- home

- /

- Services

- /

- Engine repair

Engine repair is a complex process that should be carried out in a car service center if you want the power unit to serve for a long time.

Timely diagnostics and high-quality engine repairs will help extend the life of the power unit several times.

"Auto-Maxima" is a specialized car service center located in the Southern Administrative District of Moscow, where you can carry out engine repairs, regardless of the make of the car. We have been providing engine repair services in Moscow for more than 10 years.

Depending on the specifics of the work, we carry out the following types of repairs:

- Current;

- Average;

- Capital.

Current engine repairs. Due to wear, loss of mechanical strength of individual parts , weakening of connections, damage, corrosion, violation of adjustments, as well as severe wear, malfunctions arise, the elimination of which requires repair of individual components and the vehicle as a whole. This type of repair is carried out as planned and most often includes partial replacement of consumables and process fluids:

- Replacing the cylinder head

- Replacing cylinder liners

- Replacing the crankshaft and bearings

- Replacing the fuel pump

- Replacement and installation of the pump section of the injection pump

- Turbocharger replacement and repair

- Changing the engine oil

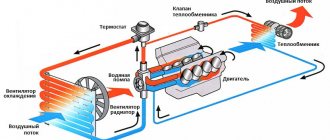

- Coolant replacement

- Replacing the oil filter

- Replacing the air filter

- Replacing spark plugs

- Replacing pistons and piston rings

- Replacement of valve seals, gaskets, etc.

- Cleaning the cooling system from scale

- Valve lapping

Average engine requires partial disassembly of the power unit. This type of repair involves eliminating minor breakdowns and replacing worn parts. Based on internal combustion engine diagnostics, we replace or modify worn engine parts: cylinder head, worn bolts, fasteners, cylinder heads, cylinder head gaskets and other work. Types of jobs:

- Cleaning carbon deposits

- Engine disassembly

- Changing bearings, tightening bearings

- Grinding, lapping and adjusting valves

- Replacing pistons, piston rings and pins

- Replacing inlet and outlet pipes and flywheel

- Engine assembly

- Cylinder head repair and valve grinding

- Cylinder head grinding

- Repair or manufacture of connecting rod

- Cylinder block boring

- Compression check

- Repair of turbochargers, etc.

Engine overhaul . In case of severe damage and critical wear of parts, we carry out a major overhaul of the engine. This type of repair includes removal and complete disassembly of the engine, replacement and restoration of components and individual elements. In some cases, when it is not practical to overhaul the engine, we recommend replacing the engine with a new one.

If you notice extraneous sounds or unusual engine operation, call and make an appointment for diagnostics. We will diagnose the engine, identify the cause of the breakdown and restore the power unit in a short time and at a reasonable price.

A minor malfunction always leads to more serious damage, so it should be eliminated promptly and efficiently.

Why do you trust our car service specialists for engine repairs in Moscow?

- Experienced and competent specialists. Our car service center employs experienced locksmiths with more than 10 years of experience.

- Spare parts and consumables are always available WITHOUT overpayments. The service center is equipped with a warehouse with original spare parts and consumables. We will select spare parts and consumables according to the make of your car without overpayment; if the parts are not in stock, we will buy them from a reliable supplier.

- Guarantee for work performed. We do quality work and provide a guarantee of 6 to 12 months for all work performed.

- Modern equipment with the necessary equipment. Our car service center is equipped with modern certified equipment and stands for prompt performance of high-precision work.

- Affordable pricing policy. We do not inflate the cost of our services. As bonuses, we develop promotions for our clients, thereby saving you money.

In our work we use modern high-precision equipment, and the level of our specialists allows us to quickly and efficiently solve any tasks. If you need high-quality internal combustion engine repairs in Moscow, then come to the Auto-Maxima car service center, at the address: Varshavskoe highway 170, box No. 30

SIGN UP FOR REPAIR

Spare parts

When diagnostics have been carried out and all the parts that need to be replaced have been identified, it is worth ordering the necessary spare parts, since preparation is required before installing them on the engine. Often, when gasoline engines are repaired, the following spare parts are changed:

- Main and connecting rod bearings.

