and pressure are in constant motion, so the best repair in the event of a breakdown would be to replace the exhaust system or some of its elements.

So, let's look at the algorithm for repairing the exhaust system:

- If during diagnostics of the system no external damage was found, then the cause of the breakdown is a breakdown of the internal resonator. Then it is necessary to completely replace the resonator;

- If during diagnostics small burnouts of certain elements of the muffler were found, they can be eliminated using a special sealant. But before you start fixing this damage, you need to clean the edges from rust and carbon deposits;

- If a sufficiently large burnout area has been discovered, the hole can be repaired using special fiberglass and epoxy resin. After performing this action, start the engine and let it idle for a while, at least thirty minutes. Thanks to this, you can achieve high-quality and reliable hardening of the special substance;

- If during the diagnostic process burnouts were discovered at the junction of the tubes with the resonator, then the problem areas are sealed using welding or special synthetic resins.

The muffler is broken

The exhaust system of a car is the most unprotected part of the car. It is exposed to external influences and car enthusiasts often have to repair it. A breakdown of the system is not just an unpleasant knocking sound and other “delights” such as a decrease in car power, jerking of the car, but also the danger that toxic fumes coming out of the engine can leak into the cabin and poison people. In order for your exhaust system to function properly, it, in particular, and the car in general, must be systematically checked and taken for maintenance. If you neglect this, you risk getting into an accident at the most inopportune moment. Don't forget that muffler damage is on the list of ten reasons why you have to call a tow truck.

Corrosion protection

The muffler often suffers from fading of paint, which is why corrosion quickly renders it inoperable. One of the effective ways to protect the surface of the exhaust system from corrosion is to paint it. It should always be remembered that the temperature of the gases leaving the exhaust pipe is usually 420–760 °C, and the surface temperature of the exhaust pipe is 200–540 °C. Therefore, only heat-resistant, silicone varnishes and enamels are suitable for painting.

To paint the “glushak”, you need to proceed like this:

- First, remove the muffler and prepare it for painting (to do this, you need to thoroughly clean it of all dirt and oil, degrease it and dry it well).

- Inspect the dried muffler, not missing any areas where the factory coating has peeled off or oil stains.

- If you do find oil stains, take a rag soaked in gasoline and wipe them thoroughly.

With peeling factory paint, proceed as follows:

- Take a strong knife or putty knife and remove the previous coating.

- If you notice rust on the exhaust system, remove it immediately using coarse sandpaper or a special rust remover.

- After these manipulations, apply a layer of primer.

- After the primer has completely dried, paint as stated in the instructions for the paint you purchased.

- Then let the muffler dry a little, install it back under the car body and let the engine run for a few minutes so that the muffler warms up and the paint dries.

There are times when the rust has penetrated too deeply and it is impossible to get rid of it. If this is your option, then you should treat the muffler with a rust converter.

There are alternative ways to protect the exhaust system:

- First you need, as for painting, to clean the muffler and exhaust pipe from dirt, oil and rust, and then apply a thin layer of graphite lubricant. You can do it as follows:

- Let's go to the nearest computer store.

- We ask them to process the powder from the printer.

- Mix it with a small amount of grease.

- Then you need to coat the surface with the mixture, place it on stands and start drying with a hair dryer, blowing from the side of the resonator.

We recommend: Design and principle of operation of a modern torque converter

Until the grease completely burns out, the coating will not stop emitting a pungent odor, so carry out all manipulations in a respirator and outside, or at least in a well-ventilated room (garage).

The muffler is leaking

You carried out an inspection and found no signs of corrosion on the muffler, but saw damage. Unfortunately, this happens, because the exhaust system is the most unprotected part of the car; it is affected by both mechanical influences (for example, a bouncing stone or unsuccessful parking of a car) and chemical ones, in the form of aggressive chemical compounds, salts and even the external environment. But there are also obvious reasons for the formation of a hole: perhaps the muffler is made of poor quality material.

Muffler burnout

If you are faced with such a nuisance as a muffler burning out, then do not rush to think that the problem lies inside the car. Novice car enthusiasts believe that mufflers burn out due to too intense exhaust emissions created by the internal combustion engine. But often this is not the case. Today, many car manufacturers, even well-known brands, produce cars with low-quality parts, without normal processing, which are highly susceptible to chemicals and the environment.

