Step-by-step replacement of a VAZ-2112 pump 16 valves

The pump belongs to the vehicle's cooling system. In its unit, this part is the second most likely to break down. On a VAZ-2112 with a 16-valve engine, replacing the pump is quite easy, so even a novice motorist can do it. The pump promotes stable circulation of coolant in the vehicle system. Therefore, if it malfunctions, leaks of this substance are possible, and air often gets into the system, which is very bad. It is much less common for valves to bend and the pump to jam, which may require a complete engine repair if we are talking about the 21120 model.

Replacing the pump on a VAZ-2112 with your own hands on a 16-valve engine: choice, prices, process, video

The pump, or technically speaking, the water pump, is an integral part of the car’s cooling system. This is the second part after the thermostat that most often fails. On a 16-valve VAZ-2112, replacing this element is quite simple, and almost every motorist can handle it. The water pump itself is responsible for circulating coolant through the system. If the water pump malfunctions, coolant may leak and air may enter the system. And in the worst case scenario, the pump gets jammed and the valves bend. This does not threaten the 124th engine, but the 21120 will require a major overhaul.

Video about replacing the timing belt and pump on a 16-valve VAZ-2112:

The video material shows the process of replacing the pump, and also contains some recommendations and nuances. Before performing operations, it is recommended to watch the presented video.

Basic faults

Signs of a faulty pump are:

- hum or rustling in the timing drive area;

- leakage of coolant from the pump seat;

- mechanical damage to the timing belt (eaten teeth, delamination, cracking).

The main malfunction of the coolant pump is the failure of its bearing, which can be caused by its wear or incorrect adjustment of the timing belt tension. If this problem is detected, the pump must be replaced.

It is recommended to change the pump along with the timing belt and tension pulley every 50 thousand km, as well as when signs indicating its failure are identified. If the coolant pump is not replaced in a timely manner, this can lead to:

- damage and breakage of the timing belt, as a result of which it will be necessary to repair or change the cylinder head along with the gas distribution mechanism, as well as parts of the piston group;

- overheating of the engine, which can lead to damage to the rubber communications of the cooling system, cylinder head gasket and valve cover, and piston group parts.

The price of a pump for an eight-valve VAZ 2110 engine is 700-1000 rubles. The cost of repair work at a service station is about 1000 rubles. But you don’t have to overpay for the work. You can replace the pump yourself.

When purchasing a pump, be sure to pay attention to:

- manufacturer of the spare part (under no circumstances buy parts from unfamiliar brands);

- catalog number of the spare part (the standard pump for the eight-valve engine has the number 21081307010);

- presence of original packaging;

- gasket included;

- Availability of a warranty card for the product.

Causes and symptoms of malfunction

In order to understand whether the device is broken or not, you need to understand at least a little about the operation of the vehicle, as indicated by certain spontaneous manifestations.

Signs that the water pump is broken:

Why is this happening:

- wear of the pump shaft or bearing - unstable circulation of coolant and leaks;

- the gasket is broken due to wear;

- failure of the shaft - rotation of the shaft itself, which will be expressed by unstable circulation of fluid in the system and, as a result, large overheating;

- pulley wear is immediately determined by belt wear.

By correctly identifying the faulty part based on the above signs, you will be able to fix the problem in a timely manner with minimal negative consequences for the remaining elements of the car.

Order of Operations

A complete replacement of the coolant is not required for this type of repair if its service life has not expired. It is better to install the machine on an overpass or inspection hole. Further work is performed in the following sequence:

- Disconnect the battery by removing the negative terminal.

- First, the cover of the expansion barrel is opened, and a container with a volume of at least 5 liters is placed under the cylinders. The coolant is drained into it; after draining, the cover must be replaced.

- Then you need to remove the casing; to do this, unscrew the mounting bolts.

- Now you need to fix the crankshaft at the dead top point of the 1st cylinder. To do this, the gear is engaged and the pulley mounting bolt is turned. The correct position is determined in this way: the mark on the timing case coincides with the mark on the shaft gear.

- To statically fix the crankshaft, you need to insert a screwdriver between its teeth.