- Piston group.

- Connecting rod pins.

- Connecting rod bushings.

- Oil filter and pump.

- Pump or its repair kit.

- Inlet and exhaust valves.

- Oil scraper rings.

- Gasket set.

- Valve guides and seats.

- Other details.

Main symptoms of engine malfunction

Even if your car has covered more than 200,000 km and the engine is running normally, you should periodically inspect the engine compartment and exhaust pipe yourself. Heavy, fresh leaks of engine oil on the engine body will tell you about deformed drive shaft seals and leaky gaskets.

If you find a problem with your engine, call our service center. We will diagnose the engine, identify the cause of the malfunction, and offer you the best option for eliminating the malfunction, if any. In our Auto-Maxima car service center, computer diagnostics and current engine repairs are carried out by auto mechanics with more than 10 years of experience.

The warning lights on the dashboard are on . Alert indicators on the dashboard always indicate problems with the engine and light up when a critical limit has been reached. Key indicators that cannot be ignored:

- Check oil\ Oil level low (check oil/low oil level)

- Oil pressure low

- Check engine (check engine)

The Check Engine light is one of the main signs of engine trouble and can indicate a number of reasons. A Check engine malfunction is detected by diagnostic equipment.

If you hear uncharacteristic sounds while the engine is running, for example, clanging, grinding, tapping or vibration of the car, then this should alert you and be a reason to contact a car service specialist to identify the cause.

Problems starting the engine. Uneven engine idling. Jumping and hesitation during engine operation is a serious sign of engine trouble. The reason for this behavior may be dirty spark plugs, clogged fuel filters, a malfunction of the engine control unit and other malfunctions that cannot be determined by eye.

Problems with starting, the engine hesitates, the gear shift lever shakes, this may indicate wear of the cylinder-piston group when a pressure difference occurs in the cylinders. Malfunctions of the power supply system and the ESU (electronic control system) of the engine are also possible. Here you need computer diagnostics of the engine in order to determine fault codes, which can be used to determine the faulty module (sensor) of the engine ESU. (in such cases, “CHECK” usually lights up).

You can remove the error by connecting to the control unit yourself, using various applications on your smartphone, but you definitely won’t be able to fix the problem yourself. It is best to contact a car service.

Smoke signals. One of the main visual indicators of engine malfunctions is the color of the exhaust gases. If you observe black, gray or blue smoke from the exhaust pipe, then this is an extreme sign of a malfunction of the internal combustion engine.

- Black color of smoke indicates a significant malfunction in the fuel or gas distribution system of the engine.

- A bluish tint to the smoke indicates malfunctioning injectors and nozzles or oil entering the combustion chamber from leaky piston system rings.

- Pronounced white smoke indicates burnout of the pistons or head valves.

After the engine has warmed up, if you observe any of the above colors in the exhaust gases, this is a clear sign of engine malfunction.

The smell of exhaust gases in the car interior . If you smell exhaust gases inside the car, then most often it is a problem in the exhaust system line.

The concept and need for major repairs

Overhauling a VAZ engine is not an easy task, which will require certain knowledge about the structure and operating principles of the mechanism. Proper overhaul means disassembling the engine, cleaning, inspecting and replacing parts as necessary.

A complete overhaul is a labor-intensive and time-consuming process. Removed parts are carefully inspected for integrity and suitability for future use. One of the most important functions is performed by the crankshaft, which has a complex shape. The valves, all gaskets and seals are replaced, and the clearance on the valve stems is checked. The causes of shaft malfunctions can be wear, bending and destruction.