Example of a burned out muffler

Obviously, the main reason for system burnout is various types of environmental influences on the part. If you treat your car irresponsibly, it is stored in rain, snow or scorching sun, then you should not be surprised that part of the exhaust system quickly burns out, because this is facilitated by a natural chemical process in this case - metal oxidation.

Another common reason for part damage is idling the car and driving short distances. Do not forget that sudden temperature changes are detrimental to the muffler. At low temperatures, condensation forms in the muffler, which has a destructive effect on all metal except stainless steel.

Why does a car need an exhaust gas removal system?

So this system, contrary to all opinions, is a very necessary component of the car and it is designed to remove exhaust gases from the engine, reduce toxicity and noise, and cool them.

Even popularly, many people simply call the exhaust system a muffler. But you must admit, this is not so, because the muffler itself is one of the components of the exhaust system. The exhaust gas removal system usually has the following device:

- an exhaust manifold that combines several exhaust outlets into one;

- the exhaust pipe that connects the manifold and the catalyst;

- catalytic converter, needed to convert toxic gases into harmless ones;

- resonator, it reduces noise;

- muffler;

- connecting pipes.

Let's now take a closer look at how the exhaust system works:

The exhaust manifold is necessary for removing exhaust gases and for purging the engine cylinders. This is the only pitfall that stands between you and the withdrawal of your winnings. Many players know that making money in online casinos is much easier than it actually seems. Every gambler wants to know and understand the casino from the inside, so I recommend the website https://obzory-kazino.com.ua with a detailed description of each casino brand. Among other things, each new user of the establishment, after making a deposit, will be rewarded with a welcome gift as a bonus, calculated based on the amount of funds deposited. They block access to the casino and perform other functions. The size and shape of the exhaust manifold is done to ensure uniform and smooth resistance in the system and affects the torque and power of the engine. Since the exhaust manifold takes on elevated temperatures, it is accordingly made of heat-resistant cast iron.

A catalytic converter is necessary to convert harmful gases into harmless ones. People simply call a catalytic converter a catalyst. On different cars they differ in design and location. Multi-way catalytic converters are now used to protect against unburned hydrocarbons, nitrogen oxide and carbon monoxide.

A resonator or additional muffler is designed to reduce high-frequency noise. It consists of a perforated pipe, which is placed in a sealed housing and the space between the housing and the pipe is filled with sound-absorbing material.

The muffler or main muffler is larger in size than the secondary muffler and is also designed to reduce noise. Its task is to reduce the level of remaining noise. Muffler designs are changing for the better every year.

Also, a vibration-isolating coupling (bellows) is used in the exhaust system of a car; it is needed to isolate the system from engine vibration. A bellows is a flexible metal hose covered with a steel sheath.

Vibration-isolating coupling (bellows)

Video:

It is also necessary to remember about the particulate filter, which is used on diesel engines and plays a useful role in reducing the release of soot into the atmosphere. In the exhaust system, the filter is combined with the catalytic converter.

Muffler parts

Gearbox: purpose and principle of operation

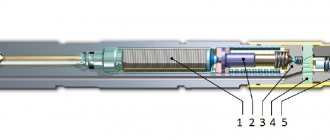

This system is not homogeneous; it is assembled from several parts, namely five of them:

- This is the exhaust manifold, now many may say that it does not belong to the muffling system, but it interacts with it directly - its main purpose is to remove gases from the engine, so I will still include it in the diagram.

- Reception pipe.

- Catalyst.

- Resonator.

- And the last part, the muffler itself.

We talked about the exhaust manifold, you can also read about it in this article. Goes straight to the exhaust pipe. It is designed to connect the exhaust manifold and the catalyst

It seems that you should pay attention to it, pipe and pipe - BUT, a so-called vibration damper (simply a corrugation) is often installed in it, which is designed to dampen vibrations from the engine and not transmit them further, either to the body or to the muffler

The catalyst is designed to combat exhaust gases, namely to clean them. The exhaust that comes from the power unit contains many harmful elements. The catalyst burns them out, making them harmless, the concentration drops significantly. Of course, it’s impossible to clean it completely, but progress is evident. If there were no catalysts, megacities would simply suffocate from exhaust fumes. We read about its device here.