- Now you need to loosen the tension on the timing belt; to do this, slightly unscrew the nut holding the roller. This is done with a special key, the direction of movement is counterclockwise.

- After this operation, the roller and belt can be removed.

- Now you can completely remove the casing. To do this, unscrew the five mounting bolts.

- The water pump is now available. You need to pry it off with a screwdriver and remove it. The seat should be cleaned.

- Now the VAZ 2110 8-valve injector pump is being directly replaced. But first you need to take a new gasket, coat it on both sides with autosealant, and install it on the pump.

- The pump is installed in place.

- Subsequent work is performed in the reverse order to that described above. It is advisable, along with replacing the VAZ 2110 8 pump, to change the roller and timing belt. This way you can accurately calculate the service life of these elements.

- After installing the belt in place, you need to check its tension. To do this, take one of its fields with your fingers and unfold it in a horizontal plane. If you cannot turn the belt more than 90 degrees, the tension is normal.

- After completing the work, add old or new coolant to the required level.

Only after positive test results of the pump can you hit the road by car. For the procedure for replacing the VAZ 2110 8 valve pump, see this video.

Replacing the water pump (pump) on a VAZ 2110 8 and 16 valves

Replacing the water pump VAZ 2110 1.6 l 16 valves

Tools:

- The key is "10".

- The key is "13".

- The key is "17".

- 5 mm hexagon.

- Flathead screwdriver.

1. Remove the negative terminal from the battery.

2. Unscrew and pull out the adsorber so that it is convenient for us.

3. Unscrew the 5 bolts of the timing belt protective cover with a 5mm hexagon.

4. Replacing the pump VAZ 2110 16 cl. passes with the help of a hexagon; for this we unscrew the 3 bolts securing the lower part of the casing.

5. Loosen the generator belt and remove it.

6. Dismantle the wheel.

7. The boot also needs to be removed.

8. Using a 17mm wrench, unscrew the generator pulley and also place an obstacle for the crankshaft.

9. Then we turn on 5th gear, and the person helping with the replacement, at the same time, presses the brake while you unscrew, you can also fix the flywheel with a flat-head screwdriver.

10. Screw the bolt into place.

11. Then replacing the VAZ 2110 pump is done by turning the crankshaft with a socket wrench “17” until the top dead center (TDC) aligns the marks on the crankshaft pulley and camshaft pulleys (if the belt is broken, we combine the marks separately).

12. It is necessary that the crankshaft mark coincides with the slot on the oil pump cover, this will be the top dead center.

13. In addition, it is necessary that the marks on the camshafts coincide with the marks on the rear timing cover.

14. Turn until the marks are at the same level.

15. Now we loosen the tightening of the 2 camshaft pulleys, they need to be strengthened (in these cases a regular intake valve can help), place it in the middle of the pulleys and tear off the nuts.

16. We unscrew the bolt from the stud; it holds the tension roller, and we do the same with the deflection roller.

17. The bolt on the support roller must be removed.

18. Pull out the tension roller and also remove the timing belt.

19. Completely unscrew and dismantle the two camshaft pulleys.

20. Remove the pulleys and make sure that the key does not pop out of the camshaft.

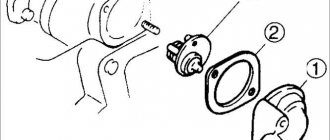

21. Unscrew the 6 bolts of the rear timing cover and 3 nuts, with which the pump itself is secured.

22. After unscrewing the rear cover, remove the pump (for convenience, pry it off with a screwdriver).

23. Remove the pump.

24. The pump should spin tightly.

How to install a new pump on a VAZ 2110 8 valves?