All nodes must be in perfect order. It is necessary to ensure that the assembled version matches the factory condition of the engine. Overhaul is required in case of complete or partial depletion of resources. There are certain signs that repairs are needed. Don't ignore even one of the signs. After all, if you continue to not repair parts, they may become completely unusable. It is almost impossible to restore them in such situations. The only solution is to purchase new spare parts, which of course will cost more than timely repairs.

There are certain rules, following which you can significantly extend the service life, as well as slightly delay major repairs.

Engine diagnostics in a specialized car service center

Engine diagnostics is a quick way to identify the cause of the breakdown, if any, and evaluate the performance of the engine as a whole. Using equipment, you can identify even minor errors, which in the future can lead to more serious damage.

Engine diagnostics in our car service includes:

- Computer diagnostics of the engine (ICE) . We check the operation of a gasoline or diesel engine using computer diagnostics. We connect the computer to the engine and read the available indicators and values of the system sensors. After which, we decipher and identify errors, if any.

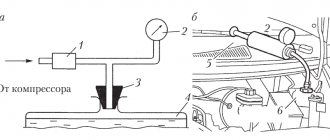

- Diagnostics of the injection system. We carefully check the system elements: drive, spark plugs, modules. We check the fuel pressure level and the tightness of the intake manifold (using a smoke generator). We check the level of exhaust gases (CO2, O2 and CO-CH), look at the signals from the oscilloscope sensor.

- Visual inspection. Diagnostics of the current state of the mechanical part without disassembly and the available resource. We check the compression, the condition of the timing belt and the position of the marks. We carry out endoscopy and check for leaks above the piston space and oil pressure. We measure geometric deviations of parts.

- Additionally, we check the power system, ECU, electronic peripherals (sensors, valves), these devices also affect the operation of the engine.

Engine disassembly, troubleshooting

Before you begin repairing a car engine, it must be freed from attachments.

We remove the generator, starter, intake and exhaust manifolds and other parts of attachments, and simultaneously assess the condition of the components.

The injectors can be washed and adjusted, the intake manifold and throttle body can be washed.

After dismantling the attachments, we begin to gradually disassemble the engine.

We remove the front engine cover, this is especially true if the timing chain drive is chain driven - you can check the condition of the chain.

After removing the front cover, we evaluate the condition of the chain, guide and tensioner.

Remove the valve cover to get to the cylinder head bolts. Optimally, if you have an assistant and a wrench with a long wrench, then you will be able to tear off the cylinder head bolts without effort.

After the cylinder head bolts are torn off, unscrew them, carefully prying them from all sides with a screwdriver.

Let's pay attention to the cylinder head. It is best to have the cylinder head tested. This process means checking the head for cracks and the condition of the components. As a rule, it is necessary to replace several guides with valves, and then the valves must be ground in to the seats.

New valve seals are installed. By the way, when doing engine repairs with your own hands, it is important to check the condition of the camshaft cams - if they are severely beating and worn, replacement will be required. At the service station, the head plane is ground to a perfectly flat state, and the plane can also be milled a few millimeters.

When the head is ready, we move on to the cylinder block. Initially, evaluate the gap between the piston and cylinder. If the cylinder has a blue tint, it means it has overheated.

The cylinder block also needs to be taken for measurement, where, by using a professional tool, the results of wear on the cylinder surface will be known. Usually it is necessary to hone the surface of the cylinders or bore them to the repair size of the piston.

At this time, check the crankshaft for runout. If the runout is within tolerances, which allows the journals to be ground to the repair size, then the crankshaft is bored.

After purchasing new pistons and rings, you can give them to the craftsmen, who will hang the connecting rods and pistons separately and together, adjusting them by weight and installing them in the cylinder block with the required torque.

It is important to assess the condition of the oil pump. If their sprockets are not ground off, you can get by with regular pump washing and cleaning the oil receiver mesh. In general, the DIY engine repair is complete, all that remains is to assemble it.

Engine repair cost

The price of engine repair depends on the make of the car, which is explained by the discrepancy in the cost of spare parts. Parts for luxury models are much more expensive than parts for a budget car. In addition, the volume and complexity of the work may vary.