Resonator and muffler - these two parts already fight the flow of gases and sound; they are designed primarily to dampen sound and only secondarily to reduce temperature. The gases that have passed through the catalyst first reach the resonator through pipes, and only then the muffler itself.

Neutralizer.

The catalyst plays the role of reducing the level of toxic impurities in the exhaust gases. This element has become widespread in the current automotive industry due to increasing environmental requirements for vehicles. Depending on the manufacturer and brand of vehicle, the shape and location of the catalytic converter may vary. But, regardless of the structure of this component of the exhaust system, its main function remains to reduce the level of toxicity in burnt gases.

Modern vehicles are equipped with more advanced catalysts, which include three filter components. Such a catalytic converter reduces the level of harmful substances contained in the spent fuel mixture. With this design of the exhaust system, the exhaust gas is released into the environment with virtually no residue of carbon, nitrogen oxide and carbon monoxide.

DIY resonator

Before designing and assembling a resonator of your own design, you need to understand one simple thing. The thicker the material from which the exhaust system is made (including the resonator), the more effective the fight against vibrations and resulting noise will be. It is for this reason that the exhaust manifold, which is the first to receive gases from the cylinder head, has such an impressive weight.

However, when choosing a material, you should not overdo it and choose too massive blanks. Otherwise, the mass of the resonator will be significant, and this will affect the dynamic characteristics of the car and the load on its chassis.

There are a number of reasons why car owners make their own exhaust resonators. One of them is to reduce the noise that a standard factory muffler produces. Usually, for this purpose, an additional resonator is installed in the exhaust system. The second reason is the manufacture and installation of a direct-flow car resonator. Its features are as follows:

- reduction in engine power loss (actually insignificant, about 5.10%);

- changing the sound background of the engine and exhaust system (for lovers of low sound).

To make a direct-flow resonator you will need:

- a set of locksmith tools;

- welding machine (it is advisable to use modern semi-automatic machines or inverters);

- angle grinder with a set of cutting and grinding discs.

The design of the resonator will differ depending on the materials used and the imagination of the car owner. We offer you one of the options for self-manufacturing a direct-flow automotive resonator:

- Pre-prepare the pipe that will serve as the internal base of the resonator. It should be the same or slightly larger diameter than the factory one. Make sure that it can be easily welded to the existing system in the future, so do not choose a diameter that is too large (unless it is possible to connect the pipe using a flange).

- Next, you need to drill holes in this pipe, similar to the stock resonator.

- After this, you need to find a pipe with a slightly larger diameter (about 3.5 cm) that will serve as the outer casing. Its length needs to be made smaller (depending on the design, on average by 5.10 cm on each side).

- The plugs necessary to seal the housing at the ends are made. For this, sheet metal is used, where the outer diameters of the large and small pipes are drawn. Afterwards, the blanks are cut out and processed using a grinding machine.

- A pipe with a larger diameter is placed on a pipe with a smaller diameter, and the cavity between them is filled with glass wool (or better yet, modern mineral wool with good heat and sound insulation characteristics).

- Next, you need to weld the ends around the edges of the pipe with a large diameter using pre-made plugs.

- After welding work, clean the seams using an angle grinder. After this you should paint them.

- The last stage is welding the new resonator into the car's exhaust system. After carrying out the work, also clean the welding seams.

DIY resonator

The given algorithm is approximate. There are a wide variety of options for homemade resonators. In some cases, they are simply thrown out of the system, replacing them with a piece of pipe. However, we do not advise you to do this, since you will not receive a significant addition to the car’s power, but an additional roar from the exhaust pipe is guaranteed!

Additional problems

After installing a self-made resonator, the car owner will likely encounter a number of problems that must be solved. First of all, we are talking about increasing the mass of the gas exhaust system, and, accordingly, the car as a whole. This is true if you used heavy metal elements to make the resonator. Therefore, a situation may arise when it is necessary to replace the brackets and/or shock absorbers. That is, strengthen them. Otherwise, the car body will “sag”, and the chassis will experience additional load.

