How does a car work?

Every car owner needs to know, at least in theory, how a car works. This knowledge will reveal an understanding of the structure and the principle of its functioning. Any machine is equipped with:

- engine;

- body;

- chassis;

- transmission;

- chassis;

- braking system;

- control system;

- electrical equipment.

Let's look at each component detail in more detail.

Depending on the type of car, there are different types of bodies, but its functional part does not change at all. Depending on what design feature is assigned to it, the body can be:

The parts that it consists of take an active part in the use of the machine. It is in it that the following are located:

- salon;

- chassis;

- transmission;

- motor;

- control systems;

- generator and much more.

It is also worth noting that thanks to the body, all electrical circuits are closed in the negative. Another problem that is solved by the car body is safety. In the event of an accident or adverse weather conditions, this element will protect all road users from impacts.

The engine is actually the “heart” of any car, because thanks to it the car is set in motion. The most common are ICE (internal combustion) engines, which use cylinders and pistons. When fuel enters and burns, a powerful flow of thermal energy is created. The energy is released outside the car, giving rotation to the crankshaft along the way. This in turn sets the car in motion.

Transmission and car chassis

The car chassis has many different mechanisms that must transmit torque directly to the wheels. The chassis system also includes the transmission, chassis and vehicle control systems. For efficient operation, the car is equipped with a gearbox. It can be either mechanical or automatic. Thanks to the gearbox, torque from the engine is transmitted at low or high speed. An important component of the transmission is the junction box, which is equipped only with all-wheel drive vehicles. It is worth mentioning the presence of a differential, which causes the car’s wheels to rotate at different speeds on the same axis.

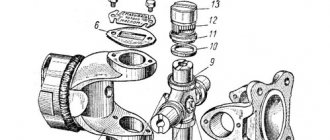

No transmission can do without a clutch. It performs the function of decoupling the engine and transmission during gear changes without the need to stop the vehicle. How does a car's clutch work? It includes the mechanical part and the drive. The drive ensures the serviceability of the machine, and the other component mechanisms are put into operation. It can be either mechanical or hydraulic. The hydraulic drive includes:

- pedal;

- several types of cylinders: working and main;

- switch off plug;

- pressure bearing;

- pipeline.

When the clutch is depressed, pressure is created, which, thanks to the rod and piston, flows to the master cylinder. This is followed by movement of the release fork and pressure bearing to transfer forces directly to the mechanism.

The mechanical part of the clutch is equipped with:

- driving disk;

- disc with pads.

- crankcase;

- spring pressure disc;

- casing.

This part plays a vital role, because without the clutch it would be impossible to change gears and ensure a smooth ride of the car.

This part of the car includes two axles (front and rear), suspension, frame and wheels. The frame is designed to mount all elements of the car. Often the functions of this part in passenger cars are performed by its body. Axles located at the front and rear support the frame and body. Through them the wheels receive vertical load. Due to the suspension, the body is connected to the wheels and axles.

Car wheels provide stability on the road surface and allow it to move.

The car is controlled using the steering wheel. It allows you to set the desired direction of movement. But the entire control system has several more components:

- steering column;

- steering mechanism;

- turning levers;

- connecting rods.

History of automobile engine development

Translated from the original Latin language, engine or motor means “set in motion.” Today, an engine is a specific device designed to convert one type of energy into mechanical energy. The most popular today are internal combustion engines, of which there are different types. The first such motor appeared in 1801, when Philippe Lebon from France patented a motor that operated on lamp gas. After this, August Otto and Jean Etienne Lenoir presented their developments. It is known that August Otto was the first to patent a 4-stroke engine. To this day, the structure of the engine has remained virtually unchanged.

In 1872, the American engine debuted, running on kerosene. However, this attempt could hardly be called successful, since kerosene could not explode normally in the cylinders. Just 10 years later, Gottlieb Daimler presented his version of the engine, which ran on gasoline, and worked quite well.

Let's look at modern types of car engines and figure out which one your car belongs to.

Car from A to Z: internal combustion engine design

New section, get ready! There will be a lot of educational text with pictures.

The internal combustion engine (ICE) is the heart of the car. The main feature of these engines is that fuel ignition occurs inside the combustion chamber (CC), and not in third-party external units.

During operation, the thermal energy released as a result of fuel combustion is converted into mechanical energy.

By fuel used

- light liquid (gas, gasoline)

— heavy liquid (diesel fuel)

— Gasoline engines

There are two types: gasoline carburetor and gasoline injection.

In the first case, mixture formation (mixing fuel with air) occurs in the carburetor or in the intake manifold using injectors. Next, the mixture enters the cylinder, is compressed and ignited by a spark from a candle.

In the second case, fuel is injected into the intake manifold or into the cylinder using injectors (atomizing nozzles).