Our service specialist will give you the exact price for engine repairs after a detailed analysis of the car’s condition. The cost of repairs is determined individually and is always agreed with the car owner.

| ICE repair (gasoline engine) | Price, rub |

| Removing and installing a turbocharger (turbocharger). Repair, service, replacement | From 3500 |

| Removing and installing a gasoline engine | From 6000 |

| C/U generator | From 1500 |

| Repair, replacement, starter diagnostics | From 800 |

| Compression measurement | From 1000 |

| Replacing the fuel pump (electric) | From 1500 |

| Replacing the thermostat | From 1000 |

| Replacing the camshaft oil seal | From 2000 |

| Replacing the tensioner roller | From 500 |

| Replacing the alternator belt | From 900 |

| Replacing the timing belt (chain) | From 4000 |

| Replacing the expansion tank of the cooling system | From 500 |

| Replacing the cooling radiator | From 2000 |

| Replacing the condenser radiator (with refilling) | From 3000 |

| Replacing the front oil seal (crankshaft) | From 1500 |

| Replacing the engine support (mount) | From 1000 |

| Replacing the rear oil seal (crankshaft) | From 5000 |

| Replacing the oxygen sensor (lamda probe) | From 500 |

| Replacing the water pump (pump) | From 1200 |

| ICE repair (diesel engine) | Price, rub. |

| Repair of internal combustion engine diesel 8 valves | from 30 000 |

| Repair of internal combustion engine diesel 16 valves | from 32 000 |

| Repair of internal combustion engine diesel 5 cylinders in-line | from 35 000 |

| Repair of internal combustion engine diesel 6 cylinders in-line | from 40 000 |

| Engine repair diesel V6 | from 50 000 |

| Engine repair diesel V8 | from 55 000 |

| Engine repair diesel V10 | from 60 000 |

| Detection of an internal combustion engine defect (with the cylinder head removed) | from 3 000 |

| Removing the internal combustion engine | from 8 000 |

| Installation of internal combustion engines | from 8 000 |

| Other engine repair work | |

| Oil pressure sensor - replacement | from 800 |

| Crankshaft position sensor - replacement | from 800 |

| Speed sensor - replacement | from 800 |

| Coolant temperature sensor - replacement | from 800 |

| Throttle valve, idle air valve 8V - replacement, cleaning | from 2000 |

| Throttle valve, idle air valve 16V - replacement, cleaning | from 2000 |

| Ignition coil - replacement | from 900 |

| Valves - replacement | from 8000 |

| Exhaust manifold - replacement | from 4000 |

| Valve seals 8V - replacement | from 8 000 |

| Valve seals 16V - replacement | from 10 000 |

| Piston rings - replacement | from 10 000 |

| Muffler lambda probe - replacement | from 1 000 |

| Exhaust manifold lambda probe - replacement | from 1 500 |

| Oil pump - replacement | from 2 500 |

| Rear engine mount - replacement | from 1 000 |

| Left engine mount (gearbox) - replacement | from 1 500 |

| Right engine mount - replacement | from 1 300 |

| Heater stove (radiator) - replacement | from 5 000 |

| Engine sump - replacement | from 1 500 |

| Muffler cushion - replacement | from 600 |

| Intake manifold gasket - replacement | from 2 000 |

| Exhaust manifold gasket - replacement | from 2 500 |

| Camshaft replacement | from 3 000 |

| Rear crankshaft oil seal - replacement | from 4 000 |

| Front crankshaft oil seal - replacement (with the timing belt removed) | from 400 |