In addition, replacing the resonator entails a change in the ratio of air entering the engine and the amount of exhaust gases. Therefore, it is necessary to empirically determine which optimal settings to choose and make appropriate adjustments in fuel supply and air filtration.

Differences between modern systems.

Exhaust system

As mentioned above, the exhaust system of a vehicle equipped with a diesel engine has its own characteristics. The main difference between the output system on a diesel engine is the presence of a particulate filter. This filter element, as the name implies, reduces the soot content of the exhaust mixture before it is sent into the atmosphere. In some output assemblies, the filter element is directly connected to the catalyst. This design of the output set has proven itself to be the most advanced and environmentally friendly. The number of systems that monitor the environmental level of a vehicle is constantly increasing.

As part of new generation cars, there are the following systems that reduce the toxicity level of the burnt mixture: a crankcase cooling system, a reverse circulation system for burnt gases, and a fuel mixture vapor detection system.

The oxygen analyzer transmits air flow readings in the exhaust mixture to the electronic engine control unit. Thanks to the received signals, the system that controls the operation of the engine produces an optimal mixture of fuel and air. Despite the fact that the oxygen analyzer is part of the output set, its main task remains to maintain the correct operation of the propulsion system.

As a rule, a modern vehicle contains several analyzers. One of them is located in front of the catalyst, the second is located immediately after it. In addition to the indicated controllers, the following analyzers are usually installed in the exhaust mixture output systems: a sensor for determining the temperature of the exhaust gases, a nitrogen oxide analyzer. Each of the analyzers located as part of the output set takes part in the formation of the air-fuel mixture and performs an important function during the operation of the vehicle.

System design

The muffler is the most famous element of the exhaust mixture exhaust system. This device is responsible for reducing the noise level during vehicle operation. The damping element itself includes several components: a preliminary noise reduction device (resonator) and a main noise suppression element. A small aggregate constantly changes the direction of movement of gases, which leads to a decrease in noise when the mixture exits.

The principle of operation of the exhaust system

Exhaust system location

In the classic version for gasoline engines, the exhaust system of a car works as follows:

- The engine exhaust valves open and exhaust gases with remaining unburned fuel are ejected from the cylinders.

- Gases from each cylinder enter the exhaust manifold, where they are combined into one stream.

- Through the exhaust pipe, exhaust gases from the exhaust manifold pass through the first lambda probe (oxygen sensor), which records the amount of oxygen in the exhaust. Based on this data, the electronic control unit adjusts the fuel supply and the composition of the air-fuel mixture.

- Next, the gases enter the catalyst, where they enter into a chemical reaction with oxidizing metals (platinum, palladium) and a reducing metal (rhodium). The operating temperature of the gases should not be lower than 300°C.

- At the outlet of the catalyst, the gases pass a second lambda probe, with the help of which the serviceability of the catalytic converter is assessed.

- Next, the purified exhaust gases enter the resonator and then into the muffler, where the exhaust flows are converted (narrowed, expanded, redirected, absorbed), which reduces the noise level.

- From the main muffler, exhaust gases already enter the atmosphere.

https://youtube.com/watch?v=sNVJ_RJ9FK4

The diesel engine exhaust system has some features:

- Coming out of the cylinders, the exhaust gases enter the exhaust manifold. The temperature of diesel engine exhaust gases varies in the range of 500-700 °C.

- Then they enter the turbocharger, which performs supercharging.

- The exhaust then passes through the oxygen sensor and enters the particulate filter, which removes harmful components.

- Finally, the exhaust passes through the car muffler and is released into the atmosphere.

Exhaust system, common faults.

Often, during the operation of a vehicle, you may notice extraneous noise caused by mechanical damage to one of the components of the muffling element. In case of most malfunctions, the damaged exhaust system element is replaced with a new one. If you have special equipment and the necessary skills for welding, you can restore the muffler yourself.