1. Take a new pump.

2. Place the gasket on the pump and coat it with a sealing agent on both sides.

3. We mount the pump in its place.

4. Install the rear timing cover.

5. We mount the camshaft pulleys in place.

6. During this process, keep an eye on the key.

How to determine if a VAZ 2112 pump is broken

The pump is a device with blades, centrifugal type. It is driven by a timing belt via a crankshaft pulley. The device is housed in an aluminum housing, inside which the roller rotates in a double-row bearing, with a supply of grease for the entire period of operation. The outer ring of the bearing is secured with a screw. The toothed pulley is pressed in front of the roller, the impeller is mounted at the rear end. The end of the impeller is held by a thrust ring made of a graphite-containing composition. There is an oil seal underneath it. The one-piece design does not allow for high-quality repair of the unit, therefore, if a breakdown is detected, a complete replacement of the pump on the VAZ 2112 is necessary.

Installation of an additional pump on a VAZ 2110/11/12

The interior heating system in VAZ 2110/11/12 cars often fails to cope with its responsibilities in the cold season. This problem can be solved by installing an additional pump in the cooling system.

To heat the interior of the VAZ 2110/11/12, an additional electric pump from GAZelle is installed

The VAZ 2110/11/12 stove functions normally only at speeds of at least 2 thousand rpm. At idle, slightly warm air enters the cabin. The fact is that to increase the air temperature, the coolant must circulate faster. The problem is solved by installing an additional pump and accelerating the circulation of antifreeze through the stove. As a result, the temperature in the cabin ceases to depend on engine speed. For these purposes, an electric pump from a GAZelle is installed.

Installation of an additional pump

To install an additional pump, you need to do the following:

- Coolant is drained from the cooling system.

- A part of the outlet pipe of the stove is cut out, equal to the length of the pump without taking into account the fittings.

- The fittings are coated with sealant, the hoses are put on and secured with clamps.

- To attach the pump to the body, use a special bracket that wraps around the pump and is attached to the body with two self-tapping screws. You can make such fasteners yourself or purchase them in a store. The bracket can also be attached to suitable studs on vehicle components.

- To control the pump, a button is installed in the cabin that supplies power from the positive terminal of the battery. In this case, it is advisable to supply voltage through a relay.

The process of replacing the pump (water pump)

General view of a water pump manufactured by AvtoVAZ

So, before you begin directly replacing the pump on a 16-valve VAZ 2112, you need to collect some tools. Tools you will need: a 10 and 17 wrench, a flat screwdriver, a timing belt clamping mechanism, a hammer, rags, 2 liters of coolant, a container for draining the coolant from the system.

Now that everything is available, you can proceed directly to the process. Let's look at detailed instructions for replacing the water pump:

- It is best when there is a pit or a lift, which will simplify the procedure, but in the absence of this we will change it directly in the garage.

- We dismantle the front right wheel.

To make replacement easier, remove the front right wheel from the car.

Unscrew the crankshaft pulley nut, which will later be removed

Fixing the camshafts from turning so as not to disturb the valve timing

Unscrew the timing belt pulley and loosen the belt.

Dismantling the crankshaft pulley

General diagram of timing belt disassembly

Unscrew the mounting bolts and dismantle the pump

The car pump has been replaced and for the next 40-50 thousand km this unit should not bother the car owner.

Reasons for replacement

Now, let's look at the causes of the malfunction, as well as the signs by which you can understand that the unit is not suitable for use.

So, signs of a faulty water pump:

- Bearing noise or “clatter” in the pump area.

- An increase in coolant temperature (a non-functional automatic transmission may be to blame, diagnostics and replacement).

- Leaks that come from the side of the water pump. Gasket failure or bearing wear.

Now, let's look at the reasons for pump failure:

- Worn water pump bearing or shaft , which leads to poor fluid circulation or leaks.

- Gasket failure due to wear.

- Shaft wear can also cause it to turn and therefore not have enough circulation, which will lead to a lot of heat.

- Pulley wear , which will be visible from belt wear.

The causes and symptoms are named, so any motorist will be able to diagnose this system on their own.

Choice, price and some recommendations

So, you should be careful when choosing a water pump for a VAZ 2112, since the normal functioning of the cooling system depends on this unit. So, if you do not replace the pump in time, you can not only boil on the way, but also be left without circulation, but also get deflection and deformation of the cylinder head .