| Front crankshaft oil seal - replacement | from 1 000 |

| Camshaft oil seal - replacement | from 850 |

| Generator pulley - replacement | from 2 500 |

| Replacing the engine cooling radiator | from 2 000 |

| Replacing the thermostat | from 1 000 |

| Replacing the engine cooling fan | from 1 500 |

| Replacing the pump | from 1 000 |

| Replacing the expansion tank | from 1 000 |

| Replacing the cooling system pipe | from 1 200 |

| Replacing the cooling system pipe clamp | from 300 |

Engine auxiliary units

After all the main (above) components and assemblies of the engine have been checked and restored or replaced, it is the turn of the units, which for some reason are usually called “auxiliary”, although without any of them the engine cannot function. We are talking about fuel equipment, timing drive, oil pump, water pump, cooling system radiator, etc. and so on. It is clear that with a faulty oil pump, the repaired engine will very soon require a new overhaul, and faulty fuel injectors can melt the pistons. Therefore, checking and repairing or replacing “auxiliary” units are no less important than repairing “main” ones. All parts and assemblies of an internal combustion engine work in interconnection and therefore, often a minor malfunction that is not corrected in time entails very serious consequences. That’s why there can be no trifles in an engine overhaul; there can be nothing “unimportant.” Absolutely everything is important! Let me remind you of GOST: Major repairs are repairs performed to restore serviceability and complete or close to complete restoration of the service life of the product.

Engine repair at the Auto-Maxima car service center in Southern Administrative District of Moscow

The Auto-Maxima car service center in the Southern Administrative District of Moscow specializes in the repair and maintenance of various brands of cars.

Our service center specialists provide a full range of services for repairing diesel and gasoline engines.

We are ready to conduct a complete diagnostic of the internal combustion engine, on the basis of which we can determine the condition of the engine, a list of necessary repairs, as well as the timing and cost of repairs.

The quality of the repair will affect the further operation of the power unit, therefore, engine repairs should be carried out in a car service center where there are experienced specialists and the necessary equipment.

Connecting rods

There are several types of connecting rods, which, regardless of their size, differ in design. According to the upper head of the connecting rod, connecting rods with a pressed-in piston pin and a floating piston pin fit are distinguished. According to the NGSh (lower head of the connecting rod), the connecting rods are structurally different in their connector. The connector can be flat, “step”, toothed, pin, or burst. Regardless of the design of the connecting rod, during engine overhaul it is necessary to check:

4.1 Bend of the connecting rod. If the bend exceeds the permissible value, the connecting rod must be replaced.

4.2 Geometry of the NGSh. If the geometry of the connecting rod does not meet the tolerance, in most cases, the connecting rod can be repaired. Connecting rods with a rupture connector cannot be repaired. They can only be replaced.

4.3 In the case of a connecting rod with a pressed-in piston pin, check the geometry of the piston pin and the tension. If at least one of these parameters does not meet the tolerance, the connecting rod should be replaced. If the piston pin is on a floating fit, control the geometry of the piston pin and the clearance. In case of non-compliance with the tolerance, such a connecting rod can be repaired by replacing the VGSh bushing.

4.4 In diesel engines, and even in loaded gasoline engines, an important parameter is the center distance - it must be checked and observed when repairing or replacing connecting rods.

(photo: boring the upper head of the connecting rod)

Grinding the block and crankshaft

The next stage of repair and restoration work is grinding the crankshaft, as well as the planes of the block and head. Using surface grinding and milling machines, the plane of the GBU and the block is brought into a mirror surface. As a rule, the following can be removed: 0.05mm, 0.1mm, 0.25mm, 0.5mm, 1mm or more of the thickness of the product.

As for grinding the crankshaft, there are types of repairs for this unit:

| Type of repair | Thickness, mm | Efficiency compared to new |

| Repair No. 1 | 0,25 | 80-90% |

| Repair No. 2 | 0,50 | 70-75% |

| Repair No. 3 | 0,75 | 65-70% |

| Repair No. 4 | 1,00 | 50-55% |

| Repair No. 5 | 1,25 | 40-45% |

| Repair No. 6 | 1,50 | Less than 30% |

| Repair No. 7 | 2,00 | Not applicable since 1995 |