Knowing the basic elements and operating principle of the exhaust system, you can quickly determine the cause of the malfunction and take the necessary measures in a timely manner!

https://youtube.com/watch?v=2pSTqdTTJ9M%3F

The exhaust system has a relatively simple design, which makes it possible to fix most of the breakdowns with your own hands. The best solution if one or another element of the set is damaged is to replace it. In most cases, a restored muffler quickly fails and must be replaced.

Knock out the catalysts and install flame arresters.

Knocking out catalysts and installing flame arresters is perhaps the most effective way to modernize the exhaust system of modern cars. With little expense, the car owner can forget about replacing the catalyst once and for all. Instead of the standard “filling”, a flame arrester made of high-strength stainless steel and protected by noise-insulating material is installed in the catalyst body. Such a module is capable of working with fuel of any quality, does not have a negative impact on the performance of the internal combustion engine and has an unlimited service life!

Working with errors of class P0420 and P0430.

A significant number of motorists complain about such errors. According to the basic classification, messages like P0420 and P0430 indicate a malfunction of the catalytic system. This means that the driver must repair the catalyst as soon as possible (remove, replace and install a new one). Sometimes such system errors can be caused by a poor-quality fuel mixture, however, in most cases, the catalyst is to blame. In order to cope with this problem once and for all, specialists remove the catalyst and install a specialized “deception” module

or "deception". Such a device is perceived by the system as an original catalyst (no errors occur), however, unlike the catalytic unit, it has an unlimited service life.

Replace the catalyst with a flame arrester.

The main task of the catalytic module (neutralizer) is to remove the maximum possible amount of harmful impurities from the exhaust gases. As a result of using low-quality fuel, filter elements quickly become unusable, becoming clogged with foreign inclusions. Ultimately, the exhaust gases are discharged intermittently, and significant damage is caused to the vehicle's power unit. The only way to get rid of this problem is to remove the catalyst that has become unusable. If the catalytic system malfunctions, the main vehicle control unit generates error messages (as a rule, they are numbered P0420 and P0430). The second lambda signals a failed catalyst. In most cases, such messages indicate complete failure of the catalyst.

If the above problem does arise, the car owner must immediately contact our specialized service center in Moscow, where the technicians will be able to knock out the catalyst with clogged filter elements. The most rational solution to the problem with the catalyst is to install a flame arrester. This module is manufactured in the housing of the standard catalyst and completely replaces it. The flame arrester does not need to be cleaned or replaced; its service life is equal to the service life of the car. Installing such a device will help you forget about errors P0420 and P0430 once and for all, and fully enjoy the operation of the vehicle.

Specialists from the SVS car service network in Moscow will quickly eliminate faults in the catalytic system by repairing the catalyst or replacing it (at the client’s request). In both the first and second cases, you will be satisfied with the result.

SVS car services work for you seven days a week!

Call us, make an appointment and come to replace the catalyst!

What does the exhaust system consist of?

The essence of how the exhaust system works is quite simple, once you look at it. During correct operation of the engine, combustion of the air-fuel mixture occurs inside its cylinders. As a result, we receive quite large volumes of exhaust harmful gases, which must be urgently removed from the engine system. This is required, first of all, for the further operation of the cylinder, which needs to be filled with a new volume of mixture. The exhaust system helps in the drainage process. Its three main elements allow for efficient removal of exhaust gases:

- an exhaust manifold;

- catalytic converter;

- muffler.

Next, we will try to consider each of the elements of the system in more detail.

Direct flow muffler

The production of a direct-flow muffler begins with the preparation of material with increased heat resistance and 2 tubes of different sections. The smaller one should fit freely into the pipe from the previous node. Therefore, before manufacturing, you should remove the old kit, remove the partitions from the tank and begin calculating the required dimensions.

Then you need to take a thin tube and make several holes in it around the perimeter. It is then placed into a second tube and secured using welding equipment.

The finished product is fixed in the tank, and the free space is filled with insulation material. Next, you need to fill the free space with an insulator and weld the container. This action will minimize noise during engine operation.

It is important to understand that the slightest deviations from the standard configuration can prevent normal installation of the part. Therefore, you will need to spend more than one day in the garage, solving minor problems and refining the system

Inexpensive structures rust after a few months of use, and serious defects appear within a year after installation. To prevent such problems, reliable and durable materials should be used - in this case, the service life will be extended to several years.