The modern spare parts market has a fairly large number of counterfeits, especially for spare parts for the chassis and cooling system elements. So, when choosing a pump, you need to look at the availability of relevant documents, holograms and certificates.

Original

2112-1307010 is the original catalog number of the water pump manufactured by AvtoVAZ. This part is directly designed for this 16 valve vehicle. The cost of the part is 1500 rubles .

Analogs

Now, let’s look at analogues of the original part, which is recommended for installation on the VAZ 2112. All of them have received the highest reviews from consumers, have the appropriate certificates, and also fit perfectly in terms of mounting fasteners.

| Manufacturer's name | Catalog number | Price in rubles |

| Weber | WP 2110 | 1000 |

| Master-sport | 622-N-PR-PCS-MS | 1100 |

| Fenox | HB1003L1 | 1200 |

| Dolz | L-125 | 1300 |

| SCT | SQ 006 | 1350 |

| Finwhale | WP110 | 1400 |

| Magneti marelli | WPQ 0580 | 1500 |

| Starline | VP LA103 | 1500 |

| Pilenga | WP-P 2112 | 1600 |

| Coram | WP2112 | 1700 |

| Kroner | K202012 | 2000 |

| Ruville | 67212 | 2200 |

| Bugatti | PA 6402 | 3000 |

Water pump manufactured by Fenox

Tuning

To increase engine performance and increase service life, you can install tuning spare parts. As practice and experience show, modernized spare parts have a longer service life than standard ones.

So, for the VAZ 2112 they produce tuning parts, such as ProSport and Brembo.

Of course, their cost is about 3,000 rubles, which is twice as expensive as a standard part, but they have a smaller pulley, which allows the engine to circulate fluid faster. This, in turn, contributes to better cooling of the system.

Tuning version of the pump produced by Luzar

The engine of any car will never be able to operate stably without optimal functioning of the cooling system. The circulation of coolant inside the engine is ensured by a special pump or (pump - approx.), which is located in the gas distribution mechanism (timing) drive unit. It happens that an element fails and needs to be replaced. In this article we will talk about this in detail.

The video shows the process of replacing the pump on a VAZ-2112; usually the pump is replaced along with the timing belt during scheduled maintenance:

Preparing to replace your pump

First of all, you need to make sure that all the necessary tools are available to replace the water pump.

- key for 10 and 17;

- Screwdriver Set;

- hammer;

- timing clamping mechanism;

- rags;

- container for draining old coolant;

- new coolant – 2 l.

You should immediately decide on the time, since the process may take a little longer if you are performing this manipulation for the first time.

Signs of a pump malfunction

Replacing the VAZ 2110 pump may be necessary if obvious signs of a malfunction are detected. The most pronounced and frequent defects are:

- Violation of the drive pulley clearance. If it wobbles freely, this indicates wear of the bearings and imminent failure of the pump. In addition, a characteristic rumble indicates bearing wear. As a result of this malfunction, the timing belt begins to slip and is damaged by the tension roller.

- Leaks in the oil seal area. The defect is mainly expressed in the loss of antifreeze, which causes additional financial costs for adding coolant. You should respond to a breakdown in a timely manner without resorting to systematic fluid replacement.

- Noise during operation. As for antifreeze leakage, this malfunction can wait for some time. But if noise, an uncharacteristic creaking or howling is detected while pressing the gas pedal, the VAZ 2110 16 pump requires urgent replacement or repair! This is the initial characteristic of bearing failure. The device itself does not pose a threat, but if it jams, the consequences can be especially disastrous.

- Insufficient intensity of coolant circulation.

- Free rotation of the impeller separately from the shaft.

- Increase in motor temperature.

- Reduced coolant level.

Do-it-yourself replacement of a VAZ 2110 pump

VAZ pump replacement

As a rule, replacing the VAZ 2110 pump is necessary for normal engine functionality. Thanks to the pump, coolant can circulate freely throughout the cooling system. In this case, the temperature is removed from the heating parts of the engine. A non-working pump can cause the engine to overheat, causing it to quickly fail. In order to prevent this trouble, it is necessary to carry out a process called replacing the VAZ 2110 8-valve pump.