— Diesel engines

Special diesel fuel (DF) is supplied at a certain moment (before reaching dead spots) into the cylinder under high pressure using an injector.

The movement of the piston compresses the mixture even more, the fuel heats up, followed by ignition of the combustible mixture (due to high pressure).

Such engines are characterized by low speed and high torque.

— Gas engines

The engine uses hydrocarbons as fuel. Basically, such engines run on propane, but other gases are also used as fuel.

The main difference from other engines is the high compression ratio. Such engines wear out less due to the fact that the fuel is already supplied in a gaseous state. Also, the efficiency of gas engines is obvious - gas is cheaper than gasoline.

It is also worth noting that it is environmentally friendly - there is no engine smoke.

By ignition method

- from spark (petrol)

- from compression (diesel)

By number and arrangement of cylinders

— In-line engine

The most common arrangement, the cylinders are arranged in a single row perpendicular to the crankshaft. Such engines are simple in design, but with a large number of cylinders, the size of the engine increases in length.

— V-shaped

To reduce the length of the unit, the cylinders are positioned at an angle from 60 to 120 degrees, while the longitudinal axes of the cylinders coincide with the longitudinal axis of the crankshaft.

The engine turns out to be quite small longitudinally (short).

Of the minuses: the engines are quite wide and the block heads are separate, which leads to an increase in manufacturing costs.

— Opposite

The horizontally opposed engine has smaller height dimensions, which will lower the center of gravity of the entire vehicle. The advantages include: compactness, symmetrical layout.

The main reason for replacing a car engine

Are you experiencing extraneous noise in your unit, and are your familiar experts advising you to change the engine? Don't rush to follow other people's instructions. First, familiarize yourself with the main reasons that may cause the need to replace an engine, and consider the factors that influence this replacement process:

- If the life of your power unit has reached its extreme point and the engine fails due to extreme wear of the main parts, damage to the engine housing, including as a result of a traffic accident, or it has suffered a water hammer, in these cases the engine must be unconditionally replaced;

- Also, a replacement can be made due to the desire of the motorist to improve the performance of his car, for example, by replacing its original engine with a more powerful unit. This process is called tuning, and it promises, in addition to technical ones, additional documentary difficulties when re-registering a car with the traffic police.

In any case, engine replacement is accompanied by an application to the traffic police. Despite the fact that since 2013 engines have ceased to be registered units and in the most common cases re-registration is not required when replacing them, the number on the engine can be checked in any case, and if the engine belonged to a stolen car or is missing altogether, this does not bode well.

Systems

- cooling

- lubricant

- nutrition

- ignition

- exhaust gas release

Let's take a closer look at the engine mechanisms.

crank mechanism

This mechanism is designed to convert the reciprocating motion of the piston in the cylinder into the rotational motion of the engine crankshaft.

In turn, the crank mechanism consists of:

1) cylinder block with crankcase;

2) cylinder heads;

3) engine oil pan;

6) crankshaft;

Basic engine systems

The power system serves to supply purified fuel and air to the cylinders, as well as to remove combustion products from the cylinders.

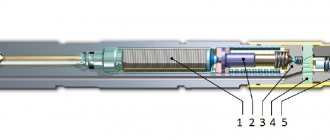

The diesel power system provides dosed portions of fuel at a certain moment in an atomized state into the engine cylinders.

The power supply system of a carburetor engine is designed to prepare a combustible mixture in the carburetor.

The ignition system for the working mixture in the cylinders is installed in carburetor engines. It serves to ignite the working mixture in the engine cylinders at a certain moment.

The lubrication system is necessary for the continuous supply of oil to the rubbing parts and the removal of heat from them.

The cooling system protects the walls of the combustion chamber from overheating and maintains normal thermal conditions in the cylinders.

The location of the components of various engine systems is shown in the figure.

Rice. Components of different engine systems: a - ZIL-508 carburetor engine: I - right view; II — left view; 1 and 15 - oil and fuel pumps; 2 — exhaust manifold; 3 — spark spark plug; 4 and 5 — oil and air filters; 6 - compressor; 7 - generator; 8 - carburetor; 9 — ignition distributor; 10 — oil dipstick tube; 11 — starter; 12 — power steering pump; 13 — power steering pump reservoir; 14 - fan; 16 — crankcase ventilation filter; b — diesel D-245 (right view): 1 — turbocharger; 2 - oil filler pipe; 3 - oil filler neck; 4 - compressor; 5 - generator; 6 — oil pan; 7 — pin-fixing the moment of fuel supply; 8 — exhaust pipeline; 9 — centrifugal oil purifier; 10 - oil dipstick

Cylinder block

It is a one-piece cast part that connects the engine cylinders. There are supporting surfaces on it for installing the crankshaft, and the cylinder head is usually attached to the upper part.

The cylinders in the block are either cast integrally with the block, or are separate replaceable bushings.