Possible malfunctions, methods for eliminating them and tuning options

The design of the exhaust system is an ideal option for tuning a passenger vehicle, thanks to the ease of installation of its components and the presence of a wide range of different parts. The most common option for tuning a muffler is to install a so-called direct-flow exhaust, when the resonator is removed from the system.

The most common malfunctions of the exhaust system are associated with loss of tightness of parts or their connections, the seals in which can be severely worn out. To replace the sealing elements, you need to purchase an exhaust system repair kit, and unscrew the fastening bolts and replace them with new ones.

Exhaust system parts made from various metal alloys are subject to significant heating, sudden temperature changes, and operate under conditions of increased loads, as a result of which they are subject to severe wear and burnout of internal parts. These breakdowns can be determined by the loud noise of a running engine and visual diagnostics of the exhaust system, after which the damaged structural part must either be replaced with a new one in case of internal faults, or its body must be repaired using electric/gas welding.

In modern cars, the operation of the power unit is controlled by a control unit, which receives certain signals from numerous sensors located on all its structural components. The design of the exhaust system contains a sensor called a lambda probe, which measures the amount of toxic substances in the exhaust gases. Only a diagnostic stand can detect its malfunction or incorrect operation, after which the sensor must be replaced.

Why does the exhaust system make loud noises?

To understand the reason for the appearance of loud sounds, you need to know the principle of operation of a standard exhaust system and the loads it is subjected to during operation. Temperature changes (cold and heat), contact with moisture, dirt and dust - all this provokes the development of corrosion. After some time, sections of pipes with perforations and those parts of the partitions that are located inside the muffler can burn out. Sound reflectors are gradually becoming unusable. In especially difficult cases, only one thing can save you from a loud exhaust system - replacing the old muffler with a new one.

Where do loud noises come from in the exhaust structure? They have different origins. Firstly, these are sounds from the expansion of gases that pass through it. Secondly, there is noise caused by vibration of exhaust components.

Purpose and general description of the exhaust system

The essence of the phenomena occurring inside the internal combustion engine can be briefly described in one word - explosion. All this is accompanied by accompanying effects - a sound wave and combustion products. It is to minimize such secondary phenomena in the operation of the internal combustion engine that the exhaust system of the car is used. Essentially, it solves the following problems:

- removal of combustion products from the engine cylinders;

- reduction of noise from engine operation;

- reduction of toxic substances in exhaust gases;

- removal outside the vehicle and preventing toxic gases from entering the cabin.

For all its apparent simplicity, the exhaust gas exhaust system installed on a car is a rather complex device, and not just a set of pipes and some cylinders of unknown purpose. Historically, it turned out that the original task of the exhaust system was to remove exhaust gases and reduce the noise of the internal combustion engine. This turned out to be realized by introducing a new specialized device into the design of the car - a muffler. As the internal combustion engine and the car itself developed, and requirements for vehicles became more stringent (reducing noise and pollution levels), the muffler was replaced by an entire exhaust gas removal system, into which new elements were introduced to successfully solve emerging problems.

Types of mufflers

Models are distinguished by characteristics and principle of operation. Noise transducers are made of metal - stainless or black steel with aluminum or zinc coating. The first type is universal, suitable for different machines, inexpensive, but has a short service life. Aluminized ones last a long time, but they are produced by a limited number of enterprises.

Muffler design diagram

Based on the operating principle of a car muffler, there are several groups:

- The simplest ones are restrictive. The part is made in the shape of a pipe, which first narrows and creates resistance, and ends with expansion. The device is used as a pre-filter, and not for exhaust gas removal.

- Reflective. Acoustic mirrors are built into the housing. A sound wave, when faced with obstacles, gradually loses its strength. This design of the car muffler is used at the output of the system.

- Resonator. The resonator devices include several chambers, which are separated by a solid partition. Frequency fluctuations in closed spaces cancel each other out. Such designs only slightly impede the exhaust flow. Silencers are placed after the exhaust pipe.

- Absorbent. Absorbers dampen noise effects using special materials. There is no labyrinth of partitions installed in the building. The space is filled with glass wool or mineral fibers. The sound insulation of such models is lower, and therefore attracts tuning supporters.