How to recognize a faulty pump

Replacing the pump on a VAZ 2110 8 valves

You can recognize a faulty pump by the following signs:

Replacing a VAZ 2110 16 valve pump

In order to verify that the pump is faulty, it is recommended to carry out some simple tests:

- You need to warm up the engine to operating temperature, and then compress the upper radiator hose. If you feel that liquid is still circulating in the system, you should conclude that the water pump is working;

- It is worth paying attention to the fact whether the pump is humming or not. The presence of a hum may indicate the “dying” of the bearing. It is not recommended to start such situations and replace the pump immediately.

In most cases, you can hear a whining sound that indicates it is time to replace the water pump without removing the alternator drive. In addition, the malfunction can be determined by other signs. For example, in the case of a domestic car, you may experience a consumption of antifreeze of approximately half a liter per day. If this symptom is detected, it is recommended to inspect the hoses, clamps and expansion tank.

Note! If the previous inspection did not produce any results, you need to pay attention to the front timing case cover, which may be damp.

It is possible that dampness will not be over the entire area, but in some places, for example, around the bolts, in the area of the inspection hatch or along the cut. There may be a dirty blue blob hanging from the engine pan. If you unclip the timing belt inspection hatch, you can immediately detect something wrong. Most likely, the belt will be wet and stripped along the edges to the polyamide cord. In the correct case, the belt should be well tensioned, but if it is faulty it will loosen a little.

Replacement

To remove the pump, you must first remove the timing drive. Sometimes you can hear opinions that you can easily do without it. But in practice, it is impossible to remove the pump without dismantling the timing drive. Of course, it is quite possible to unscrew it, but removing the pump through the existing hole is very problematic. Therefore, you still have to disassemble the floor of the motor. Getting to work, everyone who switched to a “two-wheeler” from a VAZ “classic” will be sad, replacing the pump there was much easier.

Experienced drivers time the replacement of the pump to coincide with the installation of a new timing belt. After all, the pump will soon fail anyway. It is replaced according to the following scheme:

- It is necessary to install the car on the inspection hole, if there is no hole, jack up the left wheel and remove it. The battery is removed and the coolant is drained;

- The generator mounting bolt is loosened, after which it rises up;

- We set the timing marks. This is important for subsequent assembly;

- Unscrew the crankshaft pulley. It scrolls. But you can deal with this problem in 2 ways. First, an assistant uses a mounting blade to wedge the flywheel through the window in the clutch housing. For the second one you will also need an assistant. He will engage fourth gear and keep the brake pedal depressed. This way, you will ensure that the crankshaft remains stationary, and you can use a 17mm wrench to unscrew the pulley mounting bolt;

- The bolts securing the camshaft pulleys are unscrewed. For this you will need a special holder. If it is not there, then you can lock the shafts using a spacer. Just do it carefully, do not damage the pulley teeth;

Conclusion

. Problems with the coolant pump are not uncommon. Most often problems arise with the bearing. Therefore, replacing a pump on a VAZ 2110 and 2112 16 valves is not a rare job. Therefore, every owner of this model should be able to quickly fix this problem. After all, operation with such a breakdown can lead to malfunction of the entire engine.

Step-by-step procedure for replacing a pump on a 16-valve engine

First of all, place the car on a flat surface, put wheel chocks under the rear wheels, and put the hand brake on the car itself.

Drain the coolant

Also make sure that the coolant is drained from the system. A wide container is well suited for a drain container so that the residue does not spill onto the ground and it can be used again. So, the best way for it to come out is to unscrew the screw on the cooling radiator. Now you can get to work.

Go!

Unscrew and remove the timing case

The casing is off, down with the belt!

Please note that you will have to dismantle not only the timing belt, all pulleys and drives, as well as the plastic engine protection, which is attached to it with 6 bolts. Read about what tension the timing belt should have here.

All bolts are indicated by arrows.

The pump is held in place by three bolts

Installing a new pump

Make sure that all holes on the new pump housing and on the engine match.

We coat the gasket with sealant and get ready to install the new pump

Putting it all back together