Also, the block performs another, no less important, function - oil is supplied under pressure through the holes in the block for lubrication.

The inner walls of the cylinders serve as guides for the pistons as they move.

How a car engine works - briefly about complex processes

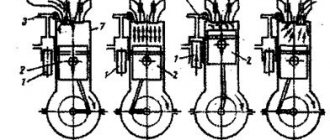

So, the limit of movement of the piston has two extreme positions - top and bottom dead centers. In the first case, the piston is at the maximum distance from the crankshaft, and the second option is the shortest distance between the piston and the crankshaft. In order to ensure that the piston passes through dead spots without stopping, a disc-shaped flywheel is used.

An important parameter for internal combustion engines is the compression ratio, which directly affects its power and efficiency.

To correctly understand the principle of operation of a car engine, you need to know that it is based on the use of gases expanded during the heating process, as a result of which the piston moves between the top and bottom dead centers. When the piston is in the upper position, combustion of the fuel entering the cylinder and mixed with air occurs. As a result, the temperature of the gases and their pressure increases significantly.

The gases perform useful work, due to which the piston moves downward. Next, through the crank mechanism, the action is transmitted to the transmission, and then to the car wheels. Waste products are removed from the cylinder through the exhaust system, and a new portion of fuel is supplied in their place. The entire process, from fuel supply to exhaust gas removal, is called the engine operating cycle.

Piston

A cylindrical part that reciprocates inside a cylinder.

The piston consists of: a bottom, a sealing part, a guide part (skirt).

The shape of the bottom depends on the tasks assigned to the piston. The concave bottom allows you to create a more efficient combustion chamber. Curved - makes the piston stronger, but reduces the efficiency of the combustion chamber.

The bottom with the sealing part forms the piston head. The sealing part contains oil scraper and compression rings.

The piston skirt serves to guide movement in the cylinder.

Scheme

The figure below shows a typical diagram of a car engine (one cylinder).

This diagram clearly shows the main elements:

A – Camshaft.

B – Valve cover.

C – Exhaust valve through which gases are removed from the combustion chamber.

D – Exhaust port.

E – Cylinder head.

F – Cavity for coolant. Most often there is antifreeze that cools the heating engine housing.

G – Motor block.

H – Oil sump.

I – Pan where all the oil drains.

J – Spark plug that produces a spark to ignite the fuel mixture.

K - Inlet valve through which the fuel mixture enters the combustion chamber.

L – Inlet port.

M – Piston that moves up and down.

N – Connecting rod connected to the piston. This is the main element that transmits force to the crankshaft and transforms linear motion (up and down) into rotational motion.

O – Connecting rod bearing.

P – Crankshaft. It rotates due to the movement of the piston.

It is also worth highlighting such an element as piston rings (they are also called oil scraper rings). They are not shown in the picture, but they are an important component of the car engine system. These rings go around the piston and create maximum seal between the walls of the cylinder and the piston. They prevent fuel from entering the oil pan and oil from entering the combustion chamber. Most old VAZ car engines and even engines from European manufacturers have worn rings that do not create an effective seal between the piston and cylinder, which can cause oil to enter the combustion chamber. In such a situation, there will be increased gasoline consumption and oil consumption.

These are the basic design elements that occur in all internal combustion engines. In fact, there are many more elements, but we won’t touch on the subtleties.

Gas distribution mechanism

- intake and exhaust valves.

Camshaft

As a rule (in modern cars) it is located in the upper part of the cylinder head.

An integral part of the camshaft are its cams. There are exactly as many of them as there are intake and exhaust valves. These cams, pressing on the valve pusher lever, open it, and “running away” from the lever, the valve closes under the action of the return spring.

valves

The valve consists of a flat cap (head) and a stem. Moreover, the diameter of the intake valve head is made slightly larger than the diameter of the exhaust valve head (this is done for better filling of the cylinders with fuel).

Engine selection

It is worth starting the entire process of selecting a new unit based on the old one, since you need to maintain not only the parameters, but also preferably the volume, all this can be done by taking the technical data from the book for your car. It also happens that the unit is the same in volume and other parameters, but does not fit in the fasteners; this is called a generation of engines. It should also be observed, since after installation on the frame there will be problems with connecting auxiliary devices. Therefore, when selecting, try to select the engine as accurately as possible.

When purchasing, pay attention to the price, as they can sell a non-working unit for an exorbitant price; usually the cost of a used engine in good condition is about 30% of the cost of the car, a new unit usually costs 50% of the cost of the car. You can buy an engine either from an official representative in a store or from a service center that services your car, at a disassembly center or a car market. With the latter, there is a big risk of buying; the unit may not work and instead of a good motor, you will buy a pile of scrap metal. After all, without installing it on a car, there is no way to check it. It is also worth considering that the engine is not light in weight, if you are going to buy it online, you will have to pay a good amount for delivery.