In sports cars, direct-flow filters are often used. This car muffler is designed more simply. A pipe with numerous holes is mounted in a body made of high-strength metal. The perforated structure is covered with fiberglass and steel mesh. Sound waves passing through the system are converted into thermal energy. The price of direct-flow models is usually higher; they are made entirely of stainless steel.

What to consider when calculating the diameter

Inexperienced tuning fans often use pipes with large diameters, which degrades power. However, when calculating, not only the output size is important, but also other factors: flow characteristics, gas movement speed. Designs with a large diameter make the flow slower, products with small sizes - on the contrary, faster. The balance between the speed of gas movement and the intake volume of the engine is important. Backpressure should be avoided when gases that cannot be quickly evacuated become trapped in the system.

Ideal system: several pipes of different sizes for each speed range. However, this solution is not affordable for many people, so a system is installed that is suitable for all speeds, including high speeds.

Some cars have a double bore system, which increases power but reduces torque. It is recommended to polish exhaust pipes so that gases can escape faster by reducing friction.

Causes of muffler failure:

- High temperature conditions inside the system, about 600 °C. Temperature promotes metal burning;

- As a result of active exposure to the external environment (water, dirt, temperature changes);

Exhaust fumes and road surfaces are two of the exhaust pipe's worst enemies.

- The main enemy of a car muffler is low quality fuel, which contains many different impurities. This contributes not only to rapid burnout, but also to contamination of the catalyst, which cleans the exhaust gases of impurities.

- Incorrectly configured ignition system parameters (high CO content).

We will make a new durable steel exhaust to order

In recent years, the exhaust manifold for BMW has been made of stainless steel to prevent rapid breakdown, burnout and other problems caused by the poor quality of Russian roads. The manifold is located between the engine and the catalyst, and in the absence of the latter, it is attached to the muffler itself. Stainless steel is heat-resistant and easily tolerates vibration, and also quickly removes excess heat from the system, cooling the collector. This material is highly expensive and is used only for individual parts of systems, so you need to be careful and carefully review the certification documents and in case of problems, replacing the muffler corrugation will be the solution. The current market offers structures made of stainless steel, aluminized steel (increases service life to five to six years and is affordable) and ordinary steel with a special coating, which, however, does not reduce its chances of undergoing severe corrosion. Parts from the latter are easy to find at a minimal price; It’s better to avoid them if you don’t want to spend extra money and have your car constantly under repair.

https://youtube.com/watch?v=vy6mJkv0ZGg

Muffler parts

This system is not homogeneous; it is assembled from several parts, namely five of them:

- This is the exhaust manifold, now many may say that it does not belong to the muffling system, but it interacts with it directly - its main purpose is to remove gases from the engine, so I will still include it in the diagram.

- Reception pipe.

- Catalyst.

- Resonator.

- And the last part, the muffler itself.

We talked about the exhaust manifold, you can also read about it in this article. Goes straight to the exhaust pipe. It is designed to connect the exhaust manifold and the catalyst

It seems that you should pay attention to it, pipe and pipe - BUT, a so-called vibration damper (simply a corrugation) is often installed in it, which is designed to dampen vibrations from the engine and not transmit them further, either to the body or to the muffler

The catalyst is designed to combat exhaust gases, namely to clean them. The exhaust that comes from the power unit contains many harmful elements. The catalyst burns them out, making them harmless, the concentration drops significantly. Of course, it’s impossible to clean it completely, but progress is evident. If there were no catalysts, megacities would simply suffocate from exhaust fumes. We read about its device here.

https://youtube.com/watch?v=_0bn3osJgYU

Muffler functions

The muffler is designed to reduce the noise level that occurs during the processing of gases and air and their release into the atmosphere. The second main function of this tool is to convert energy from processed gases, reducing their temperature and reducing their speed.

Several chambers of different sizes, separated by a partition, realize the expansion and contraction of the flow. This happens thanks to the diaphragm hole, also called a throttle.

In addition, the muffler provides for a change in the initial direction of flow of these same processed gases. This is what helps dampen high-frequency sound vibrations.